Patents

Literature

52results about How to "Reduce support stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

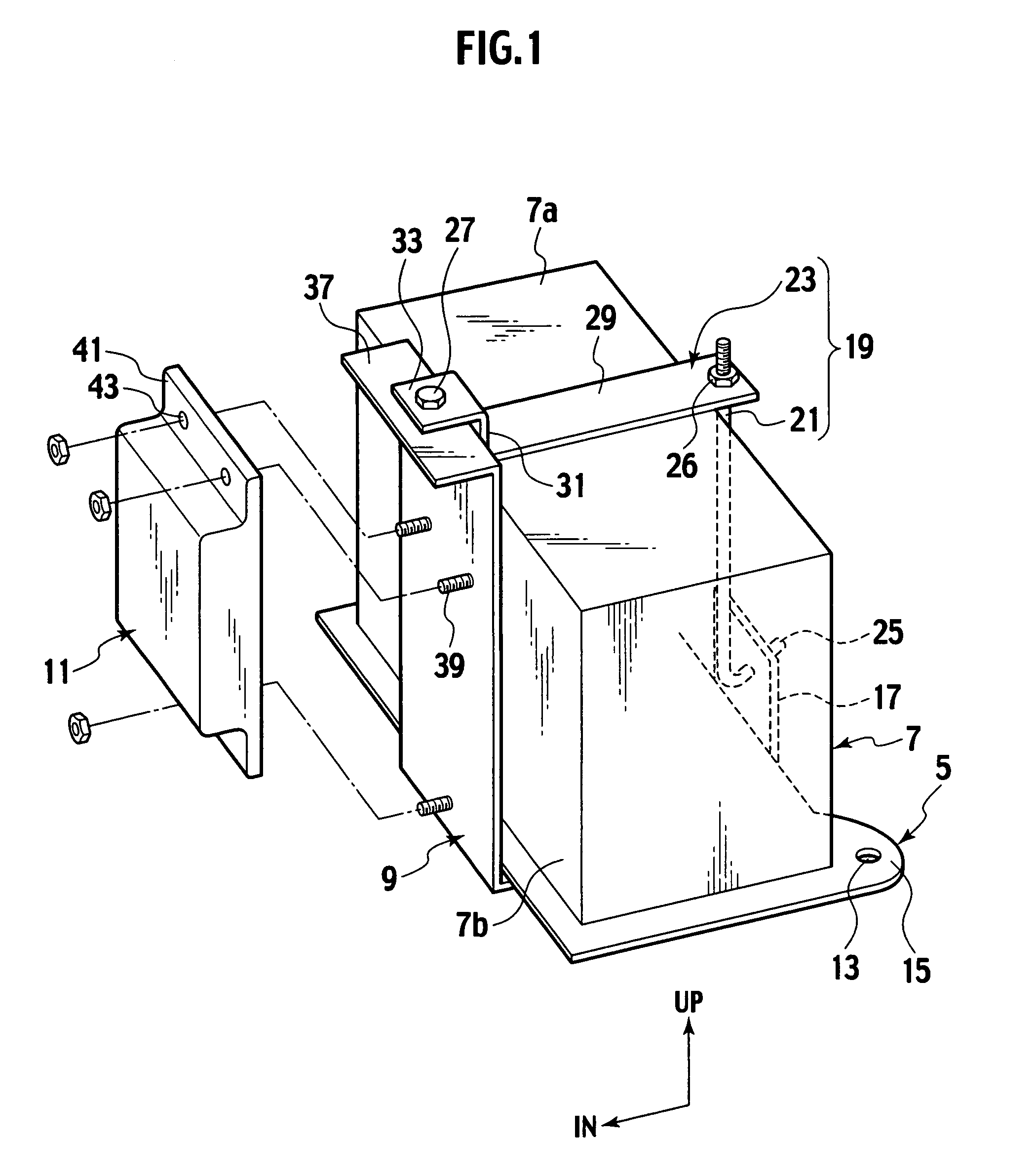

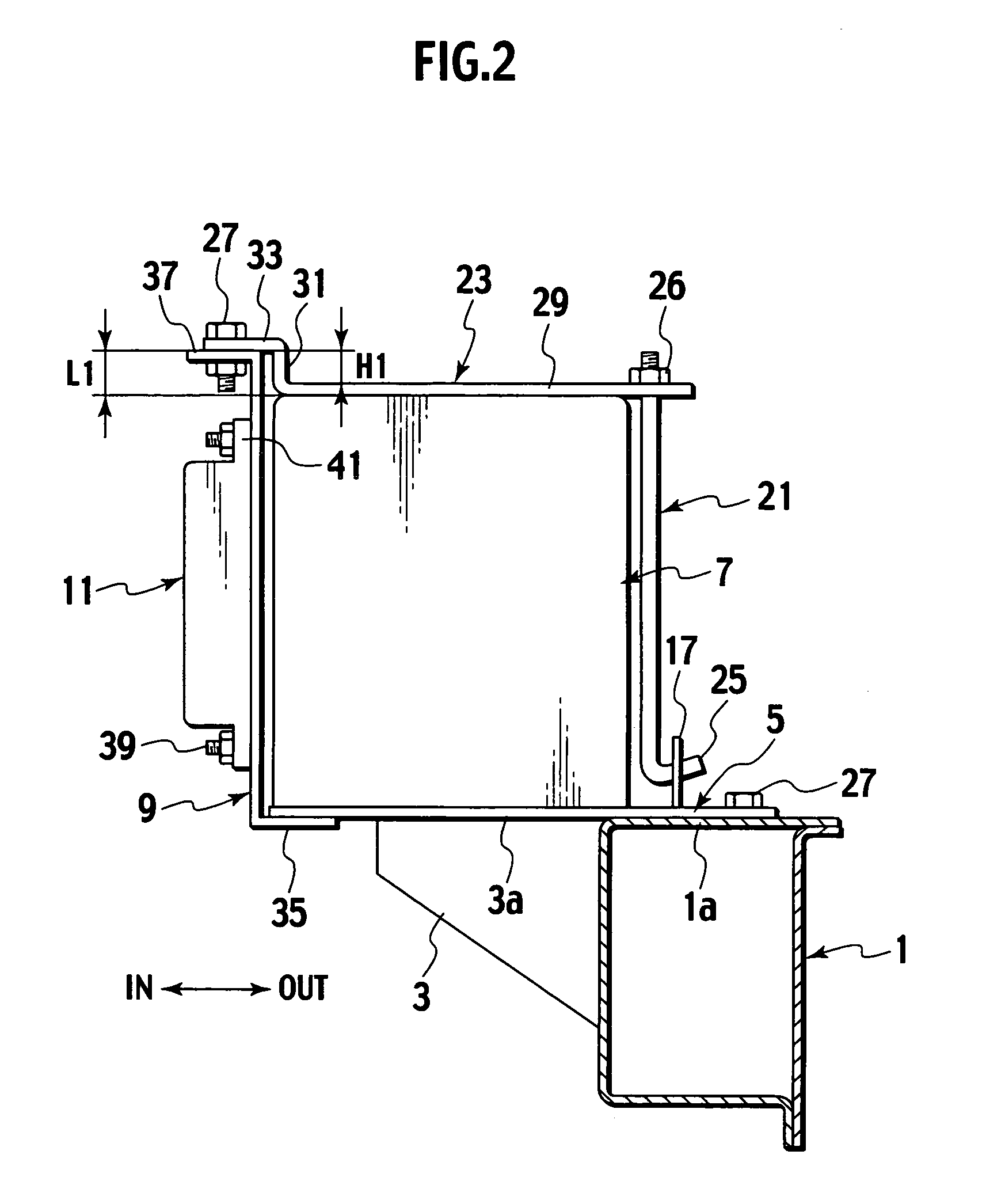

Support structure of parts for vehicle

InactiveUS7331559B2Improve rigidityReduced strengthFurniture partsSuperstructure subunitsMechanical engineeringStructural element

A support structure of parts for a vehicle including: a tray fixed to a structural member of a vehicle body for mounting a first part thereto; a retainer member for retaining the first part on the tray; and a vertically extending support member for supporting a second part on the side of the first part. The support member is connected to the tray at a lower end thereof and to the retainer member at an upper end thereof.

Owner:NISSAN MOTOR CO LTD

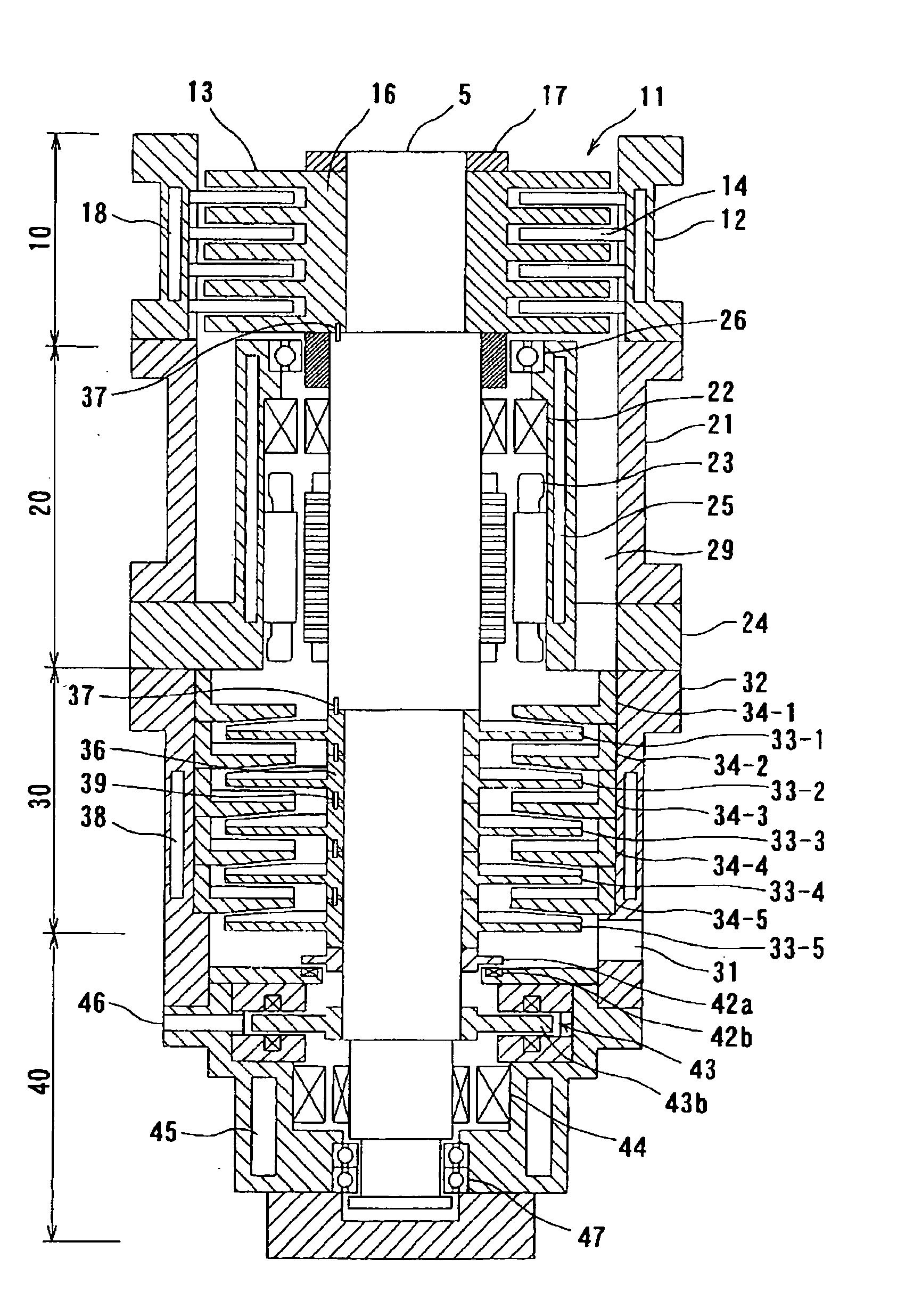

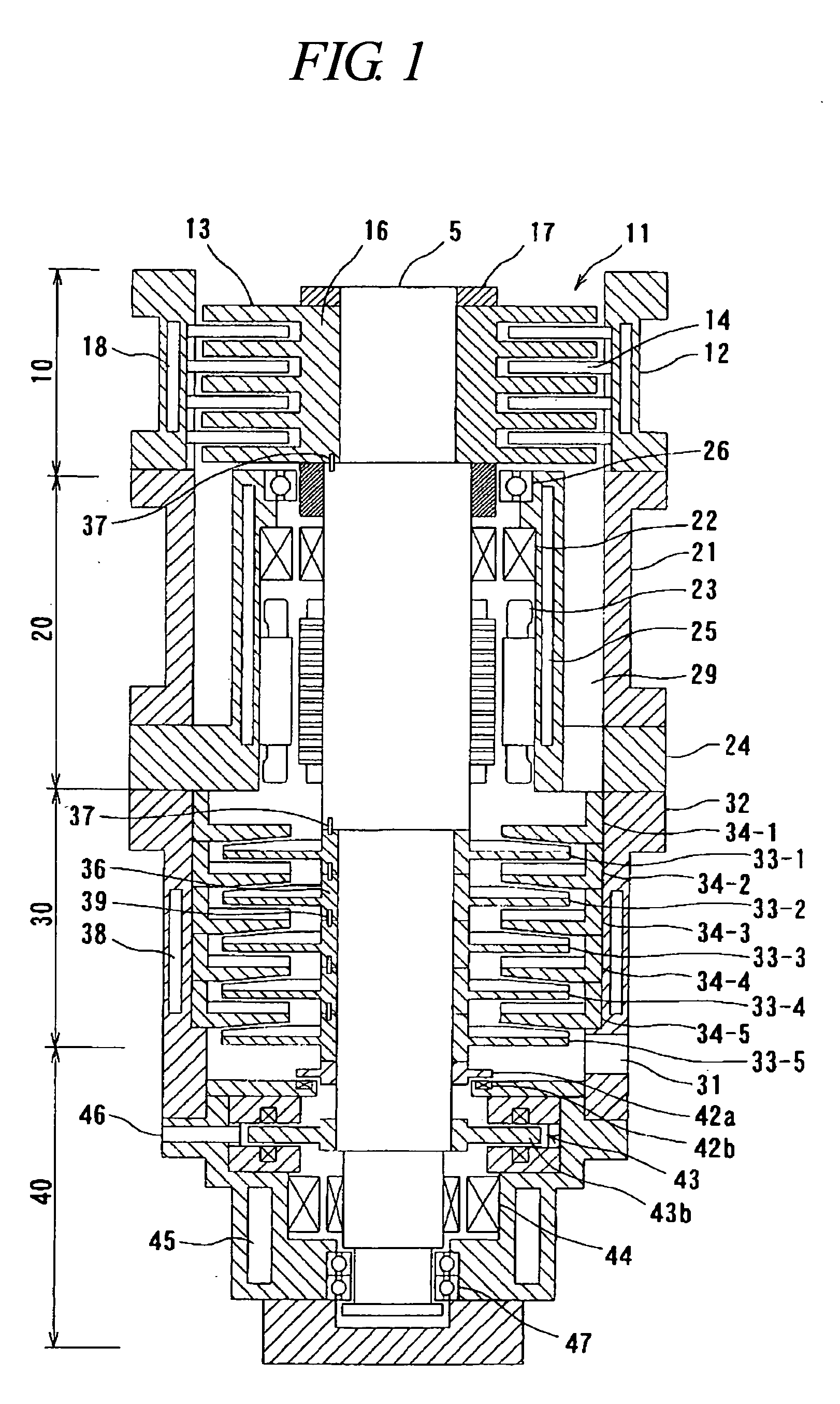

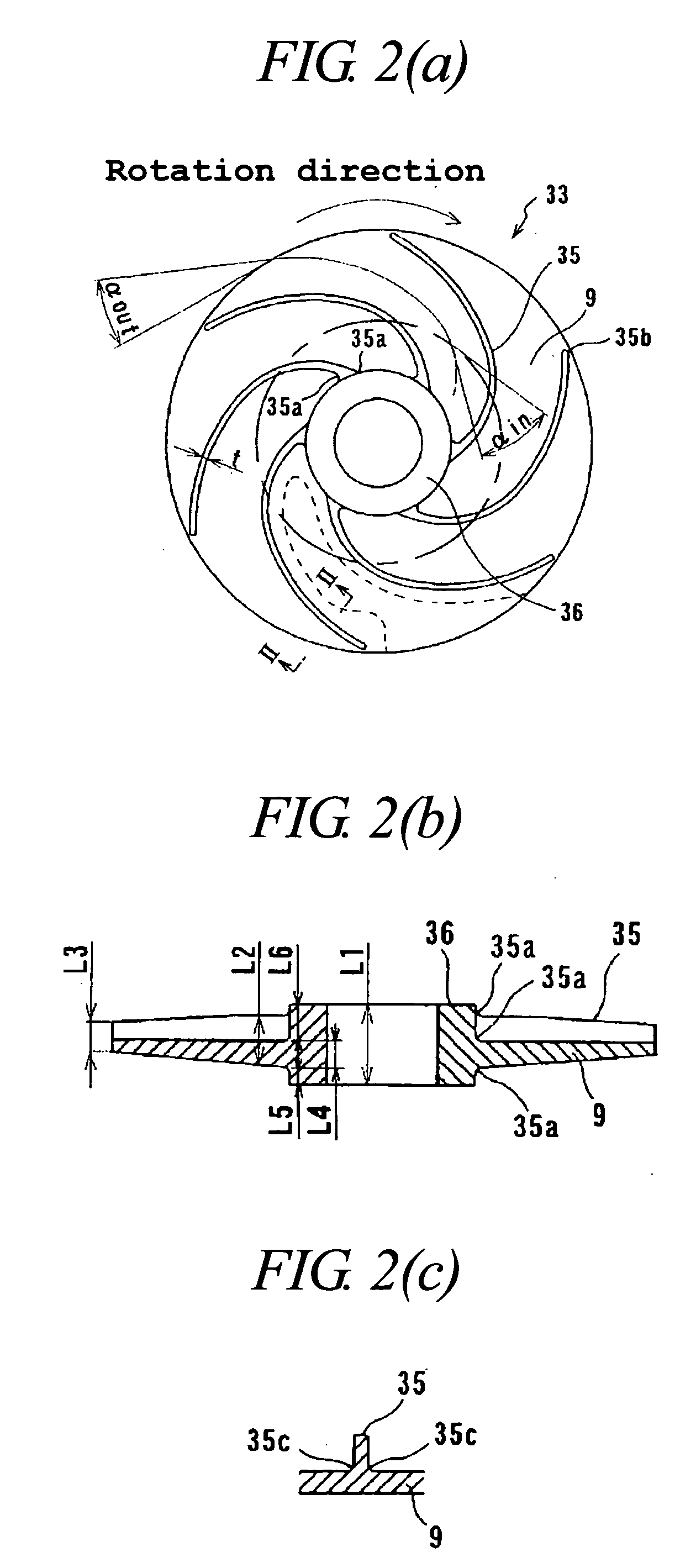

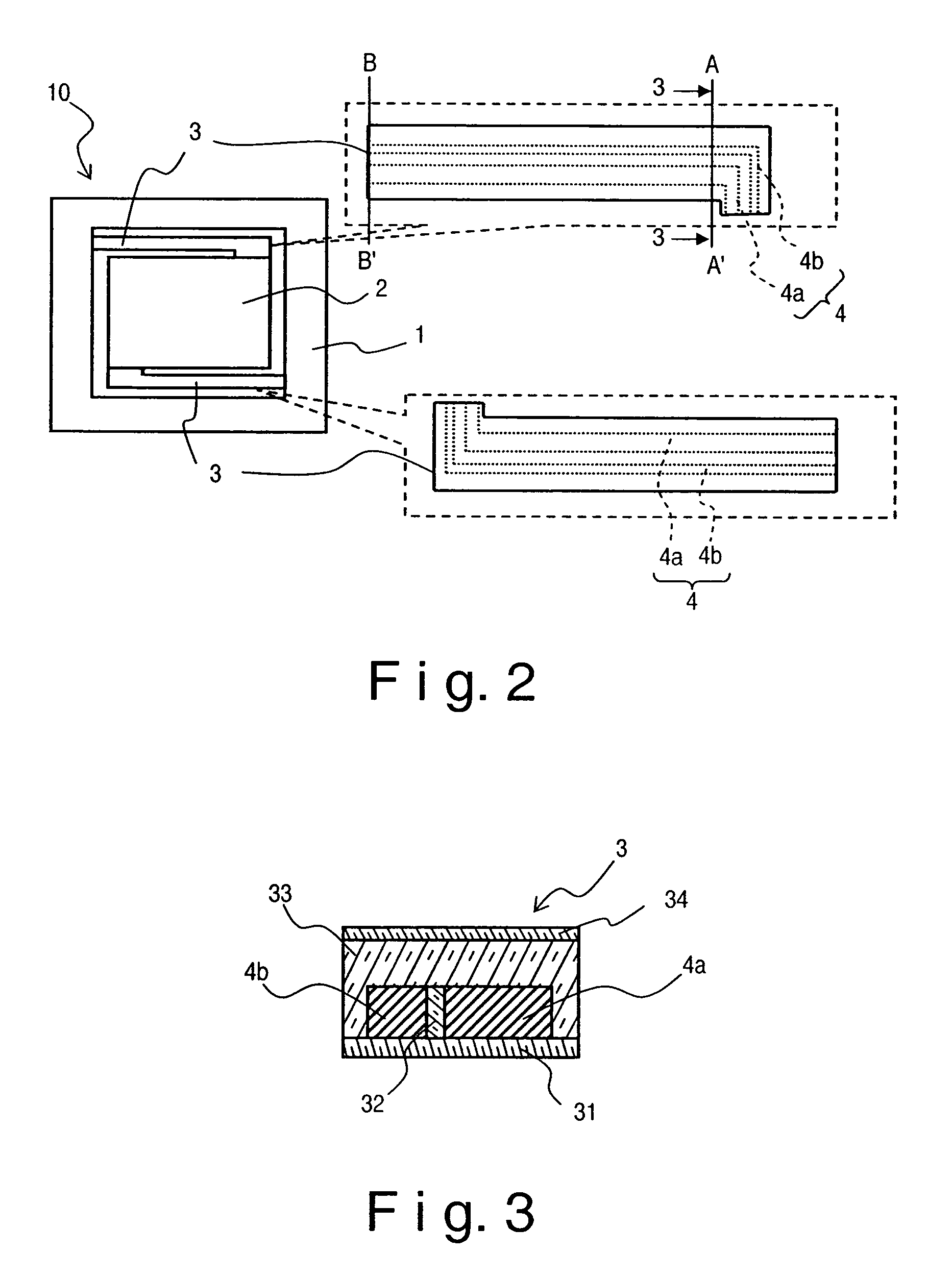

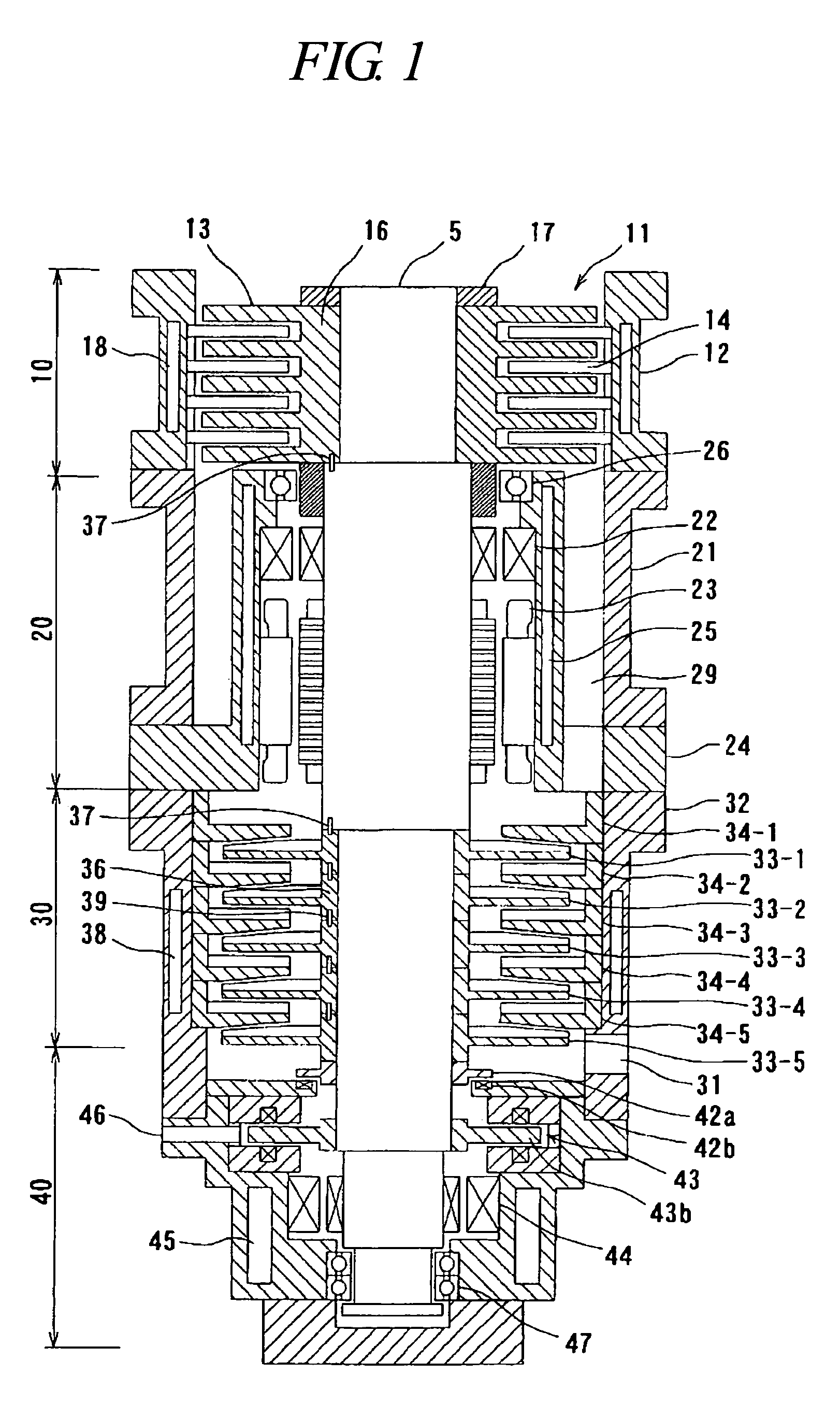

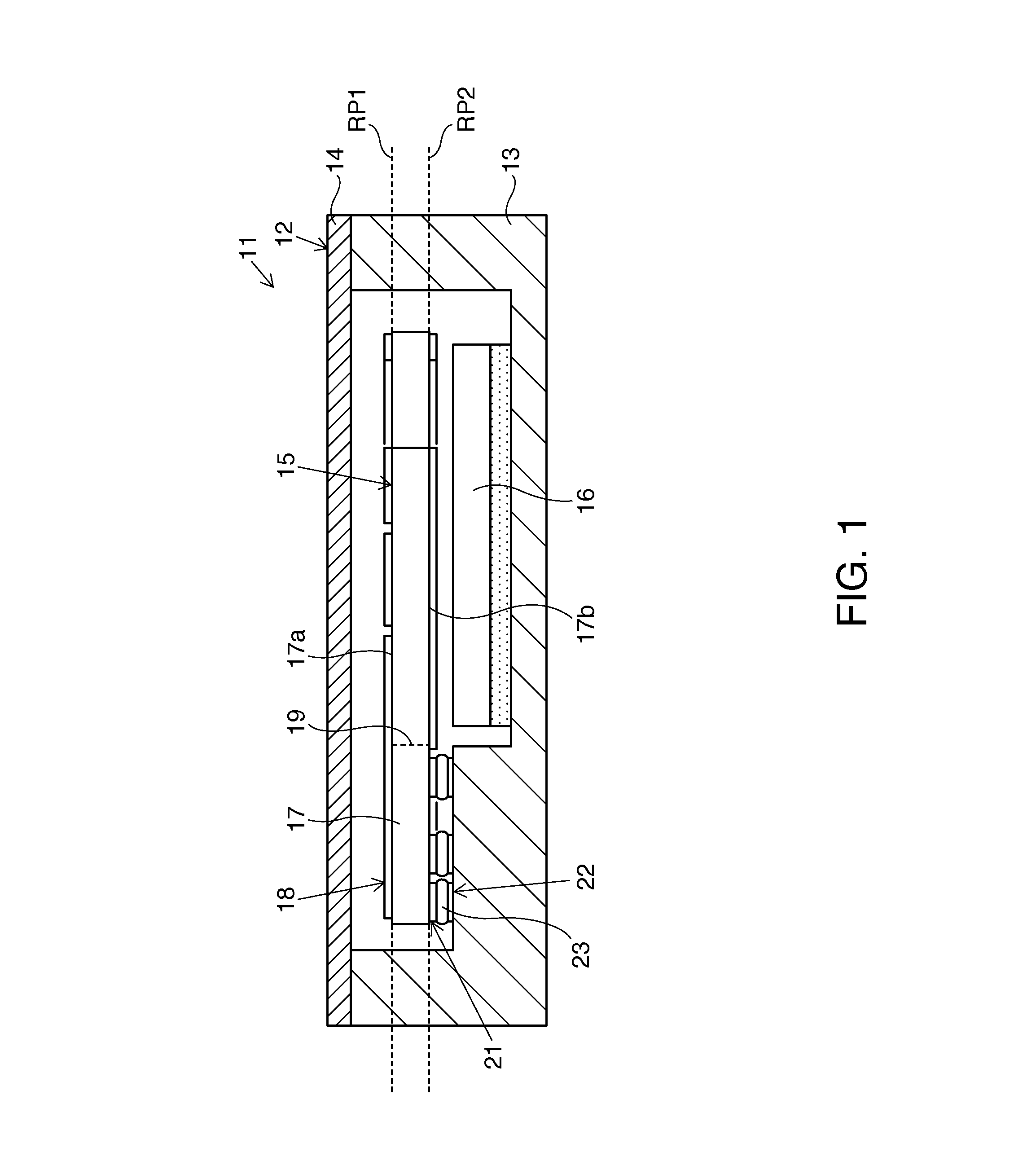

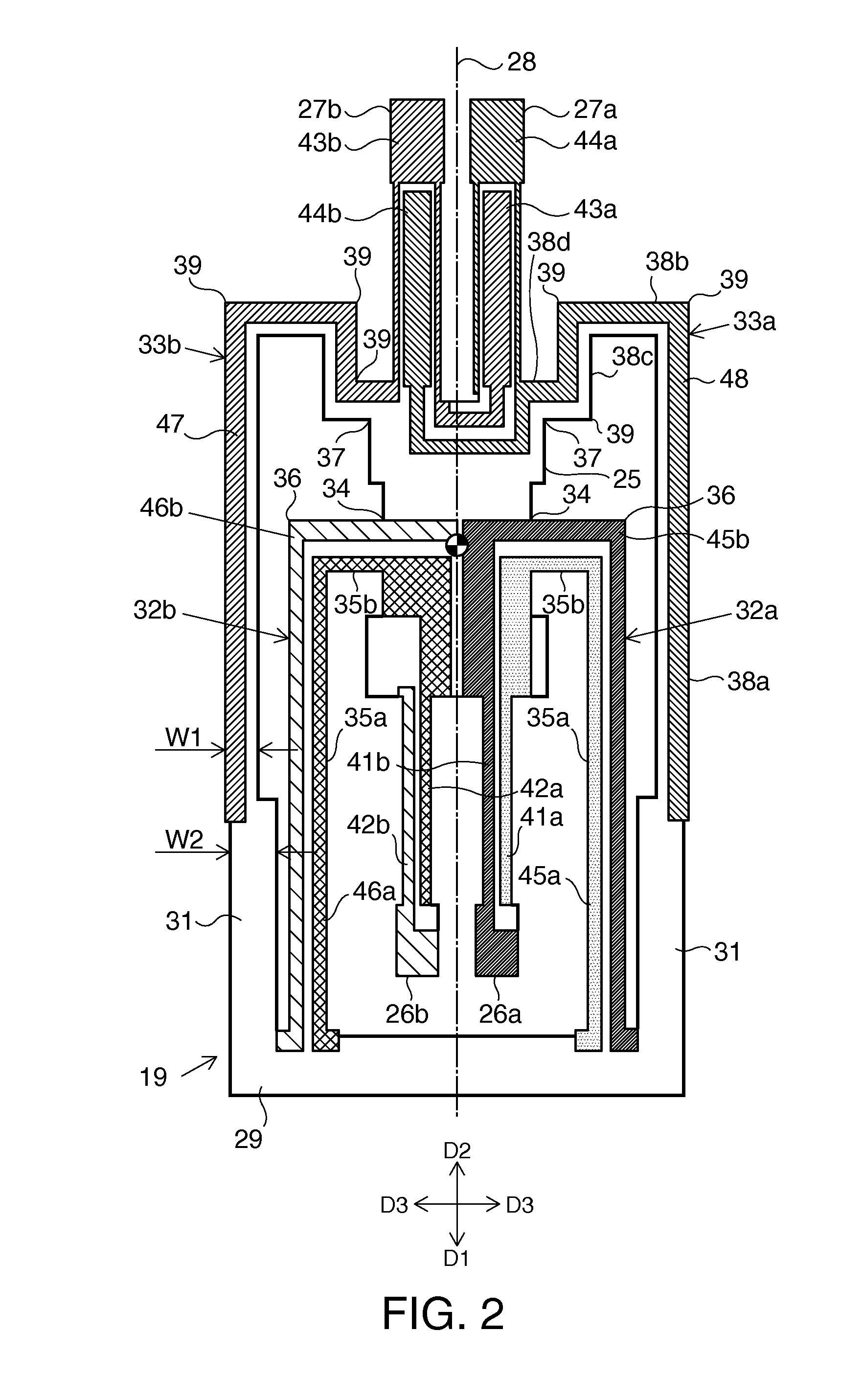

Vacuum pump and semiconductor manufacturing apparatus

InactiveUS20050025640A1Improve the exhaust effectIncreased durabilityPump componentsRotary non-positive displacement pumpsOil freeAtmospheric pressure

To provide a vacuum pump capable of evacuating in pressure ranges from an atmospheric pressure to a high vacuum, capable of rotating at a high speed to be downsized and improved in pumping performance, and capable of producing a completely oil-free vacuum. A vacuum pump for exhausting a gas comprises: a main shaft 5 rotatably supported by a bearing 22; a motor 23 for driving the main shaft 5 for rotation; a first exhaust section 10 having a first rotary vane 13 attached to the main shaft 5, a first fixed vane 14 fixed in a first casing 12, and an intake port 11; and a second exhaust section 30 having a second rotary vane 33 attached to the main shaft 5, a second fixed vane 34 fixed in a second casing 32, and an exhaust port 31. The intake port 11 is located in the vicinity of an end of the main shaft 5, and the first exhaust section 10, the bearing 22 and the second exhaust section 30 are arranged in this order axially along the main shaft 5.

Owner:EBARA CORP

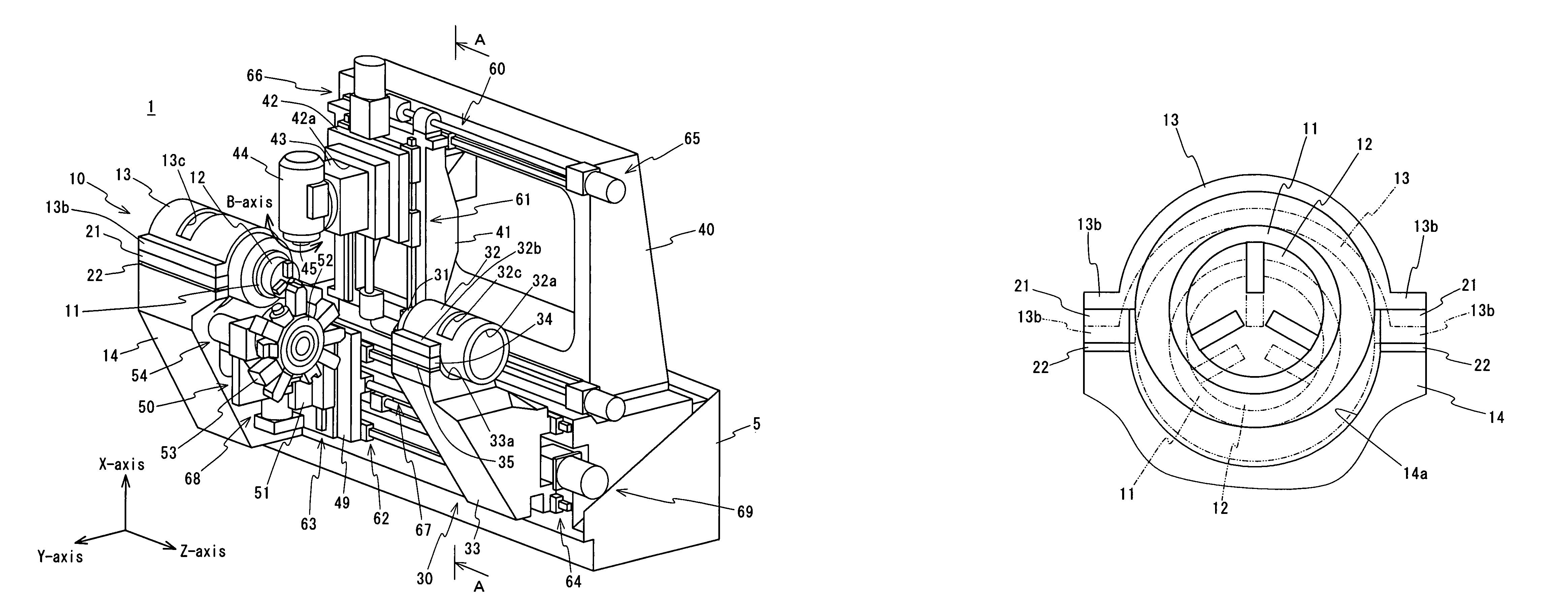

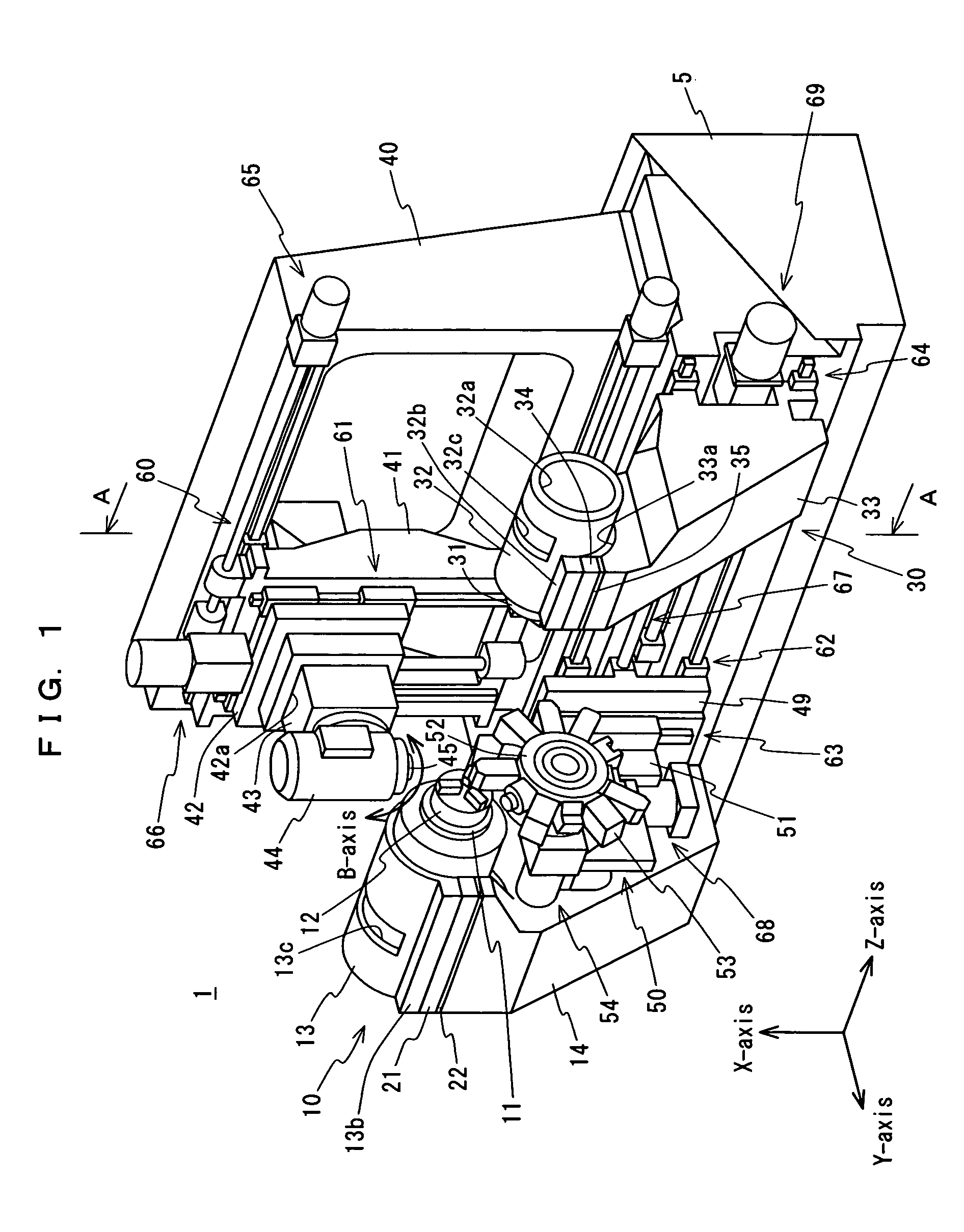

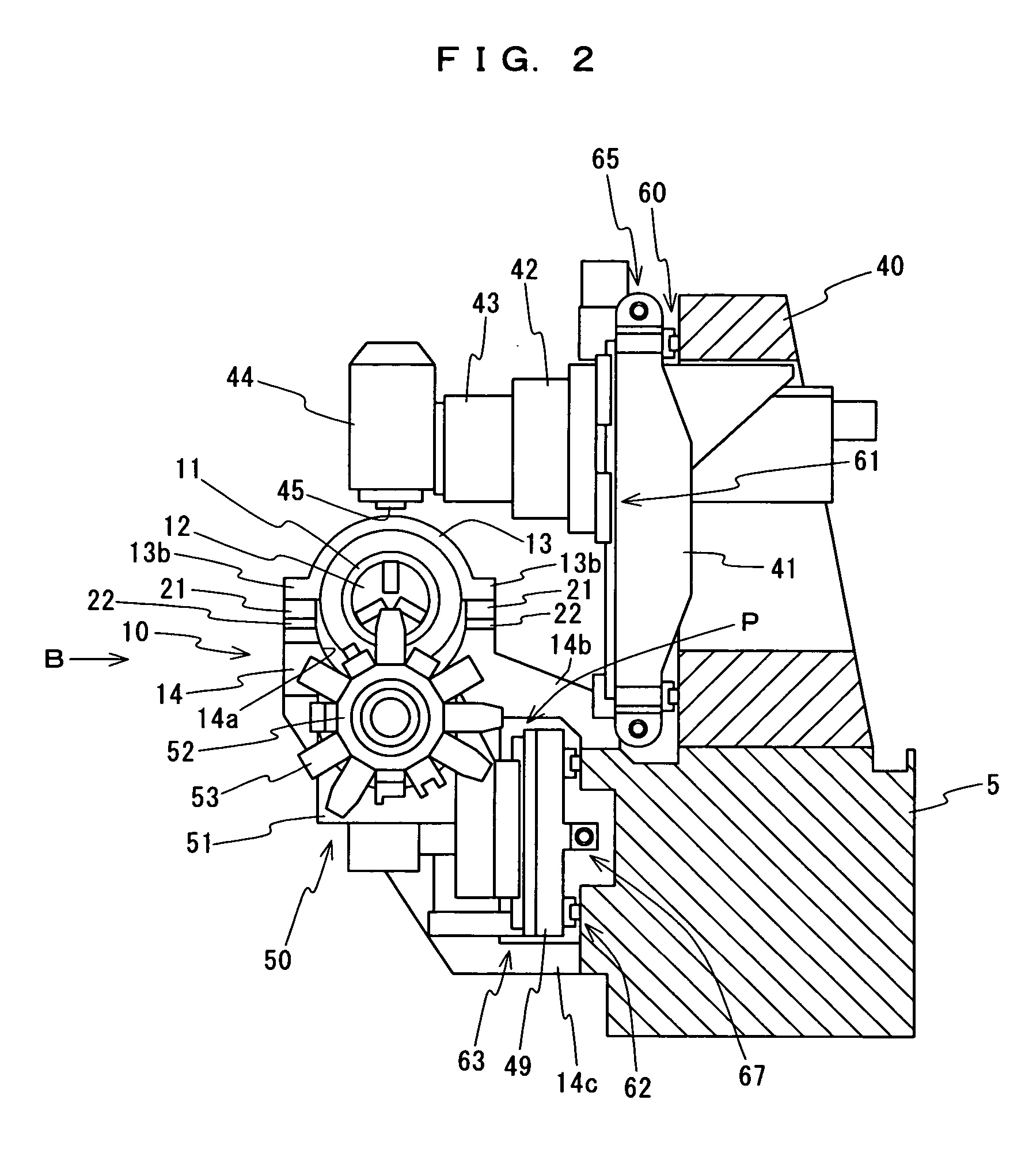

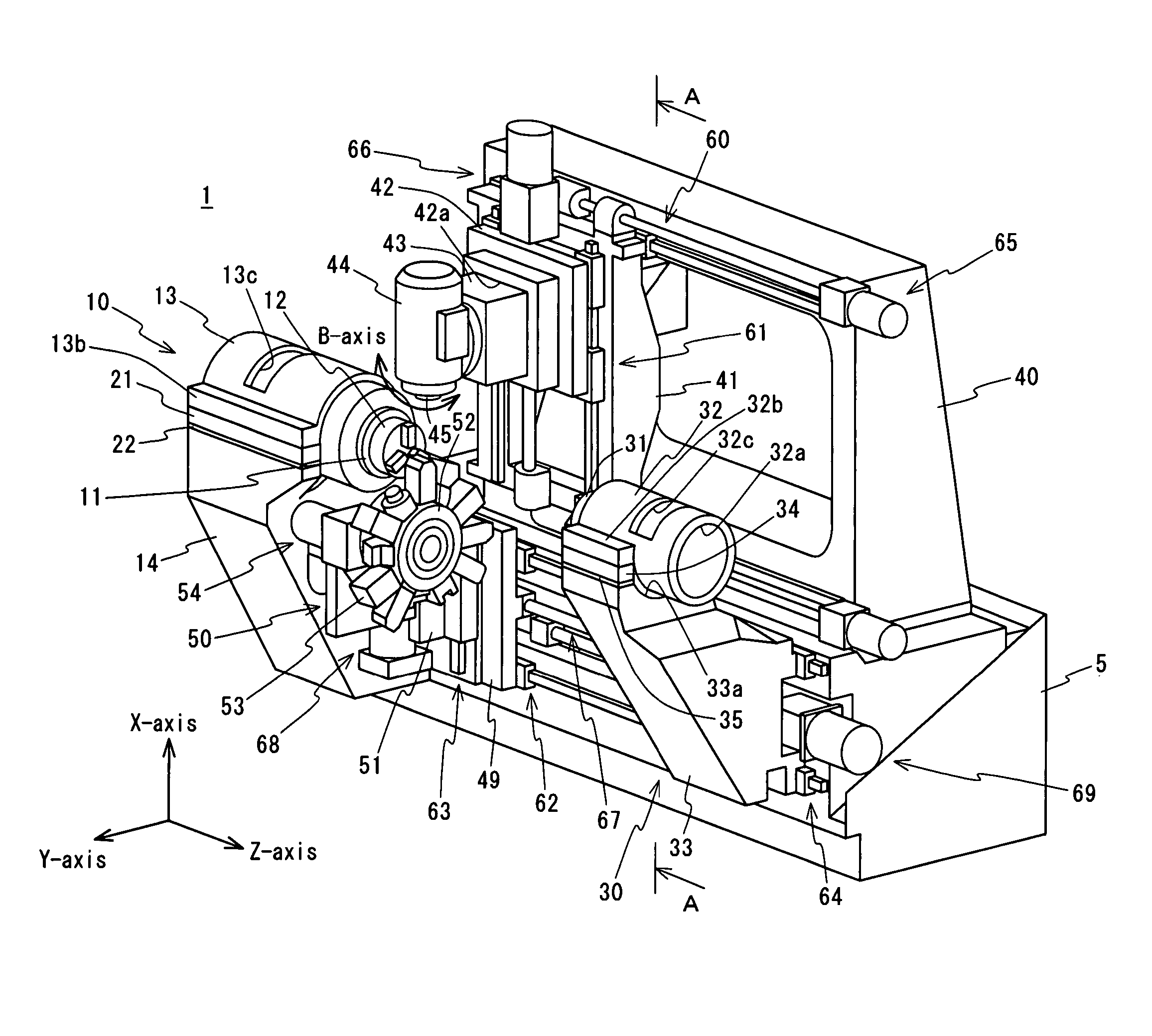

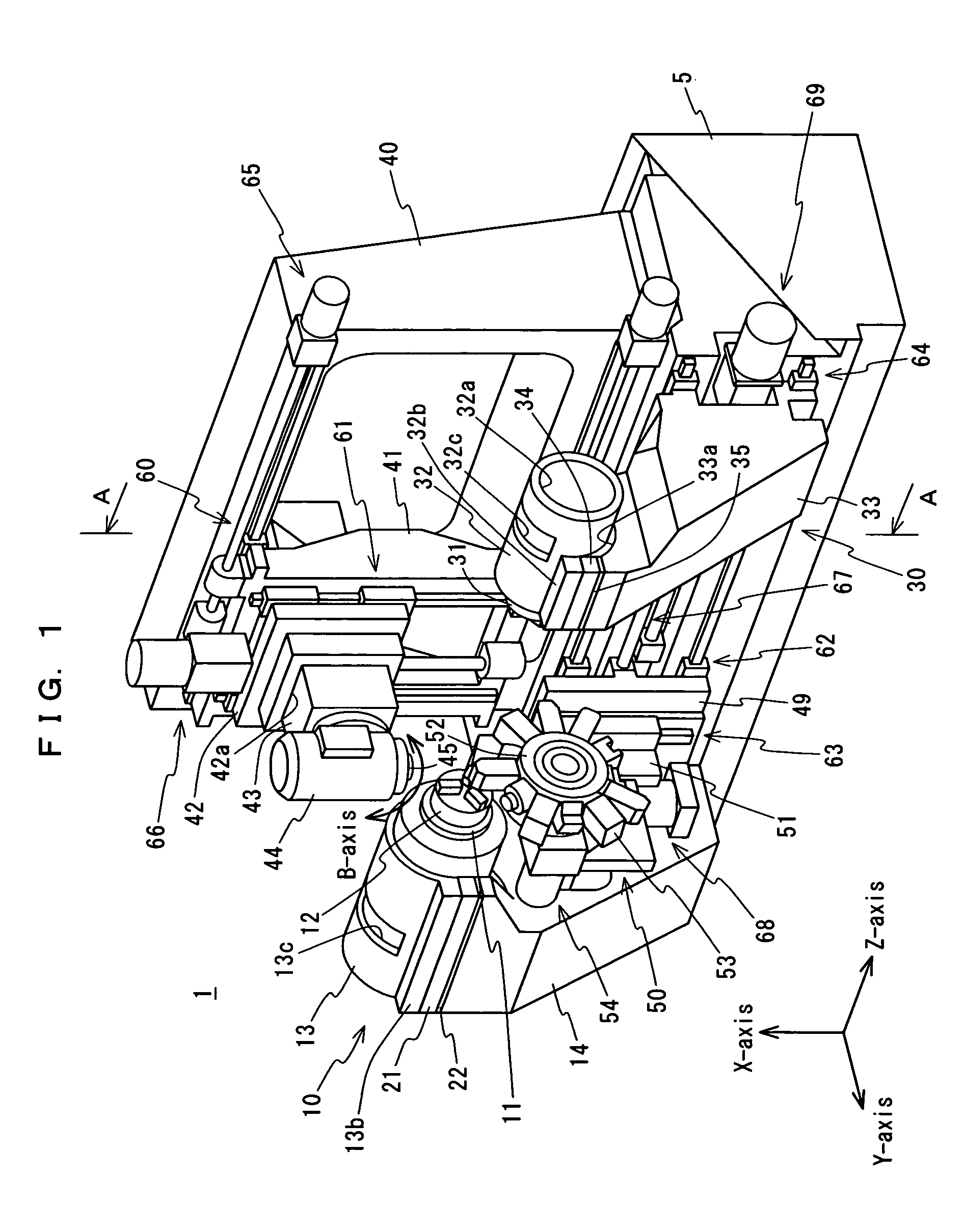

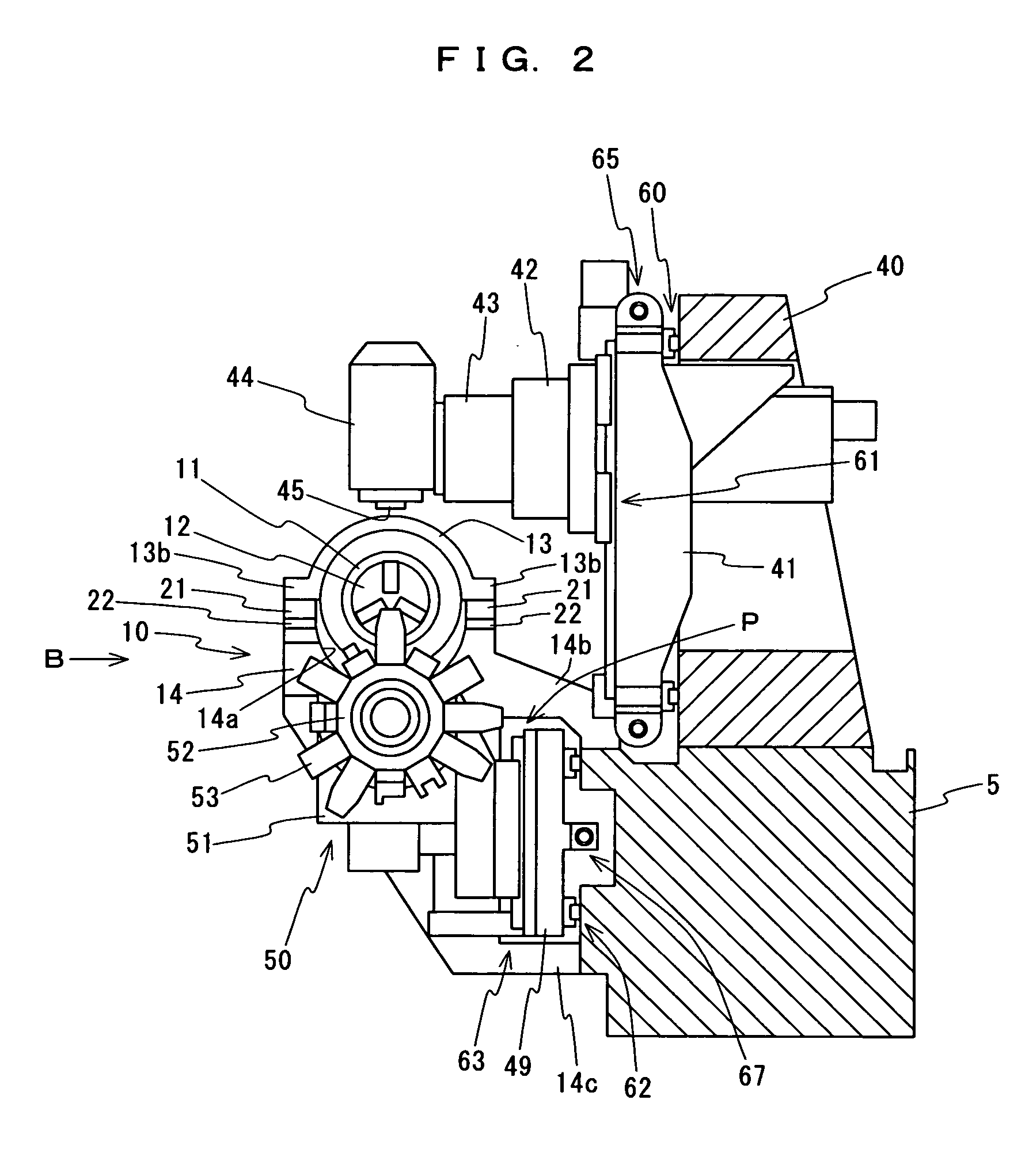

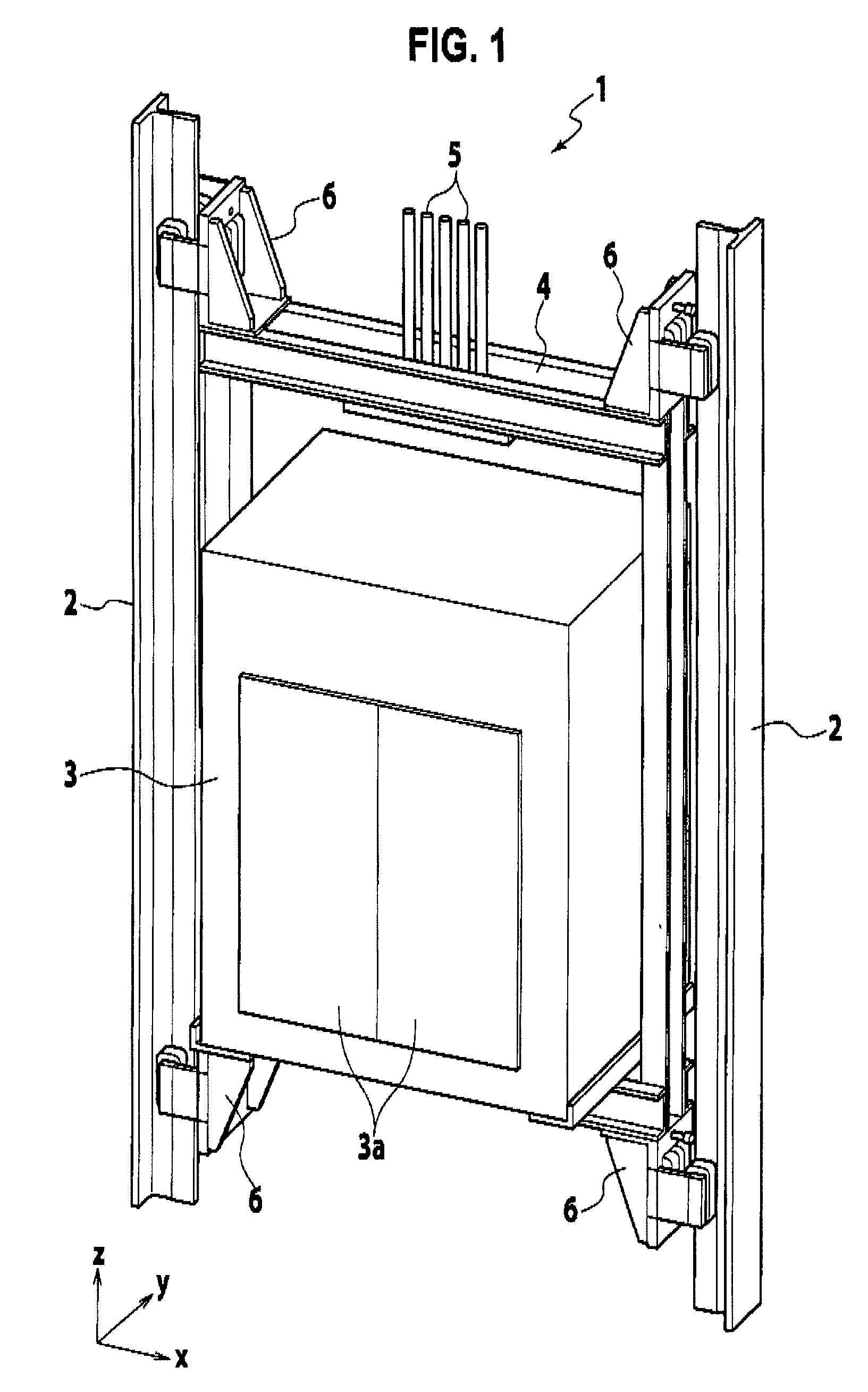

Lathe

InactiveUS7039992B2Improve accuracyHigh precision machiningAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI CO LTD

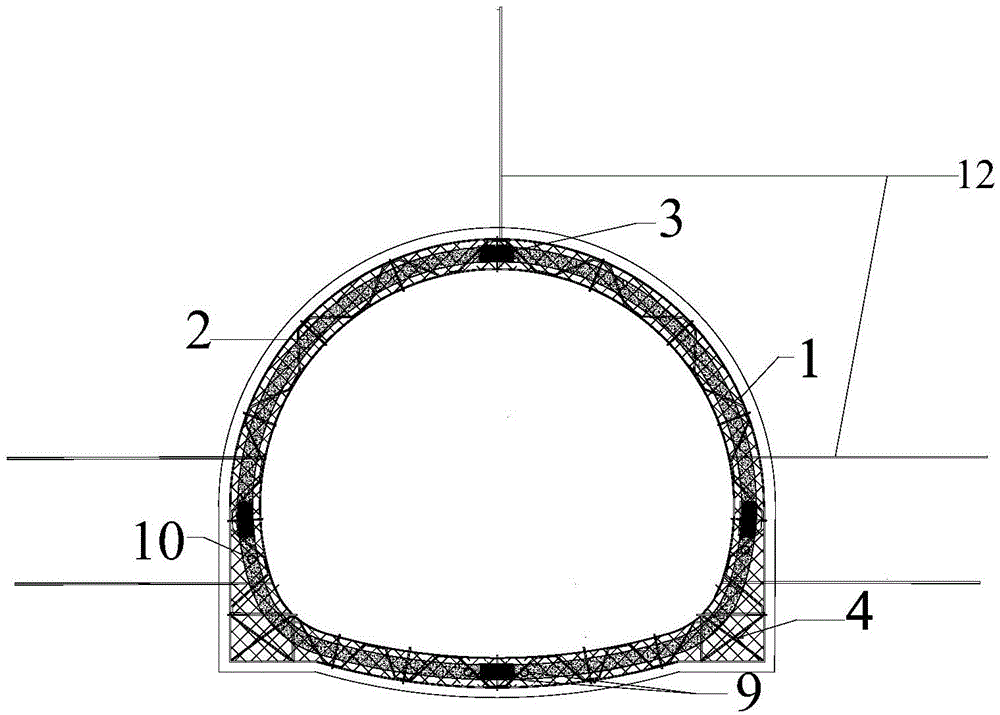

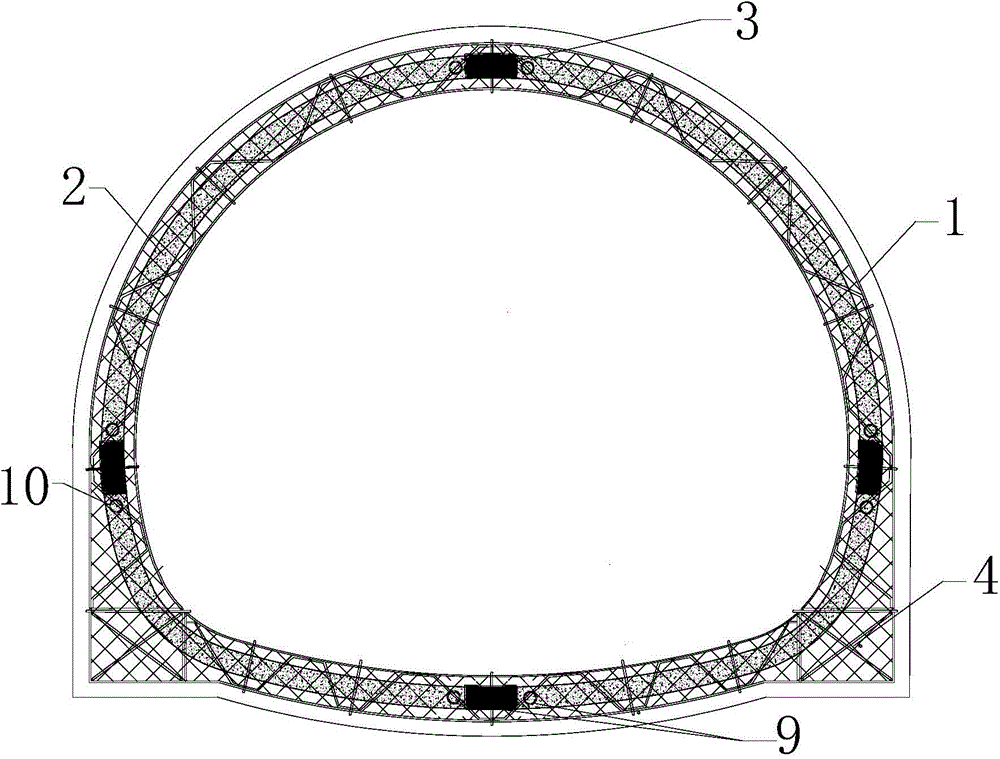

Energy-absorption yield tunnel support system and method suitable for weak broken wall rock

InactiveCN104153792AReduce support stiffnessImplement cachingUnderground chambersTunnel liningSupporting systemEnergy absorption

The invention discloses an energy-absorption yield tunnel support system and method suitable for weak broken wall rock. The system comprises a plurality of grid steel frames. The grid steel frames are consistent with the section of a tunnel in shape and of a sealed structure. Steel tubes are disposed in the grid steel frames and connected with the same through sealed yield energy-absorption devices. The combined supports formed by the grid steel frames, the steel tubes and the yield energy-absorption devices are disposed in the tunnel in an equal-interval manner. Adjacent combined supports are connected through longitudinal beams. Reserved holes are symmetrically formed in the longitudinal beams at intervals. Anchor rods or anchor cables for applying prestress are anchored into rock stratums through the reserved holes so as to form a three-dimensional integral support from the wall rock. The system has the advantage that the problem of instability and failure, caused by large wall rock deformation due to the fact that the weak broken wall rock is subjected to long-term train dynamic load, earthquake load and faulting load, of the support system is solved.

Owner:SHANDONG UNIV

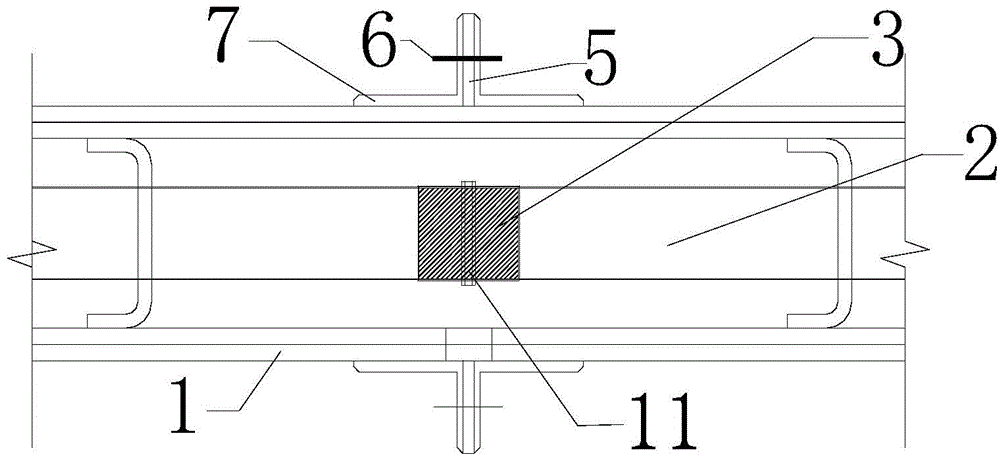

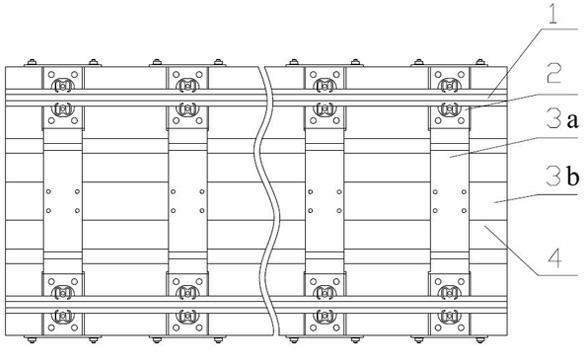

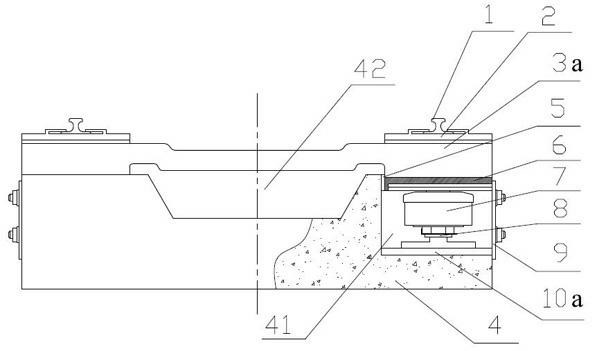

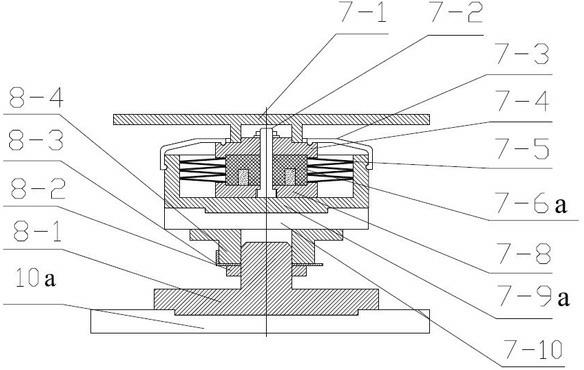

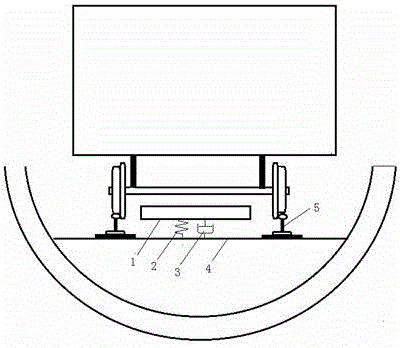

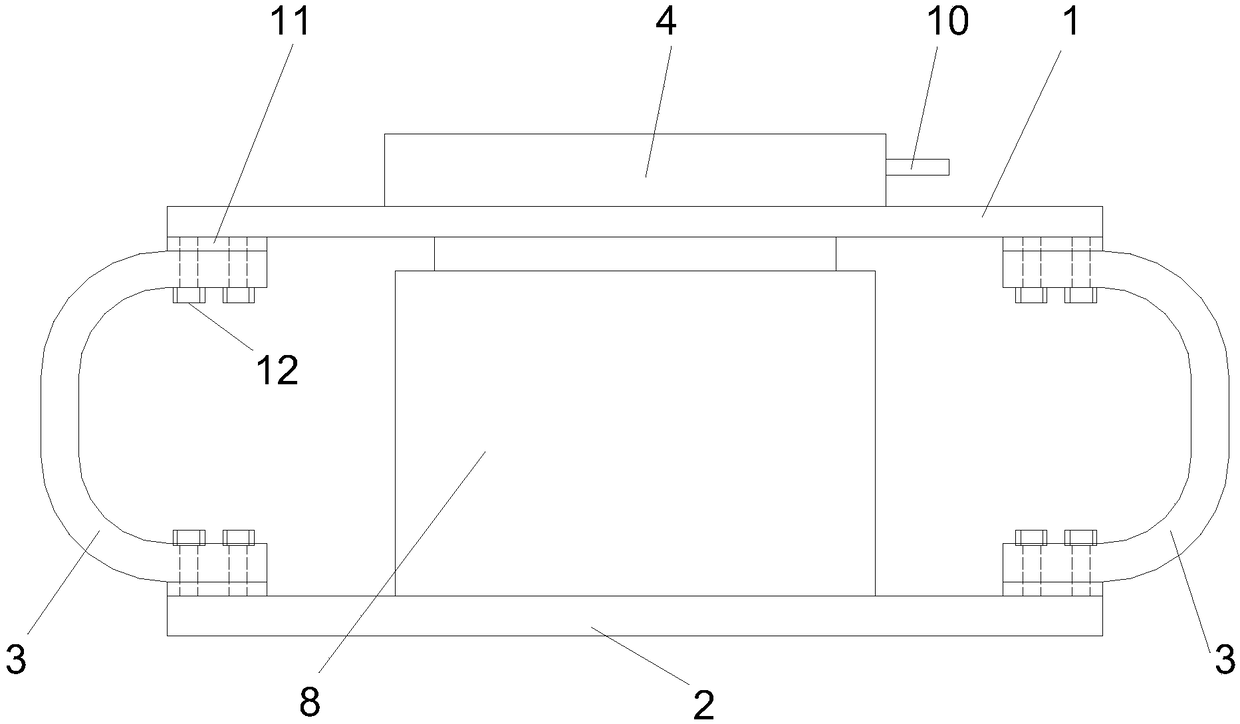

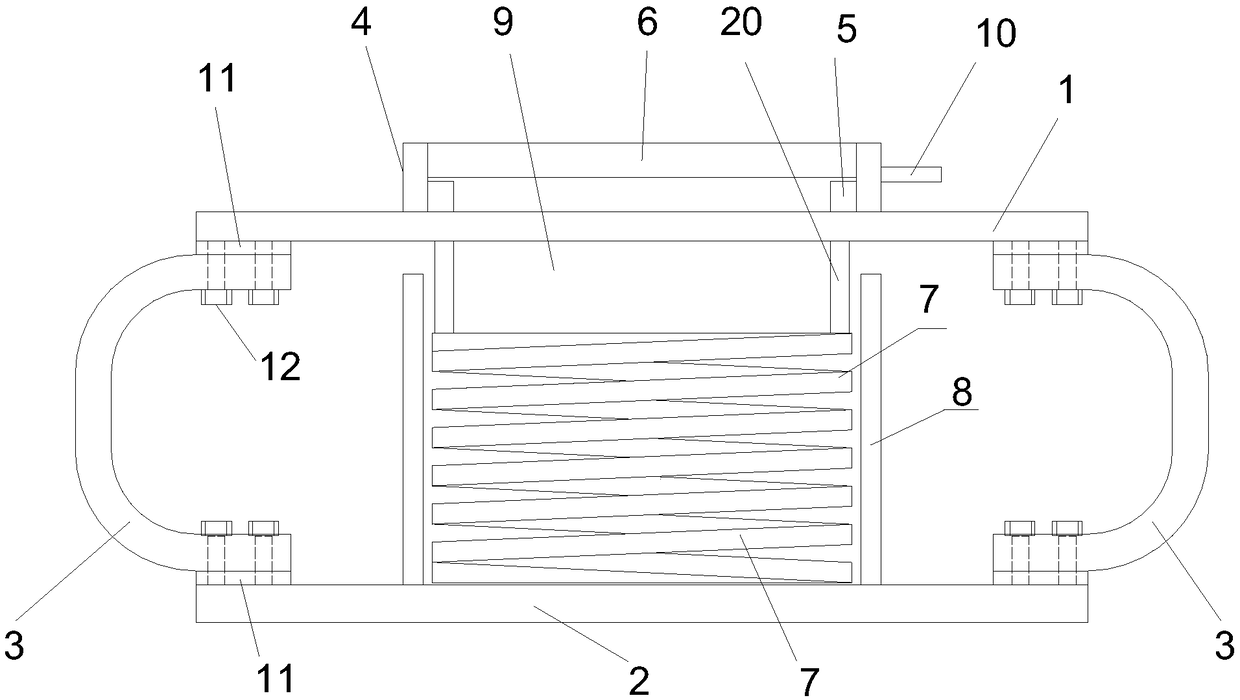

Elastic vibration-reduction ballast bed system

The invention discloses an elastic vibration-reduction ballast bed system, which comprises a concrete ballast bed and a low-frequency vibration isolator installed in the concrete ballast bed. An elastic mechanism in the low-frequency vibration isolator consists of a positive stiffness elastic element made of metal rubber or the positive stiffness elastic element and a negative stiffness elastic element which are connected in parallel. The positive stiffness elastic element is a disc spring, a spiral spring, the metal rubber, a metal rubber-spring armour, a metal rubber-lead core composite spring or any series-parallel combination of the disc spring, the spiral spring, the metal rubber, the metal rubber-spring armour and the metal rubber-lead core composite spring. The negative stiffness elastic element is a disc spring or a diaphragm spring. The elastic vibration-reduction ballast bed system can meet requirements of middle-high-grade vibration reduction and has a simple structure. The site construction process is simple and convenient, and consumed materials of the ballast bed are relatively reduced. Therefore, the elastic vibration-reduction ballast bed system is low in construction cost and suitable for popularization and application in the whole line.

Owner:河北金擘机电科技有限公司 +1

Lathe

InactiveUS20050022350A1Improve accuracyAvoid displacementAutomatic/semiautomatic turning machinesAuxillary equipmentMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI SEIKI CO LTD

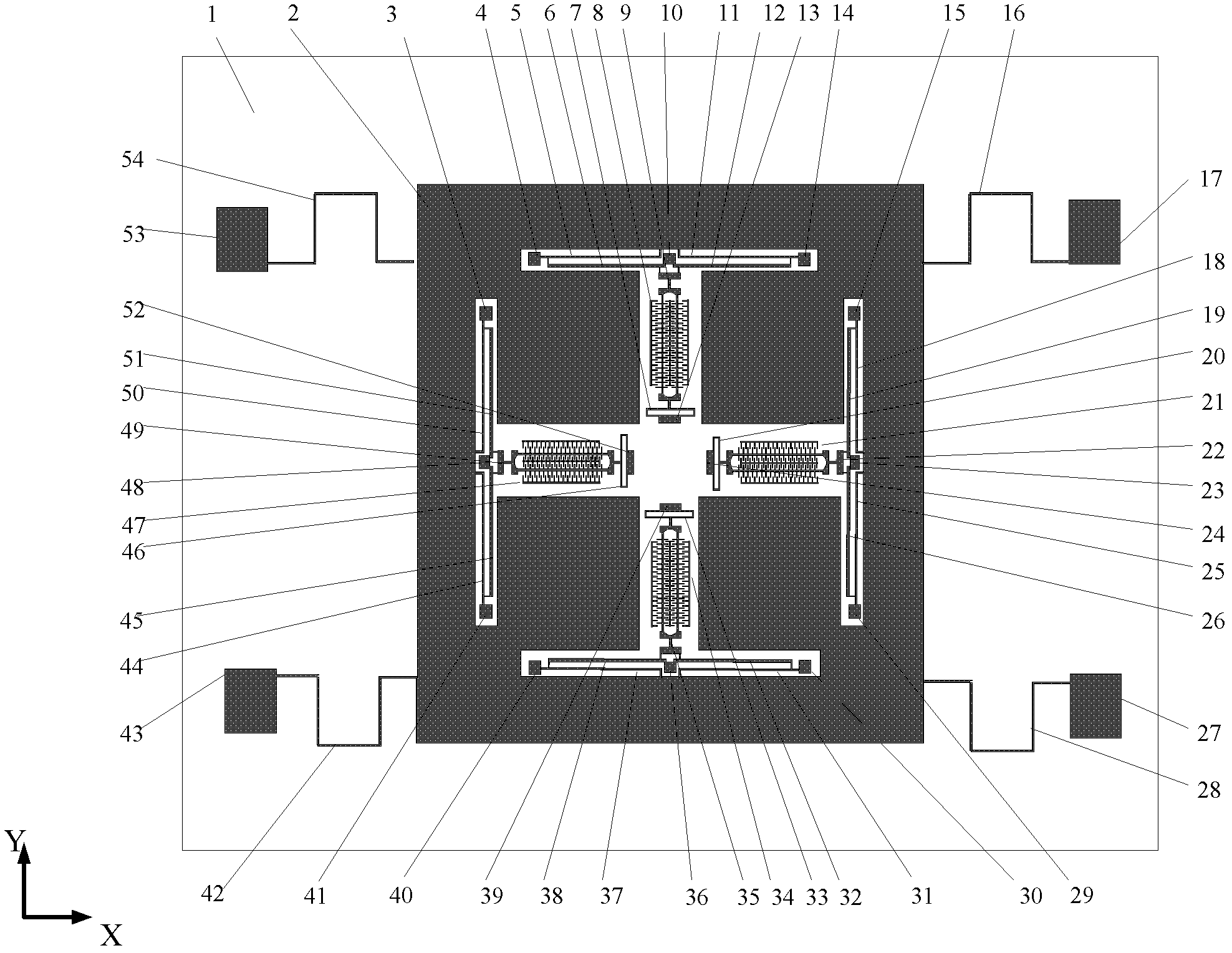

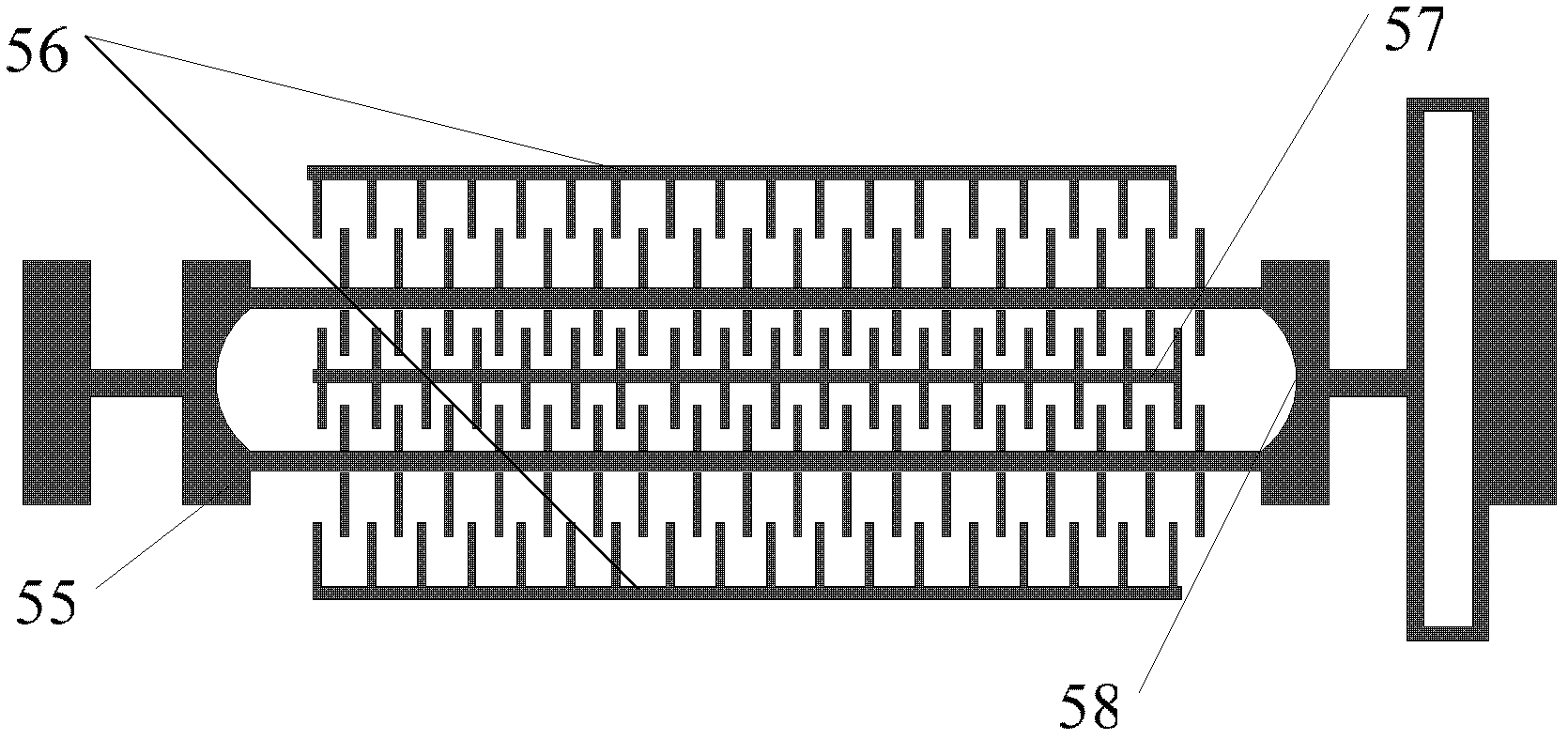

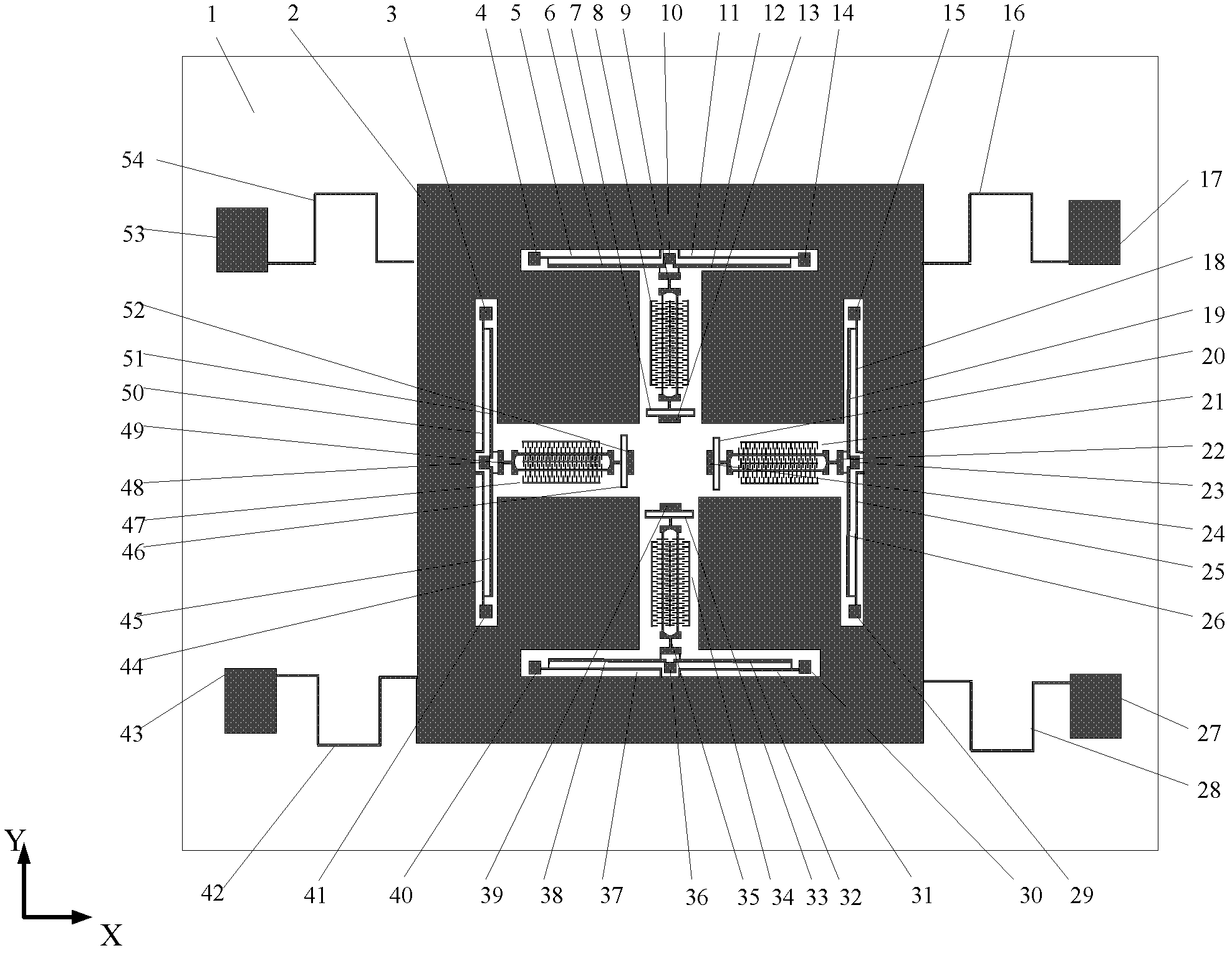

Biaxially-resonant silicon-micromachined accelerometer structure in shape of Chinese character 'tian'

InactiveCN102539832AIncrease in sizeGood anti-noiseAcceleration measurement using interia forcesSolid-state devicesAccelerometerClosed loop

The invention discloses a biaxially resonant silicon-micromachined accelerometer in the shape of a Chinese character 'tian' and aims at designing and manufacturing a high-sensitivity and high-resolution biaxially-resonant silicon-micromachined accelerometer. The structure is characterized in that (1) because a mass block structure in the shape of a Chinese character 'tian' is adopted, the volume of a mass block is maximized, and the acceleration can be converted into an inertial force more effectively; and the whole structure is symmetrically distributed, which is favorable for resisting noises and inhibiting temperature drift; (2) a support beam (in the shape of a Chinese character 'ji') arranged at the periphery of the structure facilitates the release of the residual stress and temperature stress of the structure, thereby reducing the support stiffness of the structure in a sensitive direction; (3) due to the application of a spring-like beam (in the shape of a Chinese character 'kou') at one end of a resonator, the influence of external shocks on the beam is reduced, and the spring-like beam plays a role in releasing the residual stress of the structure; and (4) an arc structure at the root part of a tuning fork in the resonator can be used for effectively reducing the energy coupling and improving the mechanical quality factor of the resonator, and is easy for realizationof closed-loop control.

Owner:BEIHANG UNIV

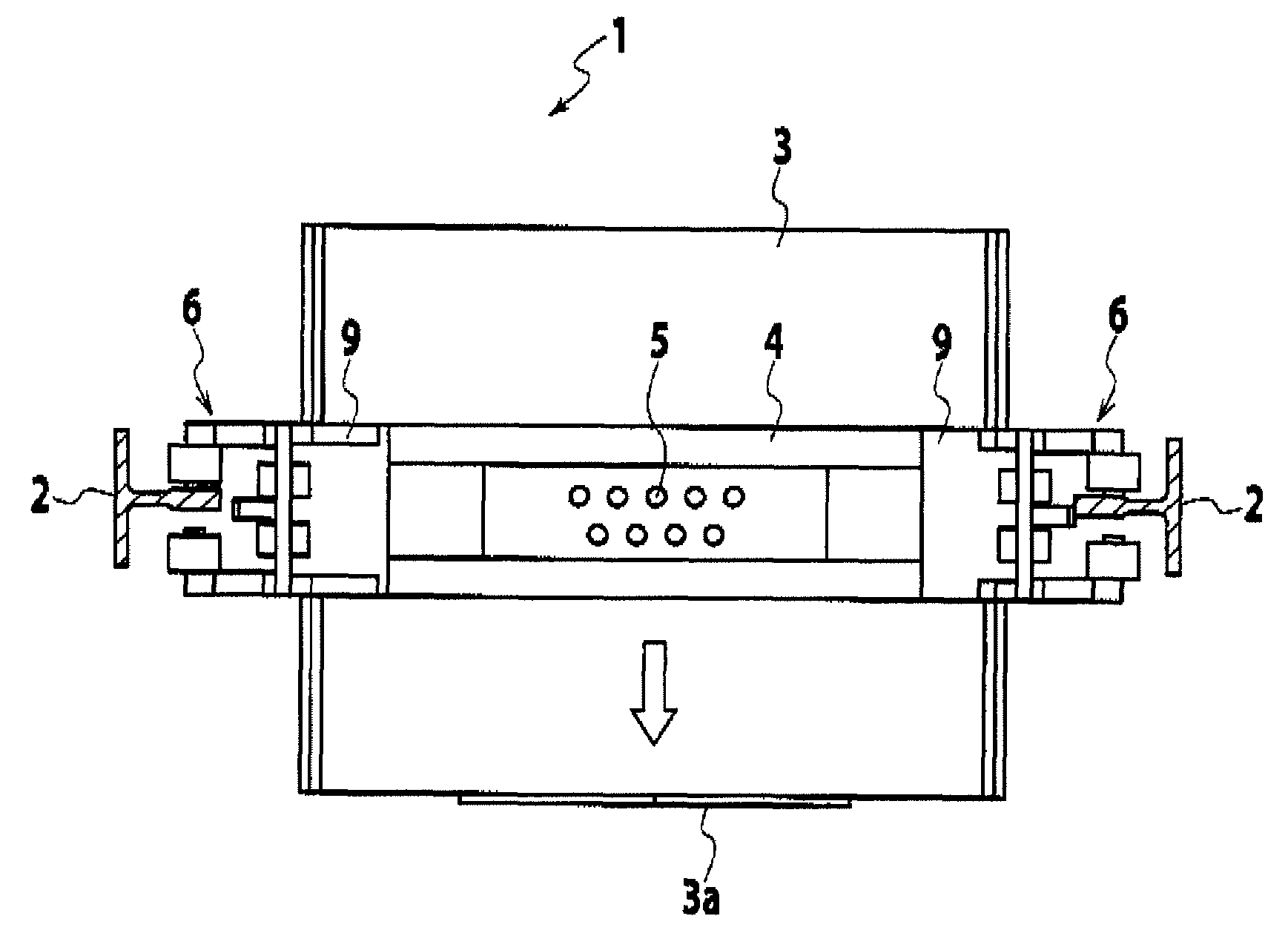

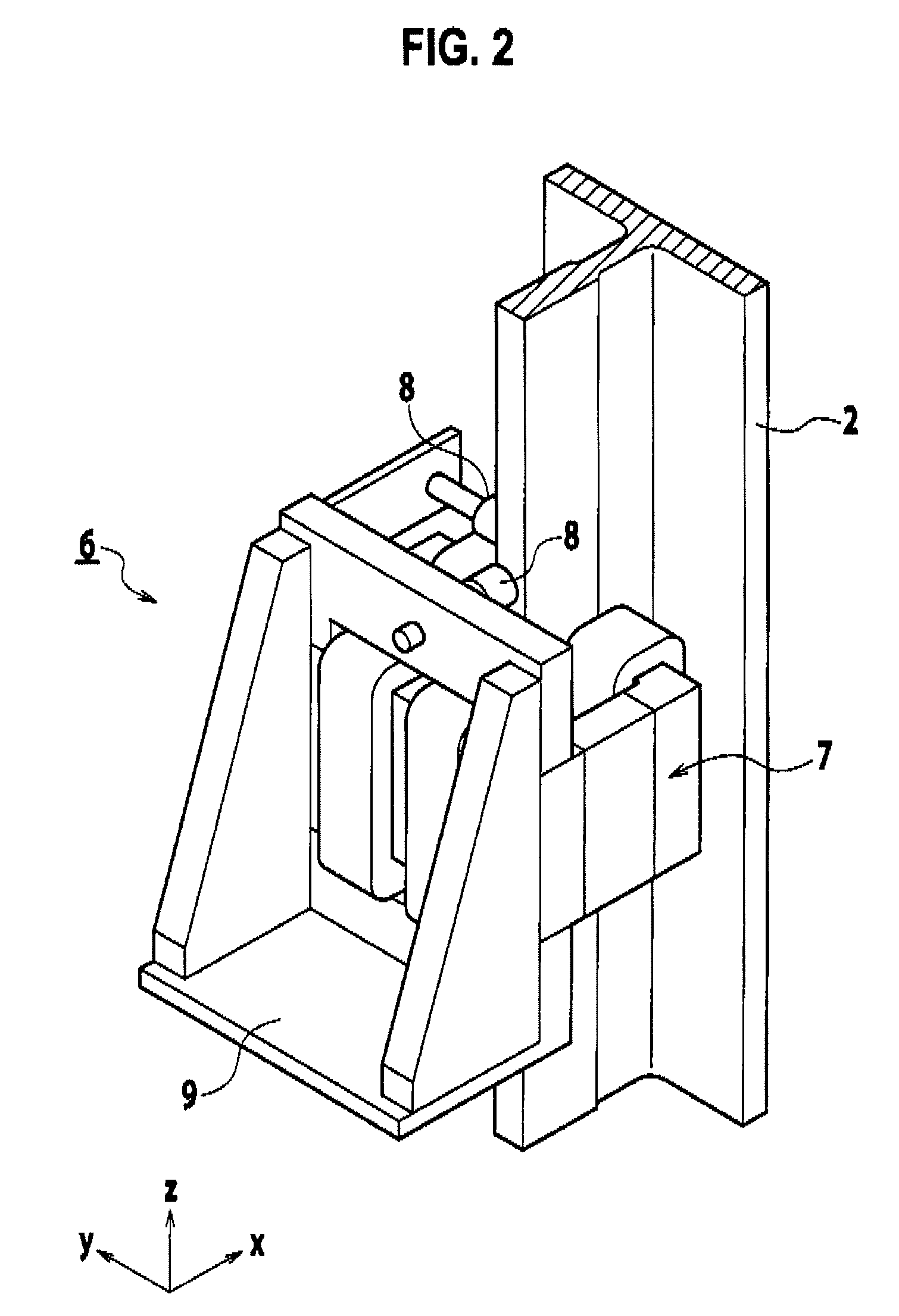

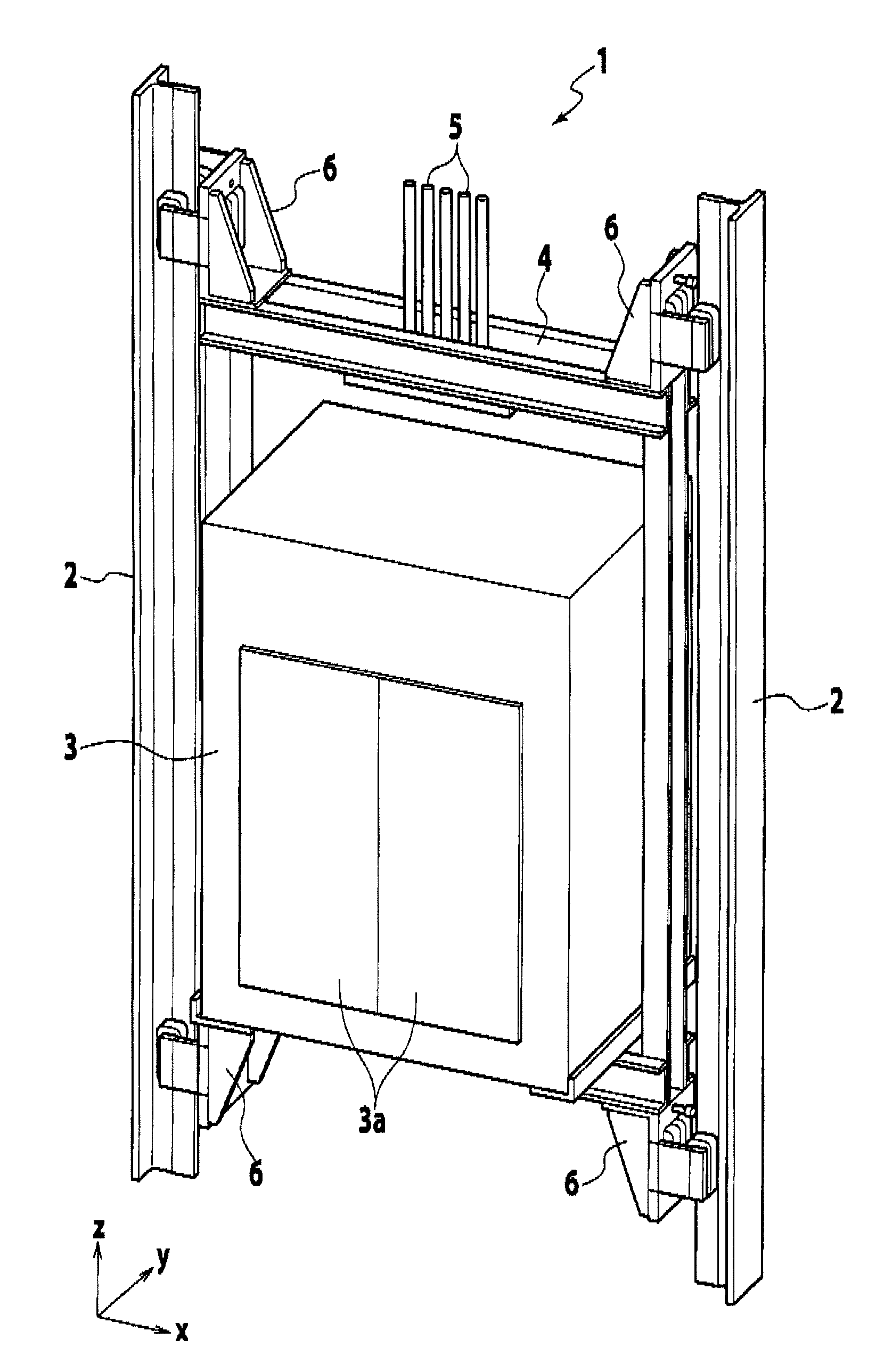

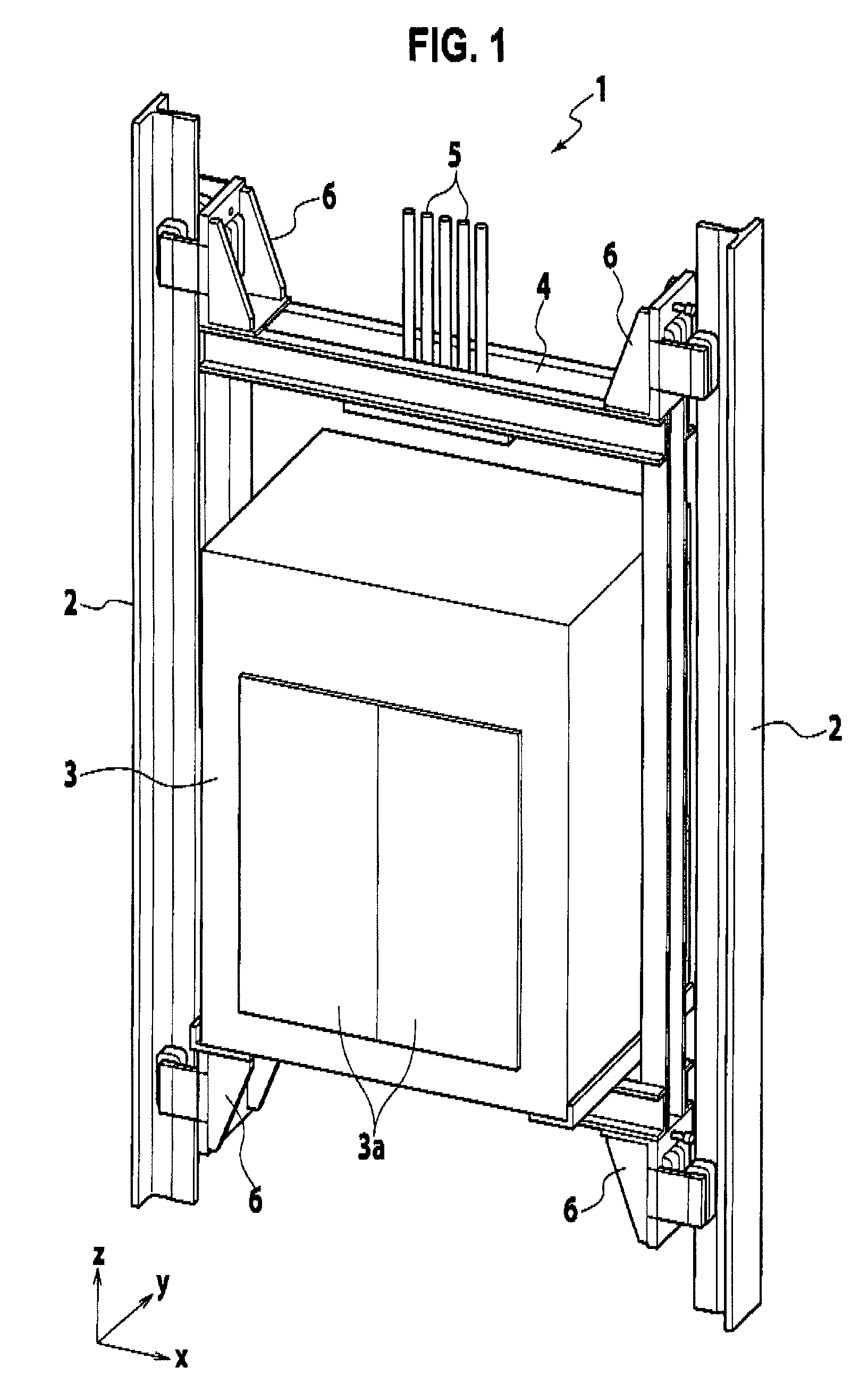

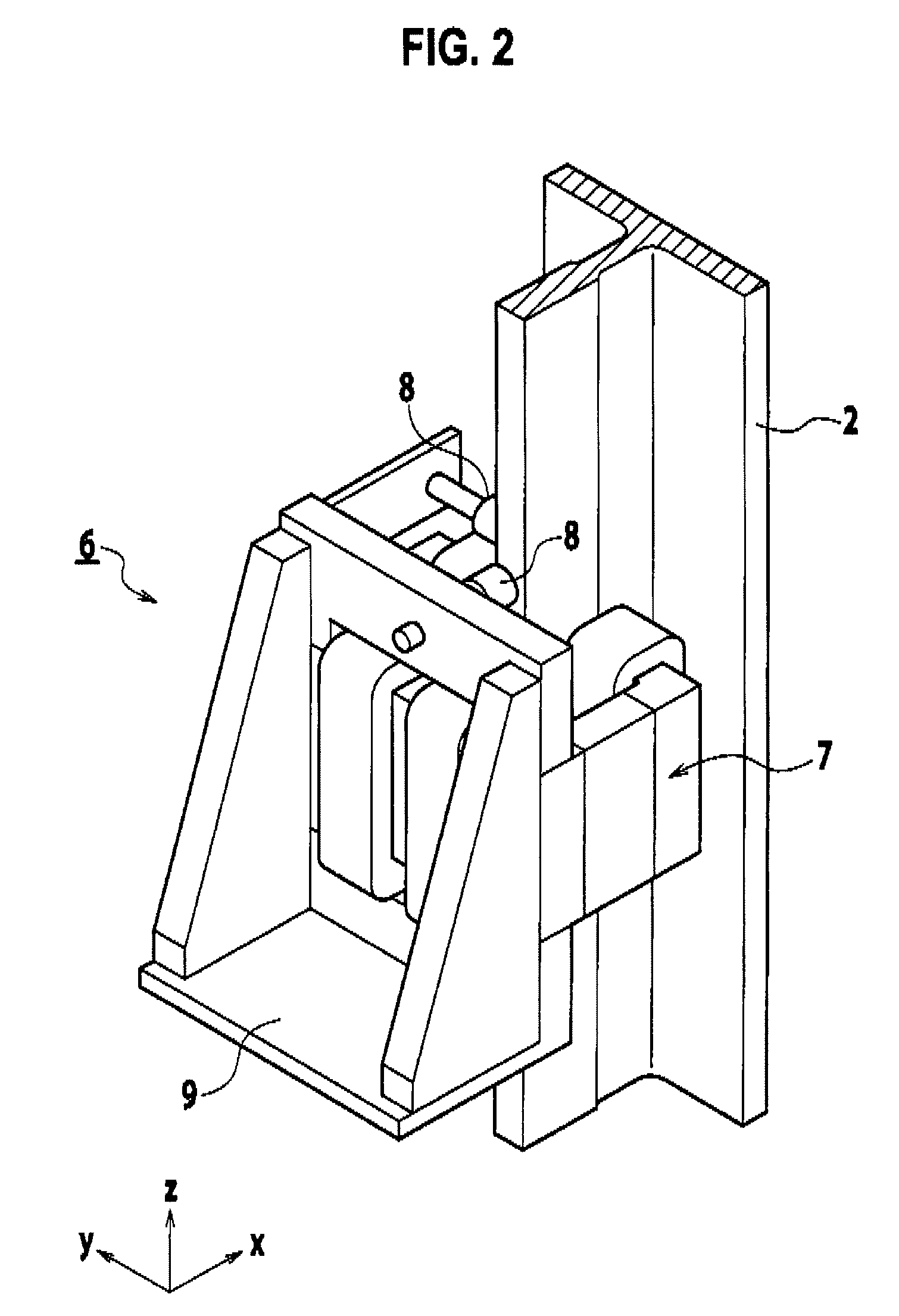

Elevator

InactiveUS20080110701A1Improve rigidityReduce the amount of powerElevatorsRelaysMagnetic tension forcePower flow

An elevator includes guide rails (2) laid in an elevator shaft vertically, an elevator car (3) moving up and down along the guide rails, guiding units (6) provided on the elevator car for guiding it, the guiding unit having a magnet unit including cores (11) and coils (12) forming electromagnets to generate a magnetic force against the guide rail through an air gap and a controller (21) for controlling the magnetic force by maneuvering an exciting current for exciting the electromagnets. The controller (21) controls the magnetic force so as to make the guiding units in non-contact with the guide rails when the elevator car is traveling and brings the guiding units into contact with the guide rails when the elevator car is stopped, so that the guiding units attract and fix the guide rails while the elevator car is stopped.

Owner:TOSHIBA ELEVATOR KK

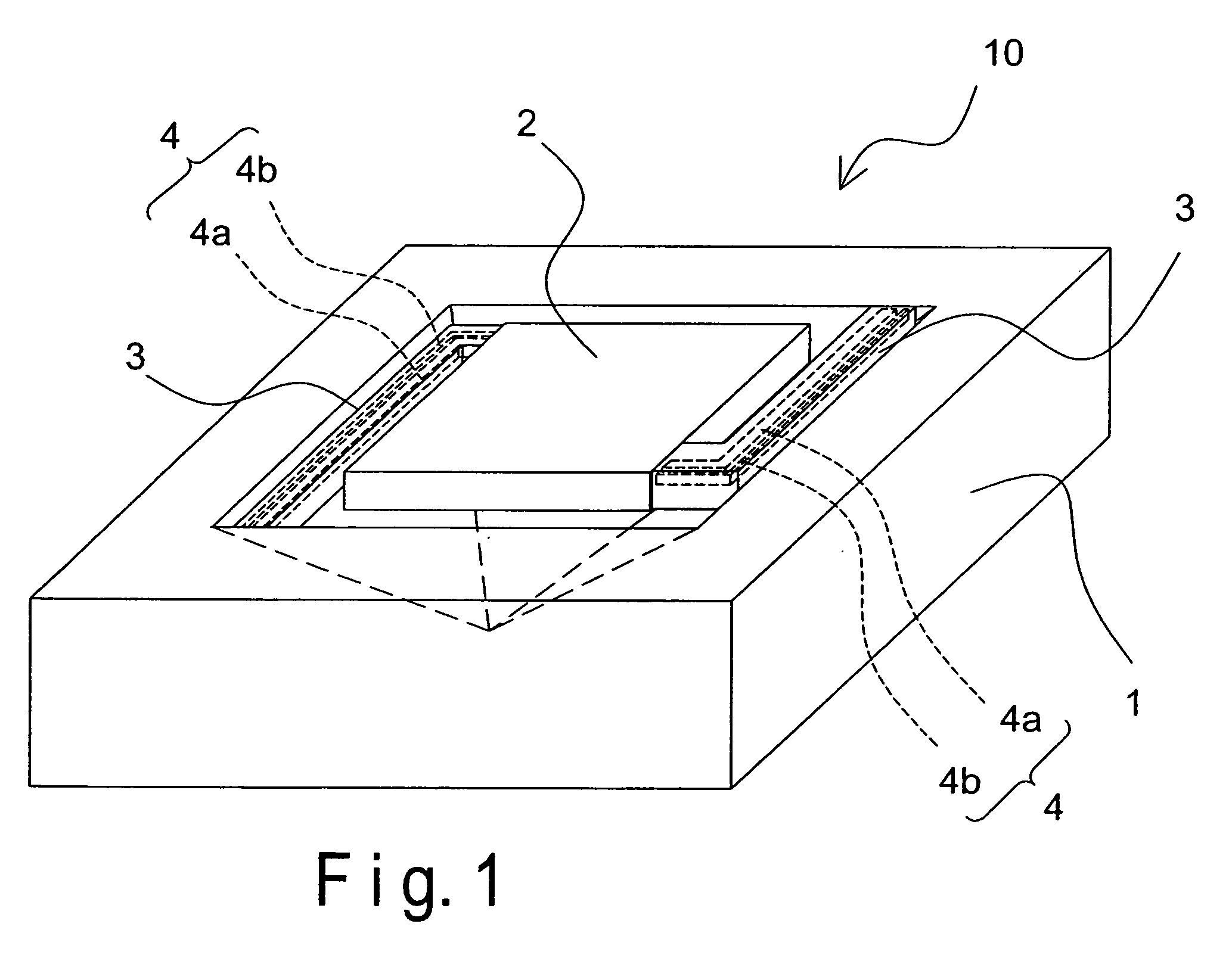

Infrared radiation detecting device

ActiveUS20060006333A1Increase structural stability and mechanical strengthReduce thermal noiseSolid-state devicesMaterial analysis by optical meansPhysicsStructural rigidity

An infrared radiation detecting device is provided that comprises a substrate, an infrared radiation absorbing unit, at least one support beam and a thermopile. The at least one support beam has a first end portion coupled to the substrate and a second end portion coupled to the infrared radiation absorbing unit. The thermopile includes first and second electrical conductors disposed on the support beam with the first and second electrical conductors having different electric conductivities. The first and second electrical conductors is dimensioned and shaped to improve structural rigidity of the support beam in comparison to an identically shaped support beam including a thermopile with a pair of first and second electrical conductors that are identically shaped and disposed parallel to each other.

Owner:NISSAN MOTOR CO LTD

Energy absorption and vibration reduction device of track structure

The invention relates to an assisting device with the energy absorption function, and the assisting device is designed on a track structure. An energy absorption and vibration reduction device is arranged between two steel rails on a track bed. The energy absorption and vibration reduction device comprises a mass block object, a rigid object and a damper. The inherent resonance frequency of the energy absorption and vibration reduction device is identical to the vibration frequency of a wheel / track on a track.

Owner:苏州同铁轨道科技有限公司

Elevator

InactiveUS7793760B2Comfortable ride qualityImprove ride qualityElevatorsRelaysElectromagnetAutomotive engineering

Owner:TOSHIBA ELEVATOR KK

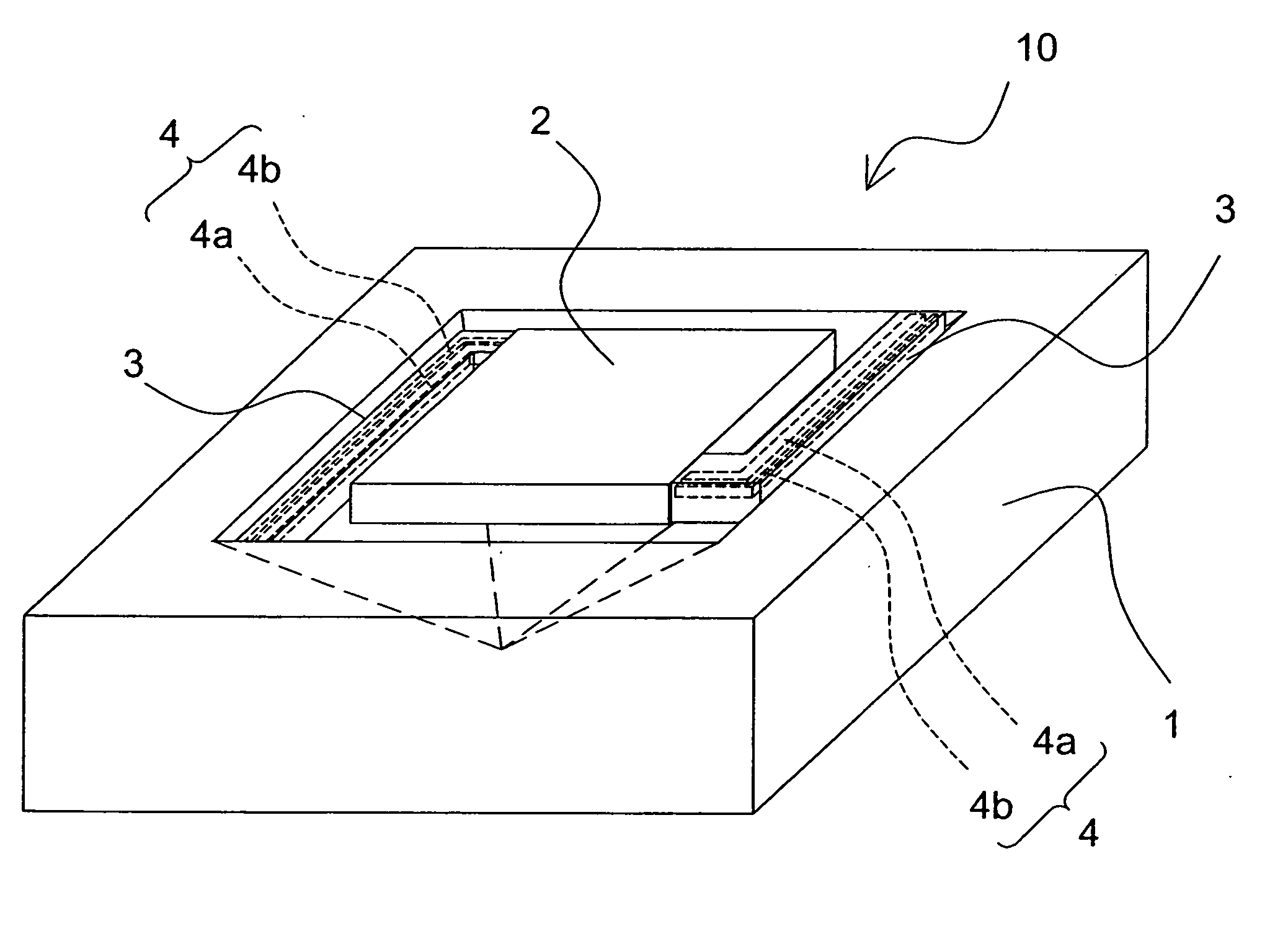

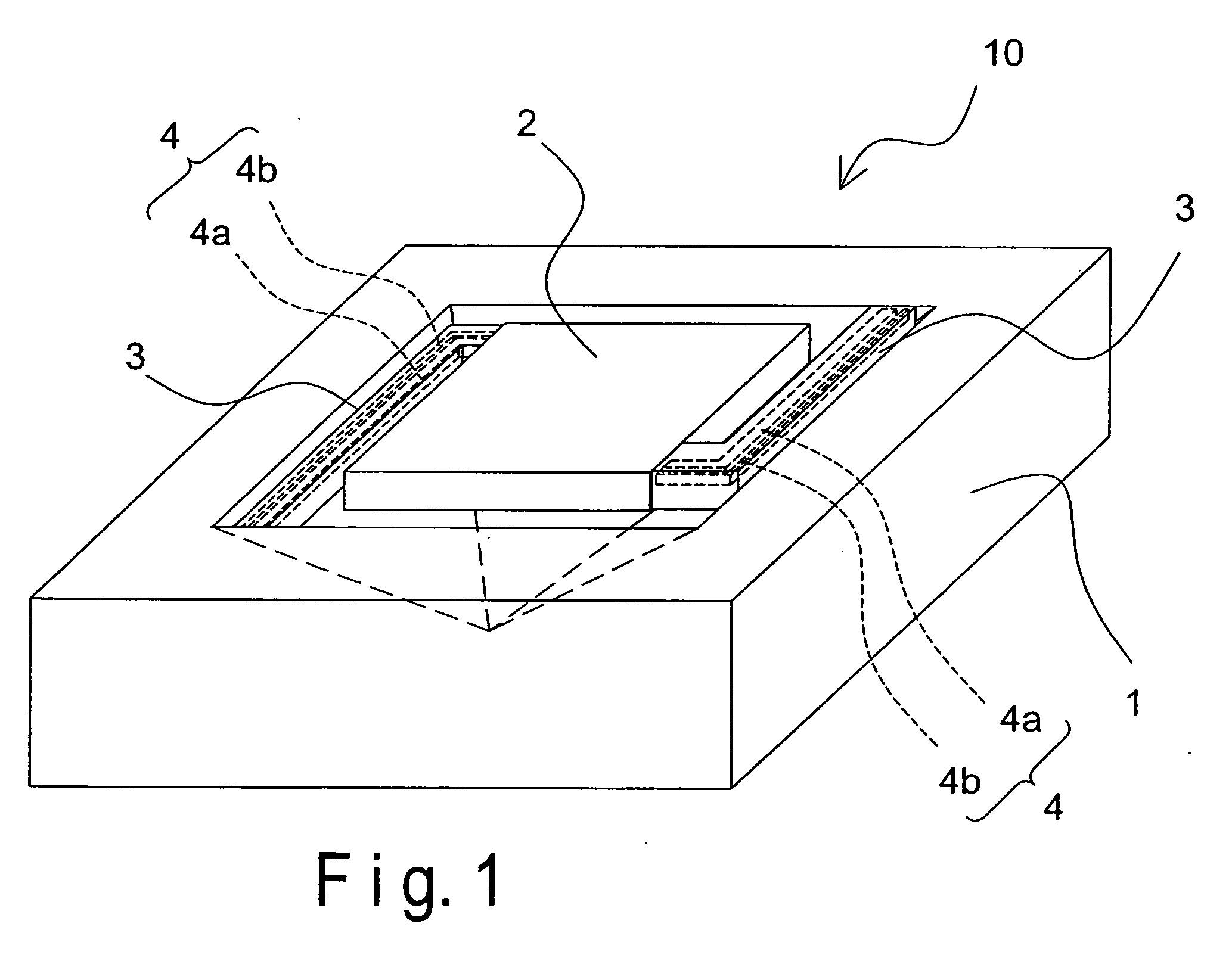

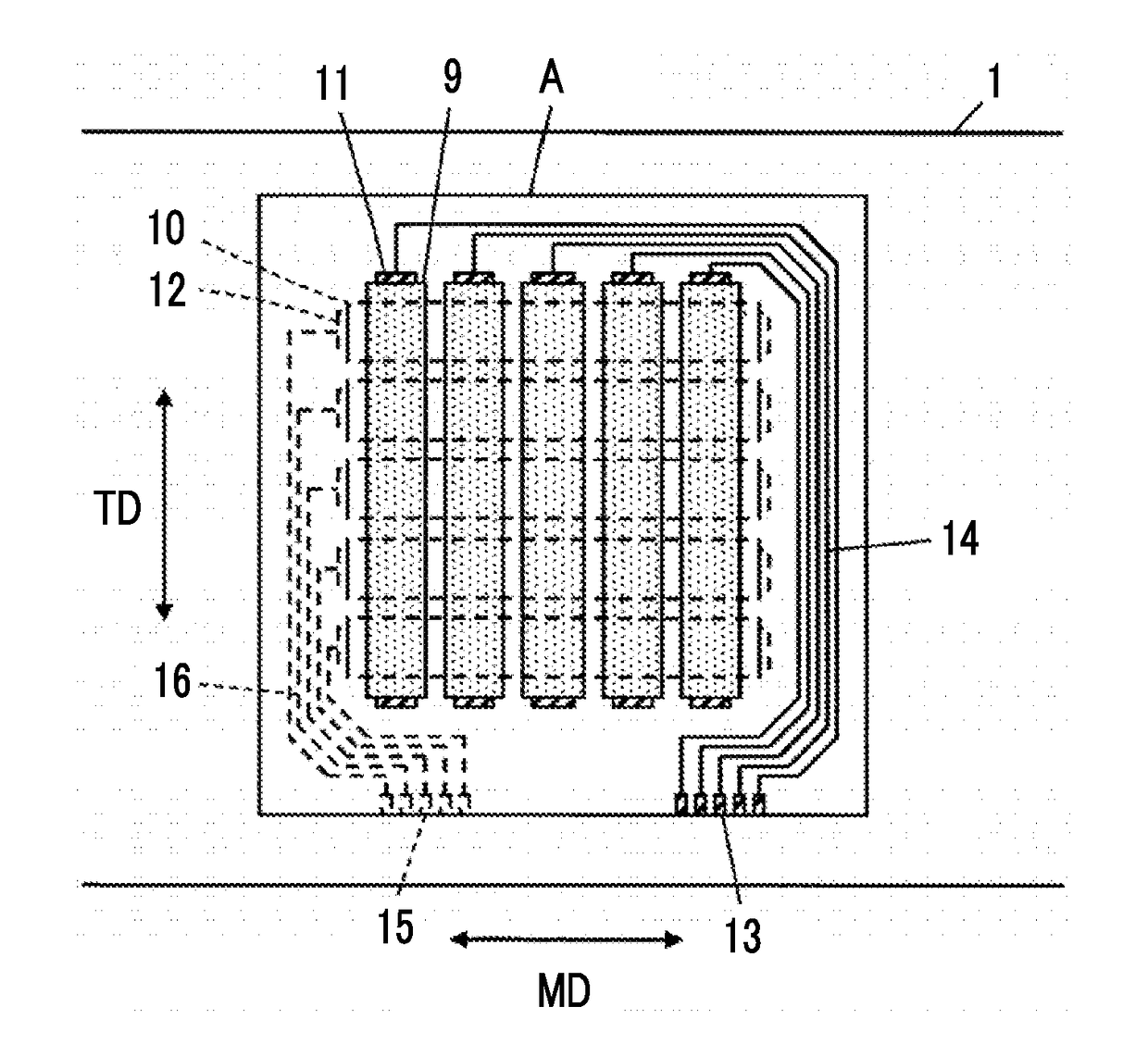

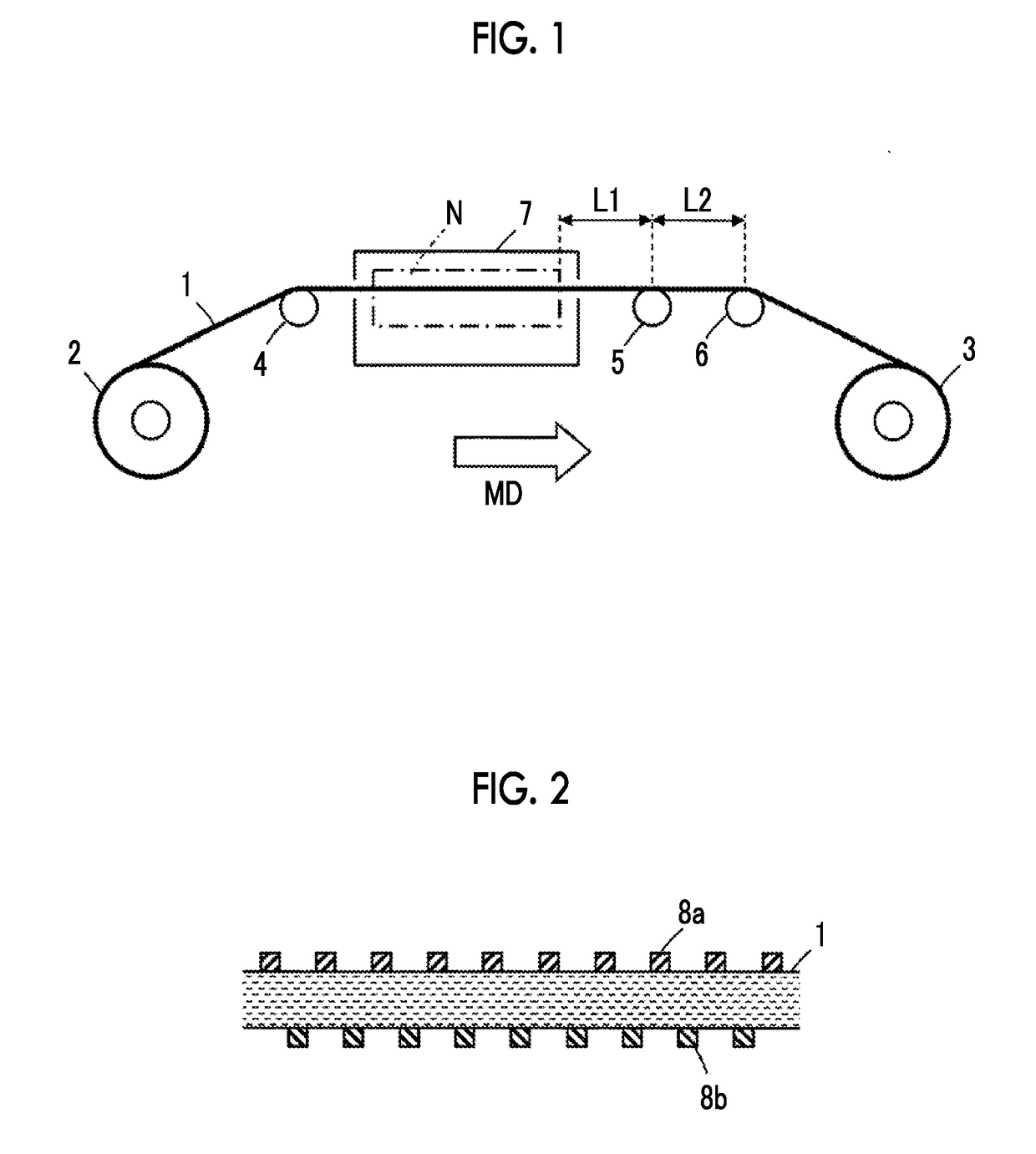

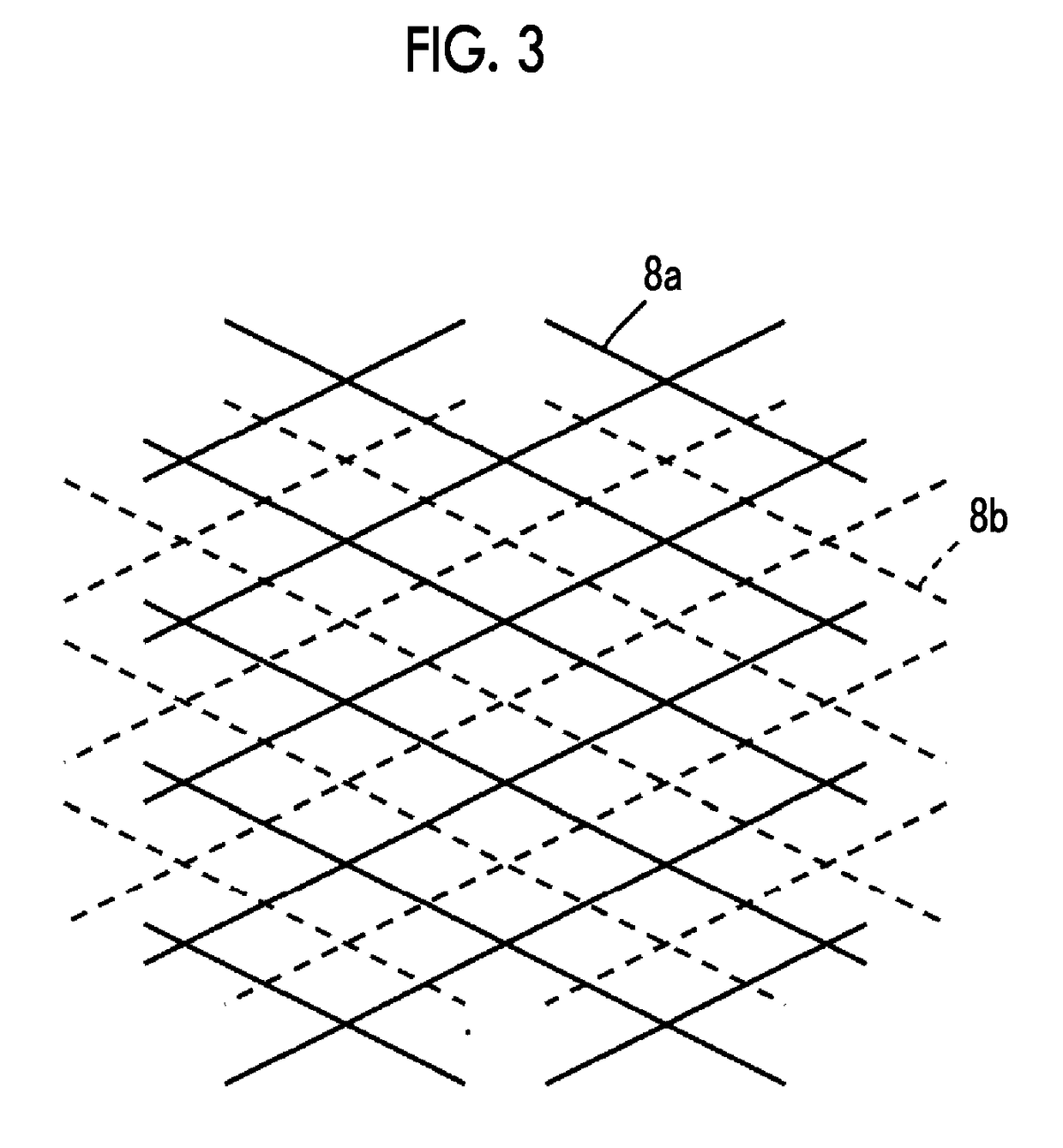

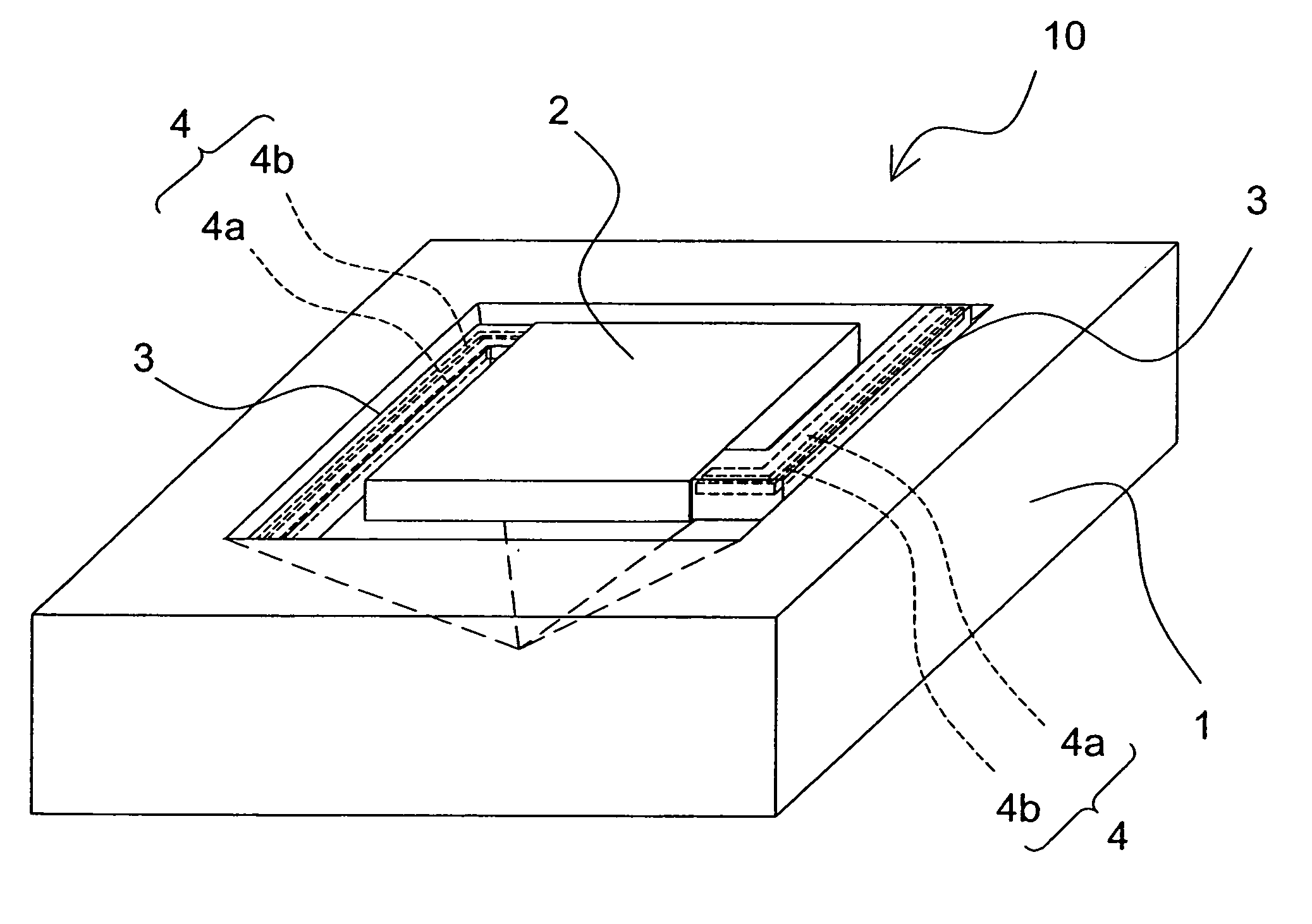

Manufacturing method of touch sensor film, touch sensor film, and touch panel

ActiveUS20170177118A1Avoid rippleLow heat shrinkageInput/output processes for data processingThin metalEngineering

A touch sensor film preventing moire occurring in accordance with deformation of a support is manufactured by performing roll transportation of an elongated transparent support 1 having a thickness smaller than 80 μm using a plurality of pass rollers 4, 5, and 6; performing annealing treatment with respect to the support 1 at a temperature which is equal to or lower than a temperature obtained by adding 35° C. to a dynamic glass transition temperature of the support 1; and forming a mesh pattern formed of thin metal wires 8a on a surface of the support 1 subjected to the annealing treatment.

Owner:FUJIFILM CORP

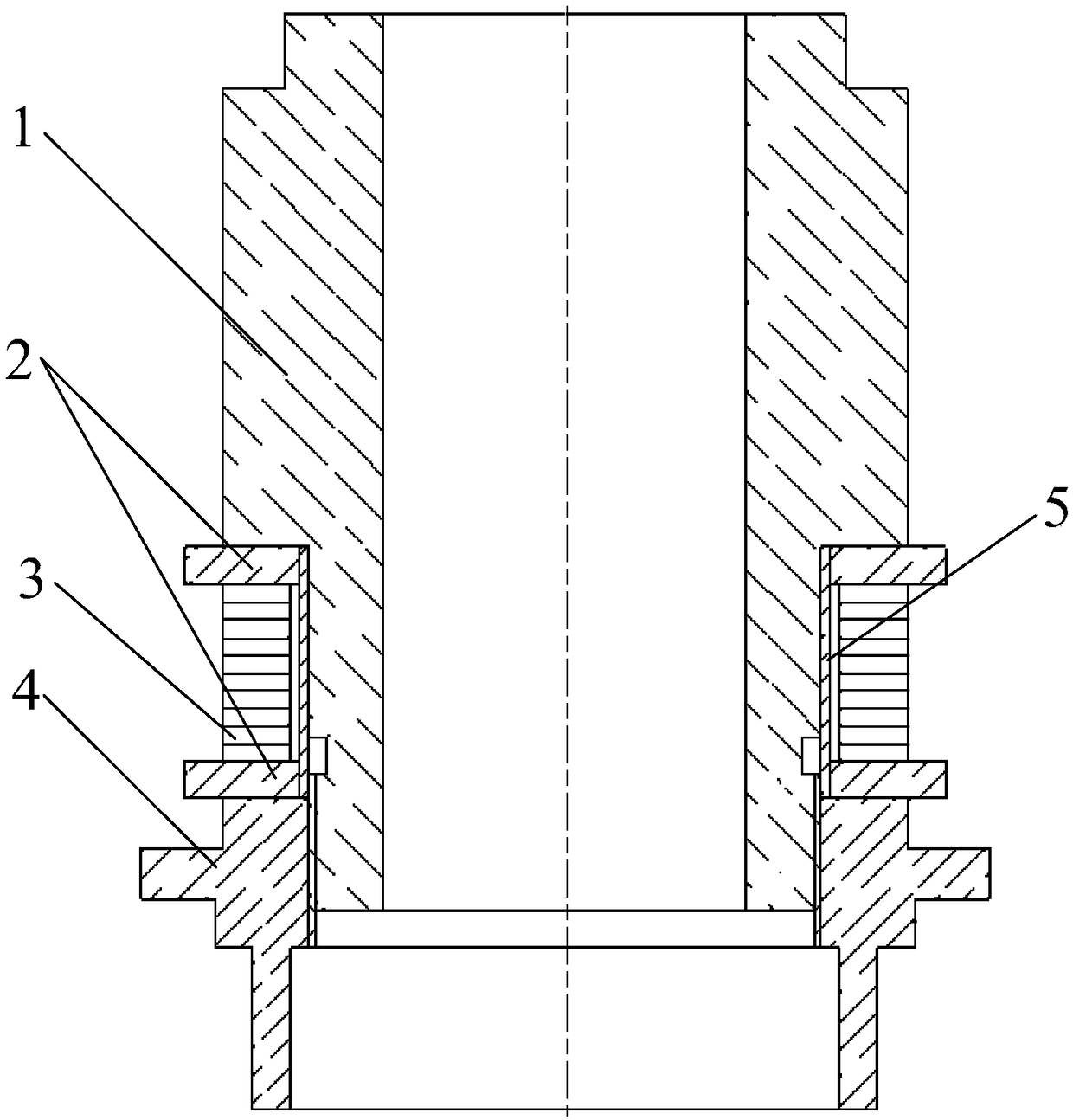

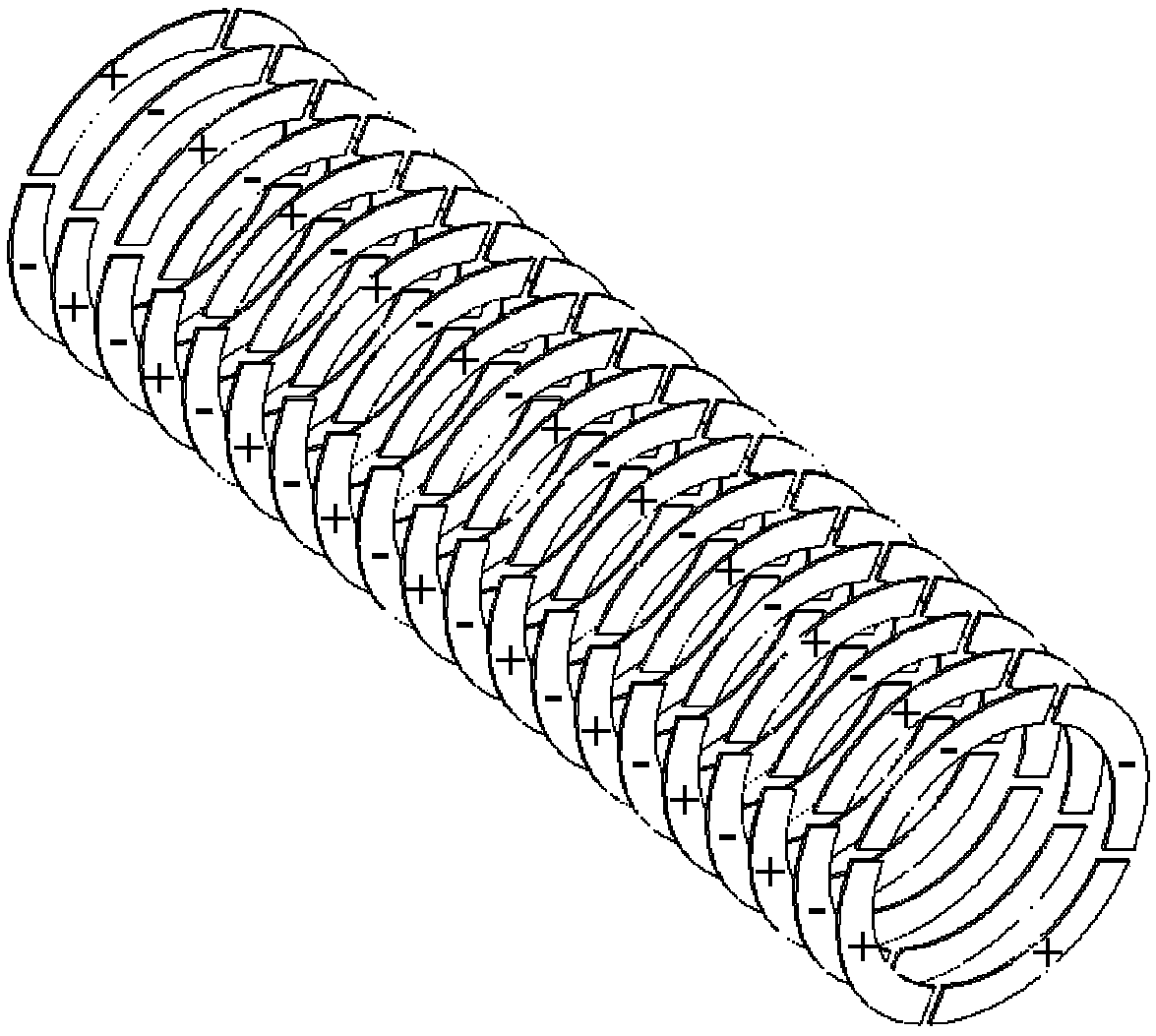

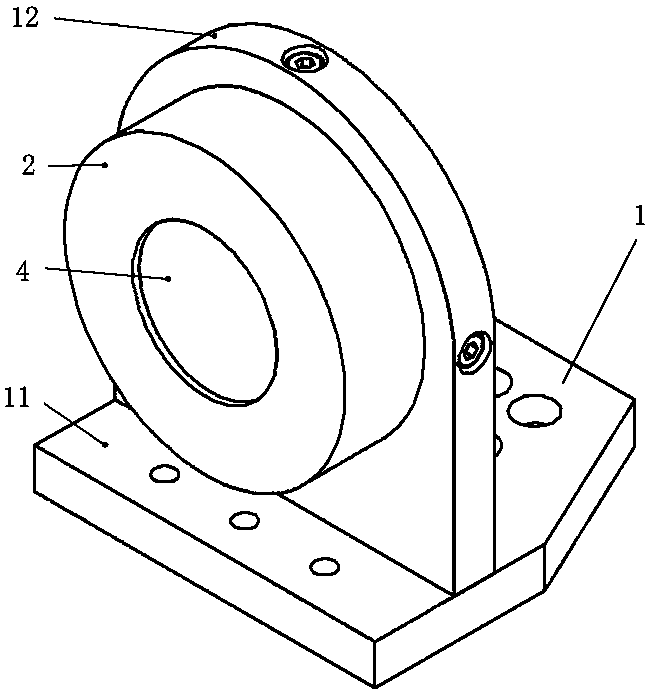

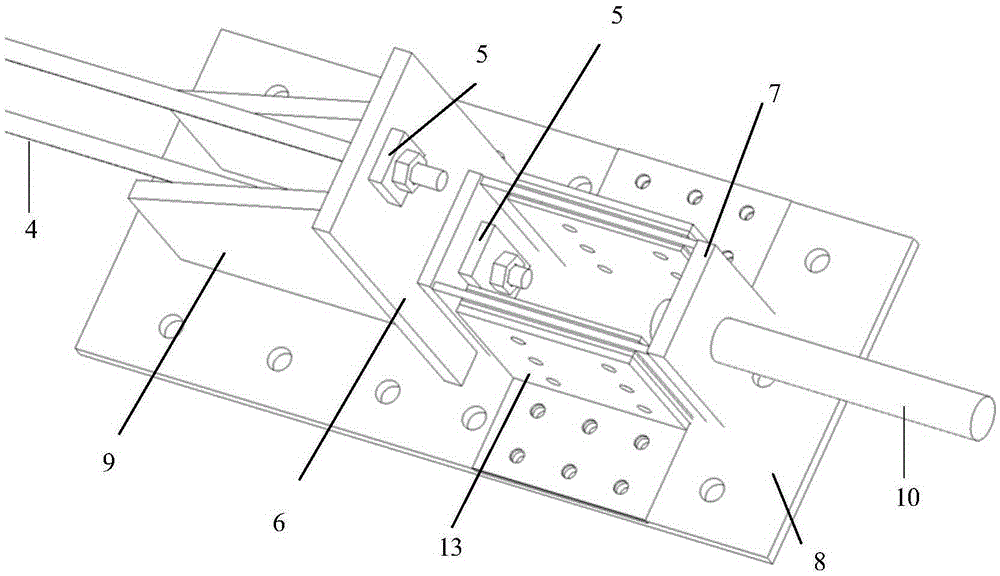

Mechanical shafting rotary error active compensation device based on piezoelectric actuator

ActiveCN109356960AHigh rotation accuracyCompensation for radial runoutSpringsPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

The invention provides a mechanical shafting rotary error active compensation device based on a piezoelectric actuator, and relates to the field of mechanical shafting rotary error active compensation. The device aims at solving the problems that the rotary precision of a traditional rolling bearing supporting shafting can hardly be improved in a breakthrough manner through machining and assembling links. The device comprises a metal end cap, two metal gaskets, the piezoelectric actuator and a base support. The piezoelectric actuator is formed by stacking multiple layers of piezoelectric ceramic pieces and metal electrode pieces, wherein the piezoelectric ceramic pieces and the metal electrode pieces are alternately arranged. Each layer of piezoelectric ceramic piece is composed of four sector rings defining a ring, and a certain gap is reserved between every two adjacent sector rings. In each layer of piezoelectric ceramic piece, the polarization directions of a pair of opposite sector rings are opposite, and the polarization directions of the sector rings corresponding to the adjacent piezoelectric ceramic pieces in the axial direction are opposite, in other words, the polarization directions in the axial direction are alternately distributed. The piezoelectric actuator is used as an actuator of the compensation device, and the beneficial effects of being high in displacementcontrol precision and high in response speed are achieved.

Owner:HARBIN INST OF TECH

Infrared radiation detecting device

ActiveUS7193212B2Increase the lengthReduce the cross-sectional areaSolid-state devicesMaterial analysis by optical meansElectrical conductorThermopile

An infrared radiation detecting device is provided that comprises a substrate, an infrared radiation absorbing unit, at least one support beam and a thermopile. The at least one support beam has a first end portion coupled to the substrate and a second end portion coupled to the infrared radiation absorbing unit. The thermopile includes first and second electrical conductors disposed on the support beam with the first and second electrical conductors having different electric conductivities. The first and second electrical conductors is dimensioned and shaped to improve structural rigidity of the support beam in comparison to an identically shaped support beam including a thermopile with a pair of first and second electrical conductors that are identically shaped and disposed parallel to each other.

Owner:NISSAN MOTOR CO LTD

Transverse piezoelectric driving deformation mirror and the assembling method thereof

InactiveCN107942508AReduce support stiffnessEasy to installOptical elementsElectricityPiezoelectric actuators

The invention discloses a transverse piezoelectric driving deformation mirror and an assembling method thereof. A transverse shell in the deformation mirror is arranged on a base, a reflecting mirrorand a piezoelectric actuator are bonded and arranged in the inner hole of the transverse shell in a sleeved mode, and an elastic gasket is arranged on the edge of the reflecting mirror. One end face of the elastic gasket is in movable contact with the transverse shell, and the pressure applying device is in threaded sleeve with the inner hole of the transverse shell, and is in contact with the elastic gasket; and an electricity receiving assembly is arranged on the pressure applying device and is connected with the piezoelectric actuator. The method comprises the following steps of s1, bondinga piezoelectric actuator with a reflector; s2 clamping and fastening on the side surface of the reflecting mirror and the upper surface and the lower surface of the edge by using an elastic gasket clamping sleeve, and arranging on a pressure applying device; s3, fixing the pressure applying device in the transverse shell sleeve and applying pressure to an elastic gasket; s4, welding a wire and the electricity receiving assembly together, and installing the electricity receiving assembly on the pressure applying device; s5, transversely fixing the transverse shell sleeve on the base. The device has the advantages of being simple in structure, convenient to manufacture and install and capable of effectively improving the deformation of each electrode.

Owner:NAT UNIV OF DEFENSE TECH

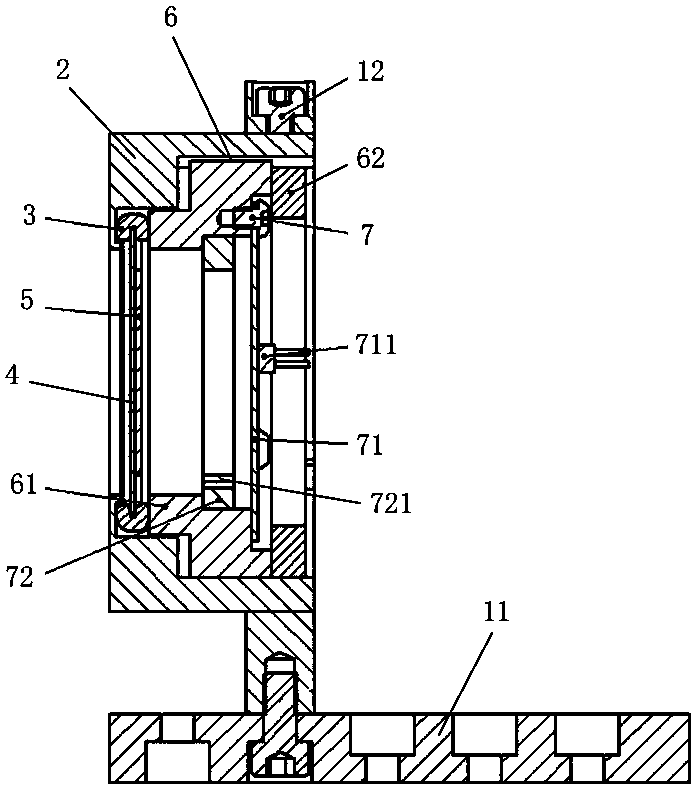

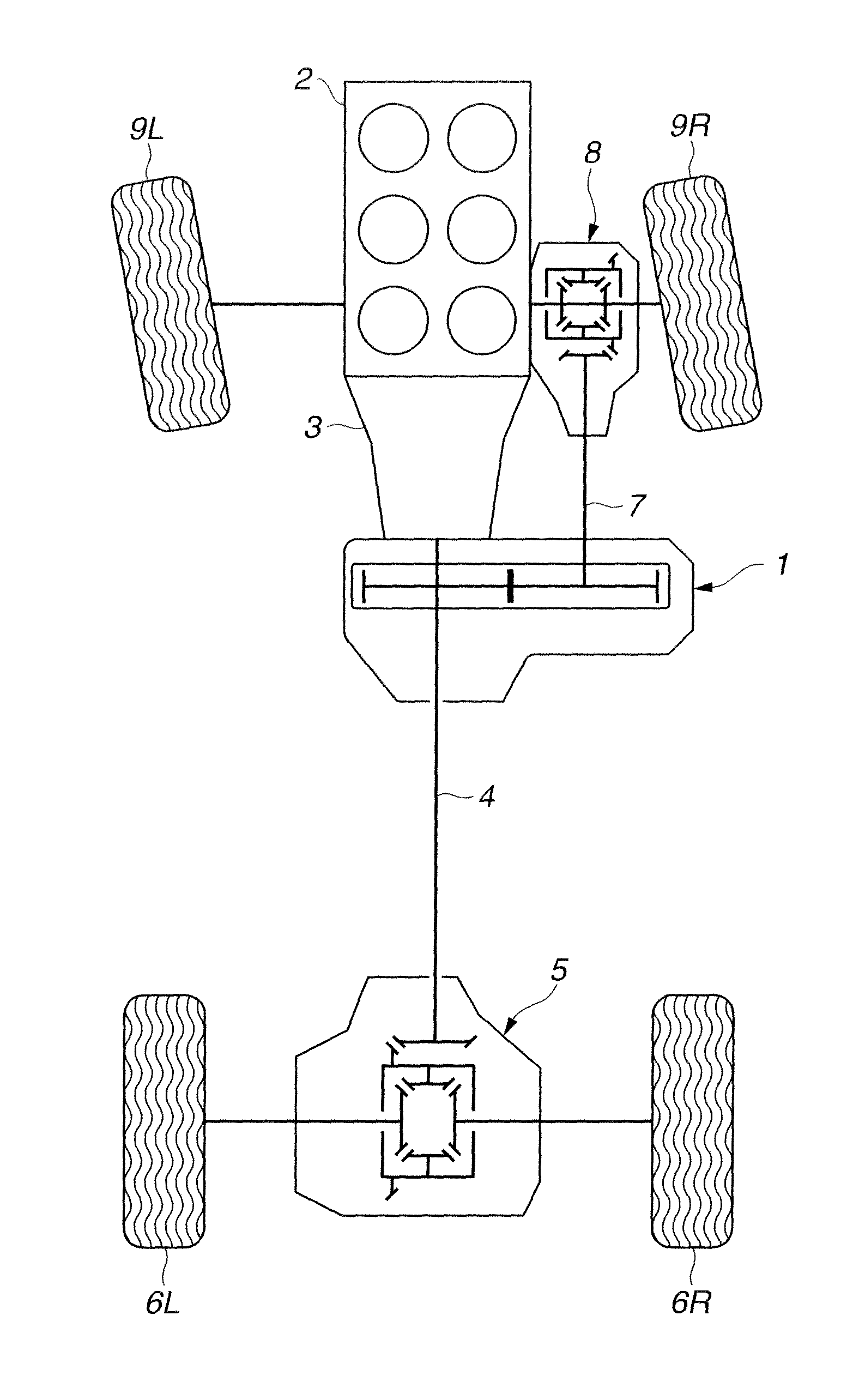

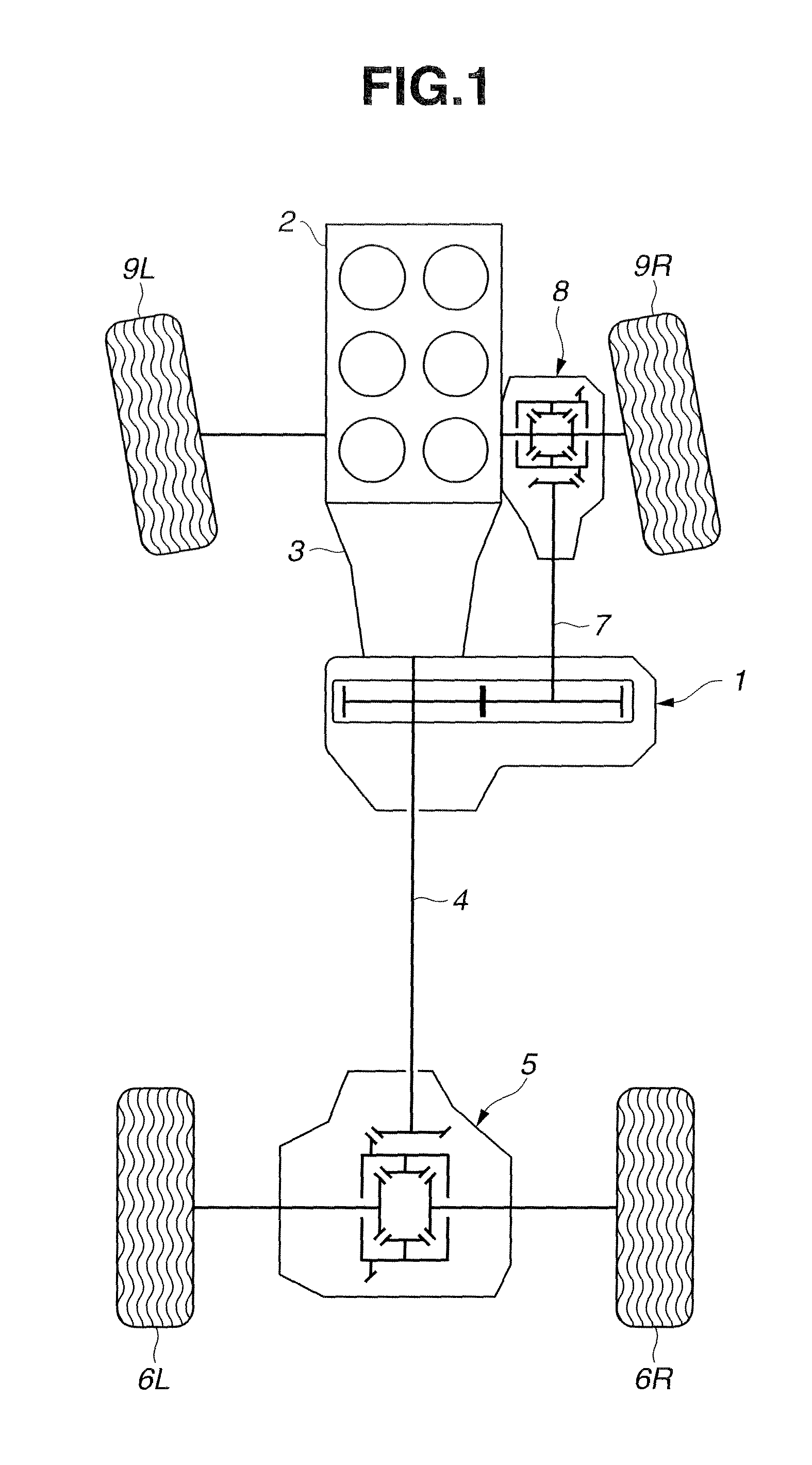

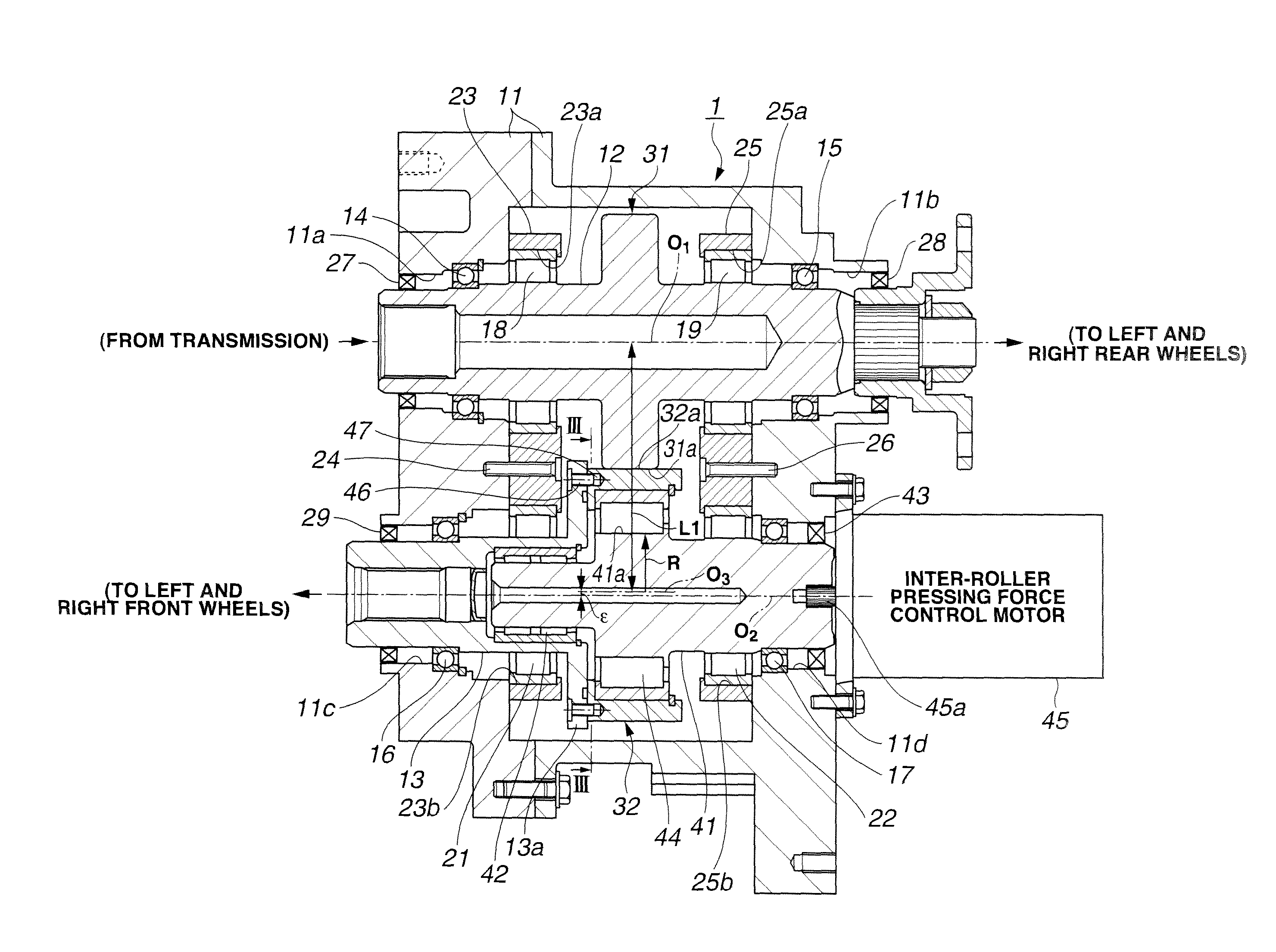

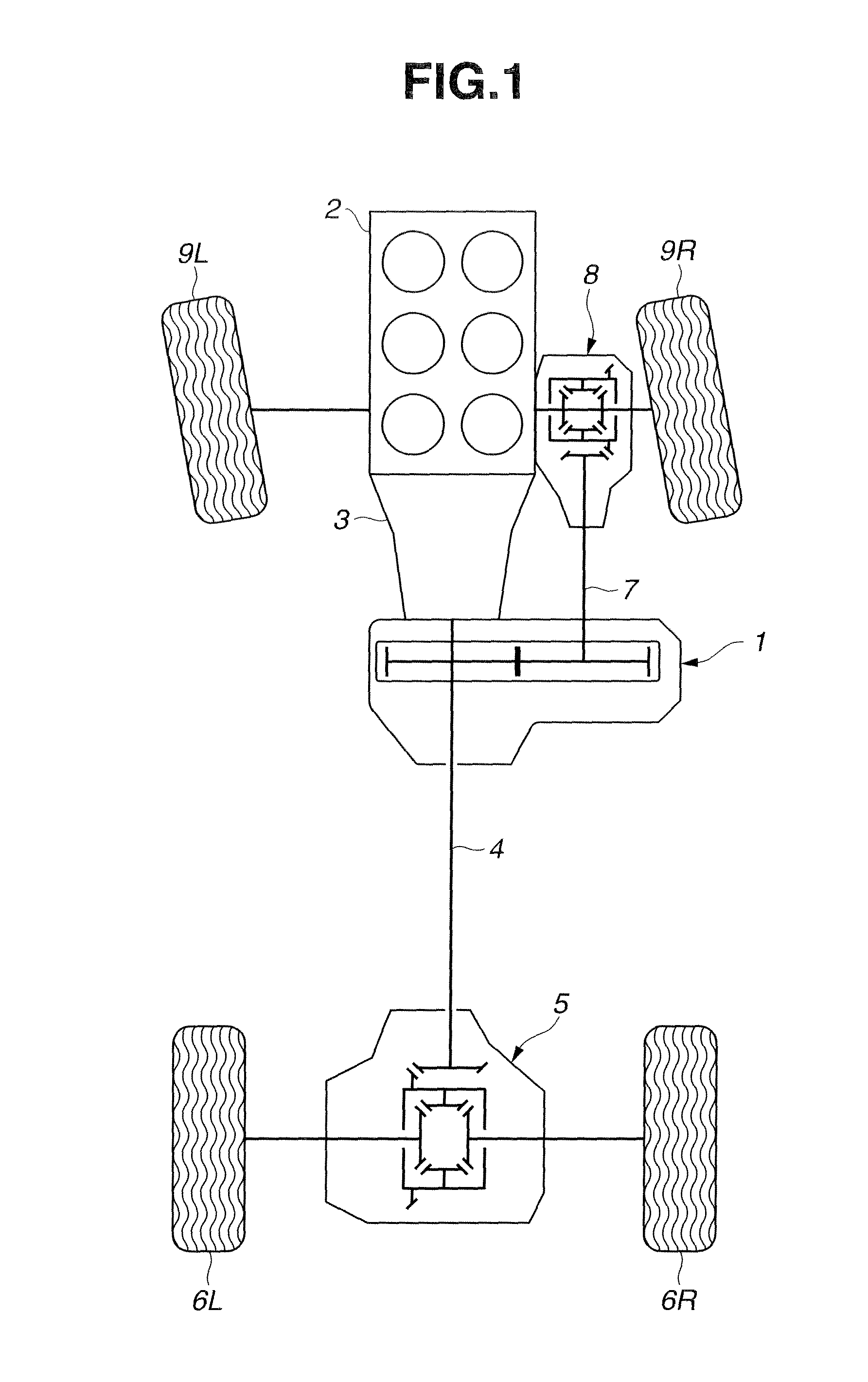

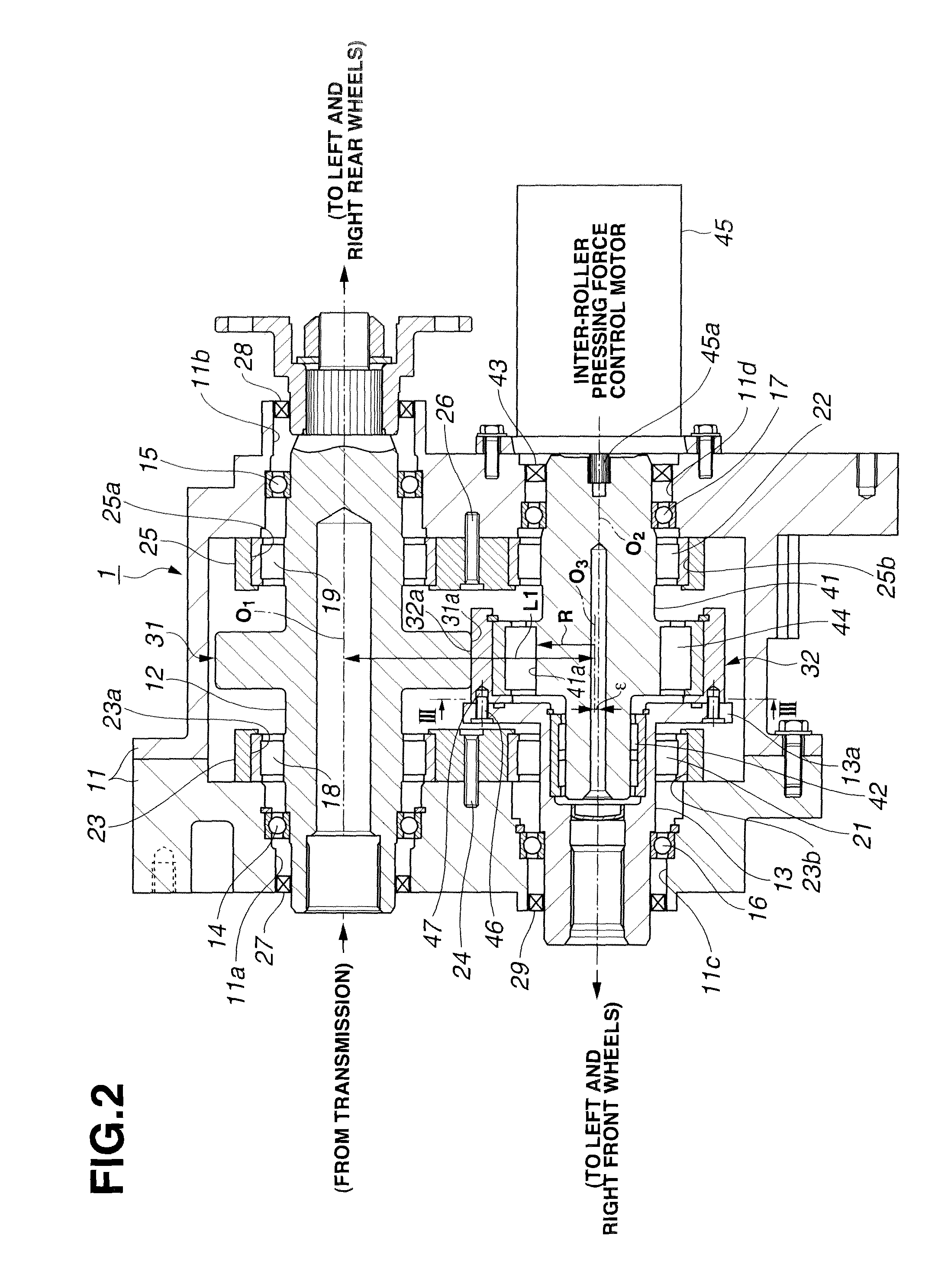

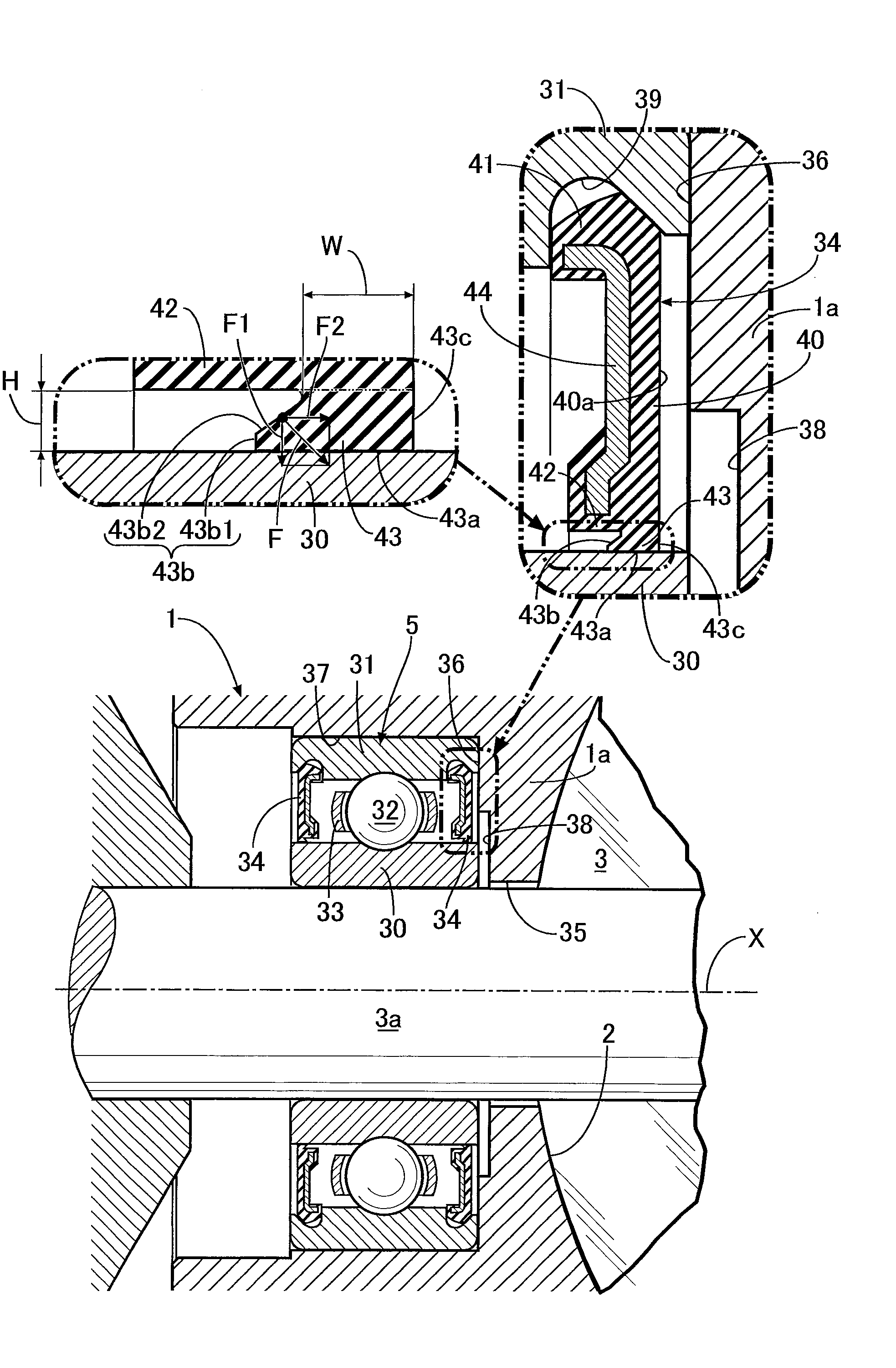

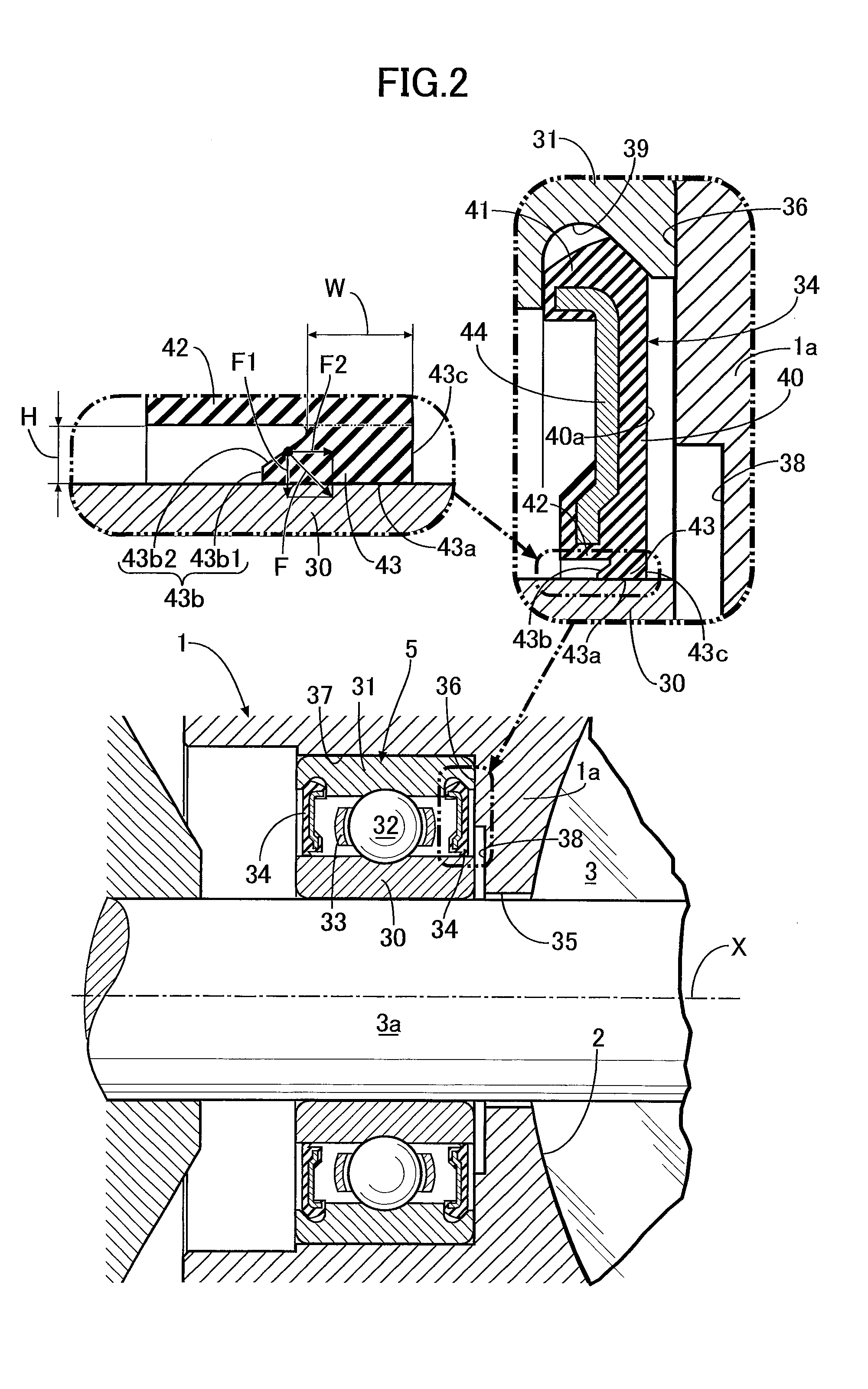

Friction-roller type transmission mechanism

InactiveUS8402851B2Reduce support stiffnessSolution to short lifeBearing componentsFriction gearingsTorque transmissionEngineering

Under control of rotation of a crankshaft 41, a friction roller 32 is pressed against a friction roller 31 in a radial direction, so as to achieve torque transmission between the rollers 31, 32. An inter-roller radial pressing reaction is canceled as an internal force in bearing supports 23, 25, with no input to a housing 11. The reaction causes a radial displacement of a bearing-fitting portion provided with inner and outer bearings 21, 42 in double layer arrangement, wherein the radial displacement is larger than that of a bearing-fitting portion provided with a bearing 18, 19, 22 in single arrangement, so as to cause unbalanced contact between rollers 31, 32. In order to prevent this, support stiffness of bearing support 23 against the inter-friction-roller radial pressing reaction is set higher than that of bearing support 25.

Owner:NISSAN MOTOR CO LTD

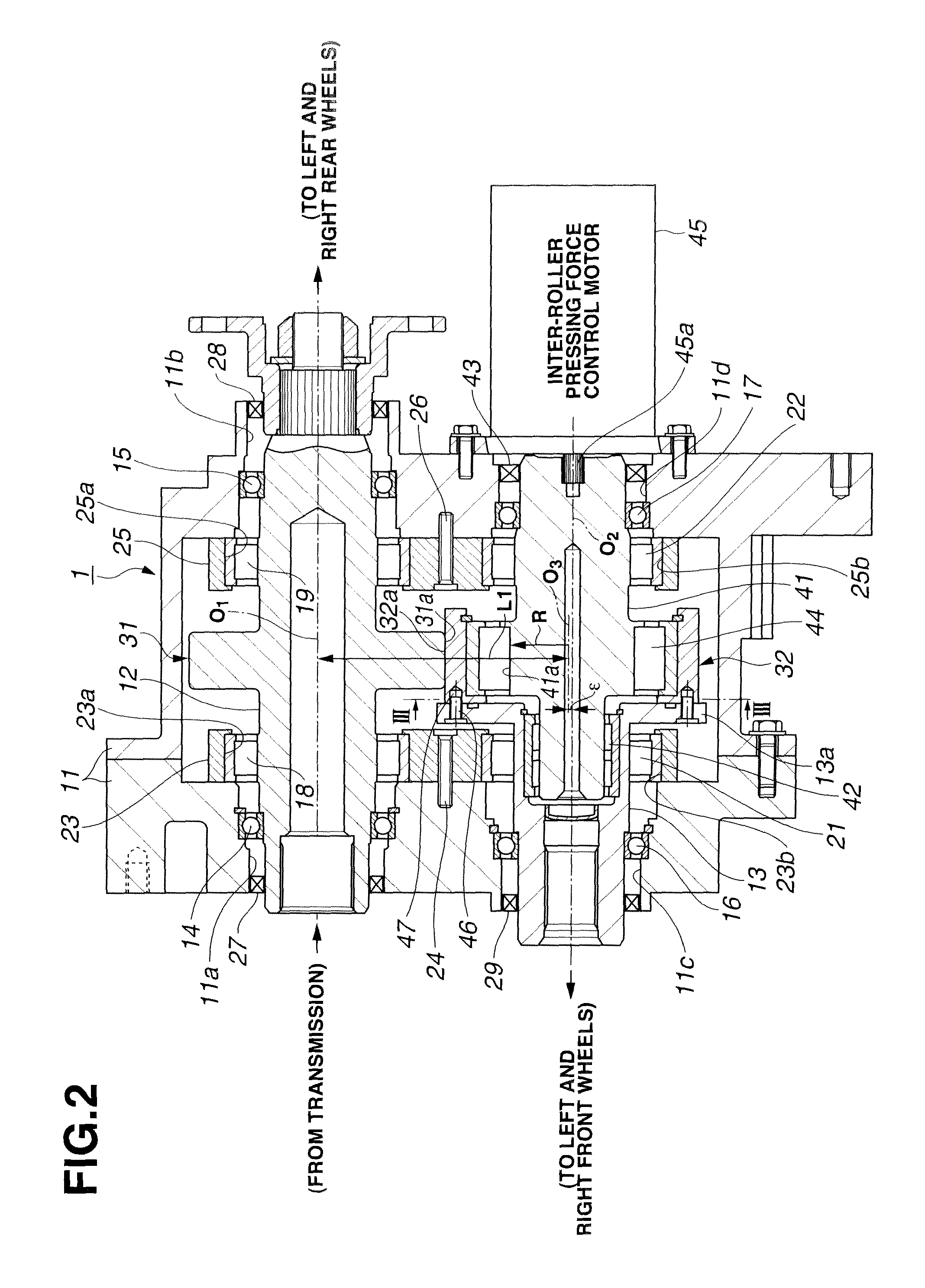

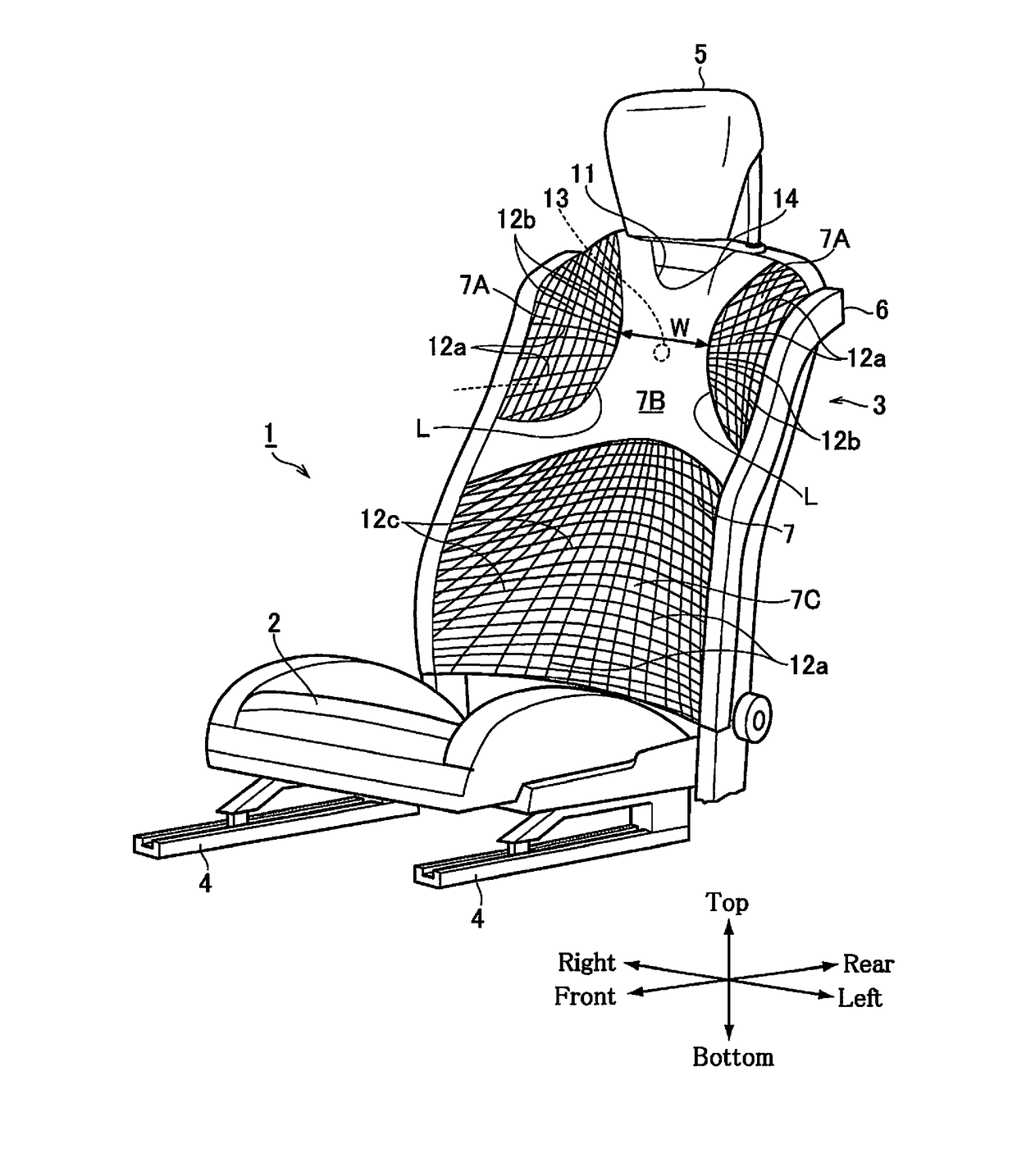

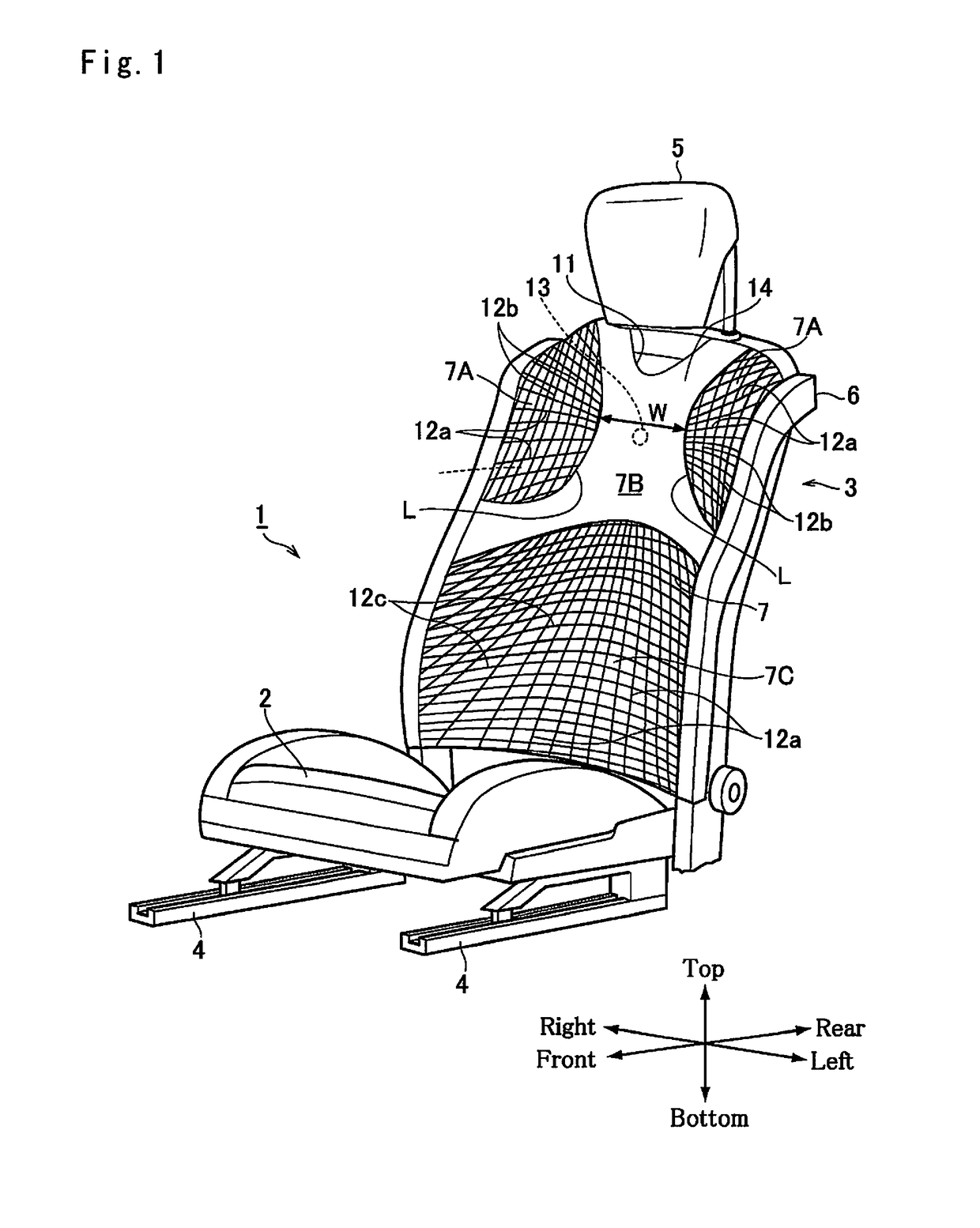

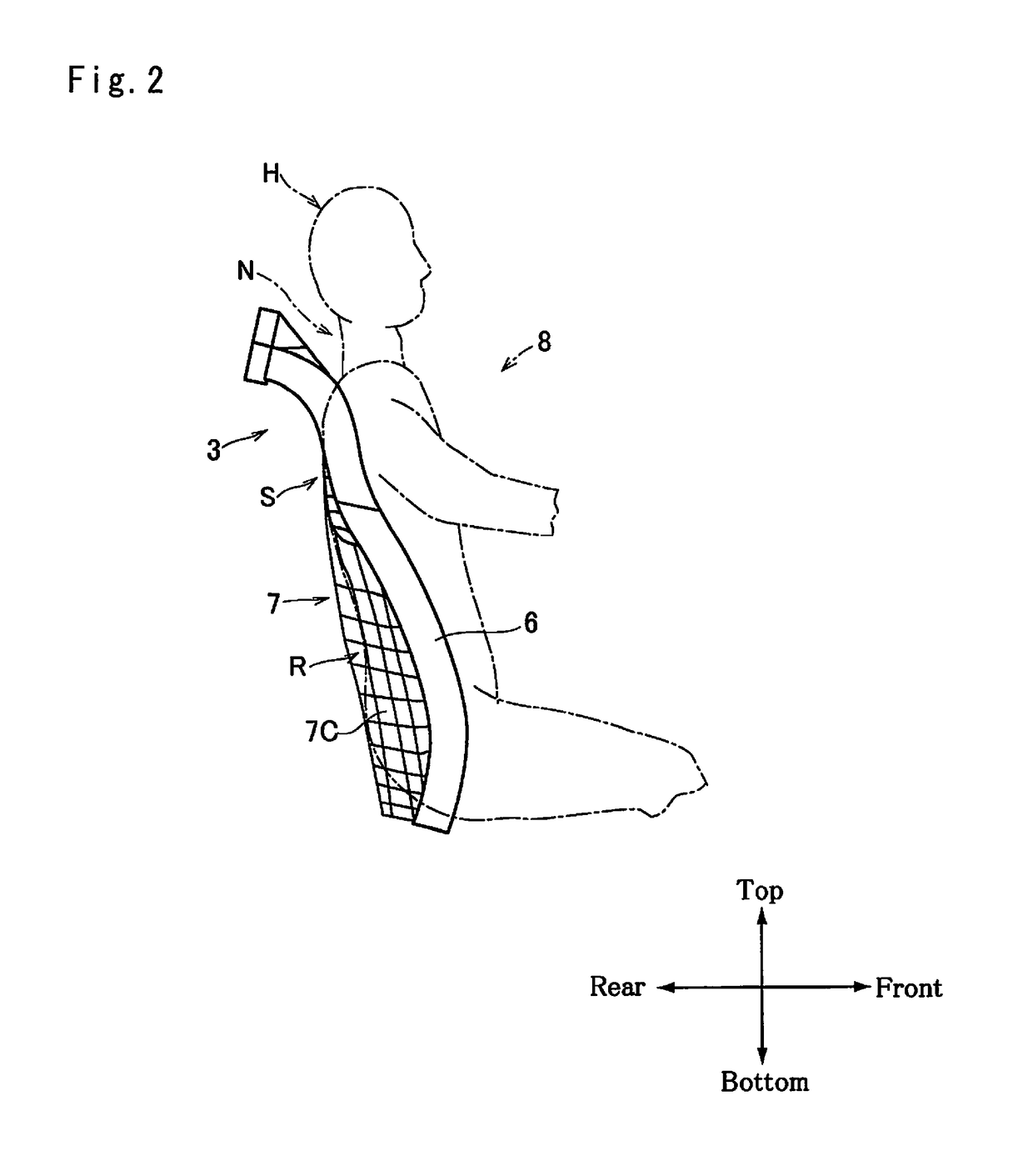

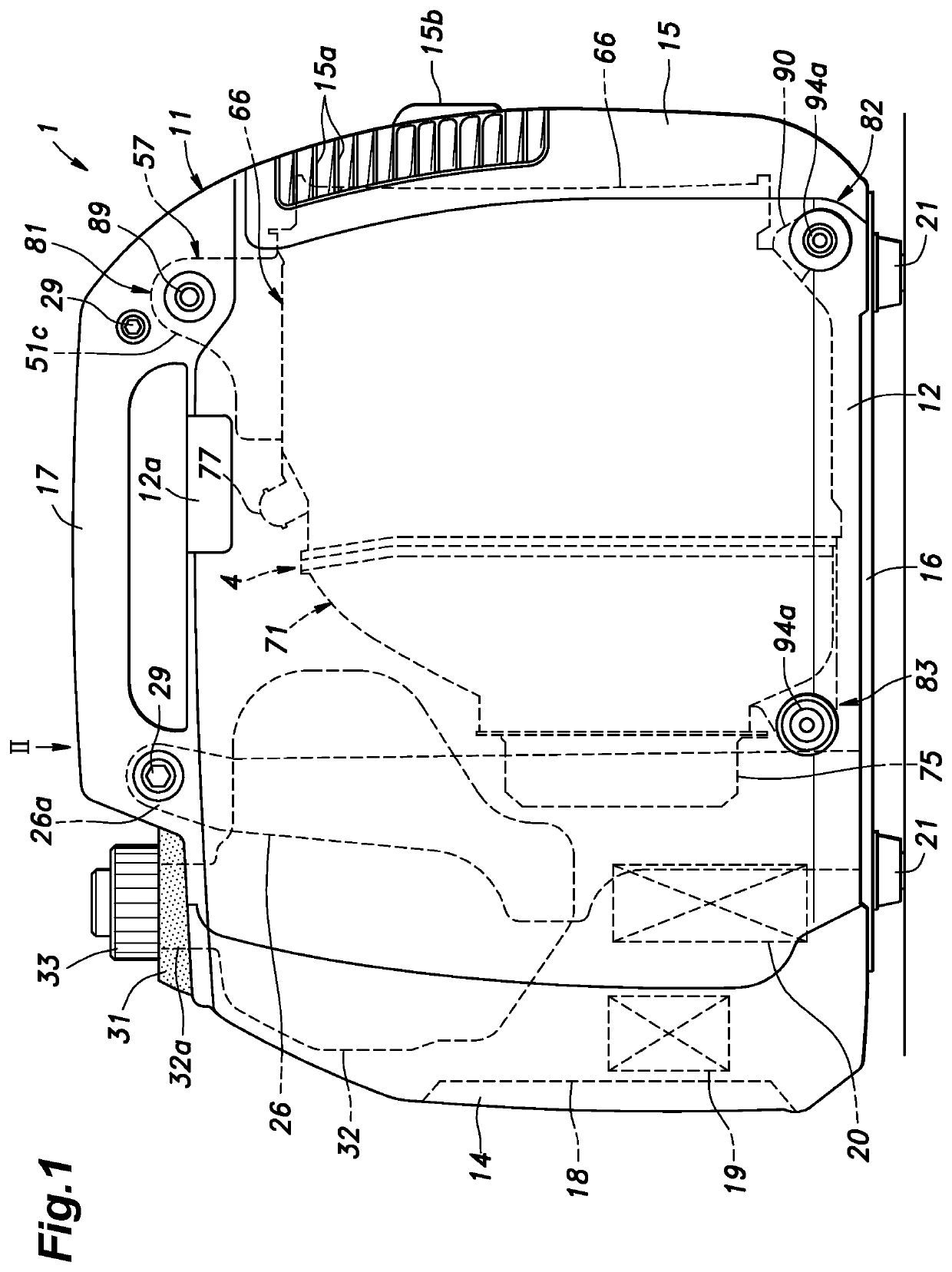

Vehicle seat

A seatback of a vehicle seat includes a seatback frame and a backrest attached to the seatback frame. The backrest includes a first supporting area configured to receive a load of a shoulder of the occupant, and a second supporting area configured to receive a load of a spine area of the occupant. Support stiffness in the first supporting area for a vertical load is lower than that in the second supporting area. Support stiffness in the second supporting area for a shearing load is higher than that in the first supporting area.

Owner:TOYOTA JIDOSHA KK

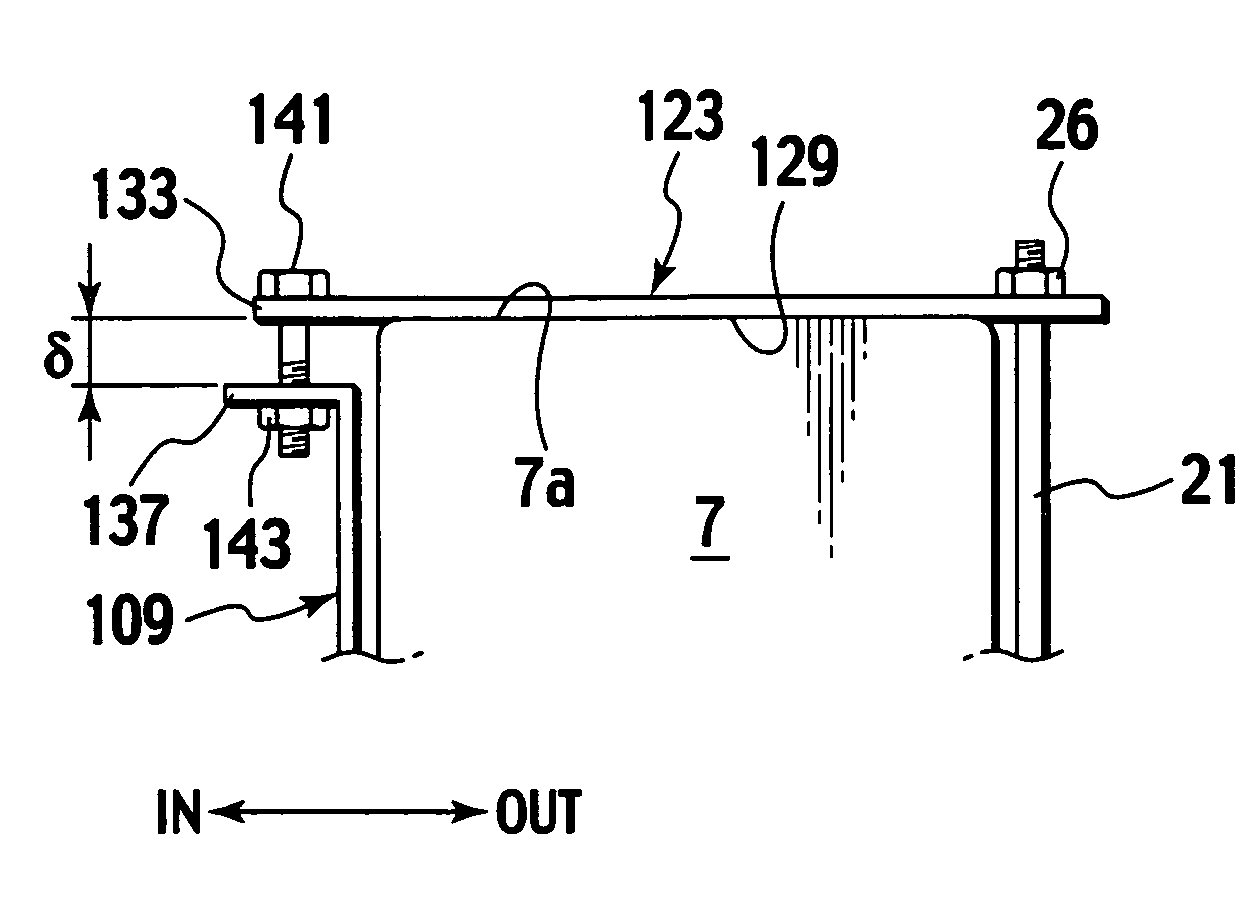

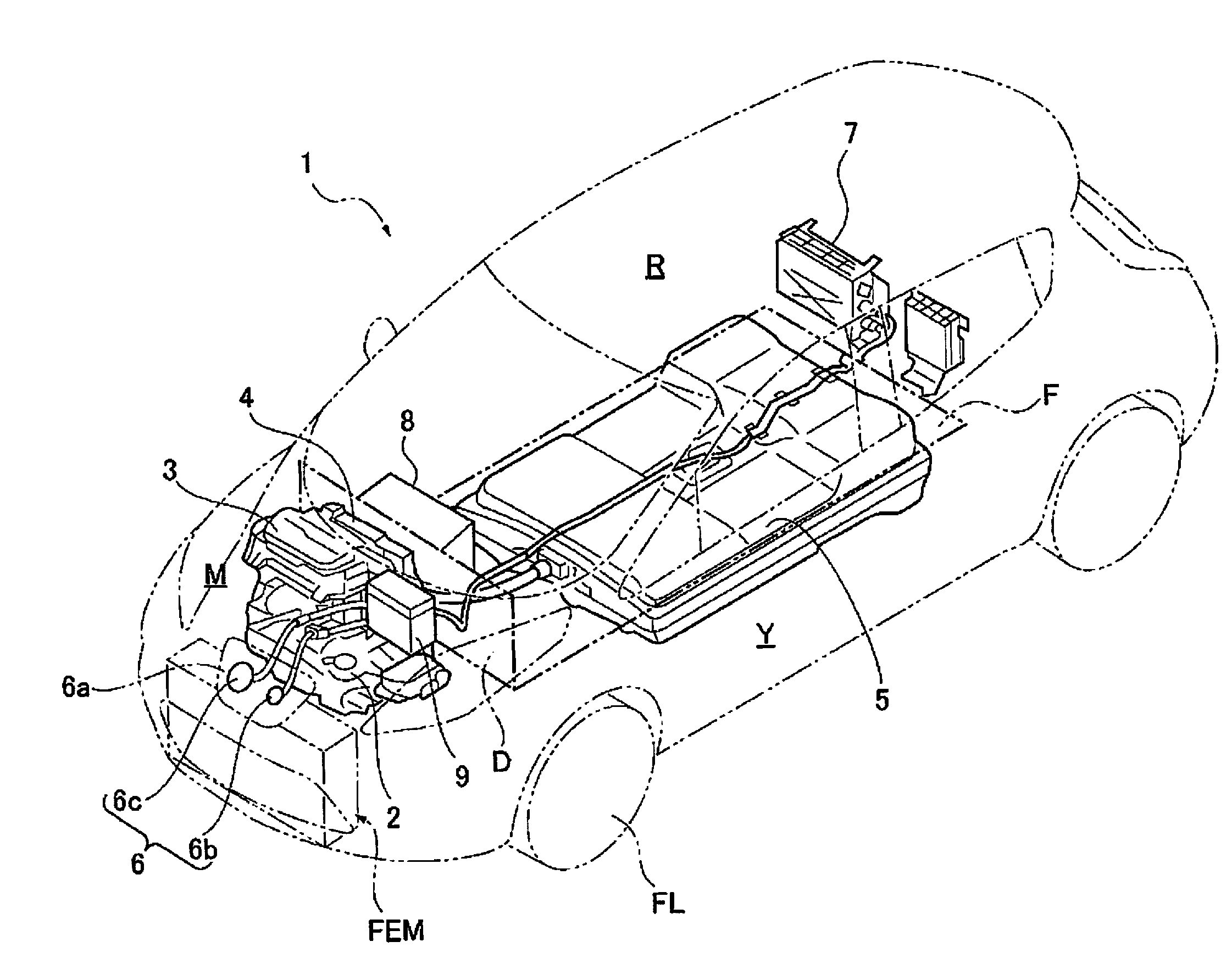

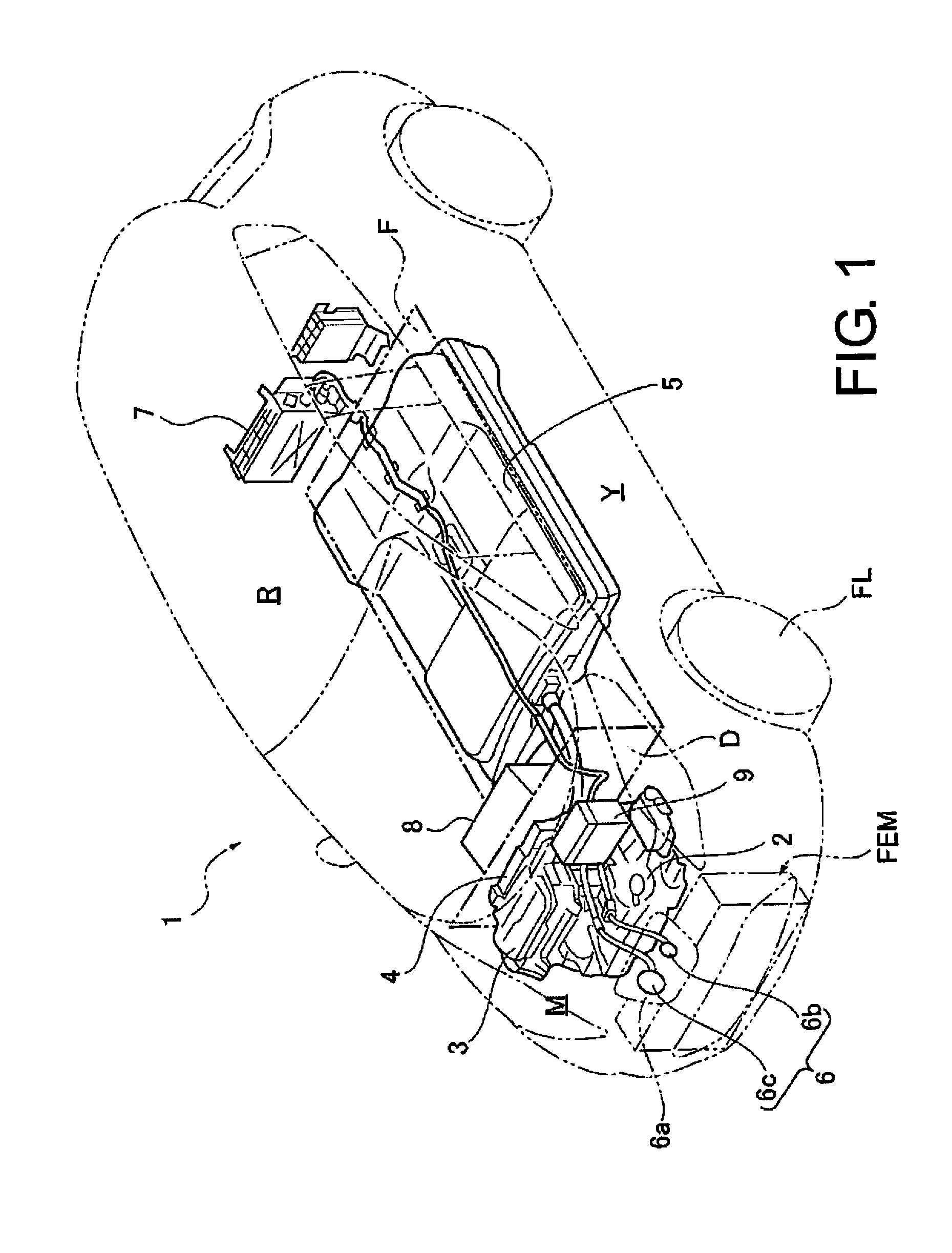

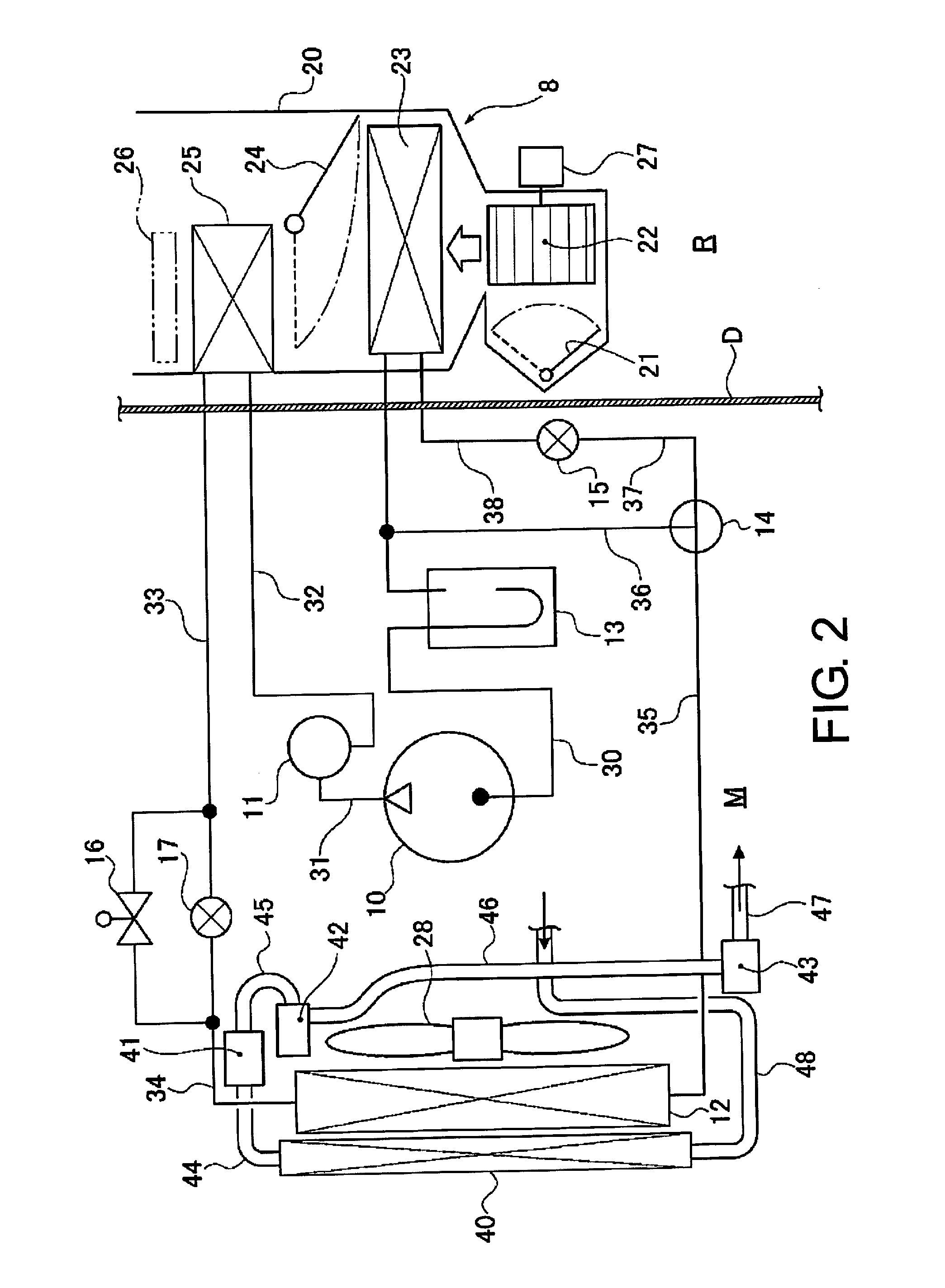

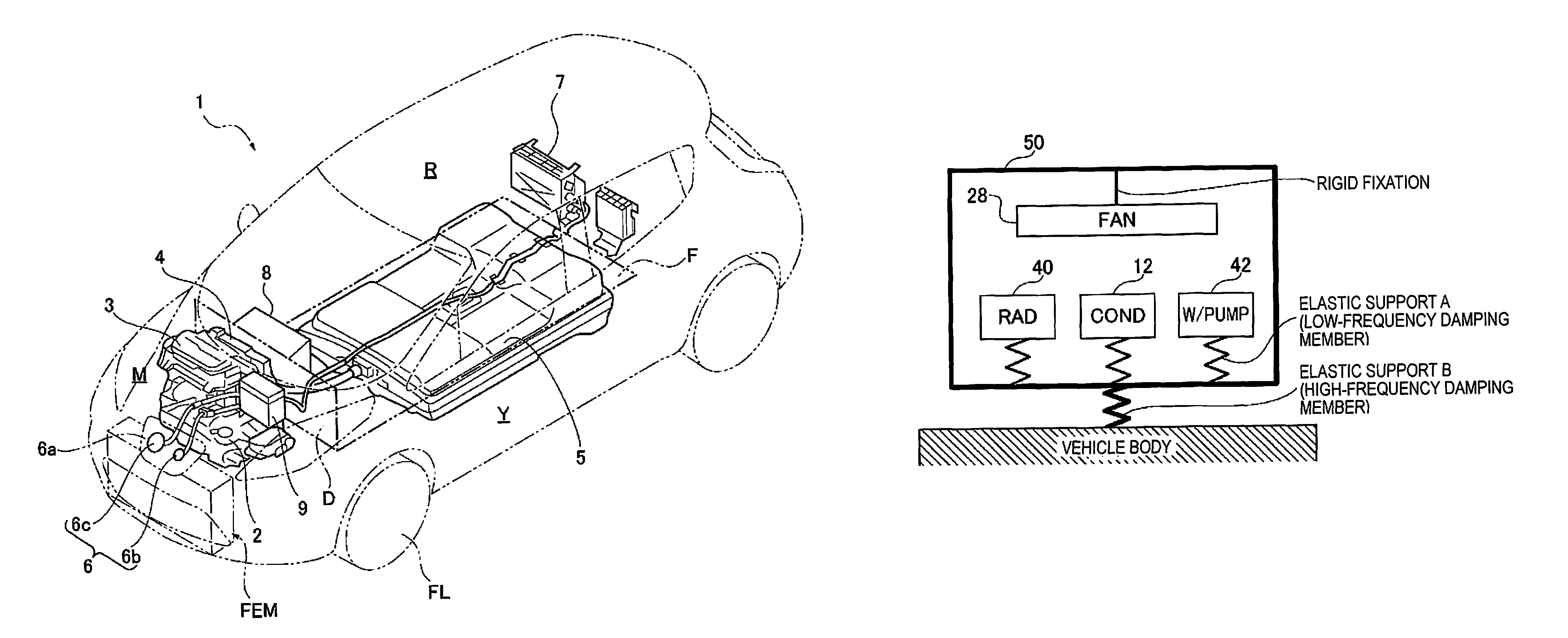

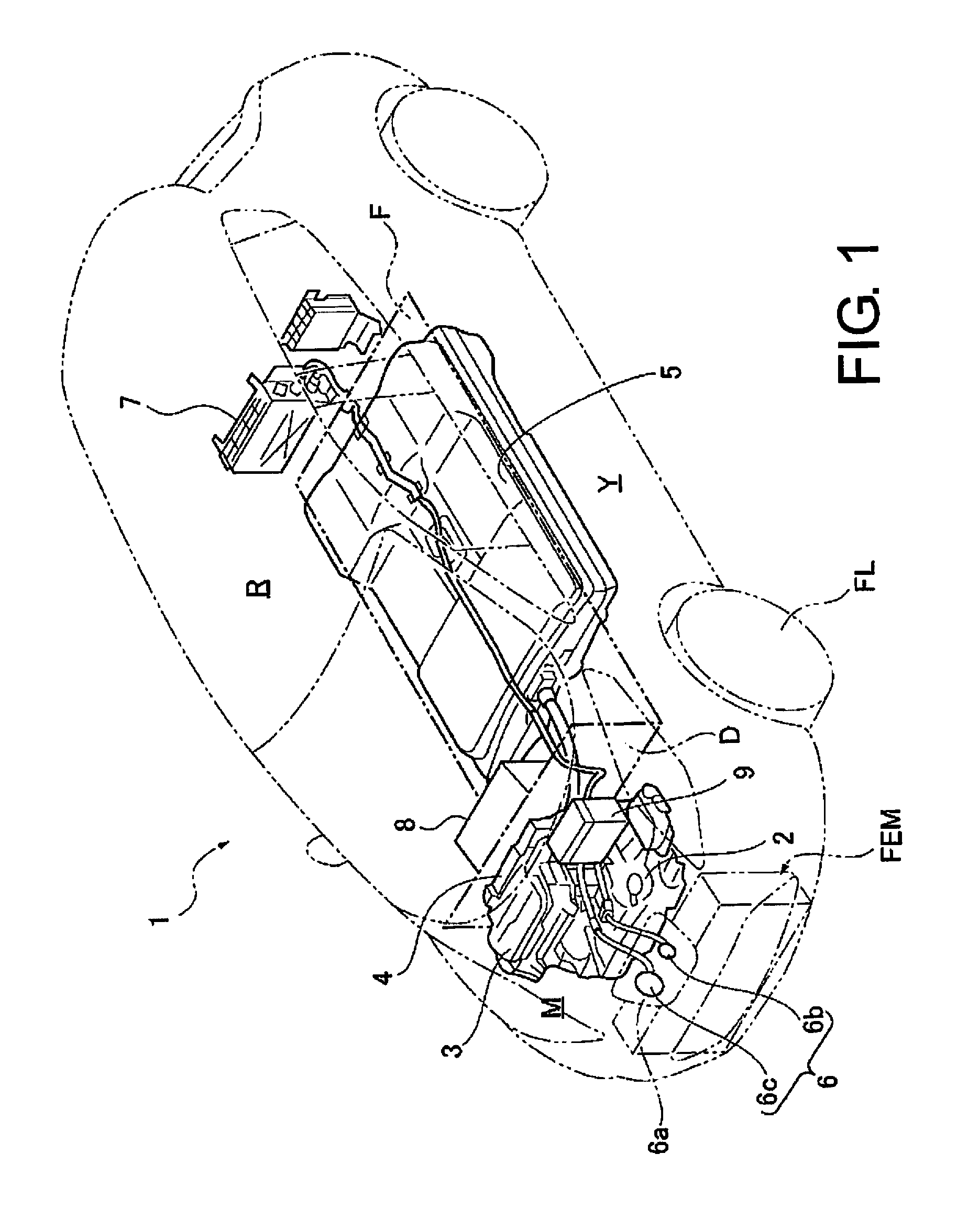

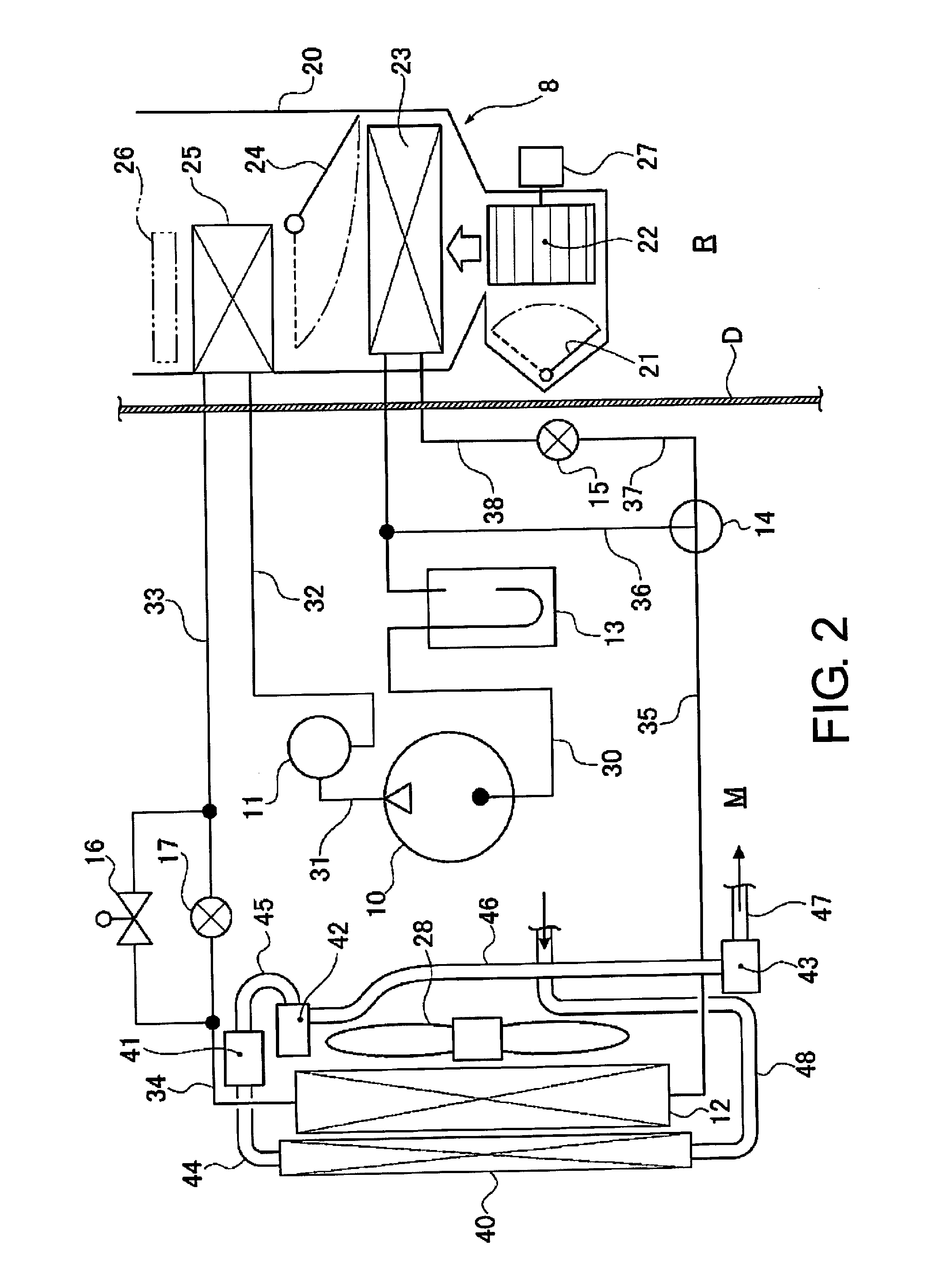

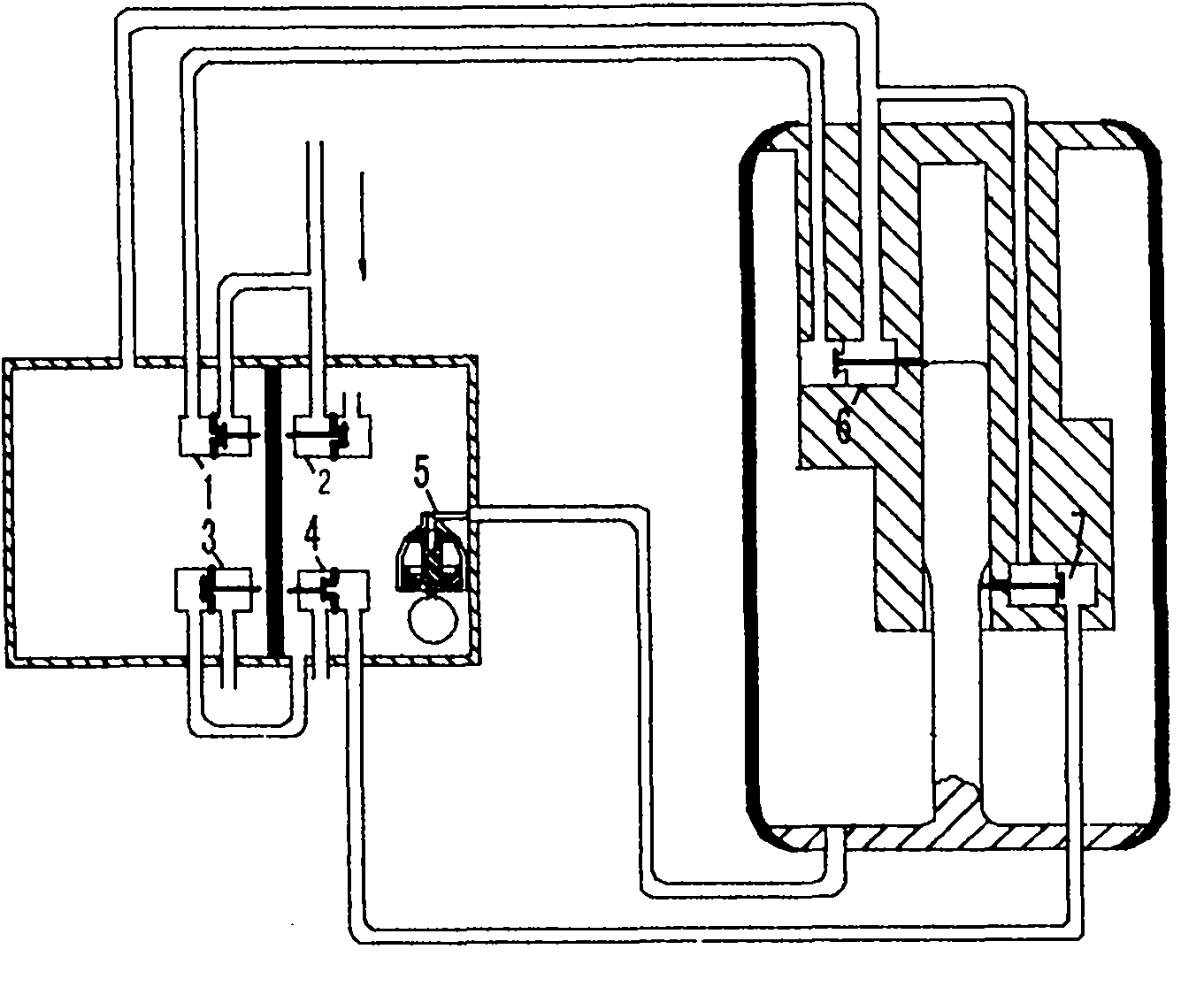

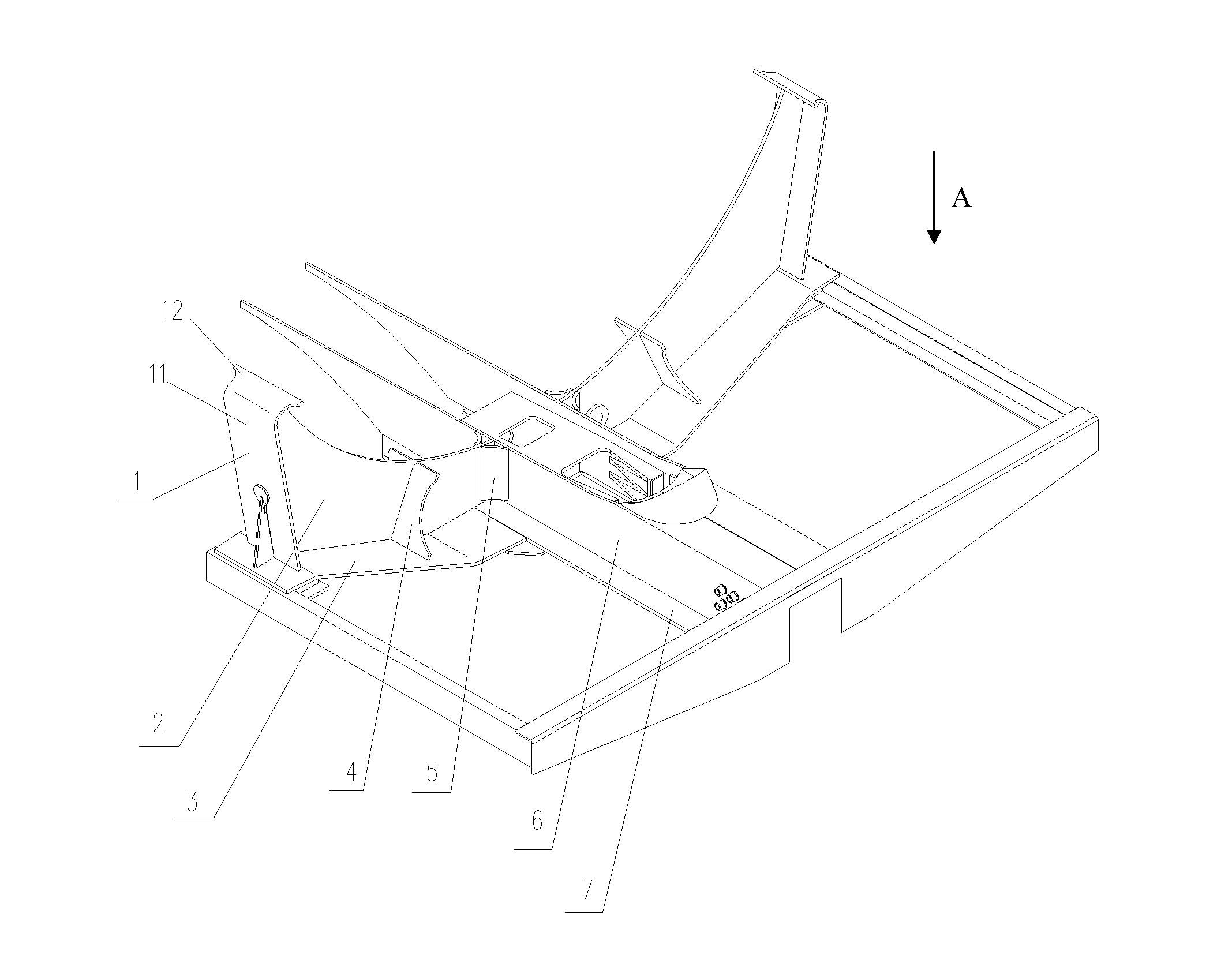

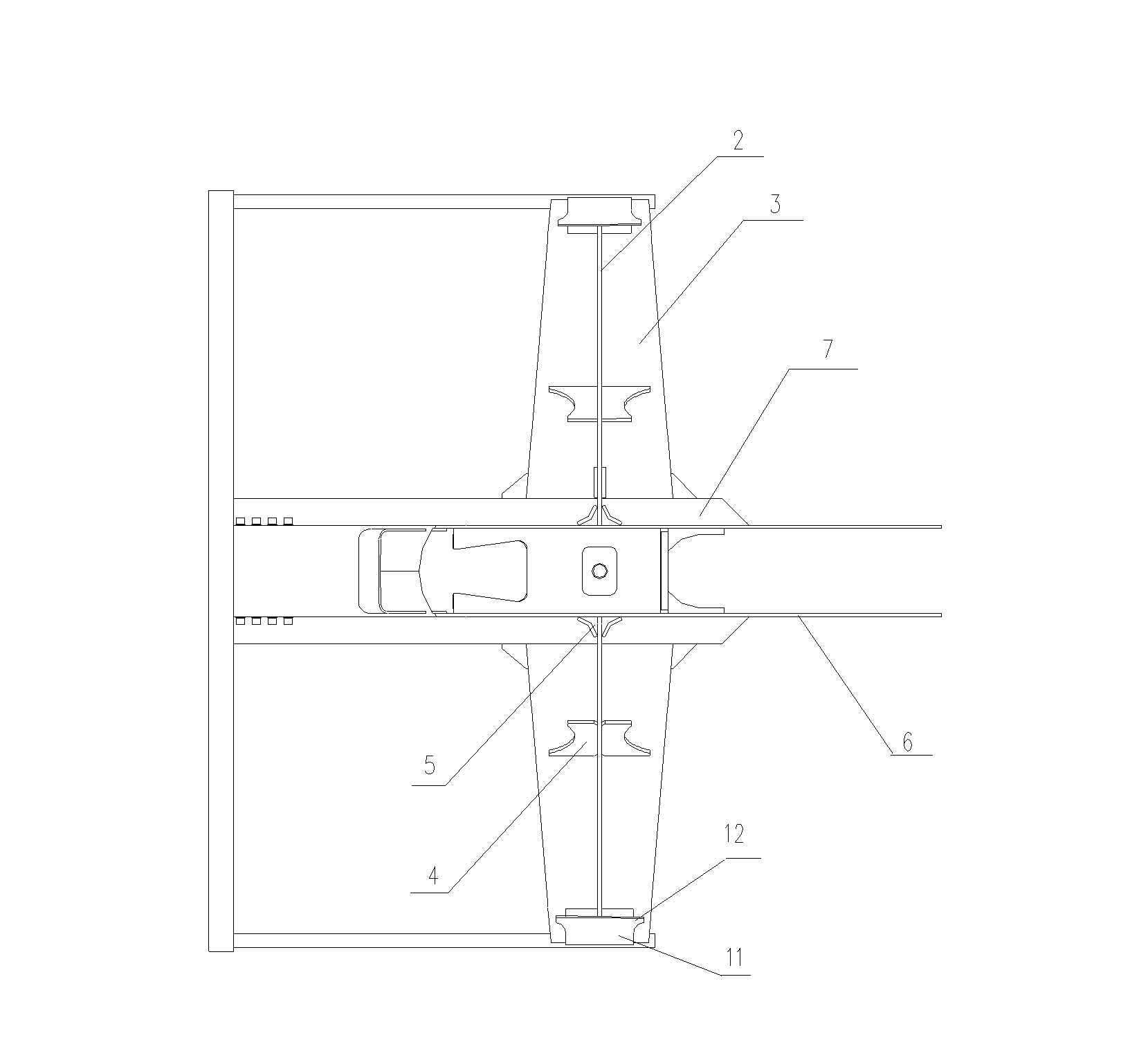

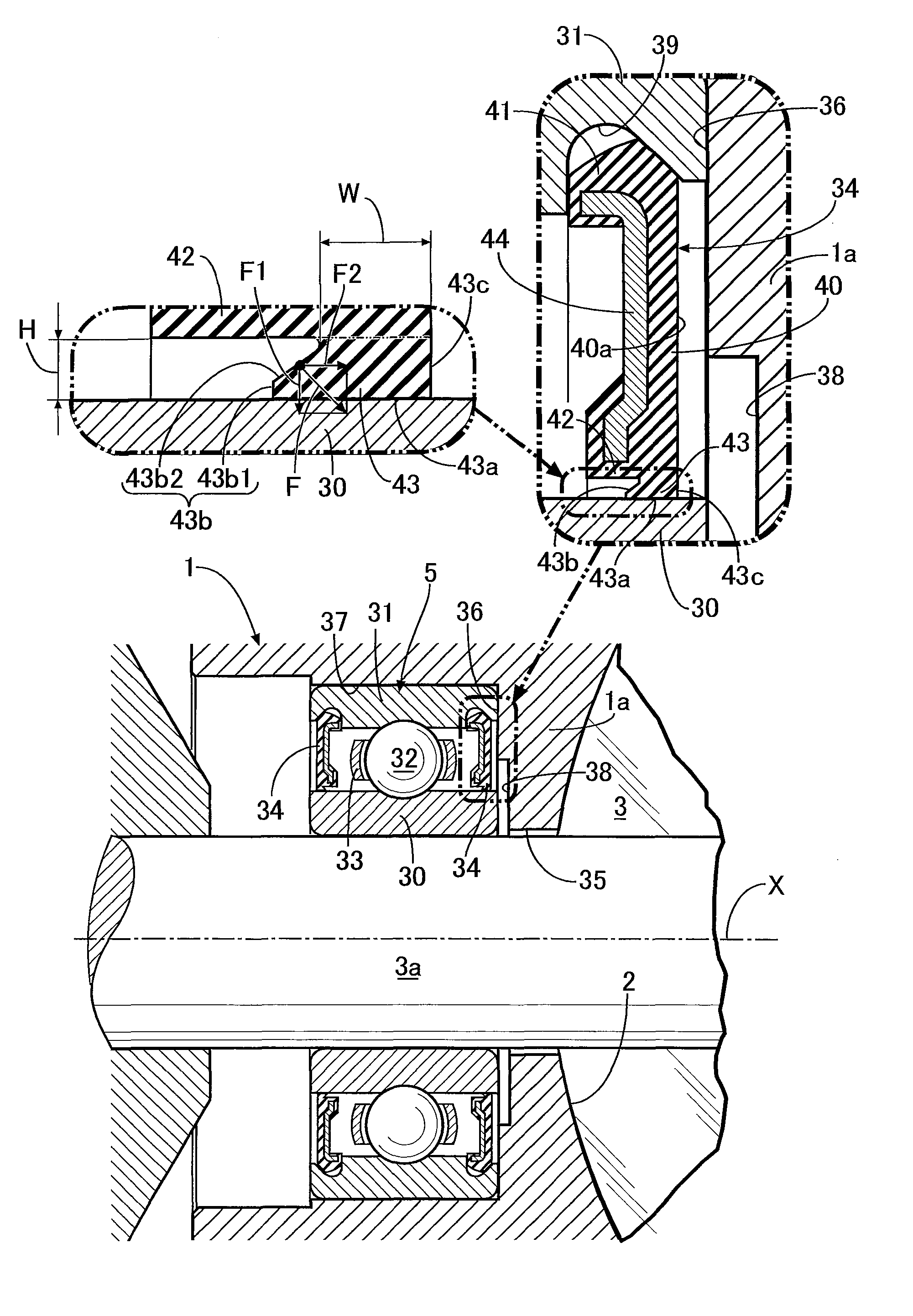

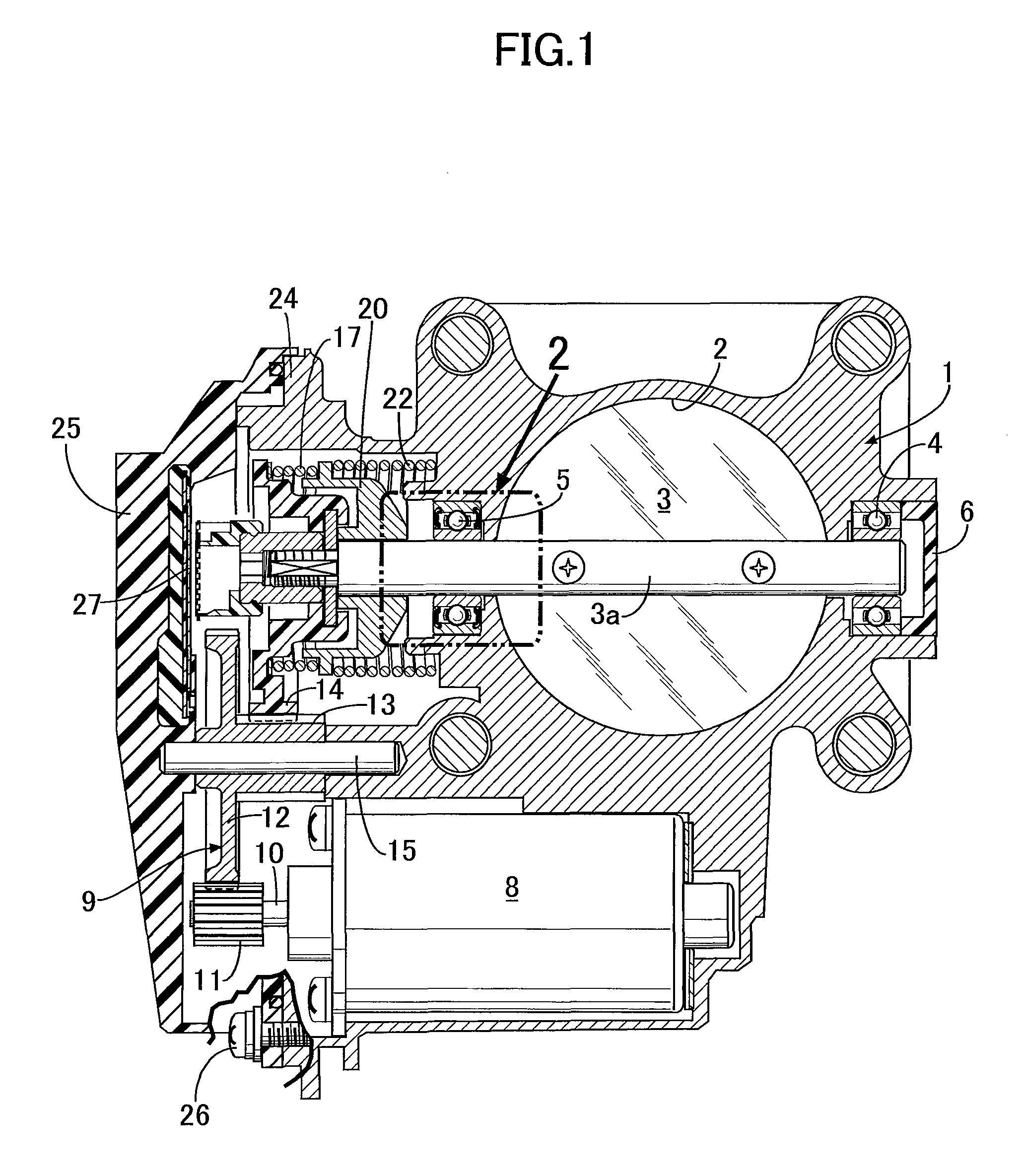

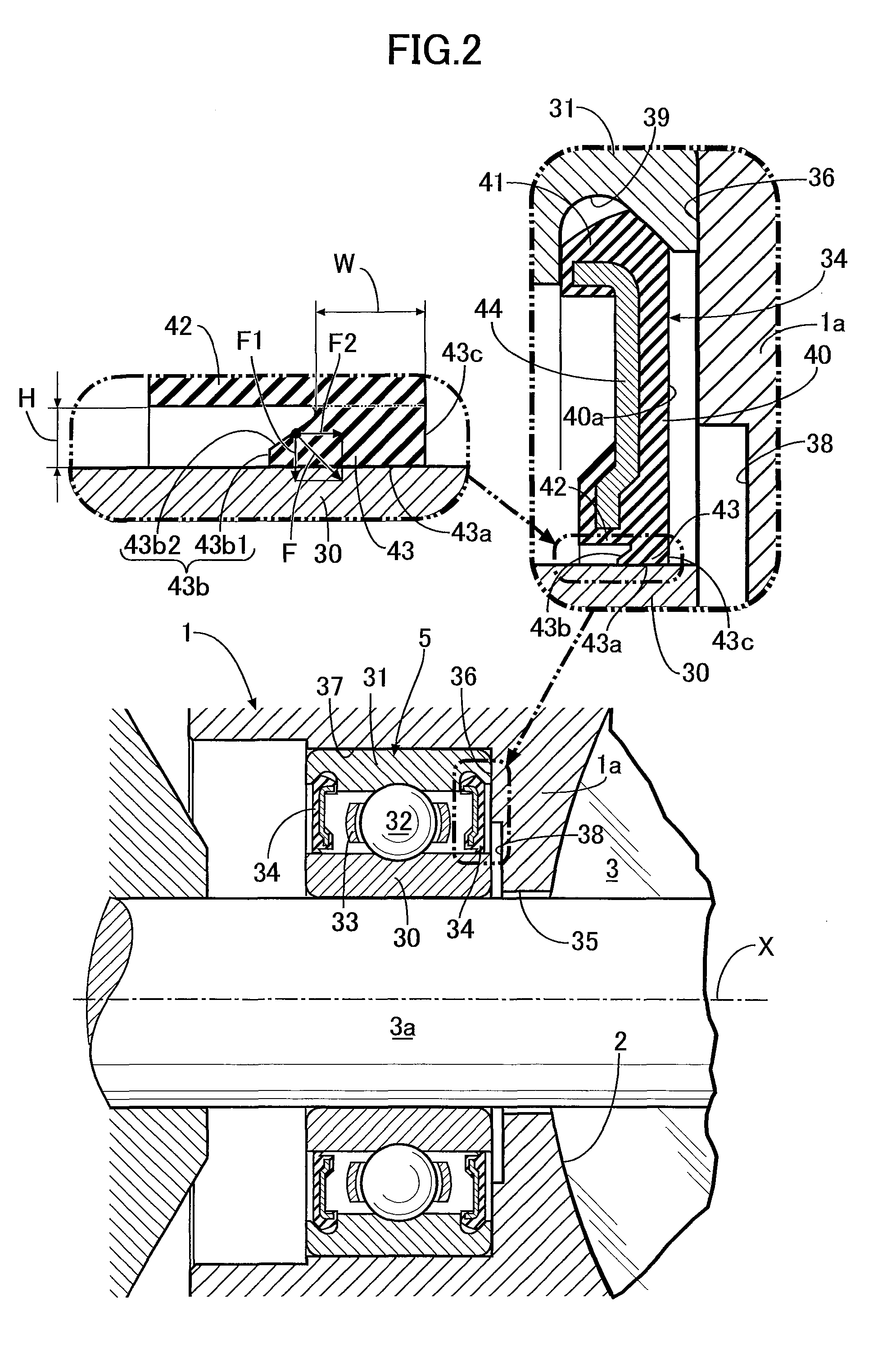

Vibration suppression structure for front-end module

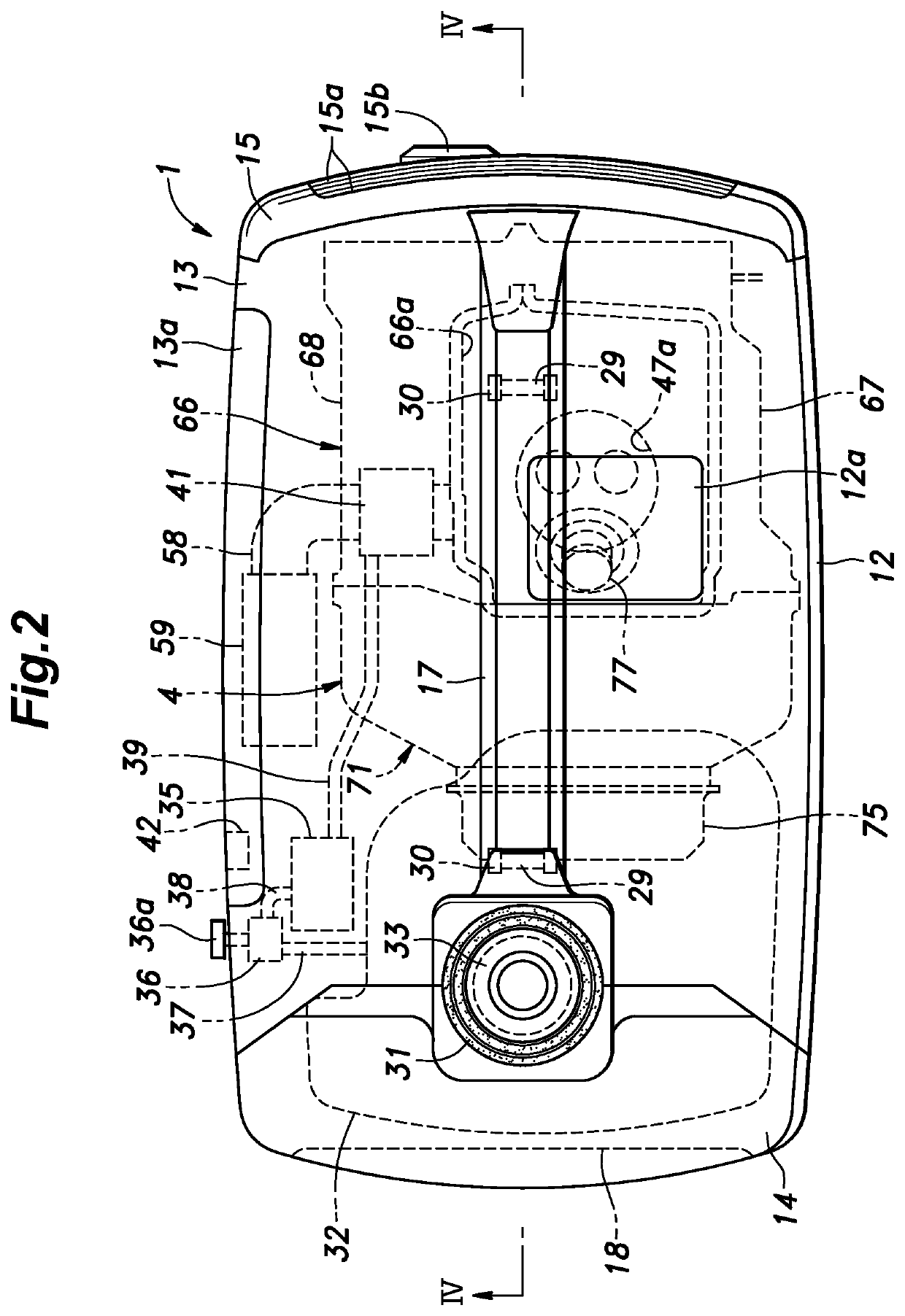

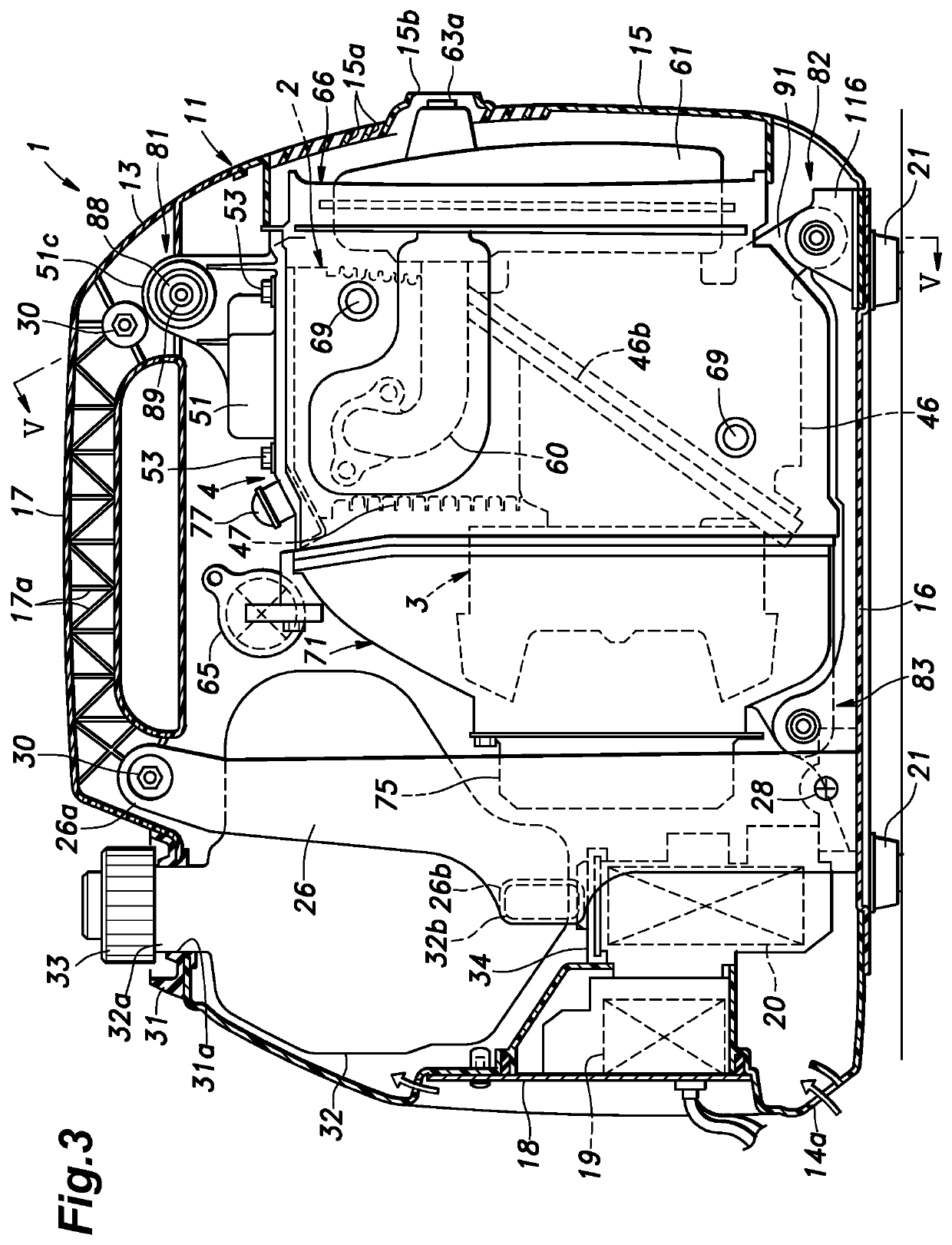

ActiveUS20150224869A1High constantSuppress pulsationPump componentsNon-rotating vibration suppressionIn vehicleComputer module

A front-end module (FEM) having in-vehicle parts incorporated in a vehicle front section are aggregated and assembled to a heat exchanger support frame, the plurality of in-vehicle parts are classified into first in-vehicle parts, which vibrate at frequencies in a first frequency band, and a second in-vehicle part, which vibrates at a frequency in a second frequency band having a frequency range higher than the frequency range in the first frequency band. The first in-vehicle parts are elastically supported by the heat exchanger support frame via first mount members. The second in-vehicle part is rigidly fixed to the heat exchanger support frame. The heat exchanger support frame is elastically supported by a vehicle body via second mount members.

Owner:NISSAN MOTOR CO LTD

Vibration suppression structure for front-end module

ActiveUS9150095B2Low costReduce the numberPump componentsNon-rotating vibration suppressionIn vehicleComputer module

A front-end module (FEM) having in-vehicle parts incorporated in a vehicle front section are aggregated and assembled to a heat exchanger support frame, the plurality of in-vehicle parts are classified into first in-vehicle parts, which vibrate at frequencies in a first frequency band, and a second in-vehicle part, which vibrates at a frequency in a second frequency band having a frequency range higher than the frequency range in the first frequency band. The first in-vehicle parts are elastically supported by the heat exchanger support frame via first mount members. The second in-vehicle part is rigidly fixed to the heat exchanger support frame. The heat exchanger support frame is elastically supported by a vehicle body via second mount members.

Owner:NISSAN MOTOR CO LTD

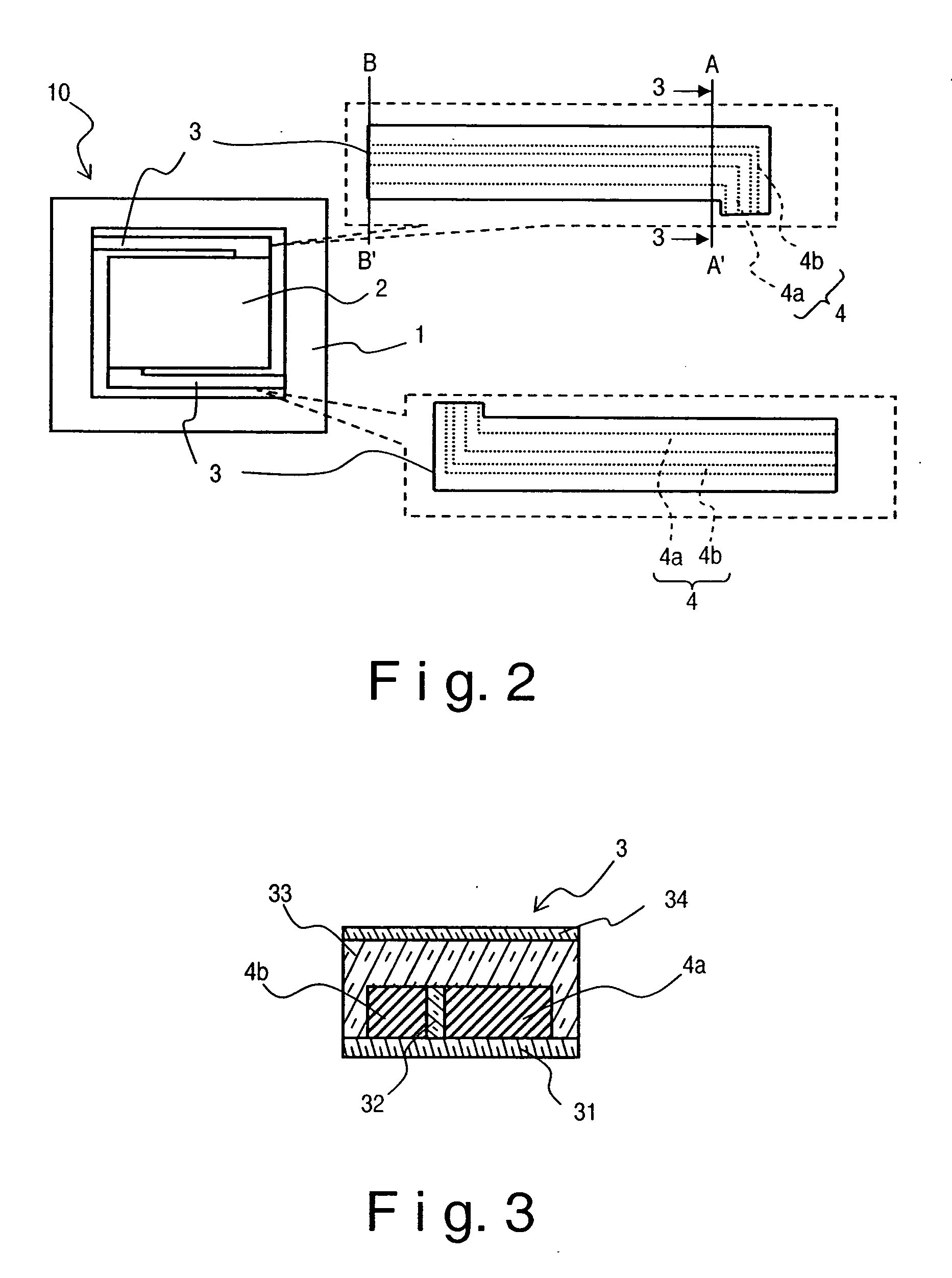

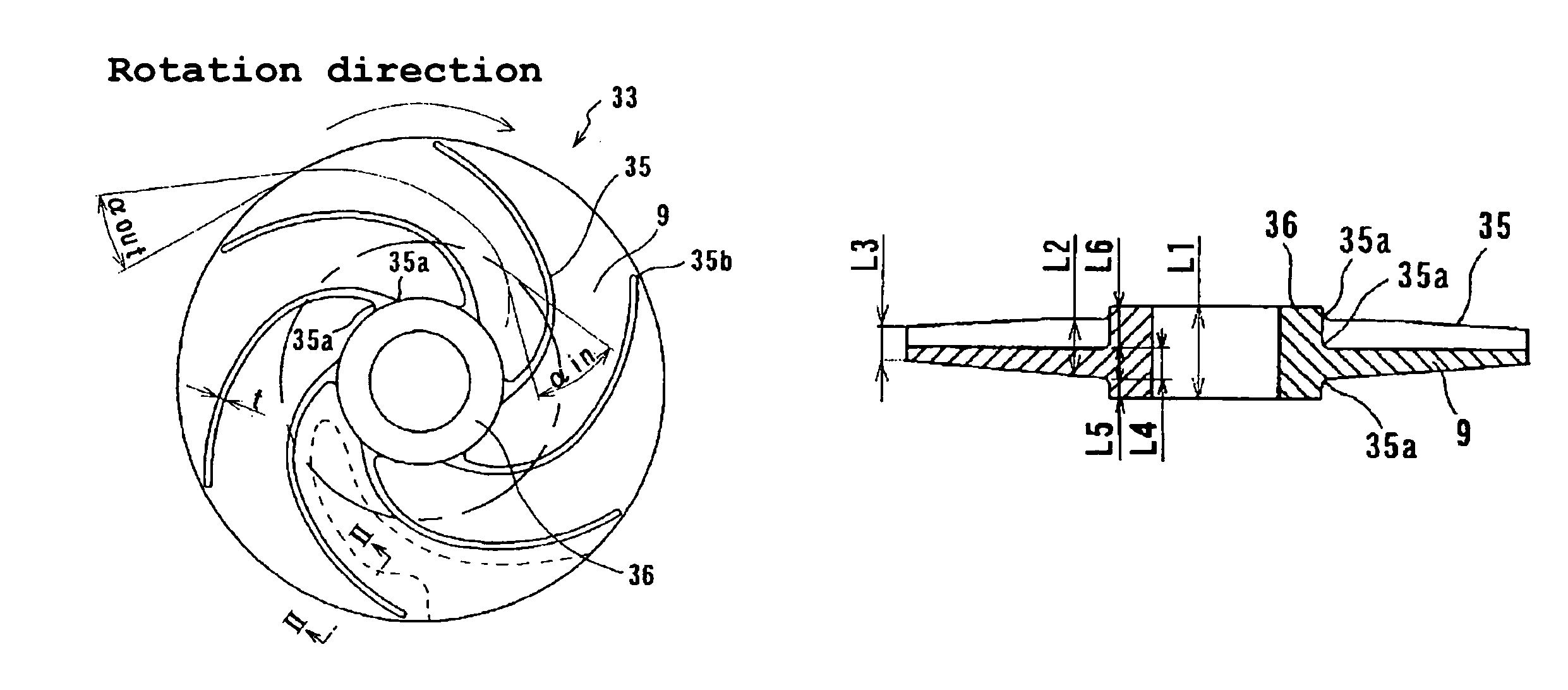

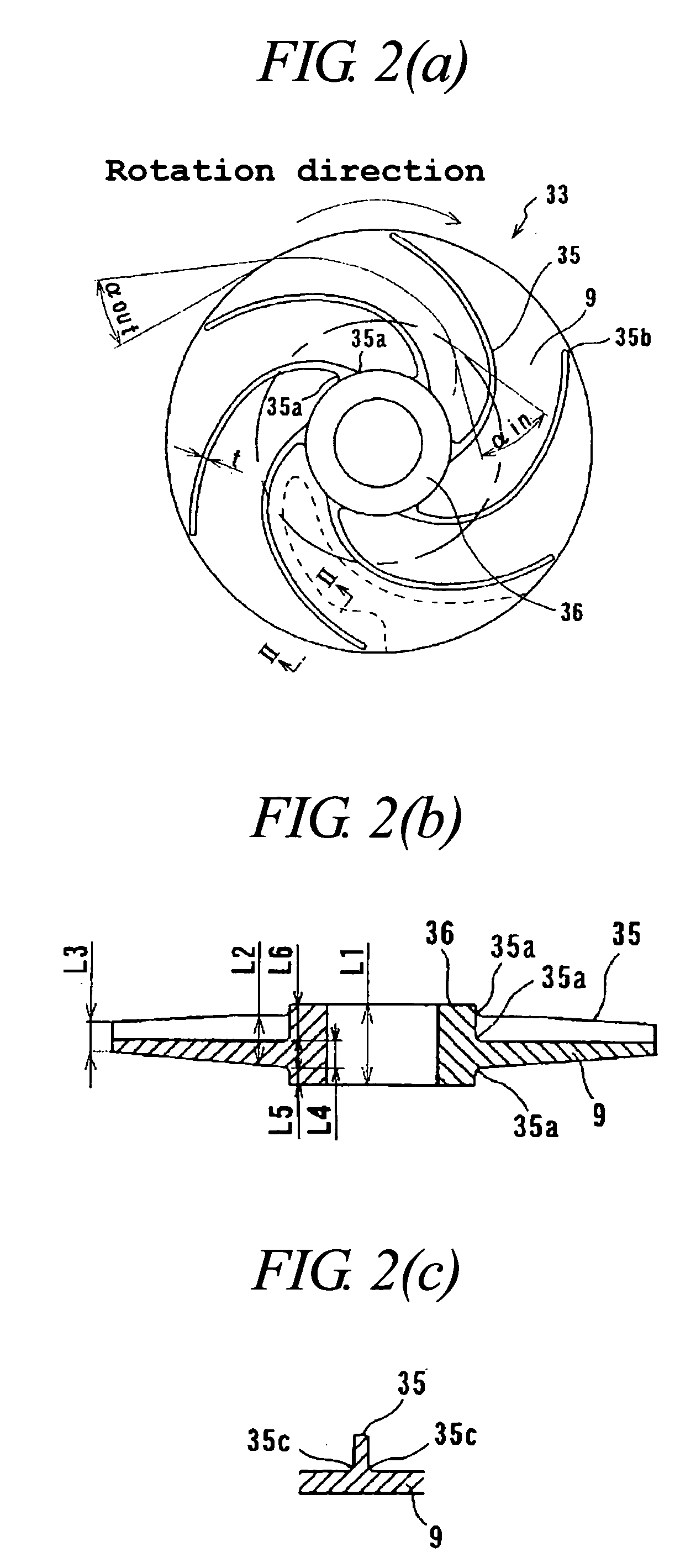

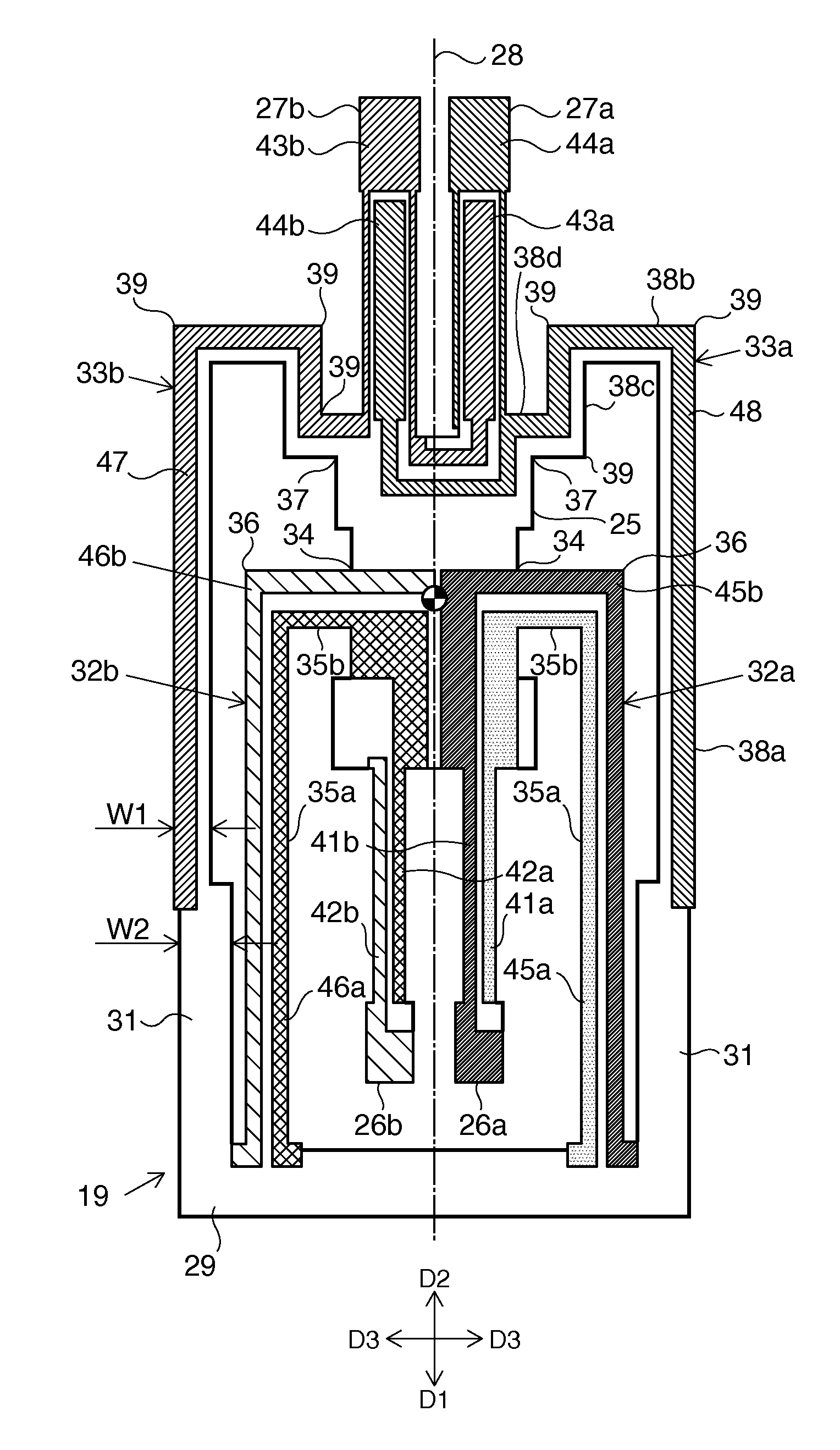

Vacuum pump and semiconductor manufacturing apparatus

InactiveUS7645126B2Reduce rigiditySmooth rotationPump componentsBlade accessoriesOil freeEngineering

To provide a vacuum pump capable of evacuating in pressure ranges from an atmospheric pressure to a high vacuum, capable of rotating at a high speed to be downsized and improved in pumping performance, and capable of producing a completely oil-free vacuum.A vacuum pump for exhausting a gas comprises: a main shaft 5 rotatably supported by a bearing 22; a motor 23 for driving the main shaft 5 for rotation; a first exhaust section 10 having a first rotary vane 13 attached to the main shaft 5, a first fixed vane 14 fixed in a first casing 12, and an intake port 11; and a second exhaust section 30 having a second rotary vane 33 attached to the main shaft 5, a second fixed vane 34 fixed in a second casing 32, and an exhaust port 31. The intake port 11 is located in the vicinity of an end of the main shaft 5, and the first exhaust section 10, the bearing 22 and the second exhaust section 30 are arranged in this order axially along the main shaft 5.

Owner:EBARA CORP

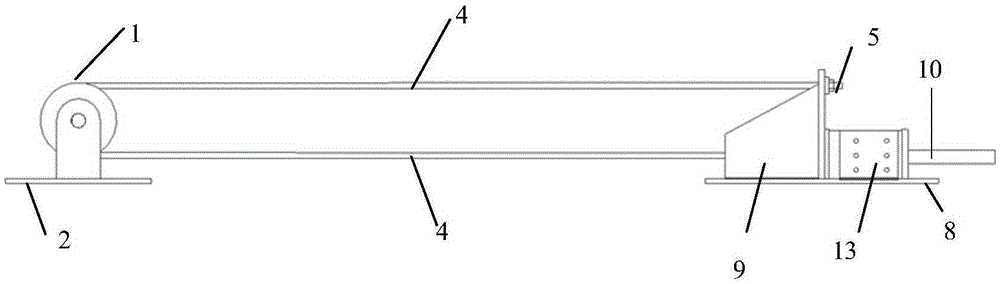

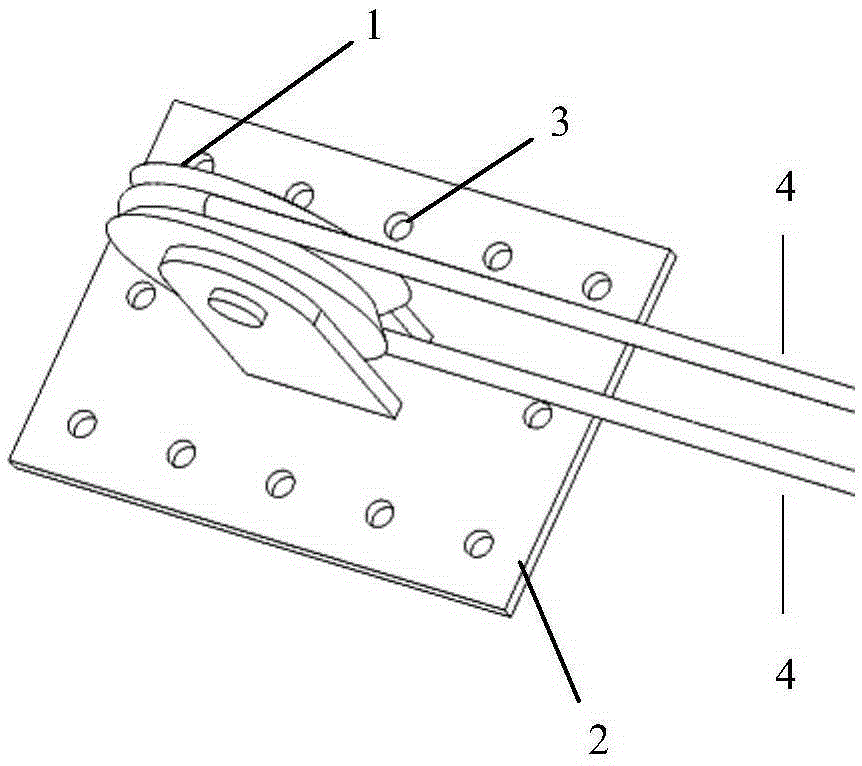

Self-resetting energy consumption inhaul cable support

ActiveCN105421608AReduced elastic elongation requirementsBroaden your optionsShock proofingWork performanceEngineering

The invention discloses a self-resetting energy consumption inhaul cable support which comprises a pulley, a pulley base, a prestress reset rib, an anchorage device, a limiting plate, a sliding frame, a bottom plate, a high-strength steel cable, a friction plate, a steel base plate and a connecting plate. The pulley is fixed to the pulley base. The pulley base is fixed to a main structure through a bolt. One end of the prestress reset rib is anchored to the limiting plate through the anchorage device. The other end of the prestress reset rib winds around the pulley, and builds prestress through a post-tensioning method to be connected with the sliding frame. The self-resetting energy consumption inhaul cable support has the advantages that the resetting capability of the support is enhanced exponentially, or the selection range of the reset rib material is widened exponentially, the structure complexity degree of the support is simplified, and the working performance of the support is ensured; 2, the cross section of the support is reduced, and therefore the earthquake effect is effectively reduced; 3, the yield stiffness designability is provided for the support.

Owner:NANJING UNIV OF TECH

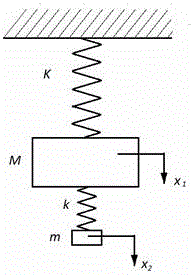

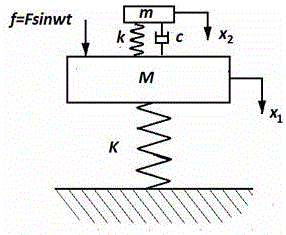

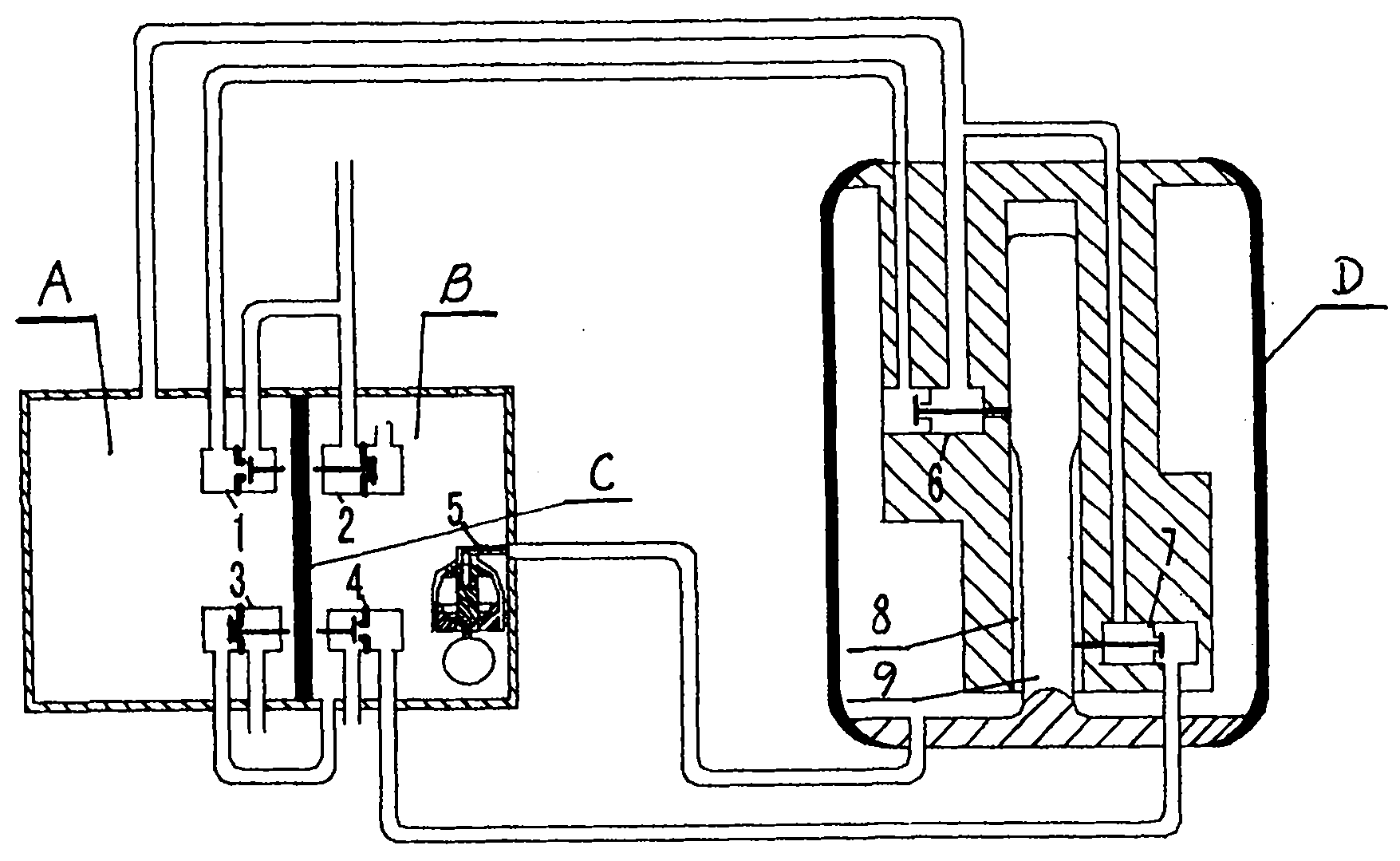

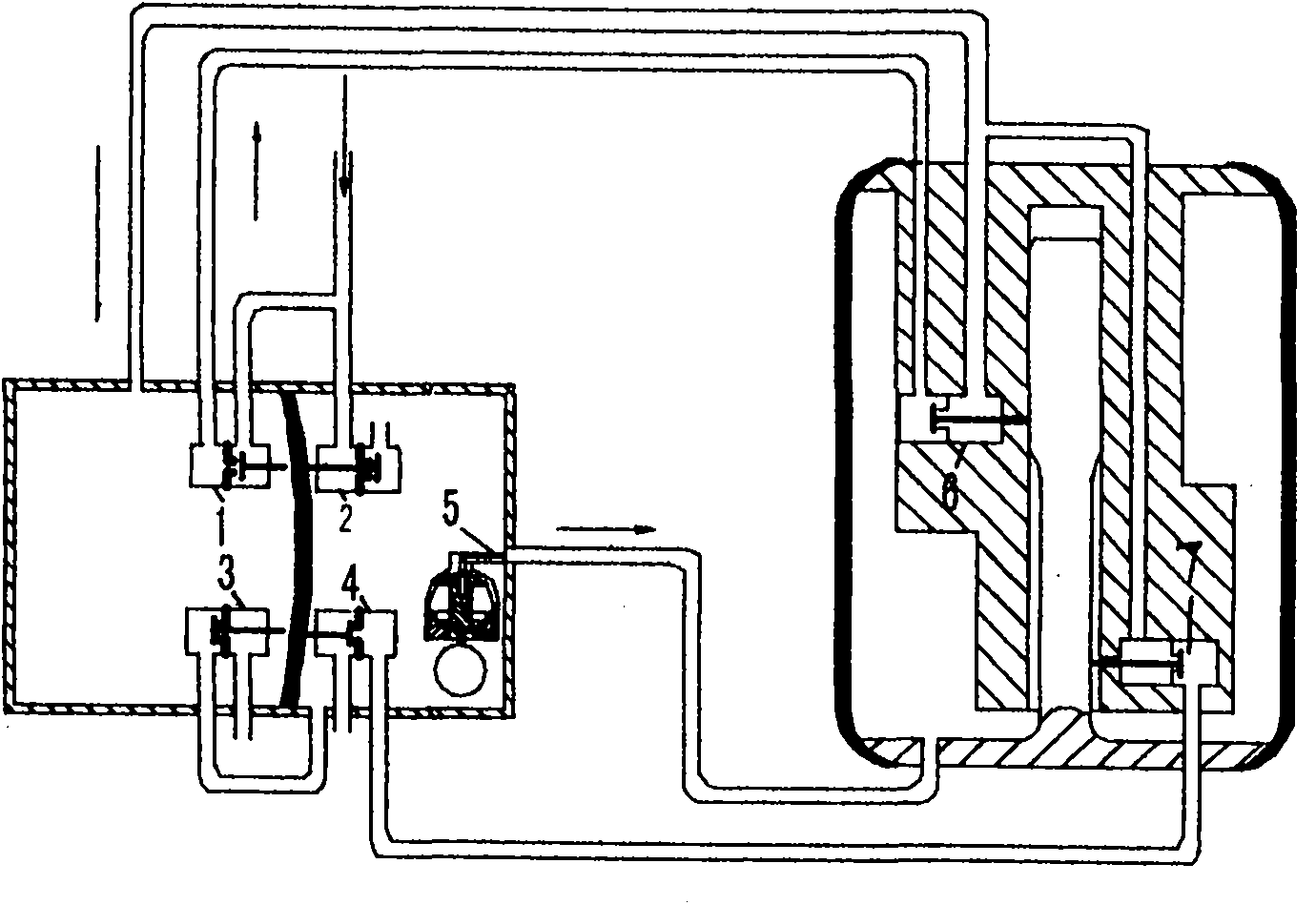

Mechanical vehicle active suspension system

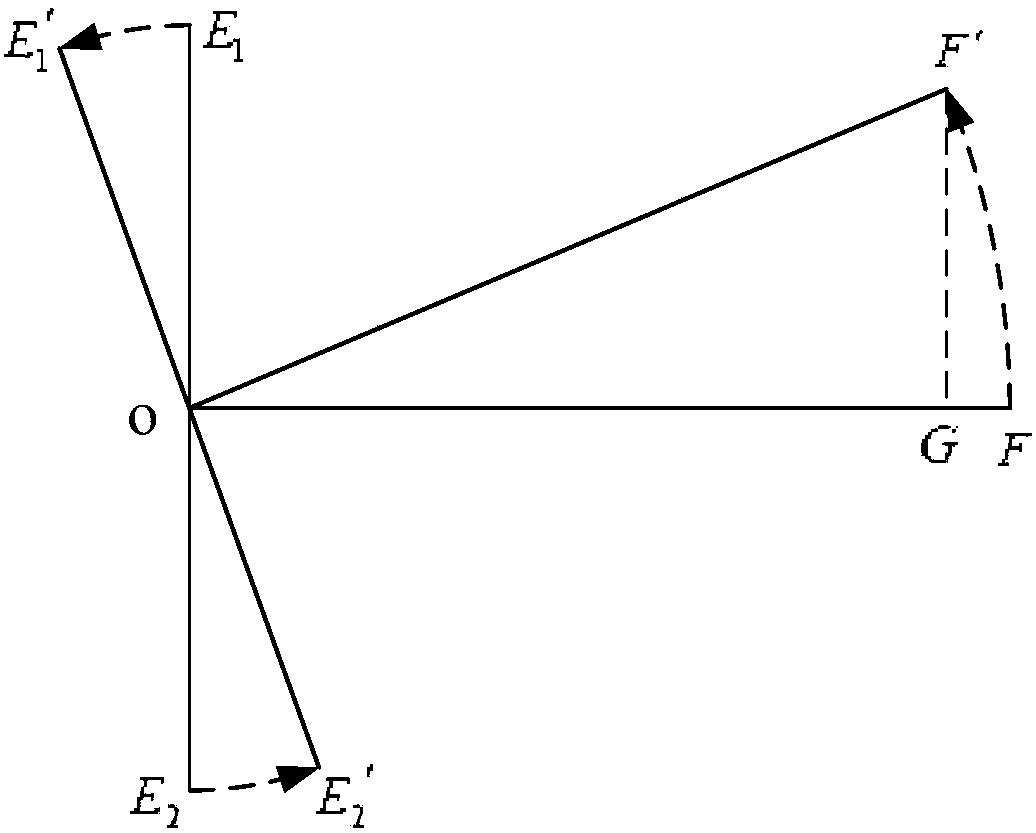

ActiveCN102092260AReduce support stiffnessReduce stiffnessResilient suspensionsControl systemControl signal

The invention discloses a mechanical vehicle active suspension device, which overcomes the defects that a device adopting an electronic technology has a control system costing 3,000 dollars and the maintenance cost is high in the prior art. The device is characterized in that: a diaphragm (C) is arranged between a reference chamber (A) and an air spring auxiliary chamber (B) with an inertia switch (5) through a pipeline; and the reference chamber (A), the air spring auxiliary chamber (B) and an air spring main chamber (D) are connected through a pipeline. The mechanical vehicle active suspension device has the advantages that: the diaphragm (C) takes pressure difference of the two chambers as a control signal and driving power to automatically adjust the suspension rigidity in a mechanical mode; the inertia switch (5) can instantaneously change the suspension rigidity, cut off a control switch and solve the contradiction of operability and comfortableness; a hole on a ball (16) realizes the cut-off function in any direction; the pipeline connection is skillful, complicated and unique, so that the functions are realized and are not interfered mutually; a complicated process does not exist, the device is easy to promote and apply, and great reformation of the vehicle suspension device is provided; and the device is used for vehicle suspension.

Owner:AVIC GUIZHOU AIRPLANE

Vibrating element, gyro sensor, electronic apparatus and moving object

ActiveUS20130291638A1Improve detection accuracyIncrease relative motionAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesCantileverMechanical engineering

Owner:SEIKO EPSON CORP

Friction-roller type transmission mechanism

InactiveUS20100292045A1Reduce support stiffnessSolution to short lifePortable liftingBearing componentsTorque transmissionEngineering

Under control of rotation of a crankshaft 41, a friction roller 32 is pressed against a friction roller 31 in a radial direction, so as to achieve torque transmission between the rollers 31, 32. An inter-roller radial pressing reaction is canceled as an internal force in bearing supports 23, 25, with no input to a housing 11. The reaction causes a radial displacement of a bearing-fitting portion provided with inner and outer bearings 21, 42 in double layer arrangement, wherein the radial displacement is larger than that of a bearing-fitting portion provided with a bearing 18, 19, 22 in single arrangement, so as to cause unbalanced contact between rollers 31, 32. In order to prevent this, support stiffness of bearing support 23 against the inter-friction-roller radial pressing reaction is set higher than that of bearing support 25.

Owner:NISSAN MOTOR CO LTD

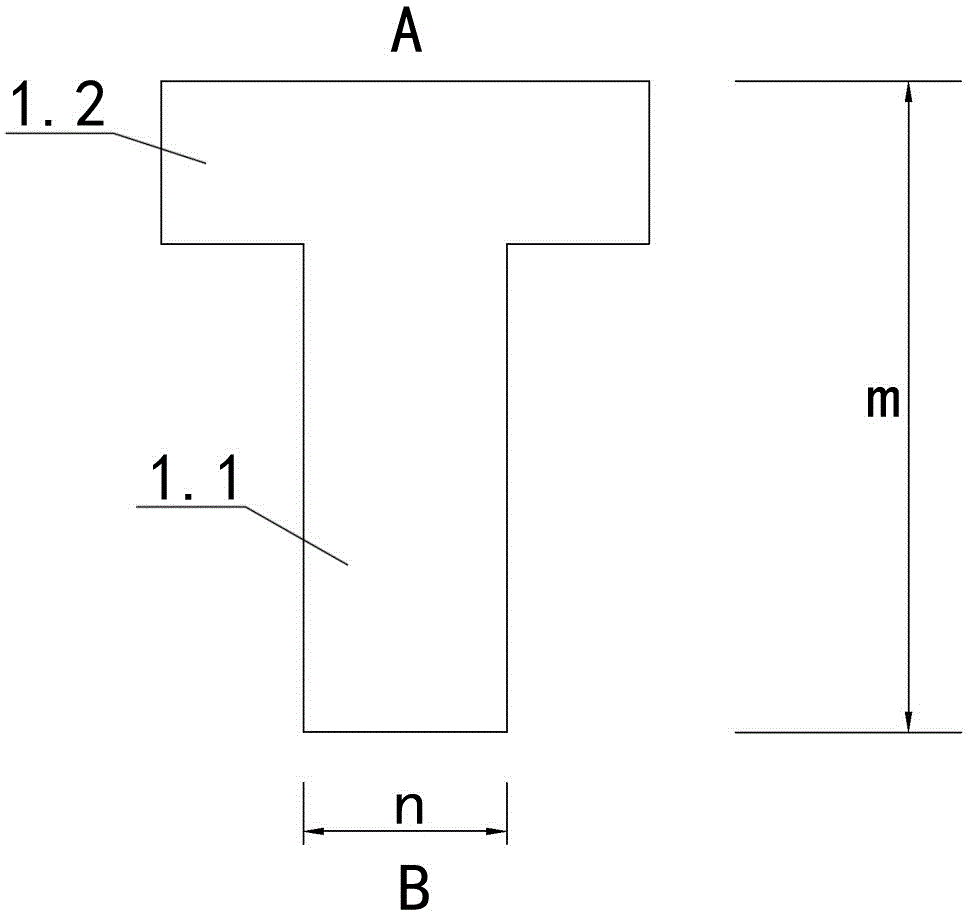

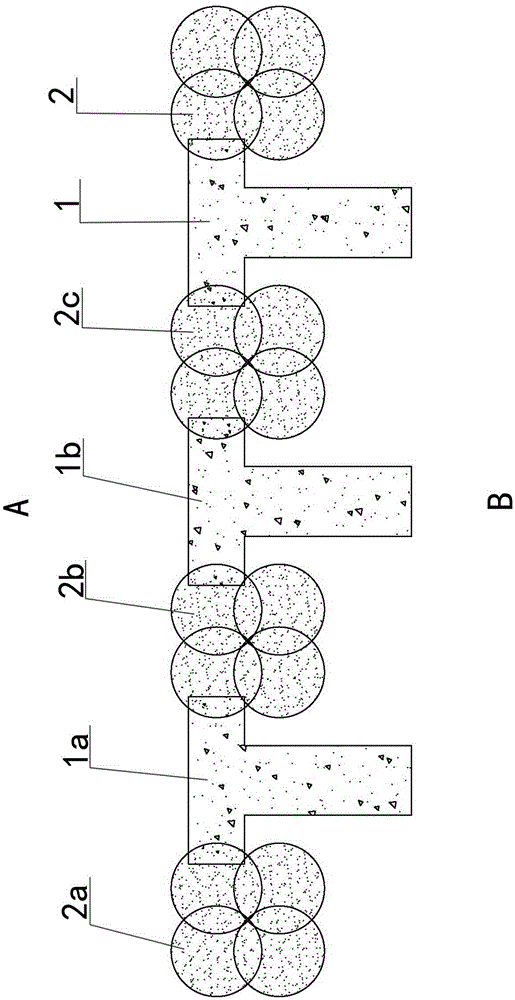

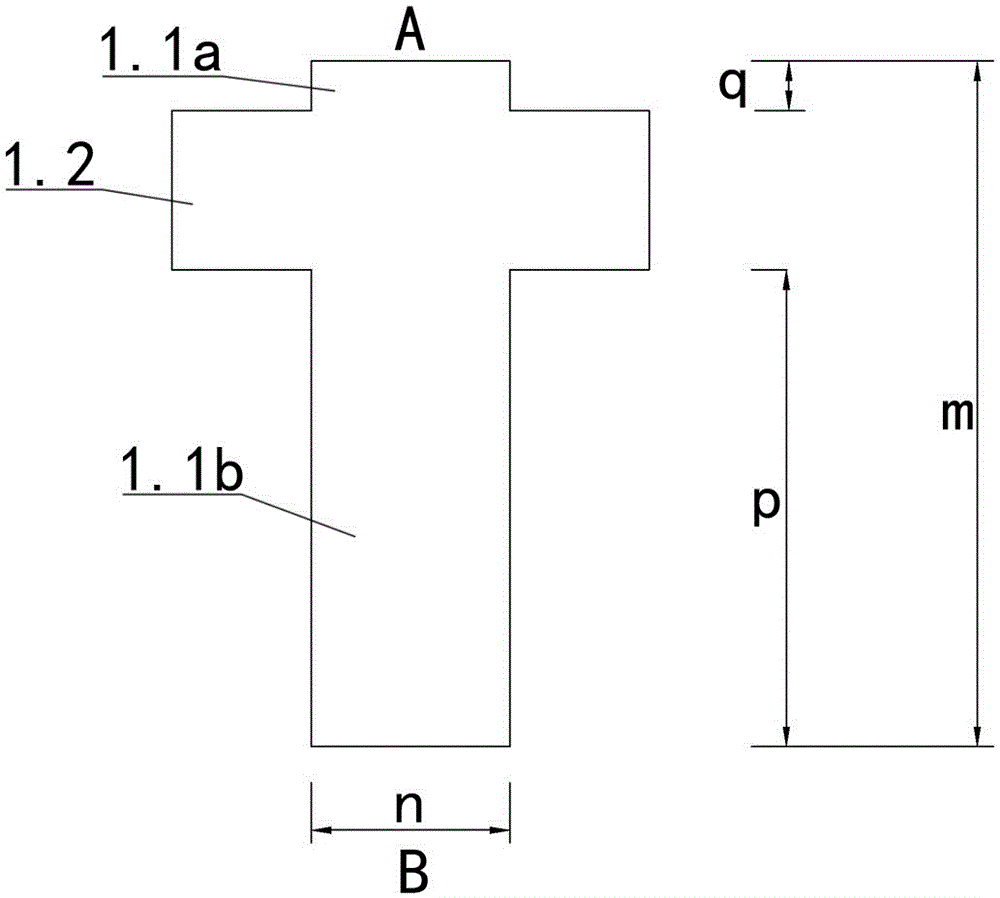

Closed enclosure system comprising supporting piles with specially-shaped sections and construction method thereof

InactiveCN105133622AOverall high bending stiffnessIncreased bending stiffnessExcavationsSlurry wallSupporting system

The invention discloses a closed enclosure system comprising supporting piles with specially-shaped sections and a construction method thereof. According to the system, a water-soil pressure is born by cast-in-place piles with cross-shaped or T-shaped sections, a space among the supporting piles with the cross-shaped or T-shaped sections is closed by cement-soil piles, and bearing and water stopping are integrated; the cast-in-place piles with the cross-shaped or T-shaped sections and high flexural rigidities are used as the supporting piles, and compared with the traditional supporting piles with circular sections, the overall rigidity of a supporting system can be remarkably increased, the displacement of a foundation pit can be reduced, and the engineering cost can be decreased; the space among the supporting piles is closed by the cement-soil piles, and a closed water-stopping curtain does not need to be additionally arranged, so that the engineering cost can be remarkably decreased; in the enclosure system, the piles with the cross-shaped sections or the piles with the T-shaped sections are engaged with the cement-soil piles at flanges, and compared with the engagement between the existing cast-in-place piles with circular sections and cement-soil piles, each lap-joint part has a long rounded flowing path and a good water-stopping effect; and the enclosure system disclosed by the invention is capable of obtaining a supporting effect which is similar to the supporting effect of an underground diaphragm wall enclosure structure, and low in construction difficulty and engineering cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Draft-sleeping structure of tank car without central beam

The invention provides a draft-sleeping structure of a tank car without a central beam. The draft-sleeping structure of the tank car without the central beam comprises a sleeper beam and a draft beam, wherein the sleeper beam is symmetrically arranged at two sides of the draft beam, the sleeper beam comprises a sleeper beam lower side cover plate, a sleeper beam rib plate and a sleeper beam web, the sleeper beam web is arranged on the sleeper beam lower side cover plate, the draft beam comprises a draft beam web and a draft beam lower wing surface perpendicular to the draft beam web, the sleeper beam rib plate is arranged on a longitudinal rib plate, close to a bending area of the draft beam, of the sleeper beam, reinforcing parts are arranged between the sleeper beam web and the draft beam web, and each reinforcing part is a cambered surface reinforcing part. According to the draft-sleeping structure of the tank car without the central beam, circular arc connection pieces are adopted at weld joints, and the problems of high stress and poor anti-fatigue performance of the vertical weld joints are resolved.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Rolling bearing with seal

A seal lip having: a cylindrical seal surface in close contact with an outer peripheral surface of an inner race with outer side and inner side surfaces standing upright respectively from an outer end and an inner end of the seal surface and reaching a lip supporting portion of a seal member, and protruding on an inner peripheral surface of the lip supporting portion. The outer side surface is a perpendicular surface standing upright from the outer end of the seal surface in a direction perpendicular to a generating line of the outer peripheral surface of the inner race. The inner side surface includes: a perpendicular surface standing upright from the inner end of the seal surface in parallel with the outer side surface; and a conical surface inclined toward the outer side surface extending outward in a radial direction from an outer peripheral end of the perpendicular surface.

Owner:HITACHI ASTEMO LTD +1

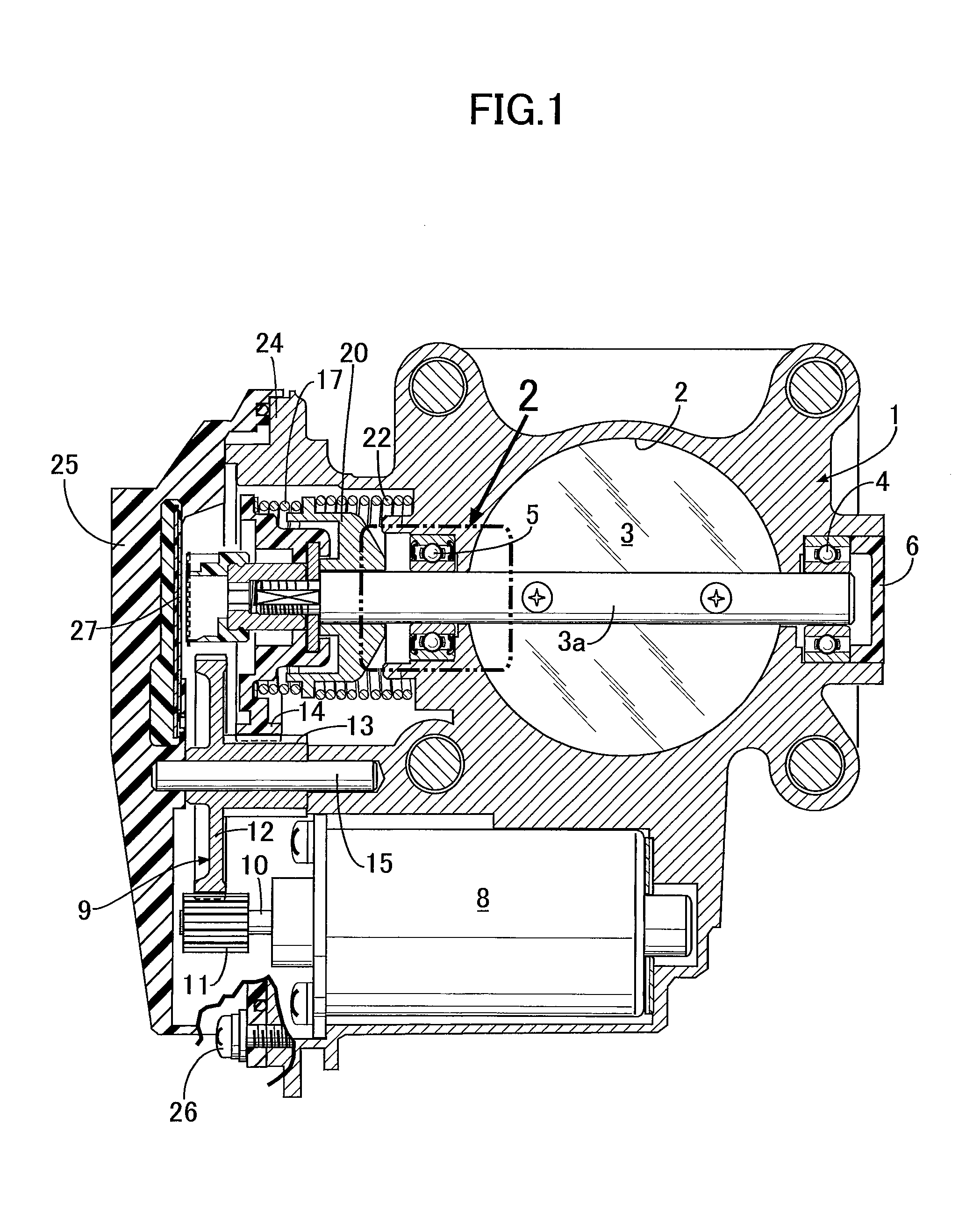

Engine device

ActiveUS20200309062A1Increase internal spaceReduce support stiffnessCasingsExhaust apparatusPhysicsMechanical engineering

Provided is an engine device that can enlarge a space inside a case without lowering support stiffness. An engine (2) is attached to a case (11) via support parts (81, 82). A rear lower portion support part (82), which is one of the support parts, includes an attachment rib (11b) as a mounting part provided in the case (11) and an attachment bracket (91) fastened to a bottom of a crankcase (46) by a fastening bolt (90) and attached to the attachment rib (11b). The fastening bolt (90) penetrates through a through hole (92a) provided in the attachment bracket (91) and is screwed into a screw hole (46e) formed obliquely inward at a corner of the bottom of the crankcase (46).

Owner:HONDA MOTOR CO LTD

Rolling bearing with seal

ActiveUS20130279839A1Improve sealing functionSimple structureEngine sealsShaftsEngineeringClose contact

A seal lip having: a cylindrical seal surface in close contact with an outer peripheral surface of an inner race with outer side and inner side surfaces standing upright respectively from an outer end and an inner end of the seal surface and reaching a lip supporting portion of a seal member, and protruding on an inner peripheral surface of the lip supporting portion. The outer side surface is a perpendicular surface standing upright from the outer end of the seal surface in a direction perpendicular to a generating line of the outer peripheral surface of the inner race. The inner side surface includes: a perpendicular surface standing upright from the inner end of the seal surface in parallel with the outer side surface; and a conical surface inclined toward the outer side surface extending outward in a radial direction from an outer peripheral end of the perpendicular surface.

Owner:HITACHI ASTEMO LTD +1

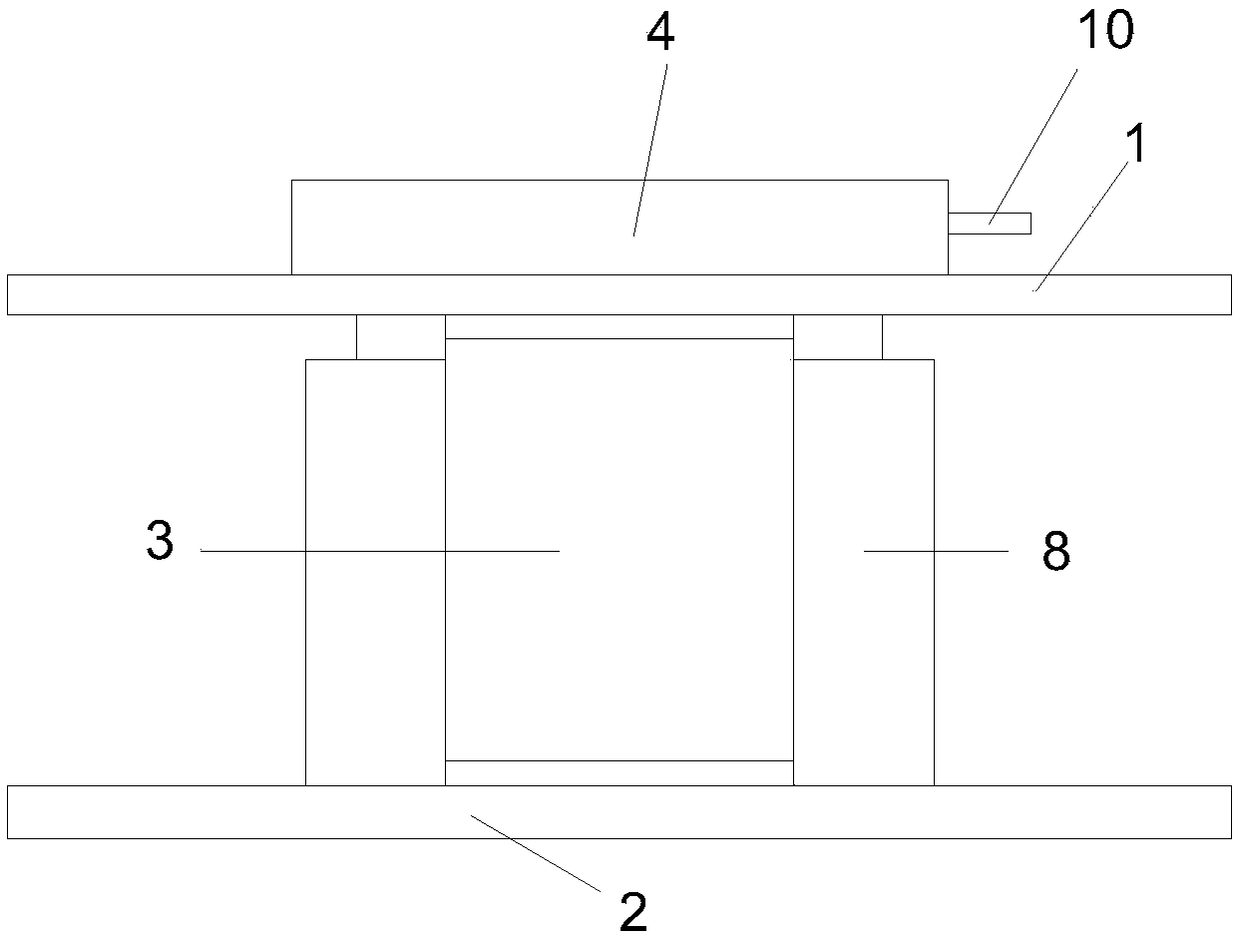

Track damping support

PendingCN109267436AReduce vertical vibration displacementLimit vertical displacementBallastwayElastic vibrationVertical displacement

The invention discloses a track vibration damping support device, which relates to the technical field of track vibration damping, comprising an upper connecting plate assembly, a lower connecting plate, an elastic vibration damping assembly and a damper, wherein the upper connecting plate assembly is used for supporting a track beam; the lower connecting plate is used for connecting with the bridge main body; the two ends of the elastic damping assembly in the vertical direction are respectively connected with the upper connecting plate assembly and the lower connecting plate, and the elasticdamping assembly can be elastically deformed at least in the vertical direction; at least one damper is arranged on both sides of the elastic damping assembly, the upper end of the damper is connected with the upper connecting plate assembly, the lower end of the damper is connected with the lower connecting plate, and the damper at least limits the vertical displacement between the upper connecting plate assembly and the lower connecting plate. The rail vibration damping support device has good vibration damping and noise reduction effect, and can reduce the vibration displacement of the rail, and ensure the stability and safety of the running of the rail vehicle.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com