Method for preventing thin strip steel from being fractured at start moment

A thin strip and broken strip technology, applied in rolling force/roll gap control, metal rolling, etc., can solve problems such as the influence of yield, broken strip, and sheathing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

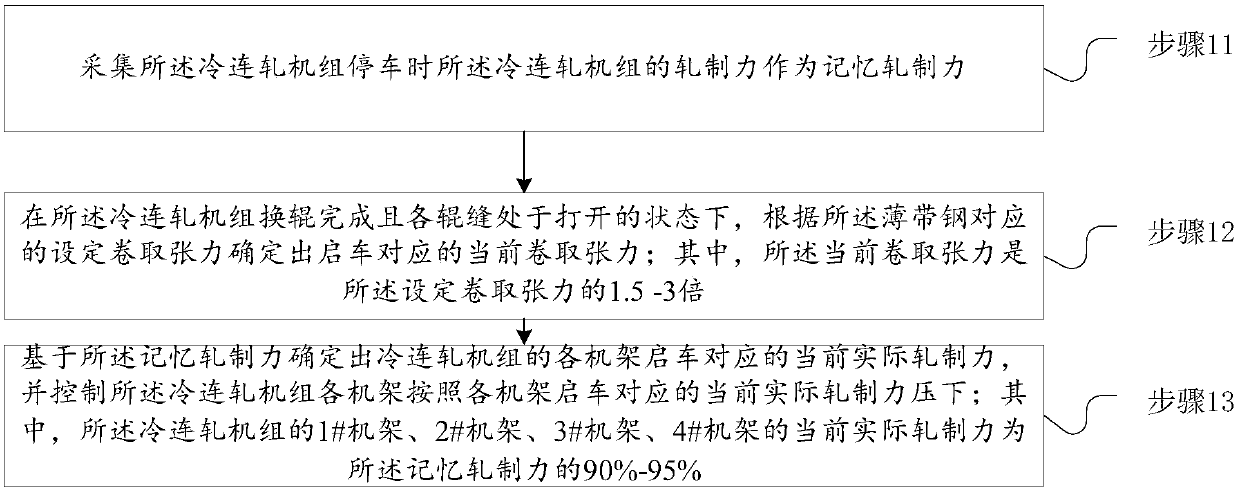

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0014] The invention discloses a method for preventing thin strip steel from being broken at start-up, and the method is applied to a cold tandem rolling mill. The thickness of the thin-gauge steel strip of the invention is less than 0.6mm.

[0015] The invention mainly solves the problem of strip breaking during thin strip rolling in a continuous cold rolling mill (that is, a five-stand continuous rolling mill) when the roll is changed and started. By digesting and analyzing the rolling process and the first-level control program of the cold tandem mill, the problems existing in the rolling process are deeply studied from the perspective of operation and control, mainly the broken strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com