Wet dust removal system for sweeping vehicle

A technology of wet dust removal and cleaning vehicles, applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of secondary dust pollution, large space, energy consumption, etc., and achieve simple and compact structure, energy saving, and isolation and settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

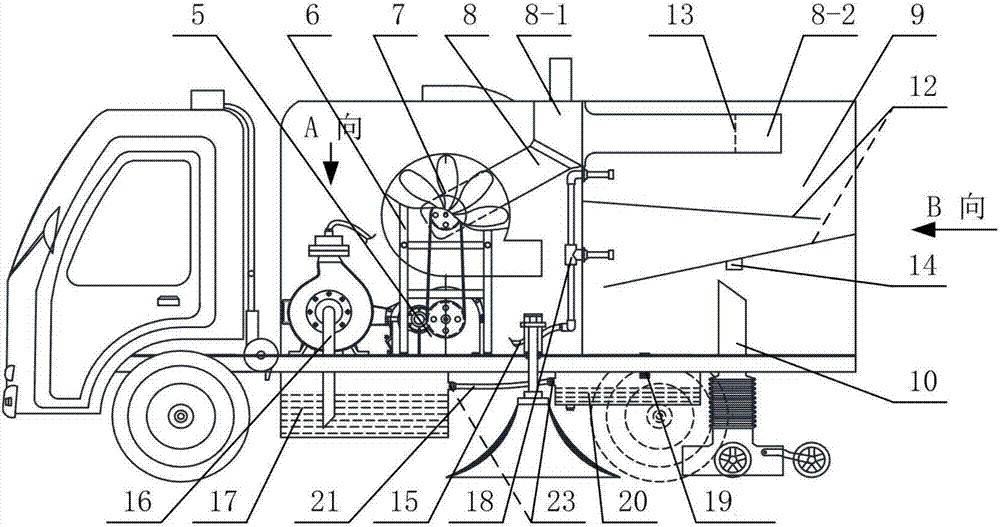

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

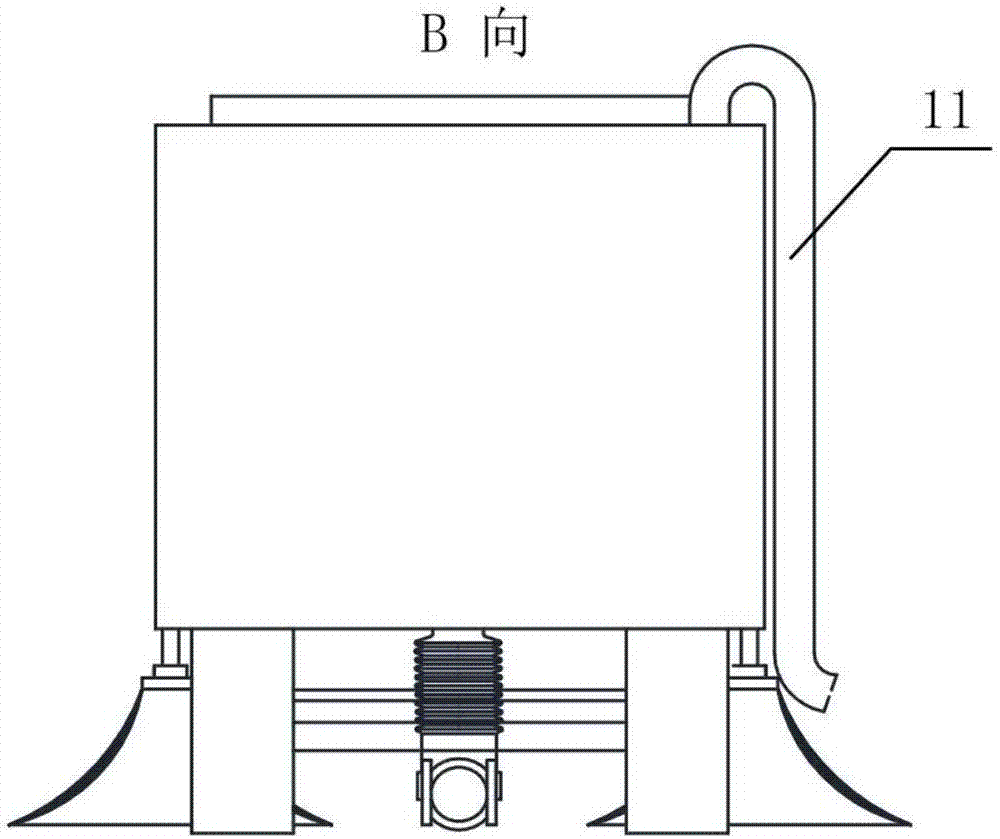

[0033] see Figure 1 to Figure 7 , the present invention includes a power system, an air circulation system and a spraying system installed on the sweeper; a dustbin 9 is installed on the sweeper, and a suction pipe 10 is arranged at the bottom of the dustbin 9 .

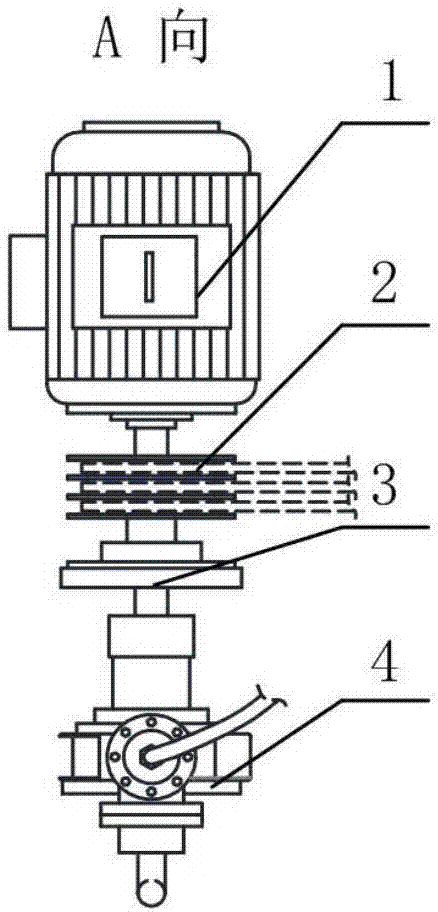

[0034] The power system adopts a motor 1, and the motor 1 is connected to a reducer 5 through a pulley 2, and the reducer 5 is connected to a fan 7. The motor 1 is connected to the water pump 4 by connecting the electromagnetic clutch 3 . A dust concentration detector 14 is installed at the outlet of the suction pipe 10, and the dust concentration detector 14 is connected with the control system, and the control system is connected with the electromagnetic clutch 3.

[0035] see figure 2 , the motor 1, the pulley 2, the electromagnetic clutch 3 and the water pump 4 are arranged coaxially.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com