Rapid switching device and method for robot end tool

A technology of end tool and changing device, applied in the field of robot end tool quick changing device, can solve problems such as time-consuming, laborious and difficult, and achieve the effect of quick disassembly and assembly process, good reliability and large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

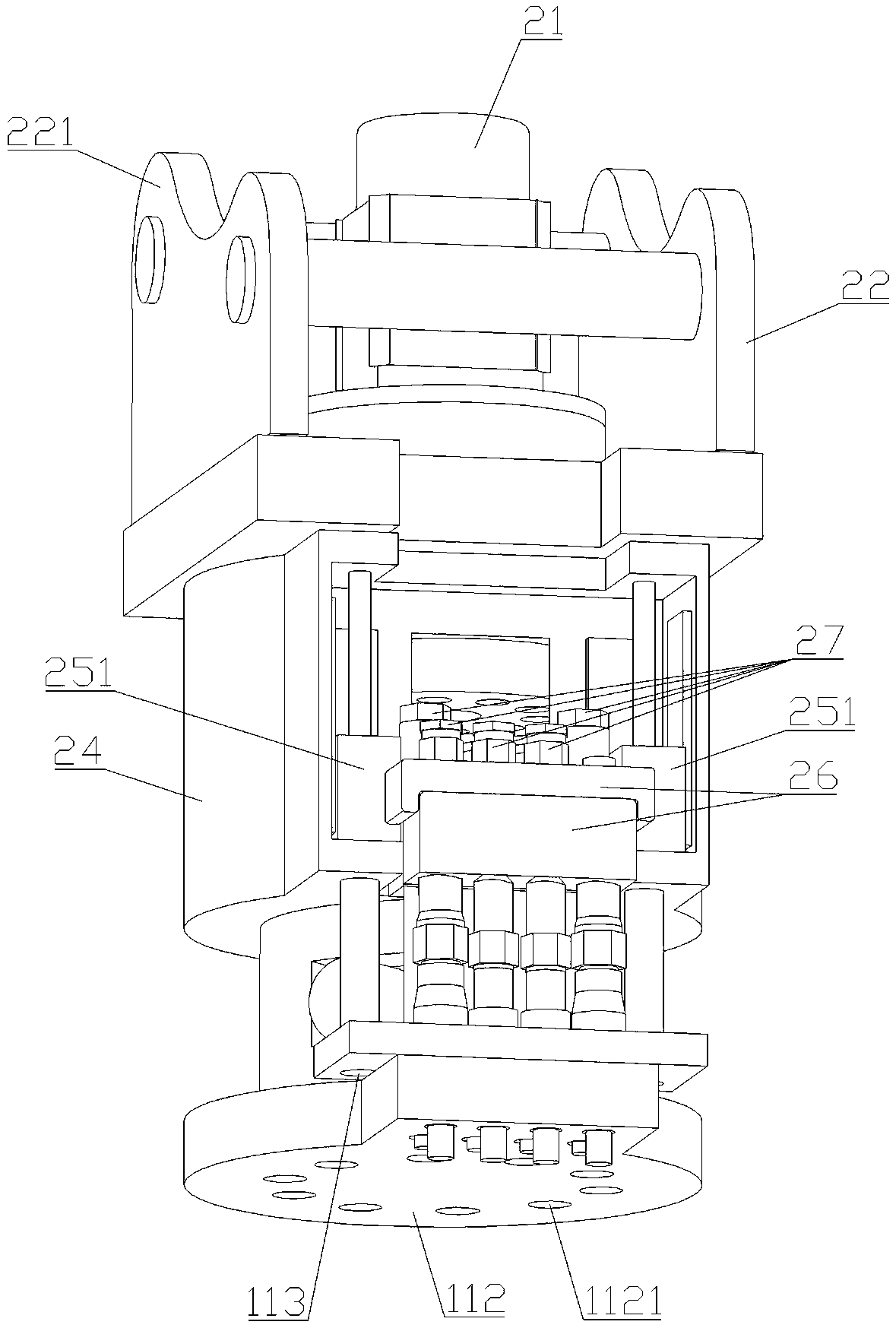

[0044] like Figure 1-7 As shown, the robot end tool quick change device includes a first assembly and a second assembly.

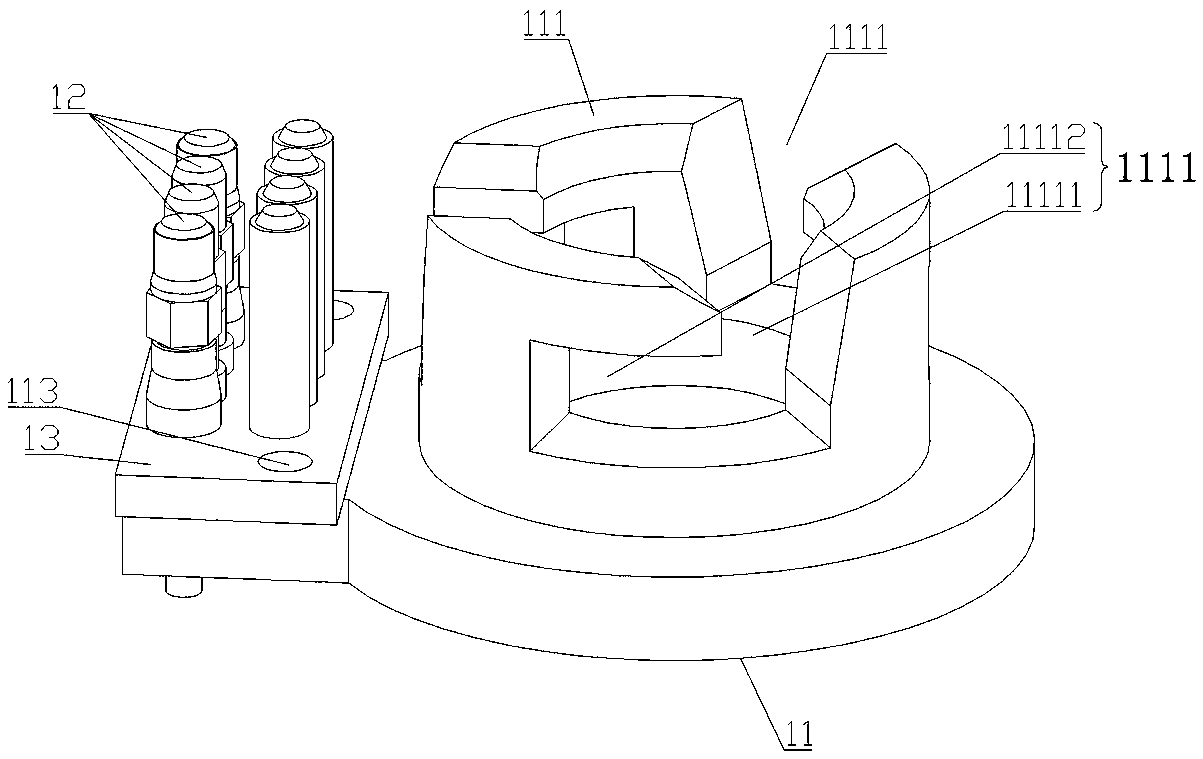

[0045] The first assembly includes a tool tray 11 , a male connector 12 and a male connector seat 13 .

[0046] One side of the tool tray 11 is provided with an engaging portion A, and the other side is provided with a tool connection surface 112 . The connecting portion A is an annular boss 111 fixed on the tool tray 11, and an L-shaped notch 1111 is provided on the annular boss. The L-shaped notch 1111 includes a vertical section 11111 and a horizontal section 11112 communicating with the vertical section 11111. The tool connection surface 112 is provided with a mounting hole A1121 for mounting a tool.

[0047] The male joint 12 is installed on the male joint seat 13 , and the male joint seat 13 is fixedly connected to the tool tray 11 .

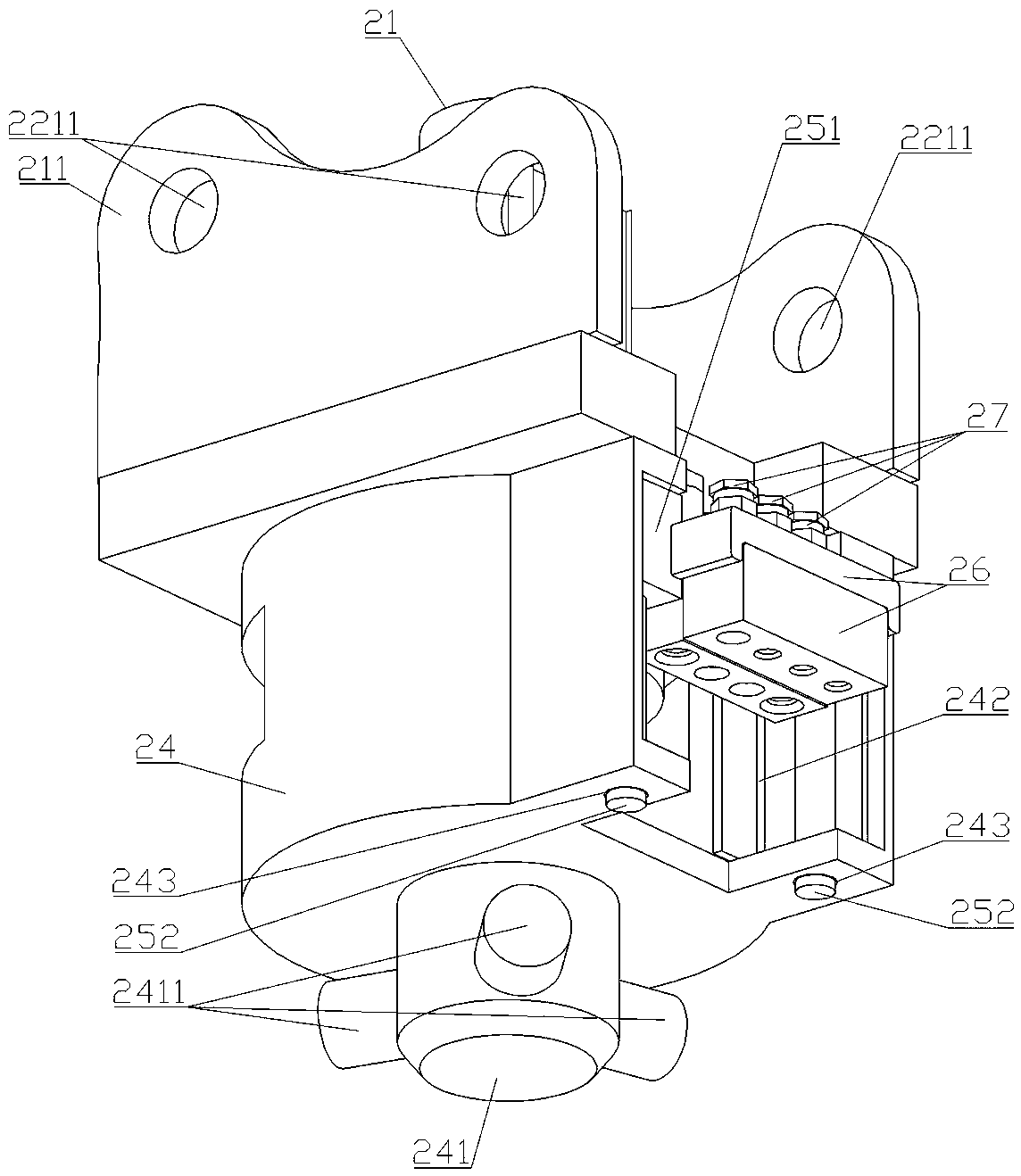

[0048] The second assembly includes a motor 21 , a connecting seat A22 , a rotating sleeve 23 , a connecting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com