Lamp optical system for automobile

A technology for optical systems and lamps, applied in the field of optical systems, can solve the problems of occupying a large body space and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

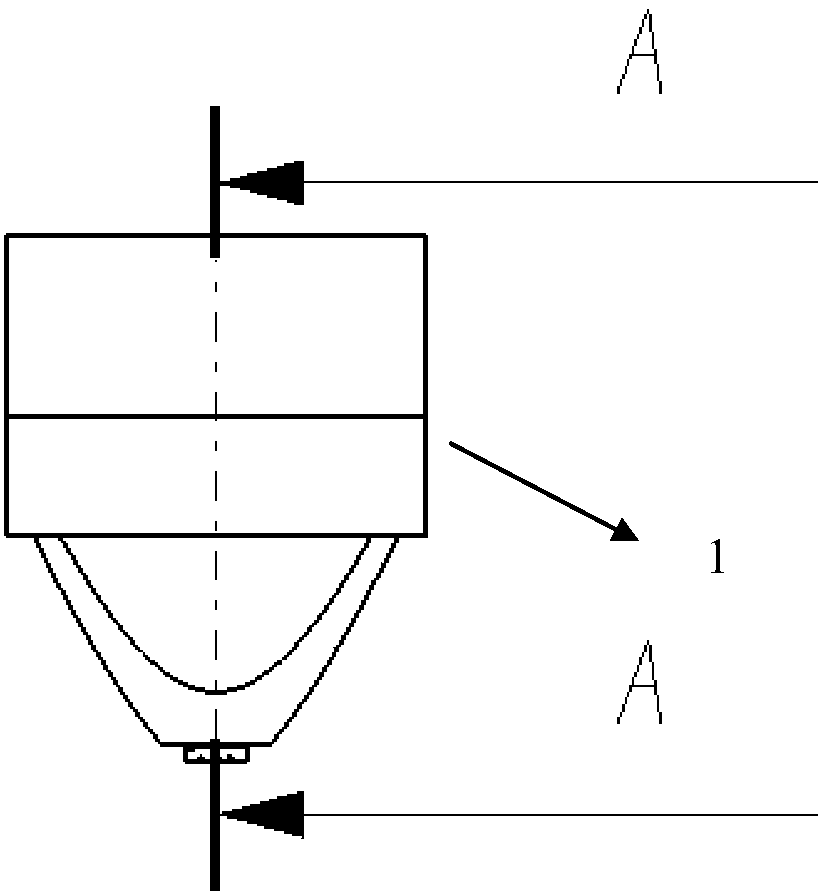

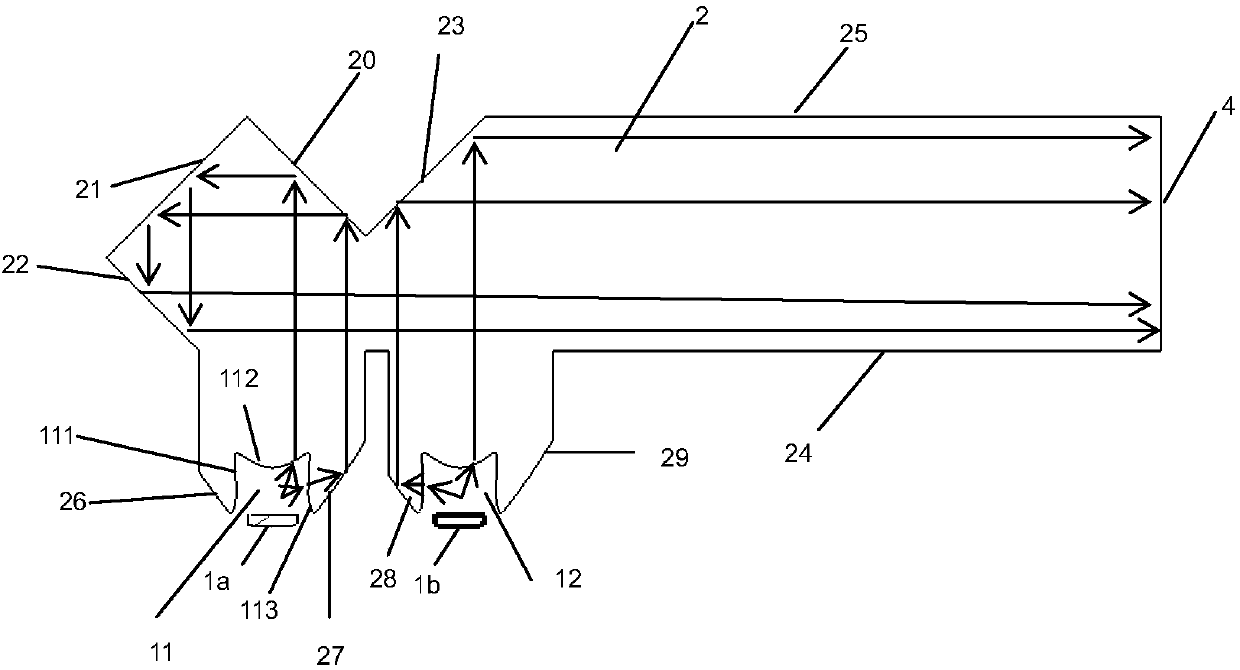

[0030] Such as Figure 1 to Figure 3 In the shown optical system of a vehicle lamp, the entire optical system of a lamp includes a light source 1 a , a light source 1 b and a thick-walled light guide 2 . The thick-walled light guide 2 is an integral polyhedron structure, and the inner wall of the polyhedron structure is mainly composed of an optical coupling surface 20, an optical coupling surface 21, an optical coupling surface 22, an optical coupling surface 23, an optical coupling surface 26, an optical coupling surface 27, an optical The coupling surface 28 , the optical coupling surface 29 , the bottom surface 24 , the top surface 25 and the light emitting surface 4 are composed.

[0031] Grooves 11 and 12 are opened on the thick-walled light guide 2, respectively corresponding to the light sources 1a and 1b. The light emitted from the light source 1a enters the thick-walled light guide 2 through the groove bottom 112 and groove walls (111 and 113) of the groove body 11,...

Embodiment 2

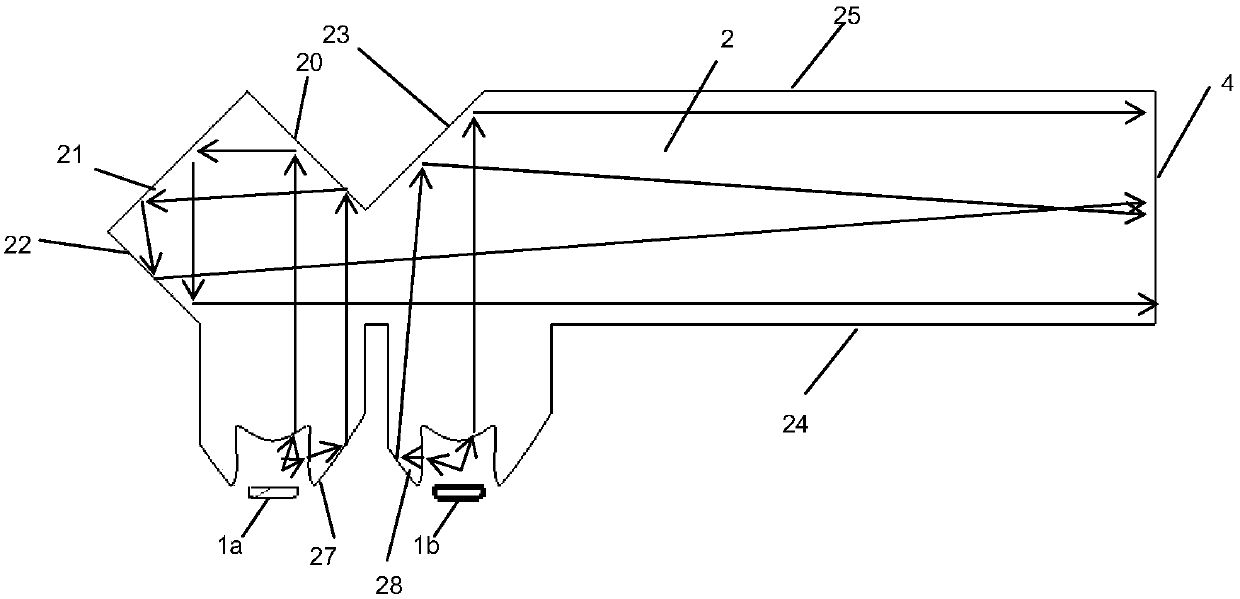

[0041] Such as Figure 4 Shown, is another embodiment of the present invention, with respect to the difference of embodiment 1, the plane of the optical coupling surface 23 in embodiment 1 is changed into the curved surface in the figure (with respect to the thick-walled light guide of polyhedron is inner convex surface ), that is, the optical coupling surface 23b in the figure.

[0042] Similarly, each optical coupling surface in Embodiment 1 can be a plane, an arc or a free-form surface

Embodiment 3

[0044] Such as Figure 5 As shown, it is another embodiment of the present invention. Compared with Embodiment 1, the difference is that the groove structure of the light-incoming regions of the two light sources is simplified as a convex surface protruding outward relative to the polyhedron, that is, in the figure The convex surfaces 51 and 52 are respectively used to receive the light emitted by the two light sources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com