maintenance car

A technology for maintenance vehicles and countertops, applied in the field of maintenance vehicles, can solve the problems of inconvenient carrying of large tools, failure to achieve maintenance results, and influence on maintenance progress, etc., and achieve the effects of low cost, reasonable structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

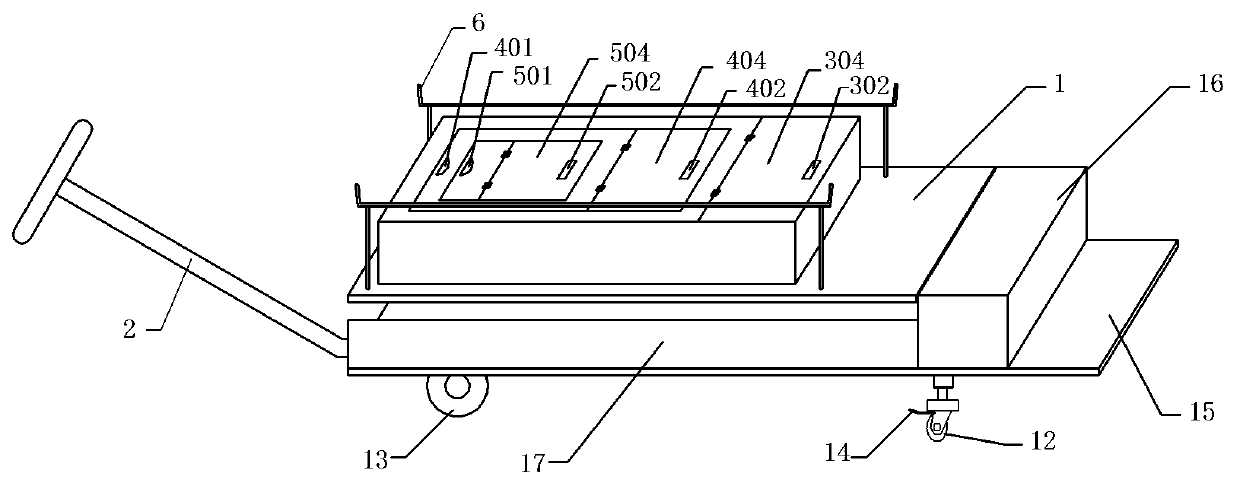

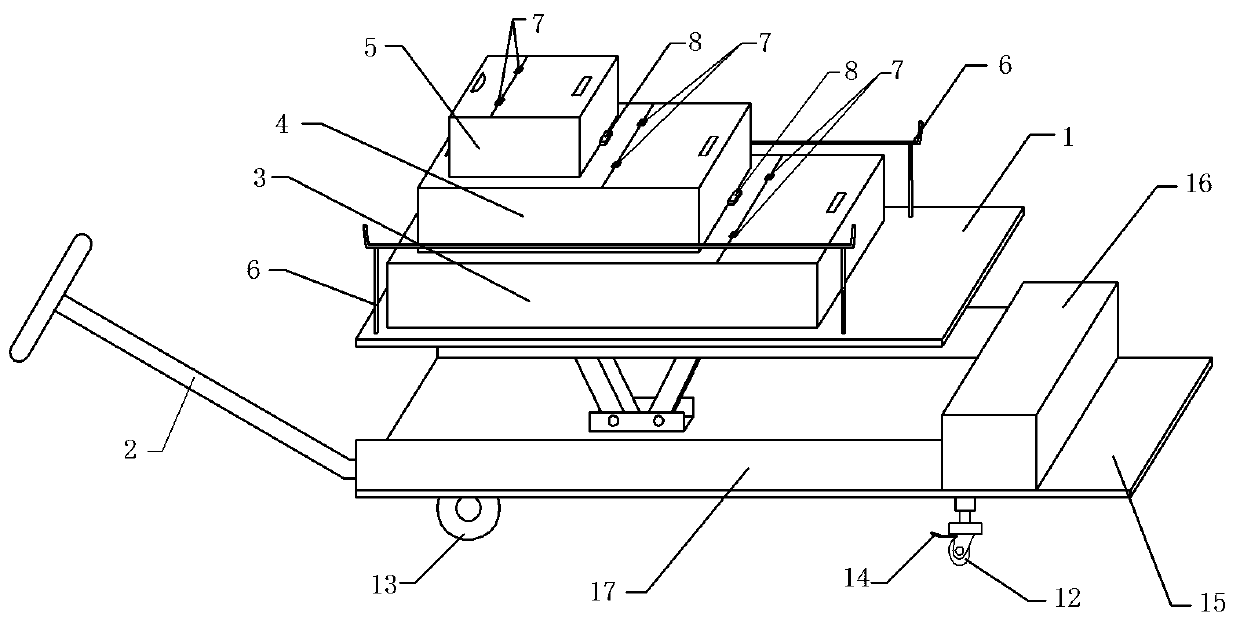

[0034] Example: as attached figure 1 As shown, the maintenance vehicle includes a table, and the table includes an upper table 1 and a lower table 15, and the lower table 15 is longer than the upper table 1.

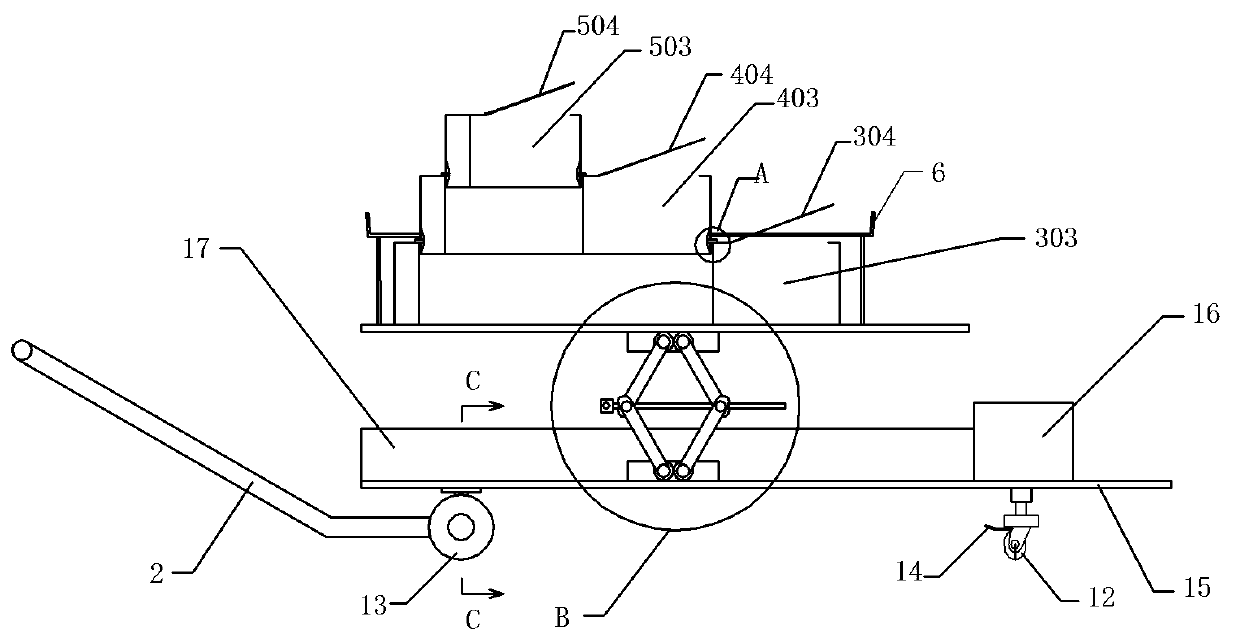

[0035] as attached Figure 5 Shown, lower platform 15 bottoms are provided with walking gear. The running gear comprises a directional wheel 12 and a steering wheel 13, and the directional wheel 12 is provided with a brake pedal 14. The quantity of the directional wheels 12 is two pieces, and the quantity of the steering wheels 13 is two pieces. It is common knowledge of those skilled in the art that the brake pedal 14 is provided on the directional wheel 12, so it will not be repeated here.

[0036] A wheel frame 18 is provided between the two steering wheels 13, and the wheel frame 13 is rotationally connected with the wheel frame 18. The wheel frame 18 is provided with a rotating shaft 19, and the lower side of the lower table surface 15 is provided with a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com