Automatic disc type grinding disc equipment

A disc type and grinding disc technology, which is applied in the field of grinding equipment and article polishing, can solve the problems of high cost, complex design, low equipment precision, etc., and achieve the effects of less energy consumption and pollution, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

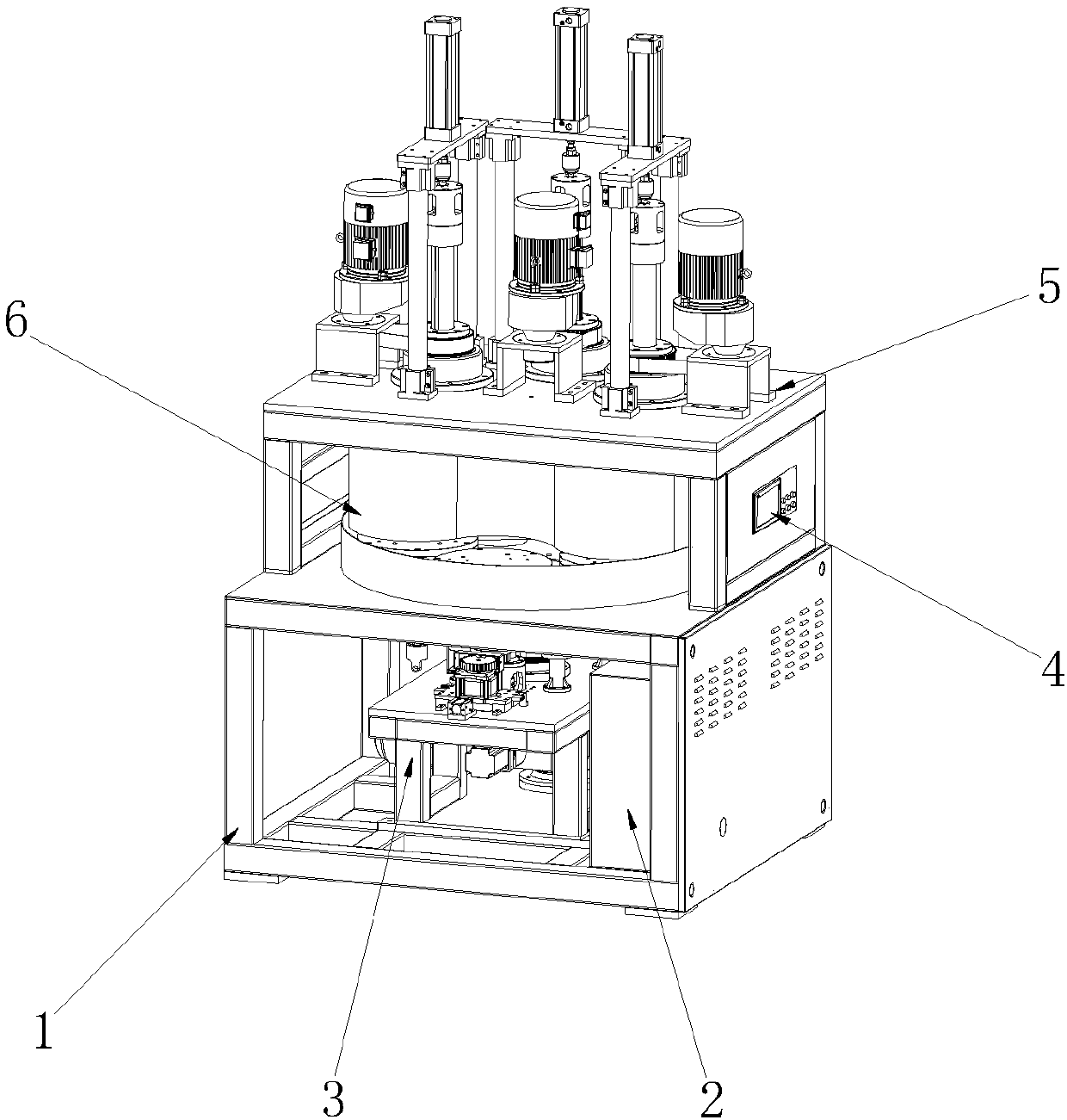

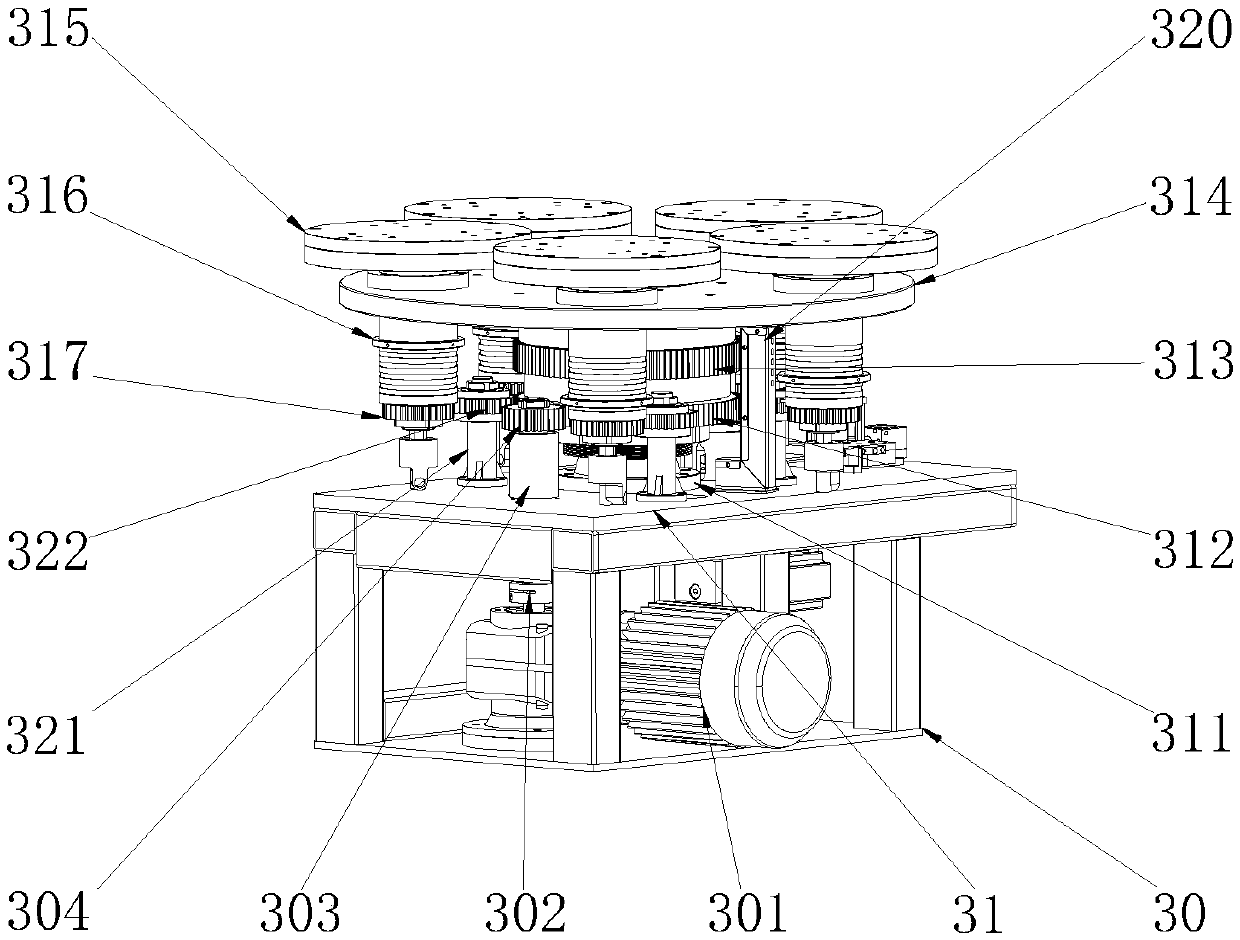

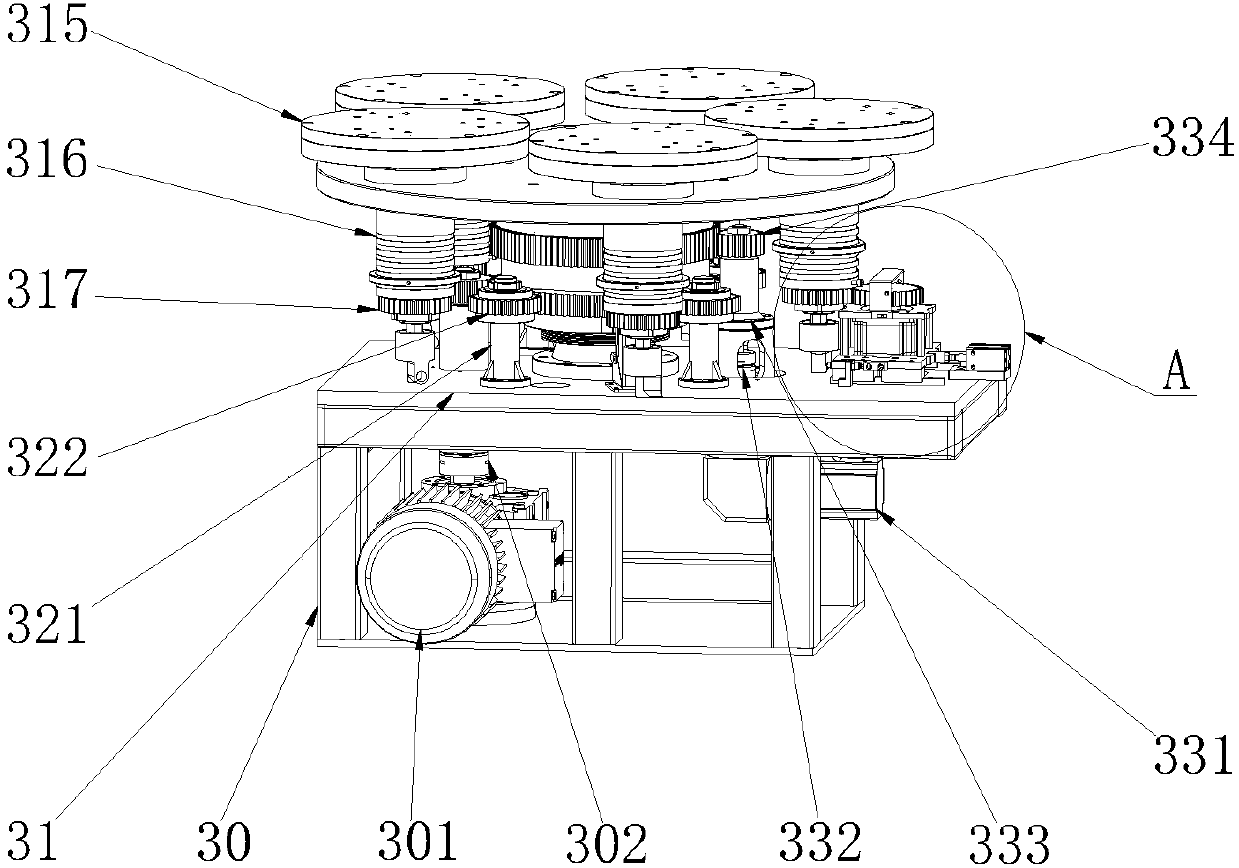

[0047] See Figure 1 to Figure 6 Shown: including the frame 1, the inside of the frame 1 is provided with an electric box 2, the lower turntable assembly 3, the upper end of the frame 1 is provided with an upper frame body 4, the upper part of the upper frame body 4 is provided with an upper polishing assembly 5, and the upper frame body 4 A control screen 7 is provided on the side, and a waterproof shield 6 is provided inside the upper frame body 4. The lower turntable assembly 3 includes a turntable mounting frame 30 and a turntable mounting table 31, and the upper polishing assembly 5 includes a polishing assembly mounting table 50. .

[0048] Described turntable mounting frame 30 is provided with five-disk motion motor 301, and turntable mounting platform 31 is provided with five-disk drive shaft 303, and five-disk motion motor 301 is connected with five-disk drive shaft 303 by five-disk motion coupling 302, The five-disk drive shaft 303 is provided with a five-disc drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com