Design Method for Shear Resistance of Orthotropic Steel-Concrete Composite Bridge Deck Interface

An orthotropic, combined bridge technology, applied in the field of bridge engineering, can solve problems such as non-universality, discreteness, large modeling and analysis workload, etc., to avoid repeated finite element modeling work, clear concepts, and applicability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The design method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

[0040] One, the design method of the present invention for orthotropic steel-concrete composite deck interface shearing comprises the following steps:

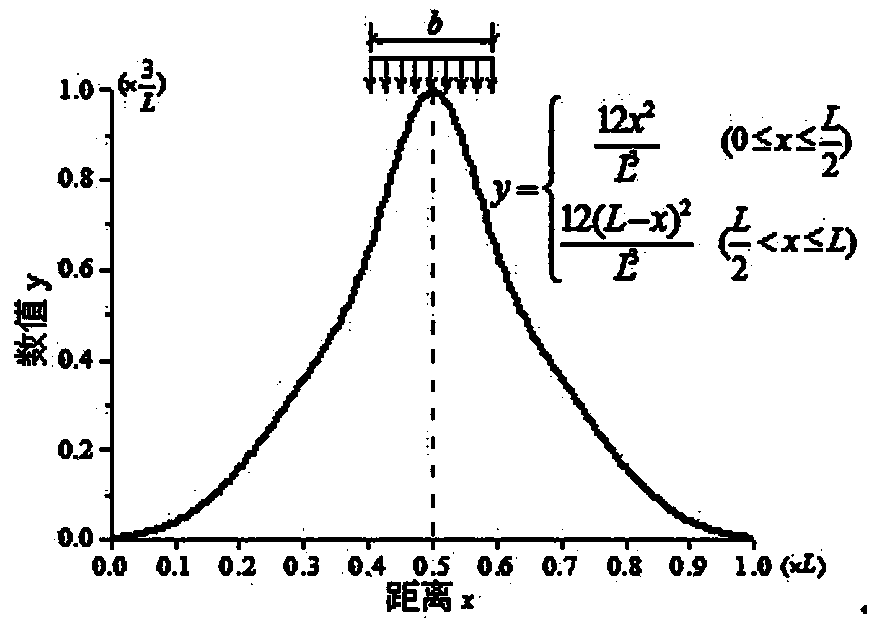

[0041] In the first step, the distribution width of a single wheel load in the transverse bridge direction is set as a , the distribution width of the longitudinal bridge is b , and the wheel load concentration of the transverse bridge is q 0, and the influence line coefficient on the mid-span bending moment of the diaphragm is mu :

[0042] Firstly, a line of influence of the longitudinal position of the inner wheel load on the mid-span section bending moment of the inner wheel load with a distance L of the diaphragm is constructed, as shown in figure 1 As shown, the influence line is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com