Grab chip structure of a chip burner

A chip structure and burner technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as low equipment work efficiency, and achieve the effects of improving accuracy, shortening assembly time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

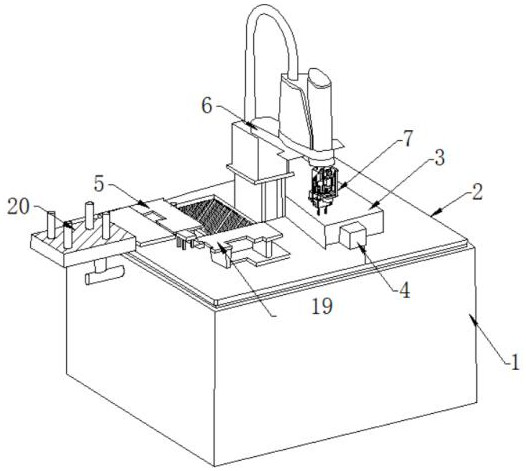

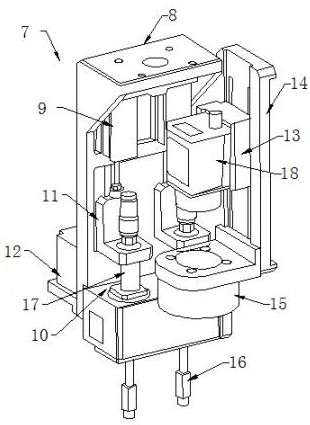

[0018] Such as Figure 1-2 As shown, a grabbing chip structure of a chip burning machine includes a Z-axis module 7, a four-axis robot arm 6 is installed above the Z-axis module 7, and a tray loading mechanism placement area 5 is provided below the four-axis robot arm 6 , And the disc loading mechanism placement area 5 is set on the console 2, the upper side panel of the console 2 is connected with the burning area 3, the burning area 3 side is provided with a tray replenishment tray 19, and the burning area 3 side The lower CCD camera working area 4 is connected. The Z-axis module 7 includes a Z-axis mounting plate 8. A Z-direction pneumatic cylinder 9 is provided under the Z-axis mounting plate 8. The lower end of the Z-direction pneumatic cylinder 9 is connected with a fixed plate 11, which is connected to the fixed plate 11 There is a chip pressing rod 17, a burning table 10 is arranged under the chip pressing rod 17, and one side of the burning table 10 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com