Efficient and environment-friendly type garbage disposal equipment

A kind of garbage disposal equipment, an environment-friendly technology, applied in the direction of grain processing, magnetic separation, solid separation, etc., can solve the problems of inability to crush, crushing equipment damage, etc., and achieve the effect of speeding up the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

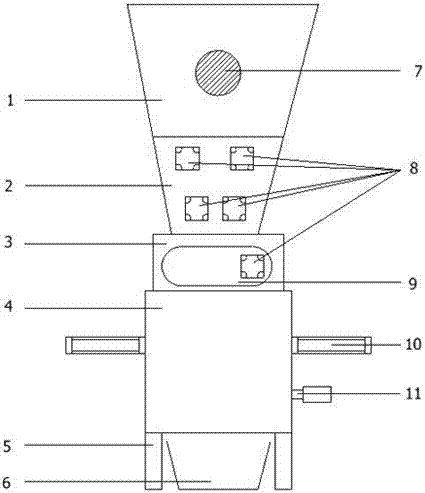

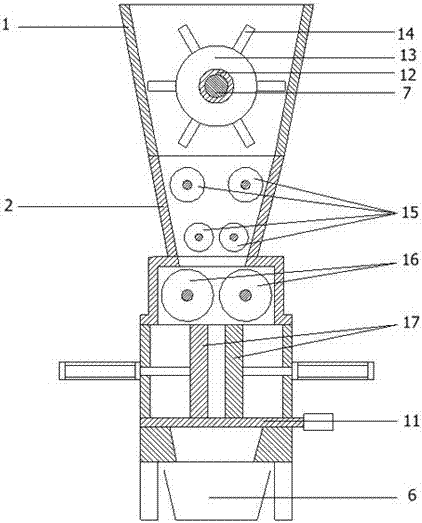

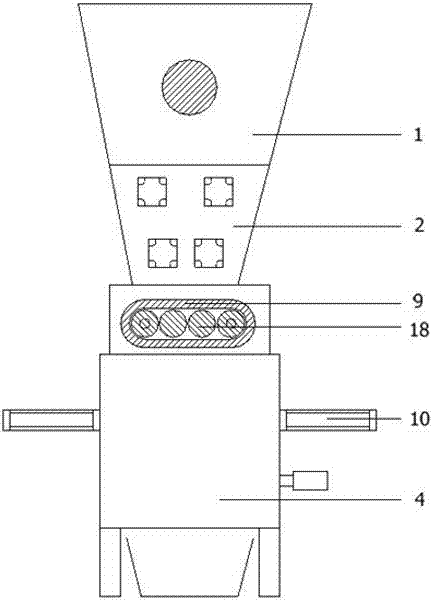

[0024] as attached figure 1 to attach image 3 Shown:

[0025] The present invention provides high-efficiency and environment-friendly garbage treatment equipment, including a screening chamber outer casing 1, a crushing chamber outer casing 2, a grinding chamber outer casing 3, a compression chamber outer casing 4, legs 5, a collection box 6, and a rotating shaft 7 , motor 8, protective cover 9, electric cylinder 10, partition 11, bearing 12, cylinder 13, magnet sieve plate 14, pulverizing roller 15, milling roller 16, extruding block 17 and gear 18; Described screening chamber The bottom of the outer casing 1 is welded to the top of the crushing chamber outer casing 2; the bottom of the crushing chamber outer casing 2 is welded to the top of the grinding chamber outer casing 3; the grinding chamber outer casing 3 The bottom is welded to the top of the compression chamber outer casing 4; the bottom of the compression chamber outer casing 4 is welded with four evenly distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com