Multistage dust removal dustbin for sweeper

A technology for sweeping vehicles and garbage cans, which is applied in the field of sweeping vehicles, can solve the problems of secondary dust pollution, cannot meet long-term cleaning operations, and has a small water tank, and achieves the effect of solving large dust and eliminating secondary dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

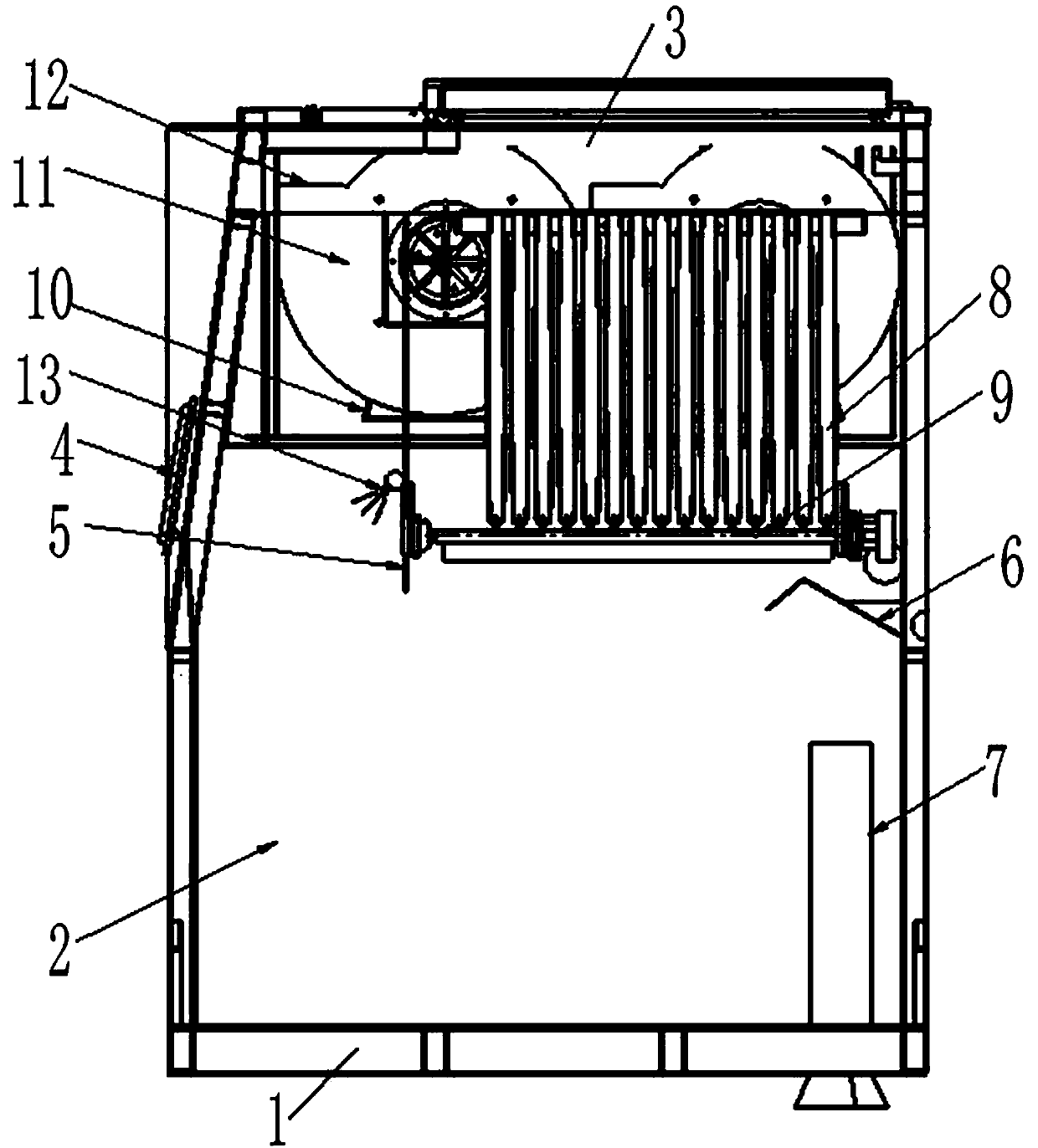

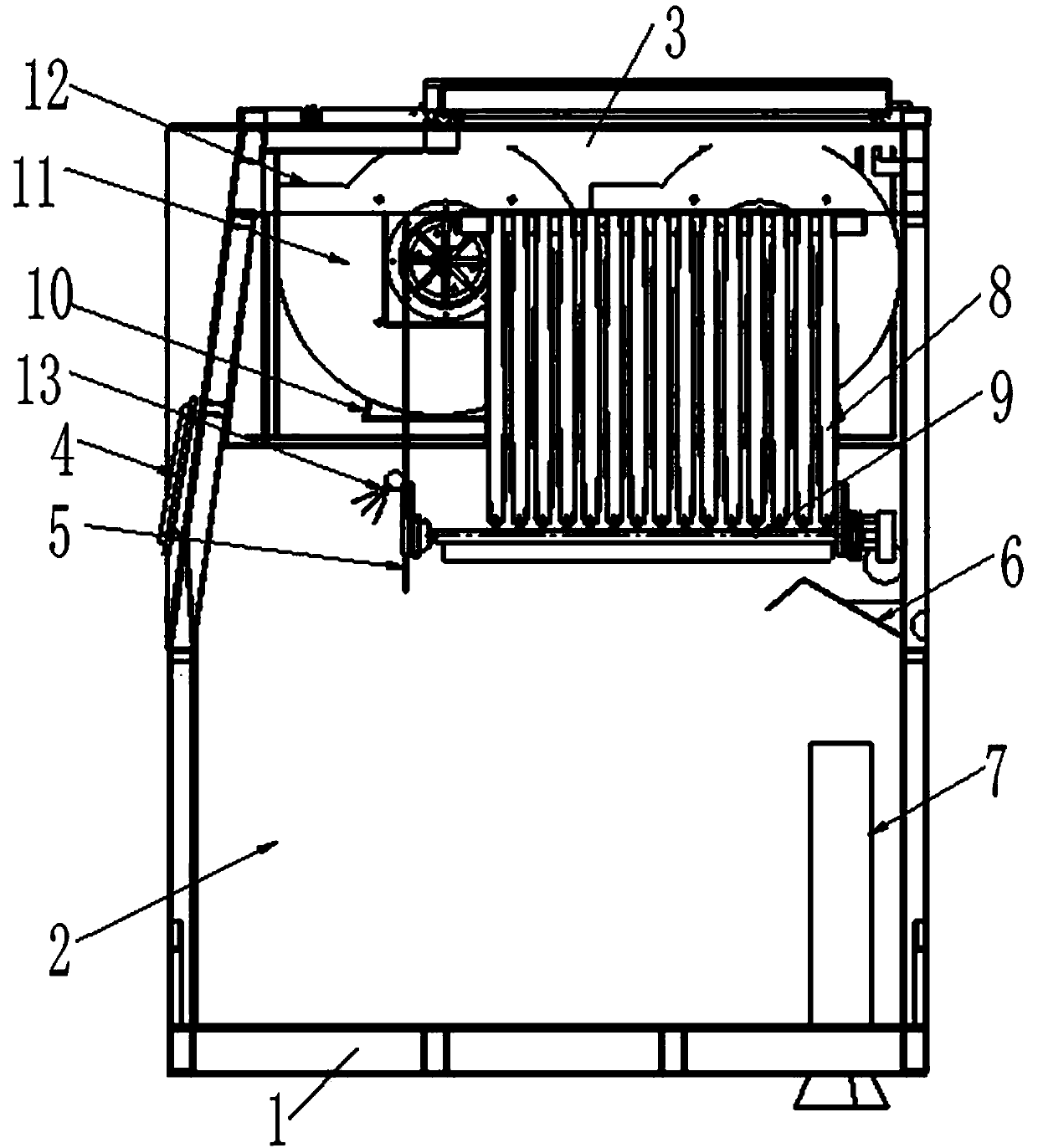

[0018] Attached below figure 1 The present invention will be further described.

[0019] A multi-stage dust-removing waste box for a sweeper, comprising: a waste box body 1, which is installed on the chassis of the sweeper, a partition plate is horizontally arranged in the waste box body, and the partition plate divides the waste box body 1 into a closed lower chamber 2 And the closed upper chamber 3 located above the lower chamber 2; the garbage dust inlet 4 is arranged on one side of the lower chamber 2, and the garbage dust inlet 4 is connected with the outlet end of the garbage conveying hanging plate of the sweeper; the dust suction pipe 7 , one end of which is connected to the lower end of the lower chamber 2, and the other end is connected to the dust suction duct in the sweeping disc of the sweeper; the filter bag 8, its inlet end is located in the lower chamber 2, and its outlet end is located in the upper chamber 3 and the dust removal fan 11 , which is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com