A kind of method that utilizes quartz sand dust to prepare polymer cement waterproof mortar

A waterproof mortar and polymer technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as secondary pollution of dust, and achieve the effect of strengthening adsorption, promoting mixing, and increasing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

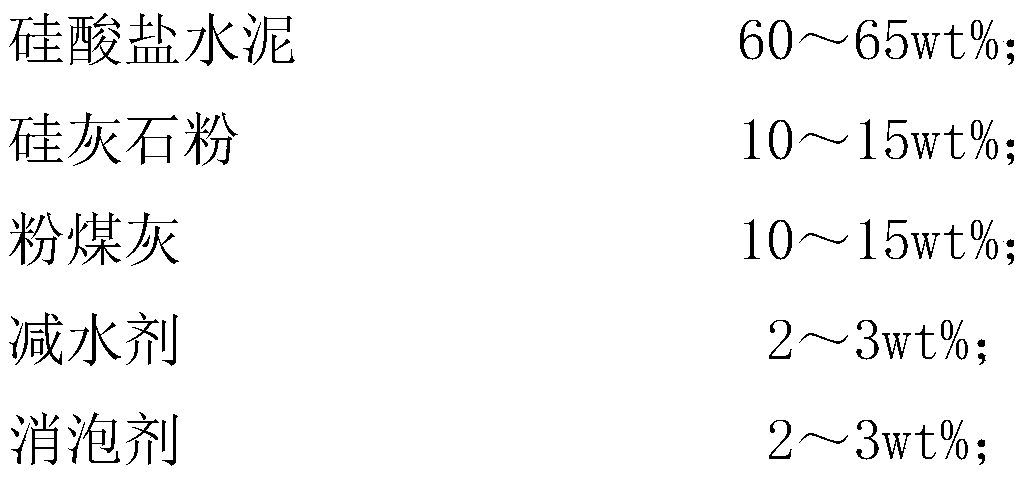

Method used

Image

Examples

Embodiment 1

[0024] The preparation process is as follows:

[0025] (1) The quartz sand dust is collected by the filter dust collector and collected in the dust collector; wherein, the inner wall of the dust collector is coated with 300g / L aminocellulose, 360g / L paraffin powder, 120g / L macroporous Silica gel, 220g / L bentonite is composed of a composite layer with a thickness of 0.8 to 1 cm. When preparing the coating solution for the composite layer, dissolve or disperse each component in an acetone solution with a volume fraction of 85%. At the same time, the dust collector A heating device is installed;

[0026] (2) When the volume of quartz sand dust collected in the dust collector reaches 1 / 2 of the volume of the dust collector, turn on the heating device of the dust collector and set the temperature at 70°C; the composite layer in step (1) It is heated and dissolved, and mixed with the quartz sand dust collected in the dust collector to form a cloudy liquid;

[0027] (3) Turn off th...

Embodiment 2

[0030] The preparation process is as follows:

[0031] The time of opening the dust collector heating device in the embodiment 1 step (2) is delayed to be when the quartz sand dust volume reaches 3 / 5 of the dust collector volume, and all the other preparation methods are also the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com