Hydrophilic antibacterial composite nano fibrous membrane and preparation method thereof

A composite nanofiber, antibacterial technology, applied in the field of preparation of polysulfone composite nanofiber membrane, can solve the problems of failing to improve the mechanical properties of the fiber membrane at the same time, insufficient cohesion of electrospinning fibers, weak cohesion, etc. The effect of improving the filtration effect, improving the mechanical properties, and improving the swelling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: a kind of preparation method of hydrophilic antibacterial composite nanofiber membrane comprises the following steps:

[0021] (1) Weigh 2g of polysulfone resin particles (weight average molecular weight is 75000), dissolve in 8g of N,N-dimethylformamide solvent at room temperature, stir and dissolve fully at room temperature, the obtained mass fraction is 20% polysulfone solution. Electrospinning is then carried out, and the spinning process parameters are as follows: the spinning voltage is 12kv, the spinning distance is 15cm, and the spinning liquid flow rate is 1.5ml / h. Obtain as-spun polysulfone fiber membrane.

[0022] (2) After the solvent in the fiber is completely volatilized, the as-spun polysulfone fiber membrane is compacted and fixed evenly, and heat-treated at 190° C. for 2 hours in an electric heating constant temperature blast drying oven.

[0023] (3) Oxygen plasma pretreatment is carried out at room temperature, and the processing par...

Embodiment 2

[0033] Embodiment two: the preparation process of the present embodiment is identical with embodiment one, and during chitosan padding process, process parameter condition is: 1.5% chitosan solution 25ml, glutaraldehyde 75 μ l, liquid carrying rate 92%, 2 %NaOH solution for 1 hour, and dried at 40°C.

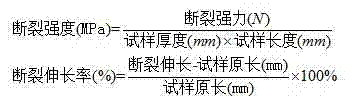

[0034] After measurement, the fracture strength of the chitosan / polysulfone composite nanofiber membrane prepared in this example is 7.66±0.56MPa, the elongation at break is 43.3±14.1%, and the strength increase rate is 27.5%; the maximum pore size is 2.92 μm, and the minimum pore size 2.65μm, the average pore size is 2.75μm, and the average pore size is reduced by 38.9%; the contact angle at 0.1s is 52.8°±1, and the deionized water droplet can be completely absorbed by the membrane within 40s, which is 127.4° compared with the original contact angle at 0.1s ±1, a reduction of 58.6%.

Embodiment 3

[0035]Embodiment three: the preparation process of the present embodiment is identical with embodiment one, and when chitosan padding is handled, process parameter condition is:

[0036] 25ml of 2% chitosan solution, 60μl of glutaraldehyde, 81% liquid retention rate, 2% NaOH solution for 1 hour, and dried at 40°C.

[0037] After measurement, the breaking strength of the chitosan / polysulfone composite nanofiber membrane prepared in this example is 8.14±0.78MPa, the elongation at break is 48.79±13.09, and the strength increase rate is 35.4%; the maximum pore size is 3.12 μm, and the minimum pore size 2.8μm, the average pore size is 2.95μm, and the average pore size is reduced by 34.4%; the contact angle at 0.1s is 90.1°±2, and the deionized water droplet can be completely absorbed by the membrane within 1min, which is 127.4° compared with the original contact angle at 0.1s ±1, a decrease of 29.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com