Fast self-leveling level frame

A sweeper and self-leveling technology, applied in the field of instrument racks, can solve the problems of small adjustment angle, large influence of instrument accuracy, poor environmental adaptability, etc., to increase the level, improve accuracy and reliability, and reduce weight requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

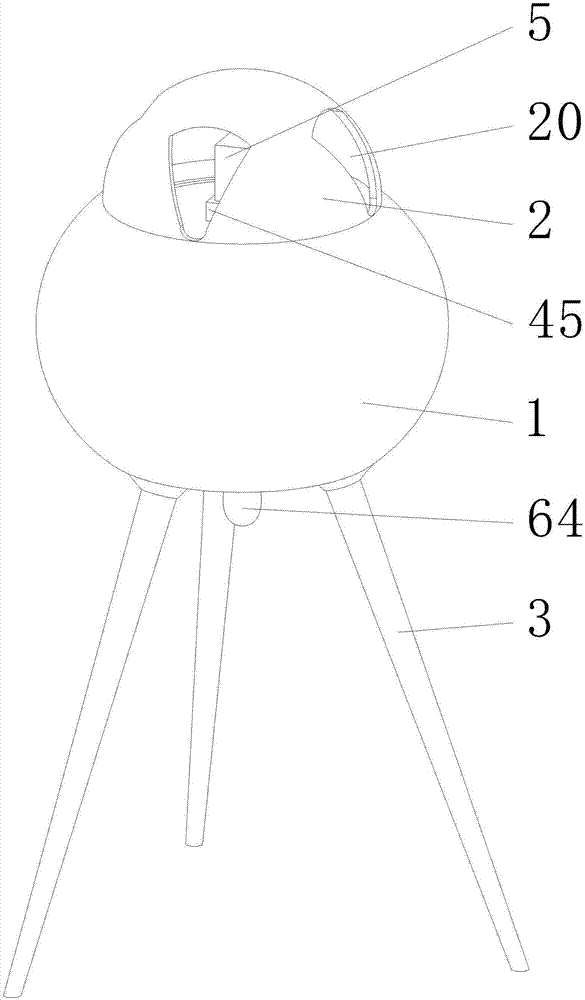

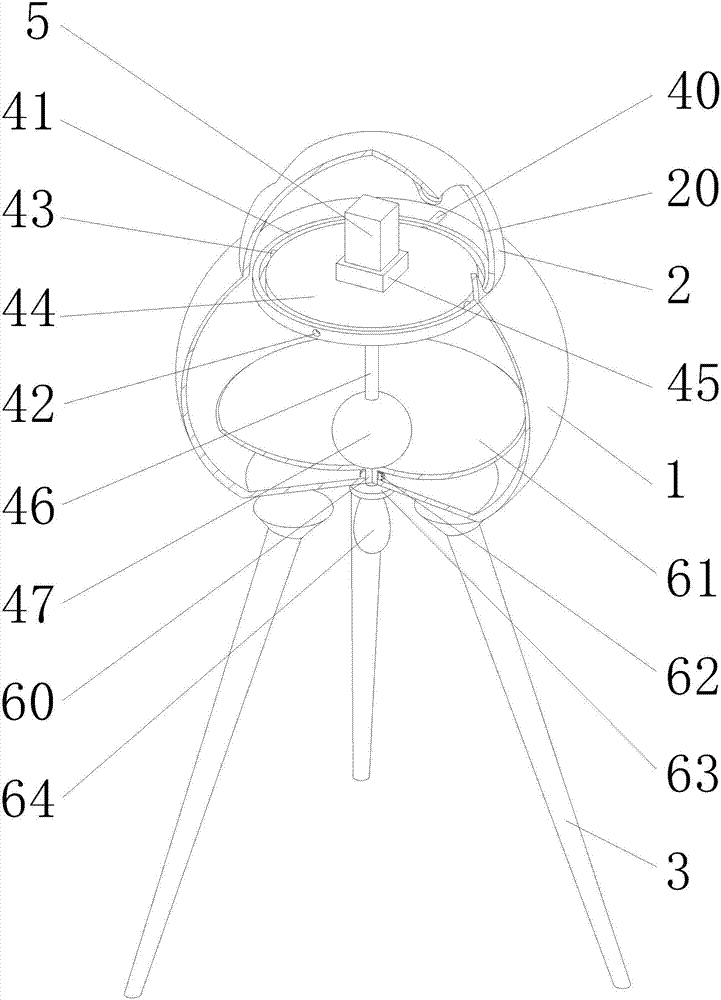

[0024] refer to Figure 1 ~ Figure 2 As shown, the present invention discloses a fast self-leveling sweeper frame, which includes a housing 1 , a protective cover 2 and supporting legs 3 .

[0025] The above-mentioned housing 1 is a spherical shell with a flat bottom and an open top.

[0026] Two ring pins 40 are oppositely arranged on the inner wall of the opening of the casing 1 . A circular ring 41 is arranged on the ring pin 40 . Two ring holes 42 are oppositely arranged on the outer peripheral wall of the ring 41 . The ring pin 40 is inserted into the ring hole 42 so that the ring 41 can freely rotate around the central axis of the ring pin 40 . The circular ring 41 can also be two quarter rings, and the ring pin 41 and the ring hole 42 are respectively arranged at its two ends.

[0027] Two platform pins 43 are arranged opposite to the inner peripheral wall of the above-mentioned circular ring 41 , and the central axis of the ring pin 40 is perpendicular to the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com