Winding and binding technology for spiral coil of transformer

A technology of spiral coils and transformers, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. It can solve the problems of small coil diameters, large numbers of wires, and difficult binding of wires, so as to achieve firm binding and improve coil winding. The quality of production and the effect of promoting the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

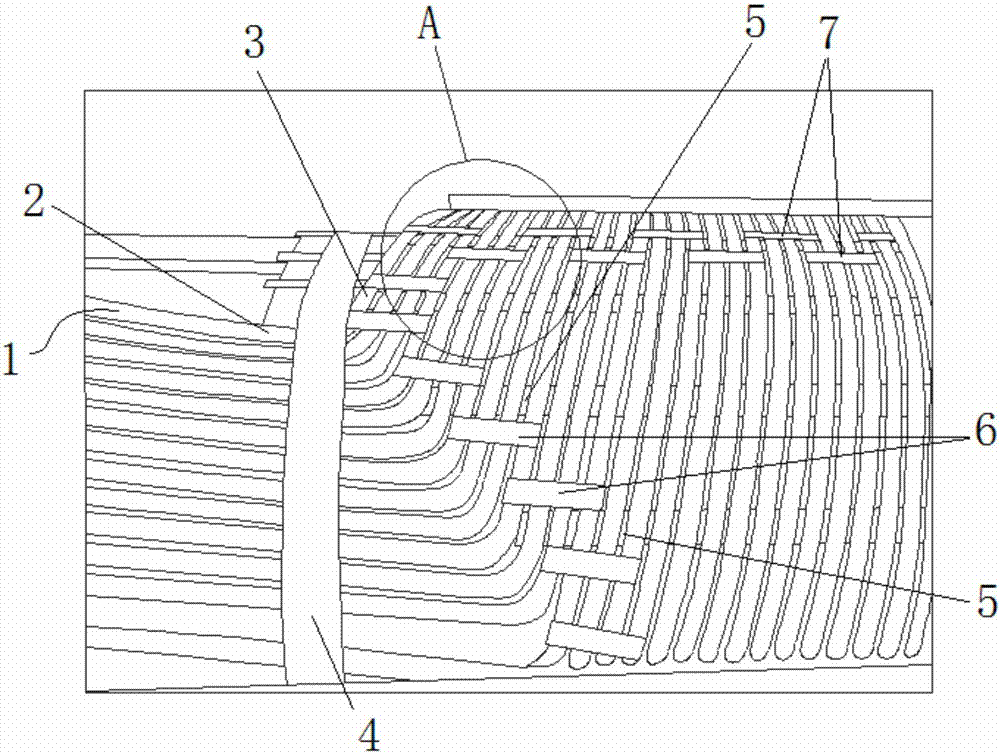

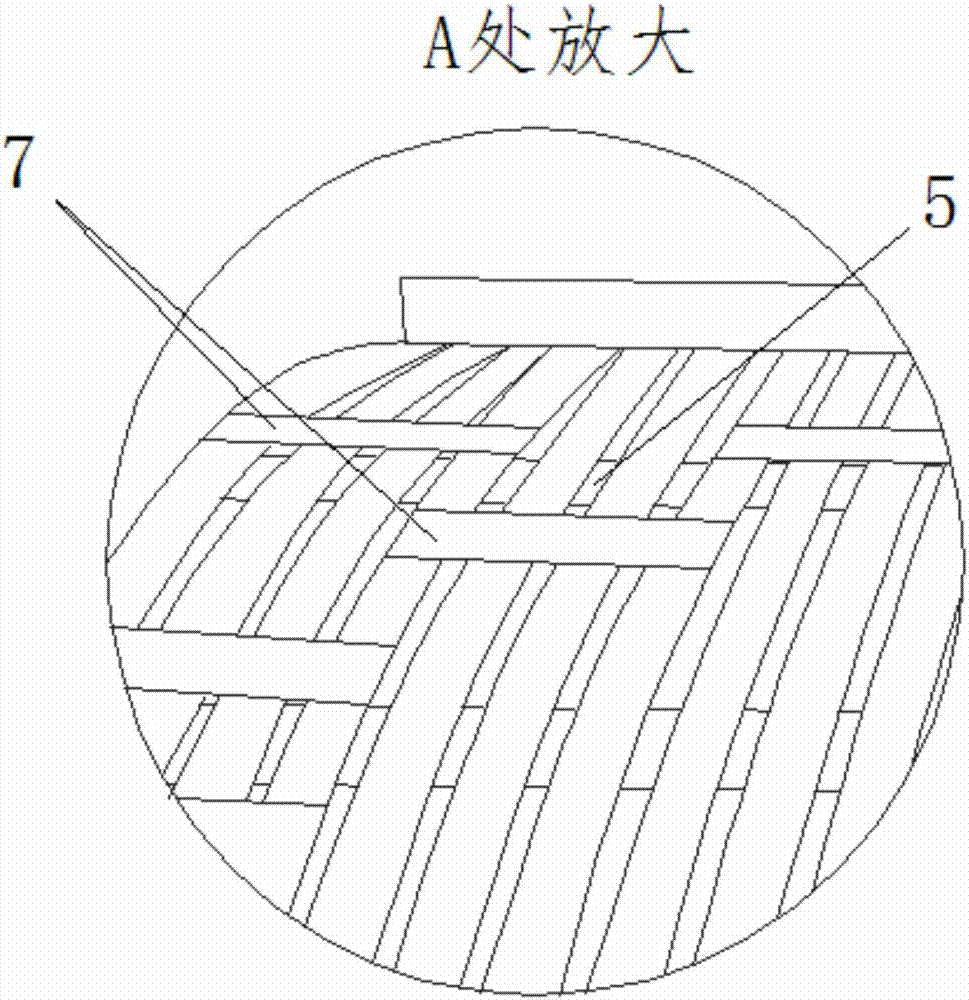

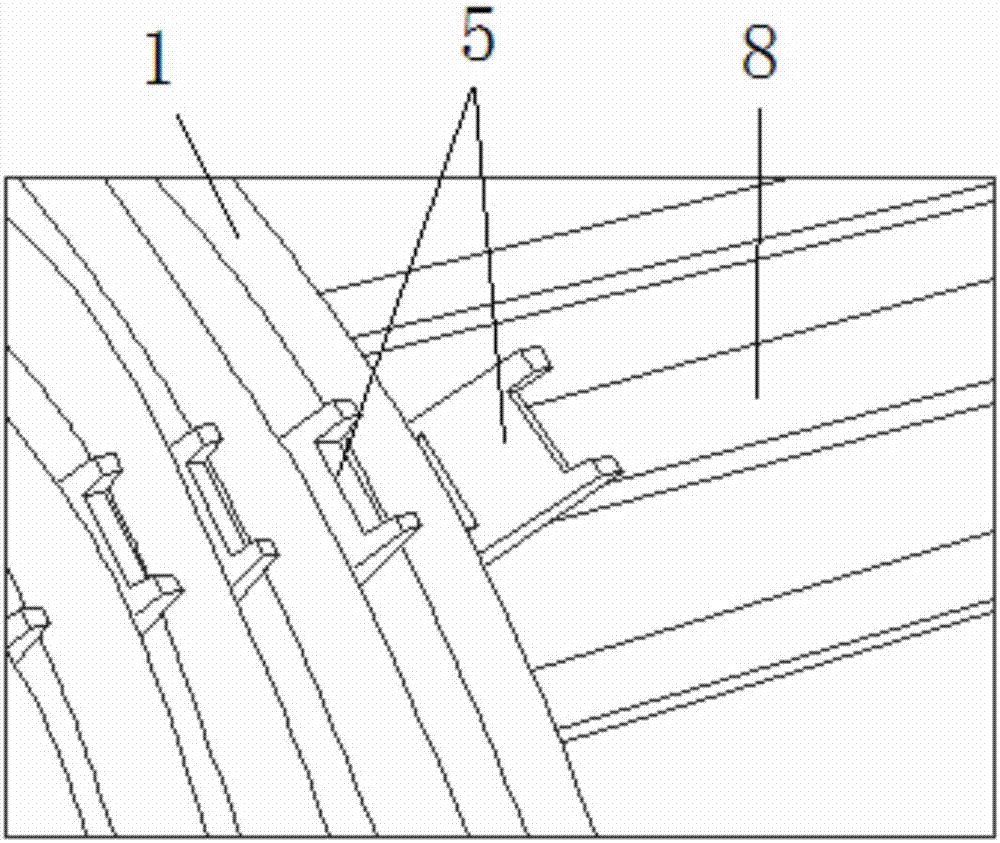

[0023] Such as Figure 1~3 As shown, the present invention includes a coil wire 1, a coil shaft, a fixing band 4 and a shrinkage band, wherein the coil wire 1 includes a wire outlet 2 and a wire body 3, and the coil shaft includes a coil winding mold shaft and a coil inner insulating cylinder, The inner insulating tube of the coil is sleeved on the shaft of the coil winding mold. The structure of the coil shaft is a well-known technology in the art. part, the wire outlet 2 is bent vertically to the same side along the axial direction of the coil axis, such as Figure 1~2 As shown, a plurality of rows of backing plates 5 are provided along the length direction of the coil shaft on the outer side of the coil inner insulating cylinder, and each backing plate 5 separates adjacent coil wires 1 respectively, as shown in FIG. image 3 As shown, a plurality of supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com