Cloth winding roller for ending stage of textile printing and dyeing

A technology for textile printing, dyeing, and fabric rolls, applied in the field of fabric rolls, can solve the problems of not allowing downtime, affecting production efficiency, and high manufacturing costs, and achieving the effects of improving the difficulty of fixing and disassembling, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

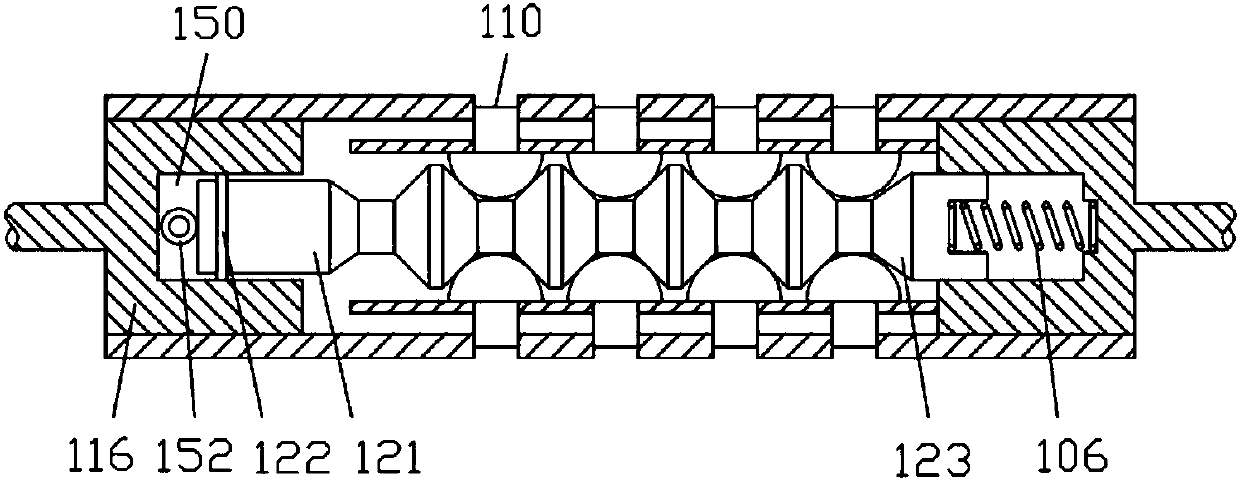

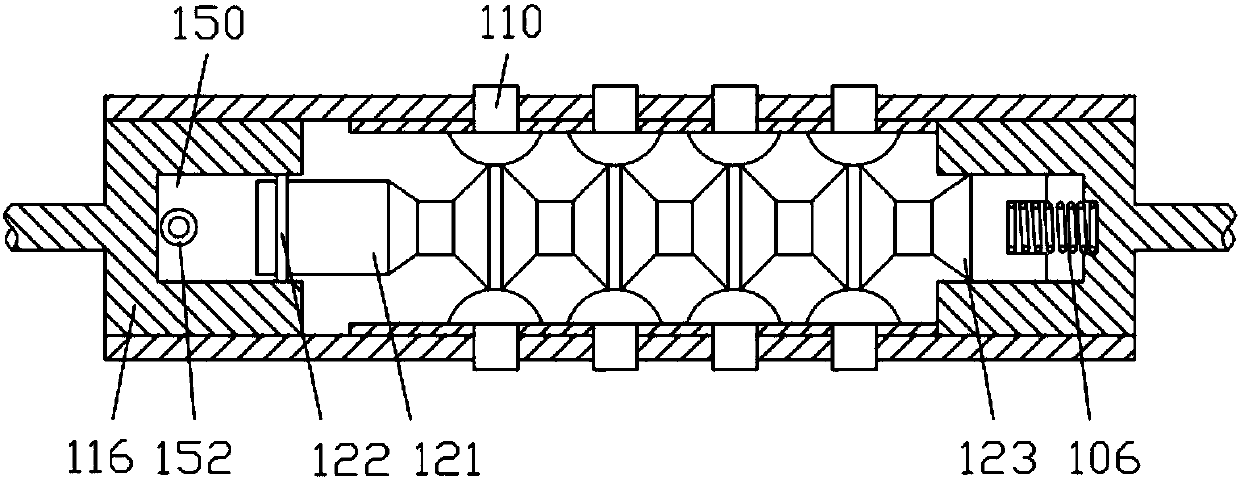

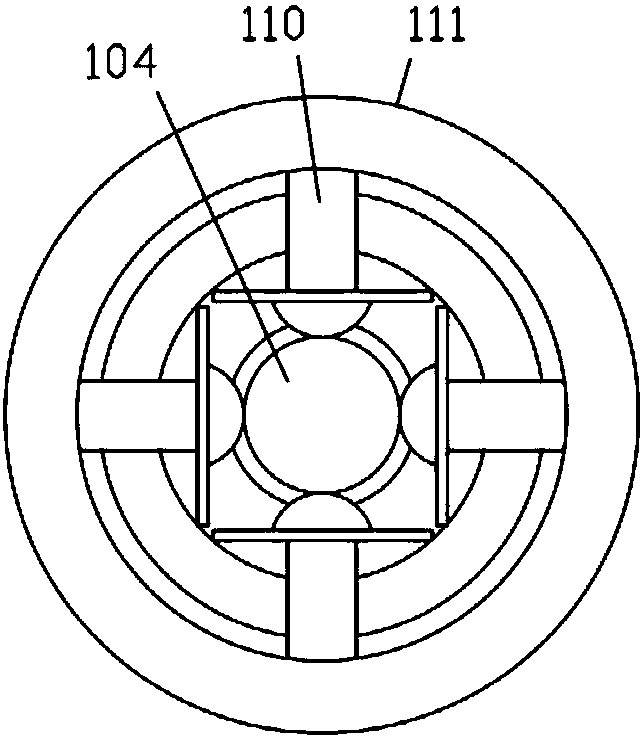

[0016] Such as Figure 1-3 As shown, a fabric roll used in the finishing stage of textile printing and dyeing, which includes an expansion shaft and a reel 111 arranged outside the expansion shaft. The expansion shaft includes a cylindrical shaft body, a plunger 104, a return spring 106, and an expansion pin holder and a plurality of expansion pins 110, the cylindrical shaft body includes the inner surface of the shaft and the outer surface of the shaft, and the left and right ends of the cylindrical shaft body are respectively formed with a first shaft end opening 116 and a second shaft end opening, the first shaft end opening 116 It communicates with the opening of the second shaft end through the hollow shaft cavity; the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com