Intelligent creel of carpet loom

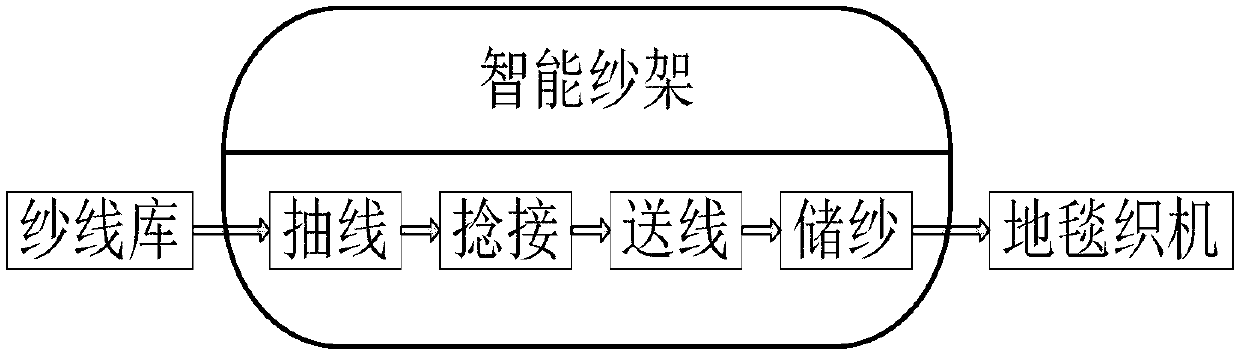

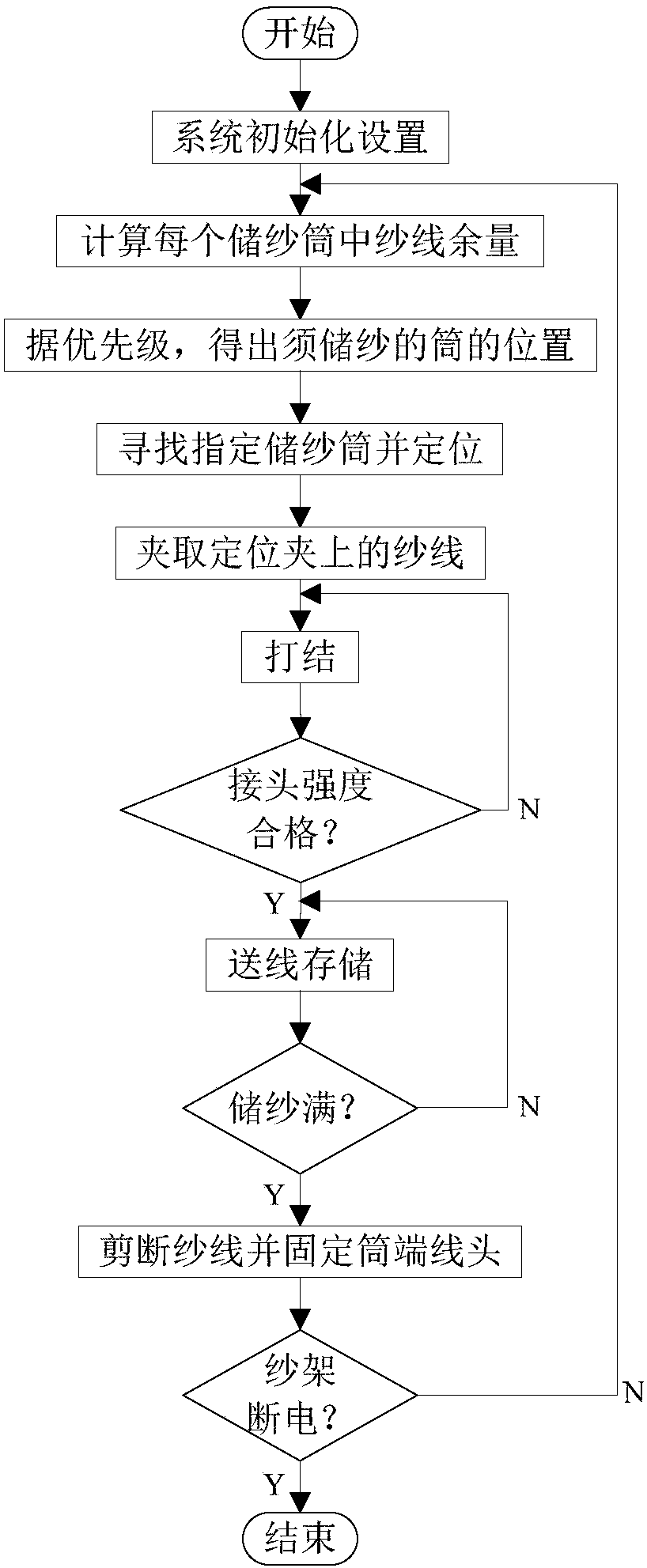

A creel and intelligent technology, applied in the fields of looms, textiles, textiles and papermaking, etc., can solve the problems affecting the production efficiency of carpets, long yarn changing cycle, increasing the burden of waste yarns, etc., so as to improve the yarn utilization rate and carpet productivity , high economic and social benefits, and the effect of reducing labor and lost time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

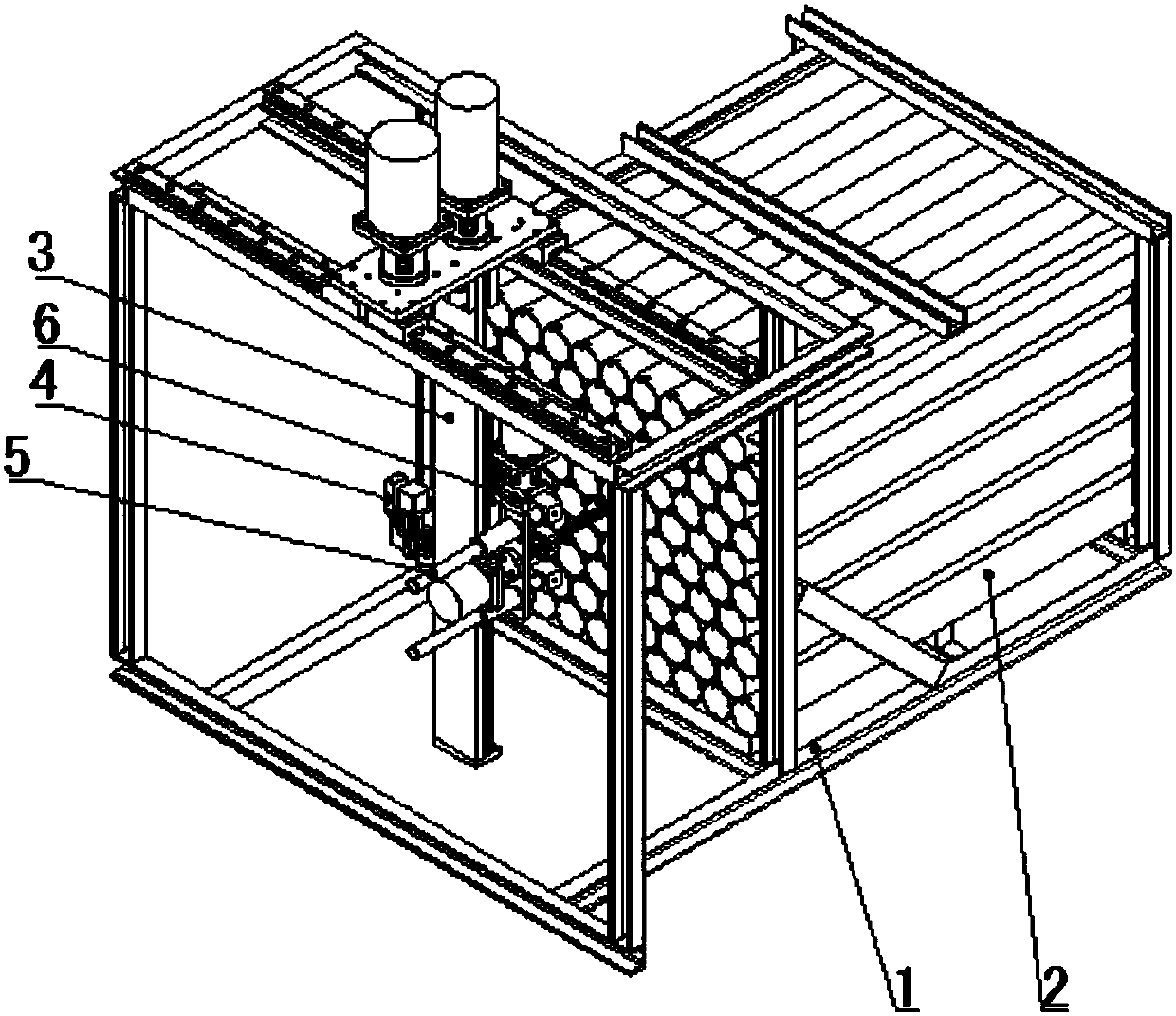

[0033] exist image 3 Among them, the yarn storage body 2 is fixed in the rear box of the frame 1, and the positioning and hunting unit 3 is suspended on the linear guide rail at the top of the frame 1, which can drive the core functional unit 4 to move two-dimensionally in the front box of the frame 1 , the core function unit 4 and the guide frame 5 control and drive the manipulator 6 to move two-dimensionally in the longitudinal plane of the creel, and the manipulator 6 completes the operation of picking and placing the yarn.

[0034] When the smart creel is initially working, that is, when there is no yarn in the yarn storage drum, the yarn cannot automatically pass through the yarn outlet at the end of the yarn storage drum and pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com