A heavy-duty packing box

A packing box and heavy-duty technology, which is applied in the direction of packaging, transportation, packaging, containers, etc., can solve the problems of packing box side plate friction or collision, side plate loosening and falling off, and side plate not connected correspondingly, so as to improve the resistance to horizontal impact Shaking ability, strong load-bearing and compression resistance, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

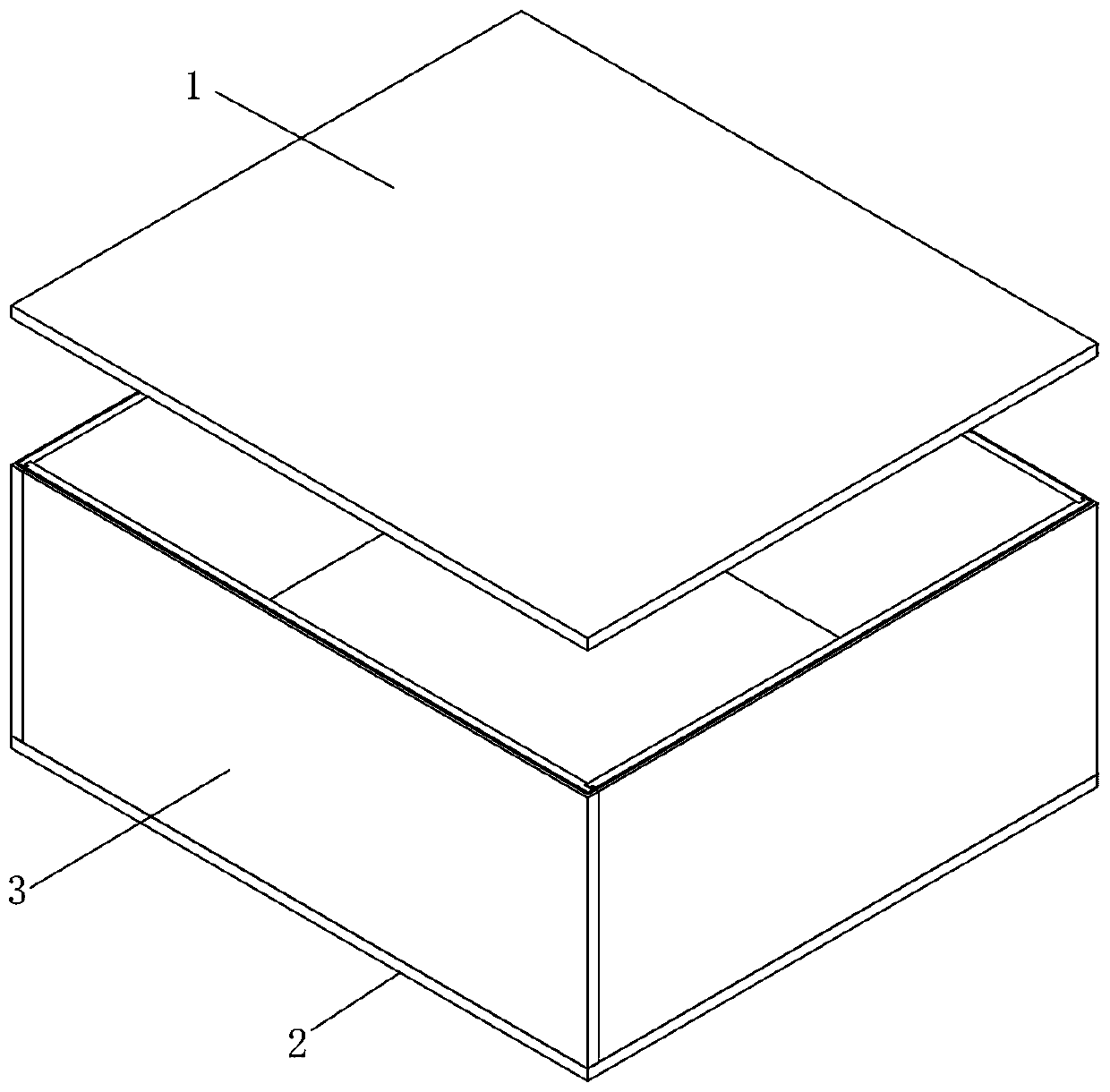

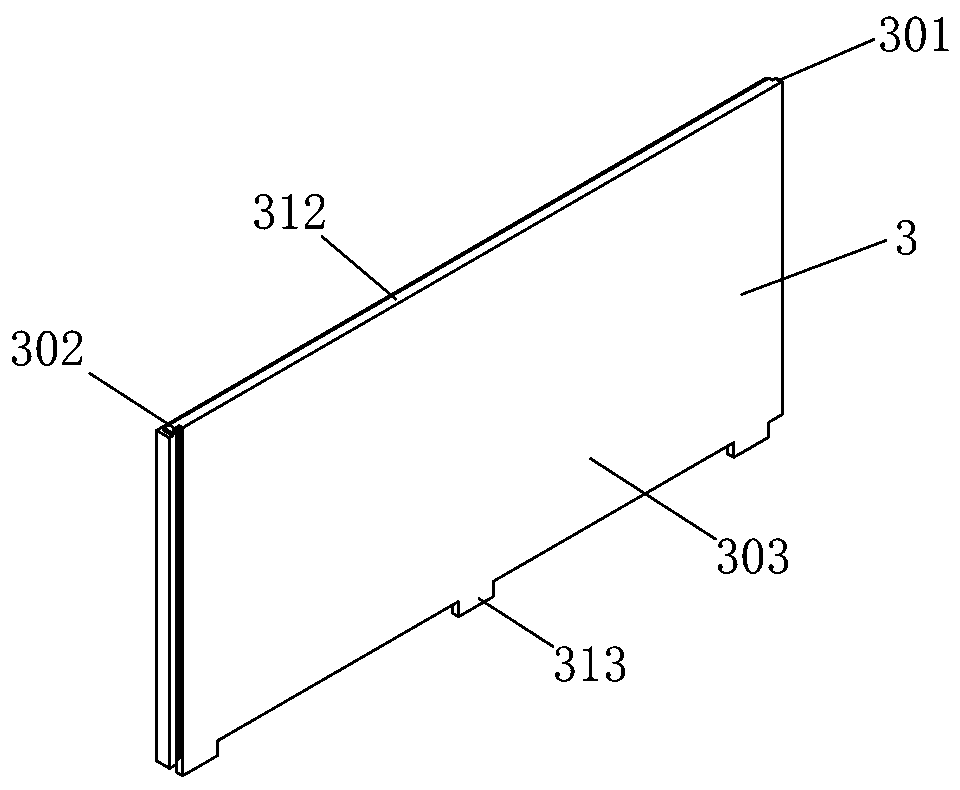

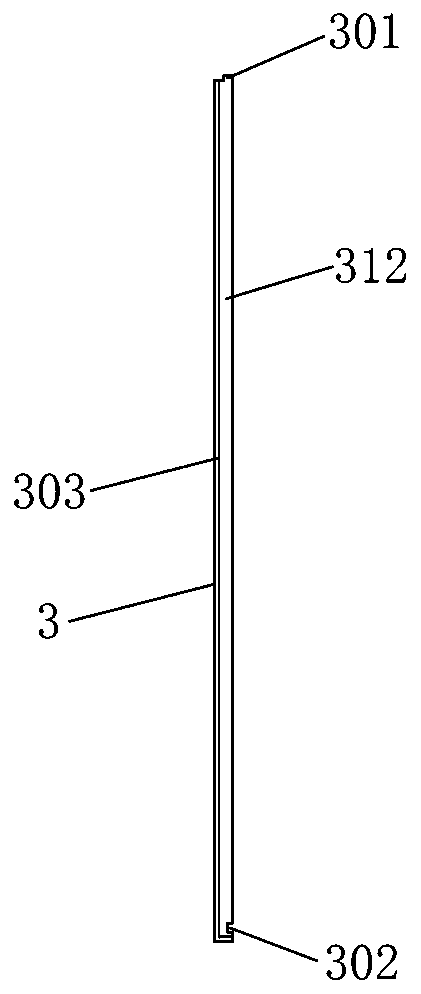

[0033] Such as Figure 1 to Figure 6 As shown, the heavy-duty packaging box of this embodiment includes a cover plate 1, a base 2 and a plurality of side plates 3 surrounded by the periphery of the base 2, the cover plate 1 is packaged on the top of the side plate 3, and one end of the side plate 3 is provided There is a tenon 301, and the other end is provided with an insertion groove 302 for the tenon 301 of the adjacent side plate 3 to be inserted and connected. Multiple side plates 3 are inserted in sequence to form a ring-shaped side of the heavy-duty packaging box. The connection structure is simple. , the ring side is in a closed self-locking state as a whole, so it has strong resistance to horizontal impact and shaking, and can protect the goods in all directions. The packing box can be disassembled and reused, avoiding waste, reducing costs and facilitating loading and unloading. The disassembly of the box is convenient and fast, and the application range is wide.

...

Embodiment 2

[0038] The heavy-duty packing box of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 7 to Figure 10 As shown, in this embodiment, the side plate 3 includes a second side plate 304, a third side plate 305, a fourth side plate 306 and a fifth side plate 307, and the third side plate 305 and the fourth side plate 306 are fixed on On the same side of one end of the second side plate 304, a gap is provided between the third side plate 305 and the fourth side plate 306 and is enclosed with the second side plate 304 to form an insertion slot 302, and one end of the fifth side plate 307 is fixed. Connected to the other end of the second side plate 304, the other end of the fifth side plate 307 protrudes as a tenon 301, and the side plate 3 obtained by fixing the four side plates is easy to process and blank, reduces the processing cost, and improves the efficiency. Production efficiency, there are no protrusions around the sides o...

Embodiment 3

[0040] The heavy-duty packing box of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 11 to Figure 12As shown, in this embodiment, the side plate 3 includes a sixth side plate 308, a seventh side plate 309 and an eighth side plate 310, the seventh side plate 309 is fixedly connected to one end of the sixth side plate 308, and the eighth side plate One end of 310 is affixed to the same side of the other end of the sixth side plate 308, and the sixth side plate 308, the seventh side plate 309 and the eighth side plate 310 encircle and form the insertion slot 302, and the other end of the eighth side plate 310 One end protrudes as a tenon 301, and the side plate 3 is made of three side plates. This structure is easy to process and blank, reduces processing costs, improves production efficiency, and has good load-bearing, compression, impact, and shaking performance of the packaging box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com