Bottled drink storage and transportation box

A beverage and box technology, applied in the field of bottled beverage storage and transportation boxes, can solve the problems of beverage bottles colliding with each other, beverage bottles broken, beverage bottle collisions, etc., to achieve the effects of convenient loading and unloading, improving safety, and avoiding mutual collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

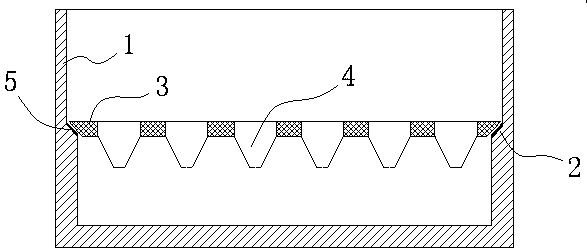

[0013] As shown in the figure, the bottled beverage storage and transportation box of the present embodiment includes a box body 1, the inner side wall of the box body 1 is provided with a step 2, and the step 2 is provided with a partition 3, and the partition 3 is connected to the step 2. The contact surface is provided with an elastic vibration-isolating layer 4; a number of cavities 5 with upward openings are distributed in an array on the partition plate 3; the cavities 5 are funnel-shaped structures with a large top and a small bottom. The height of the dividing plate 3 is positioned at the top of the cavity 5 to ensure that after the beverage bottle is installed, the center of gravity of the beverage bottle is located below the dividing plate 3, thereby improving the stability of transportation.

[0014] When the above-mentioned box body 1 is storing and transporting beverages, the beverage bottle is put into the cavity 5 upside down. Since the cavity 5 is a funnel-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com