Release valve device for reducing knocking noise of pressurizer valve

A technology of blowing valve and knocking sound, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., and can solve the problems of easy knocking sound, difficult precise control of blowing valve, and higher noise requirements of superchargers. Higher-level issues to achieve the effect of reducing the knocking sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

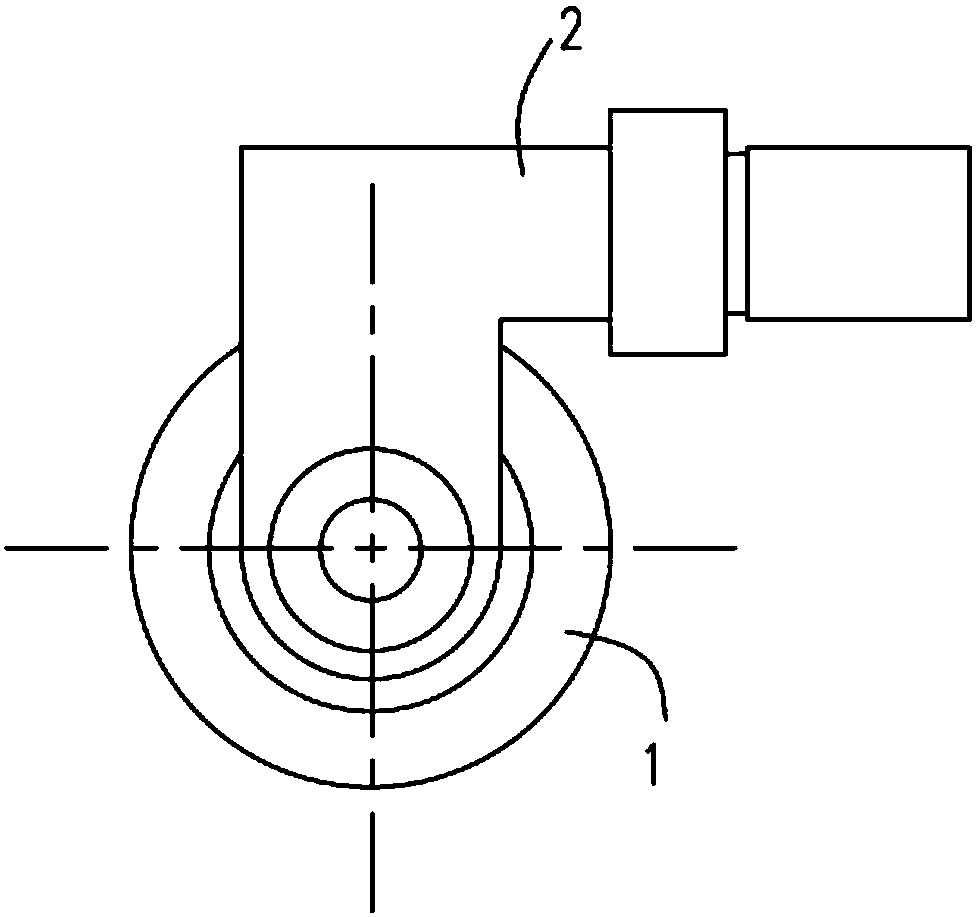

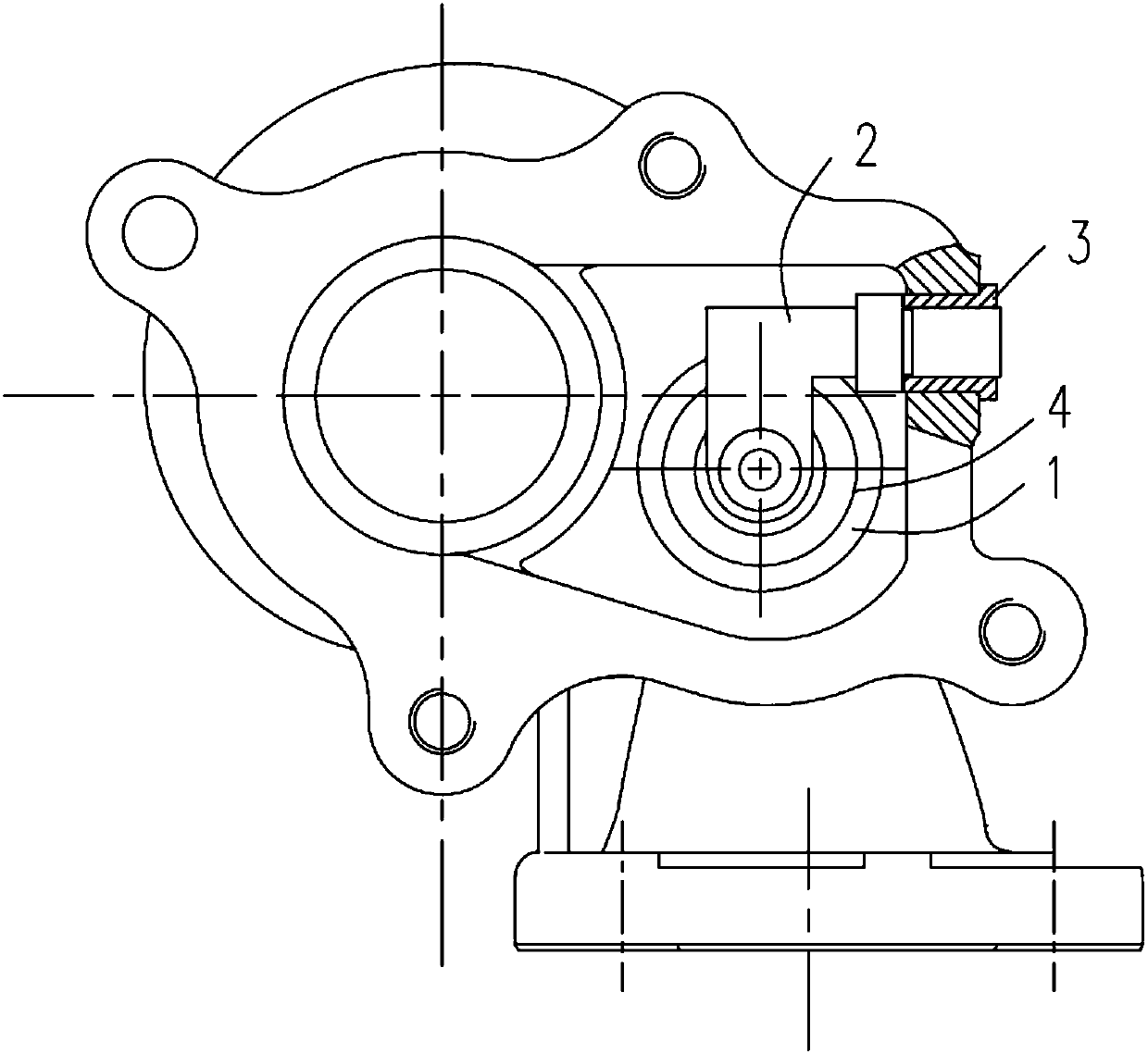

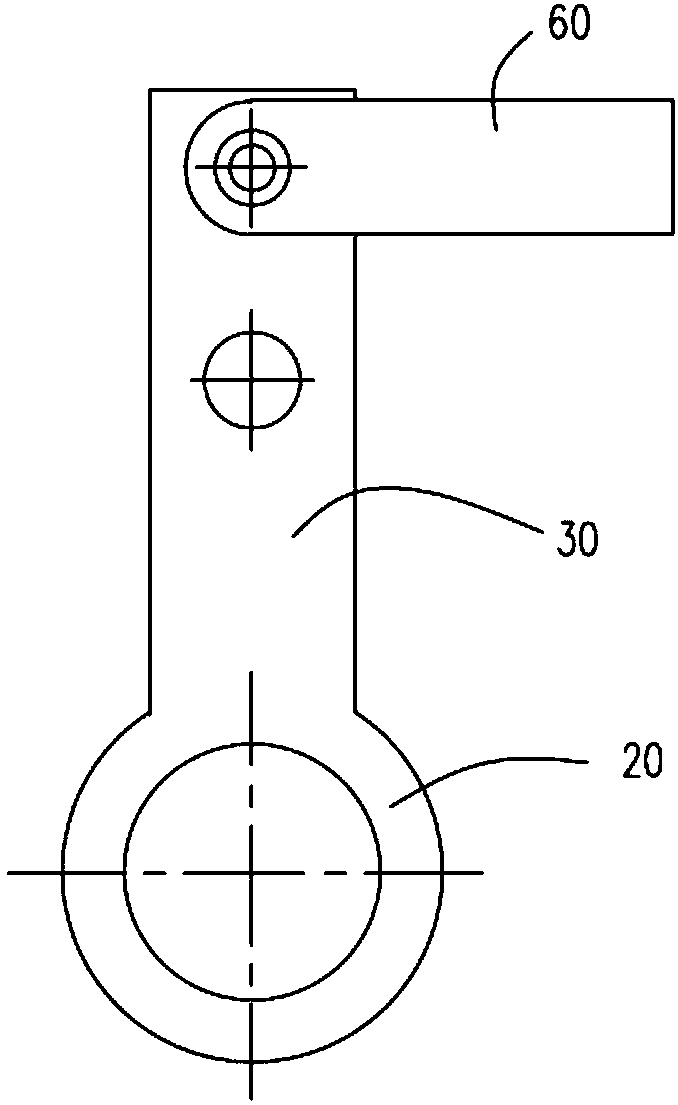

[0019] see image 3 with Figure 4 A blow-off valve device for reducing the knocking sound of the supercharger valve is shown, including a valve 20 corresponding to the bypass valve hole 11 of the turbine box 10, the valve 20 is parallel to the plane where the top of the bypass valve hole 11 is located, The valve 20 is connected to one end of the rocker arm 30 , the middle part of the rocker arm 30 is rotatably connected to the rotating pin assembly 40 arranged on the turbine box 10 , and the other end of the rocker arm 30 is hinged to the front end of the actuator push rod 60 . The rocker arm 30 and the valve 20 are integrated.

[0020] The side of the bypass valve hole 11 in this embodiment is provided with an anti-reverse blocking post 50 to prevent the valve 20 from reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com