Connecting structure of hydraulic oil cylinder top cover and oil cylinder

A technology of hydraulic oil cylinder and connection structure, applied in the field of hydraulic oil cylinder, can solve the problems of reducing the service life of the top cover, damage to bolts and threaded connection parts, and difficulty in disassembling the top cover of the oil cylinder, and achieves the effect of increasing accumulation and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

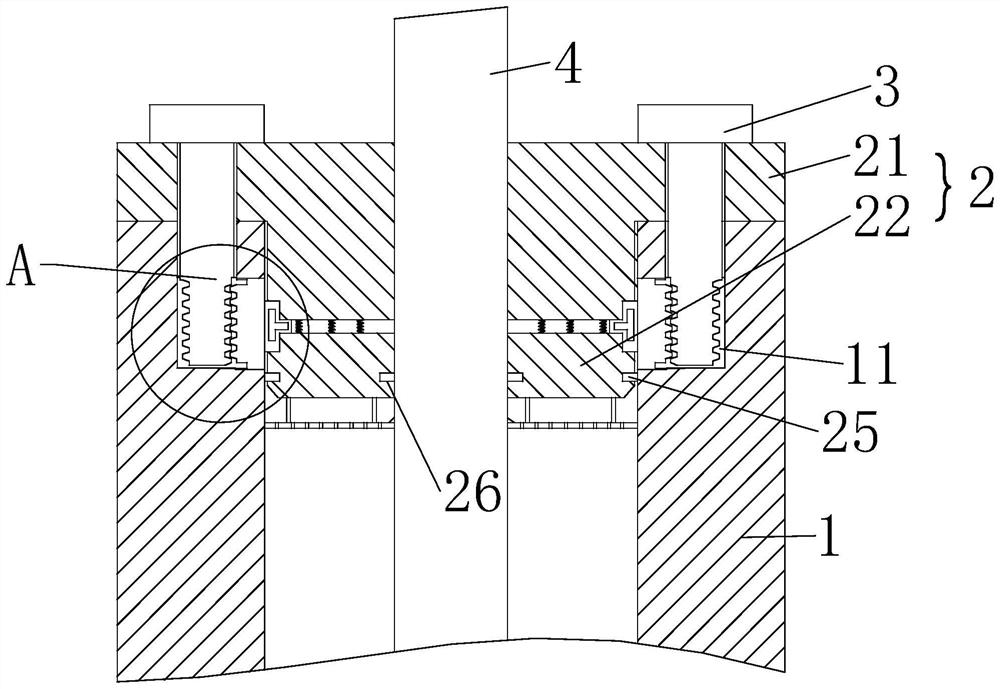

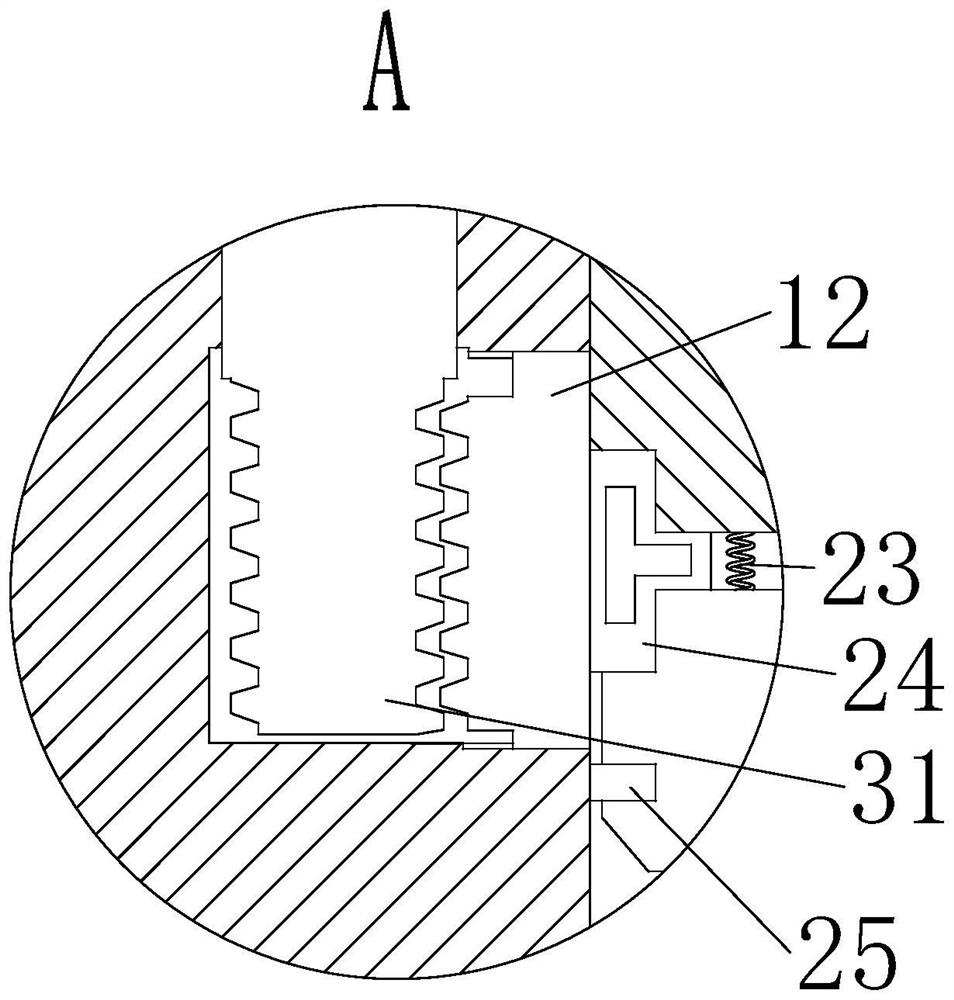

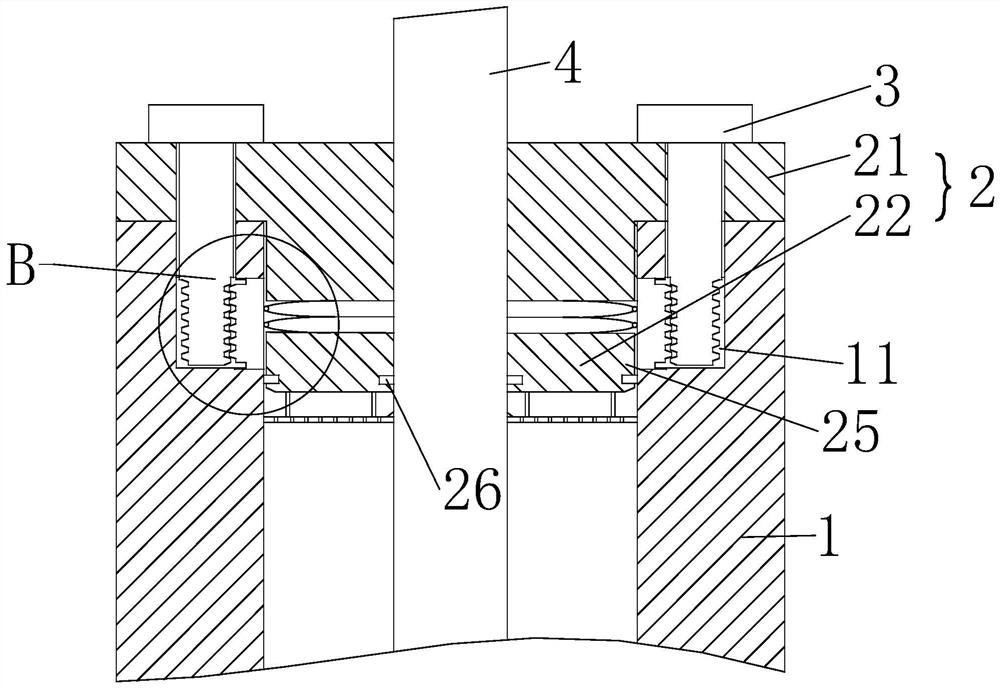

[0025] As a specific embodiment of the present invention, the inside of the No. 1 sealing ring 24 is set as a hollow structure.

[0026] When the lower top cover 22 in the cylinder body 1 is impacted by factors such as hydraulic pressure and thermal expansion, the No. 1 sealing ring 24 is squeezed by the lower top cover 22 and the upper top cover 21, so that the No. 1 sealing ring 24 is extruded and deformed. The inside of the seal ring 24 is set as a hollow structure, which can make the deformation of the No. 1 seal ring 24 larger and better push the trapezoidal tooth block 12 in the groove 11 to match the trapezoidal tooth bolt 31 on the bolt 3, and the No. 1 seal When the ring 24 is squeezed, the degree of deformation is greater to achieve a better sealing effect;

[0027] As a specific embodiment of the present invention, there are multiple springs 23 arranged evenly, and the springs 23 cooperate with the lower top cover 22 to achieve a buffering effect.

[0028] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com