Overall construction method of outer wall assembly timber formwork

An integral construction, wood formwork technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of concrete slurry leakage, low construction efficiency, and many repeated operations, etc. Reduce construction costs, ensure quality and performance, and ensure the effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention more clearly understood, the embodiments will be described in detail below in conjunction with the accompanying drawings.

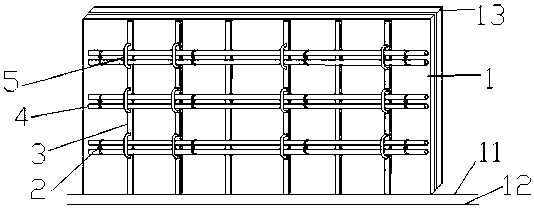

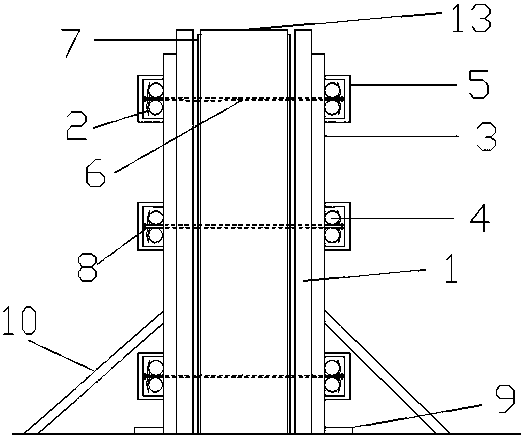

[0023] Depend on figure 1 and figure 2 It can be seen that an overall construction method for assembling wooden formwork for external walls, the method is carried out according to the following steps:

[0024] Step 1: Design formwork according to the form and characteristics of the project structure and site construction conditions, determine the layout of the formwork, and draw a complete set of formwork design drawings.

[0025] Step 2: Assemble the formwork. Assemble the formwork 1 according to the design drawing described in step 1. Reserve bolt holes on the assembled formwork 1. The outside of the formwork 1 uses square timber 3 assembled vertically as the secondary keel, and the square timber The outer side of 3 is horizontally assembled with two steel pipes 4 as a group as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com