Device and method for inspecting closed space of thermal power unit

A technology for confined spaces and thermal power units, which is applied to motor vehicles, transportation and packaging, and non-electric variable control. It can solve the problems of large observation blind spots, long headers of thermal power units, and difficulty in determining the specific position of the detection probe. The effect of site adaptability, real-time monitoring, and ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

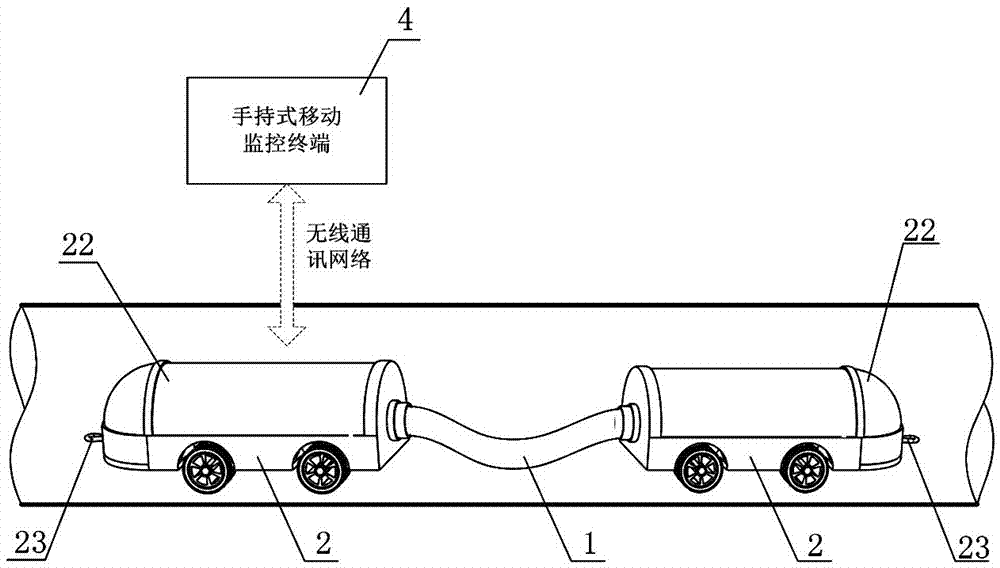

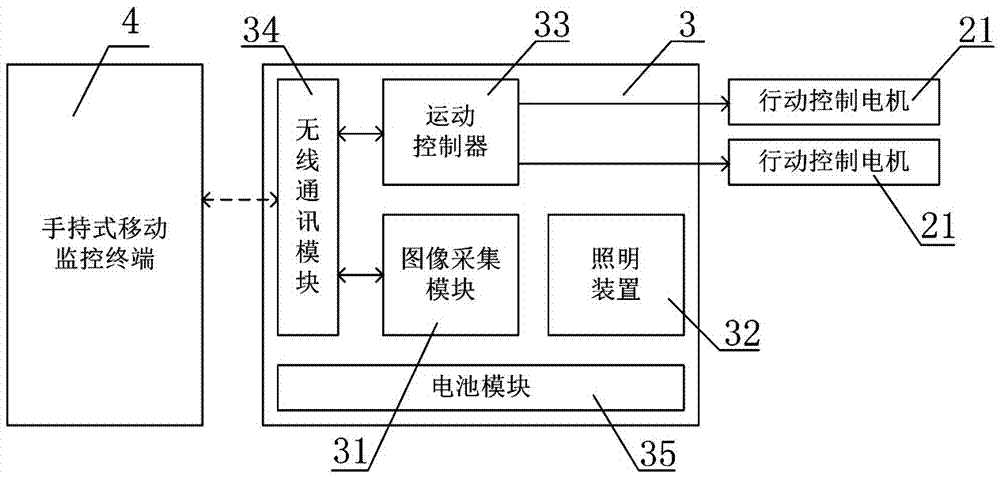

[0025] like figure 1 and figure 2 As shown, the thermal power unit confined space inspection device of this embodiment includes an inspection execution unit 3 and two inspection trolleys 2 connected through a flexible connector 1, and the inspection execution unit 3 is arranged on one or two inspection trolleys 2, the inspection execution unit 3 includes an image acquisition module 31, a lighting module 32, a motion controller 33, a wireless communication module 34, and a battery module 35, and each inspection trolley 2 is equipped with independent motion and braking control Motor 21, the output end of motion controller 33 links to each other with the wheel of patrol car 2 through motion and brake control motor 21, and image acquisition module 31, motion controller 33 are connected with wireless communication module 34 respectively, and the output end of battery module 35 They are respectively connected with the image acquisition module 31 , the lighting module 32 , the moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com