Mechanical shafting rotary error active compensation device based on piezoelectric actuator

A piezoelectric actuator and rotational error technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, mechanical equipment, etc. problem, to achieve the effect of high displacement control accuracy, low power consumption and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

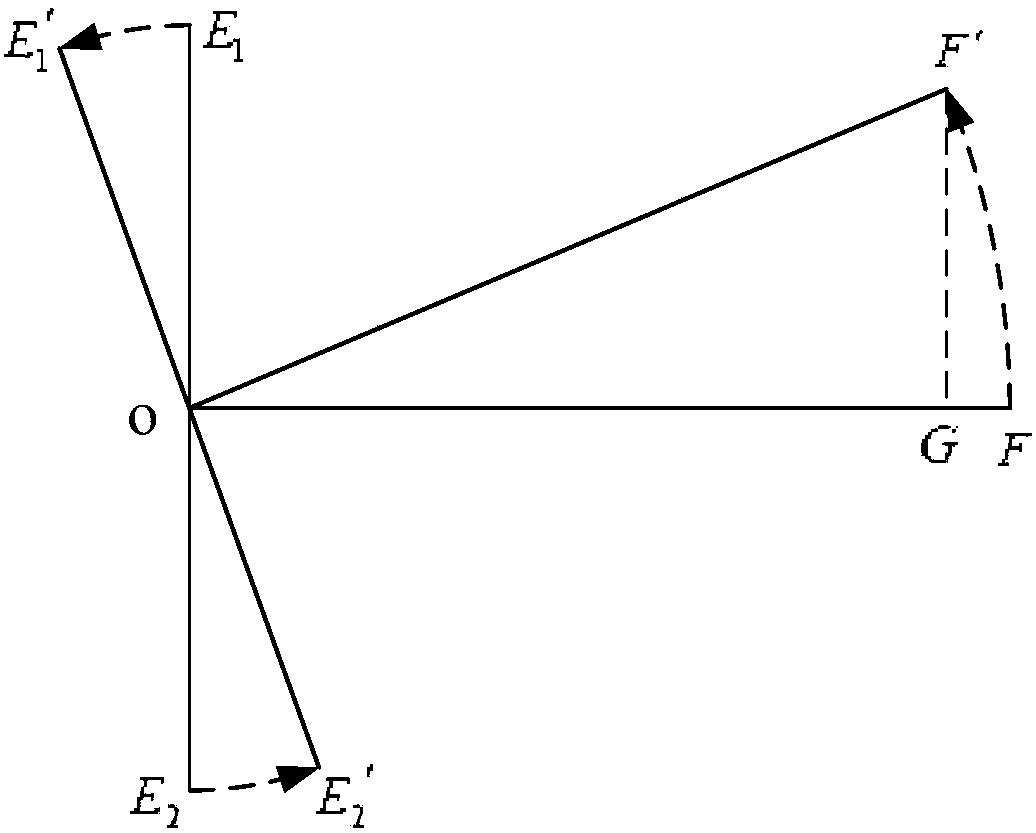

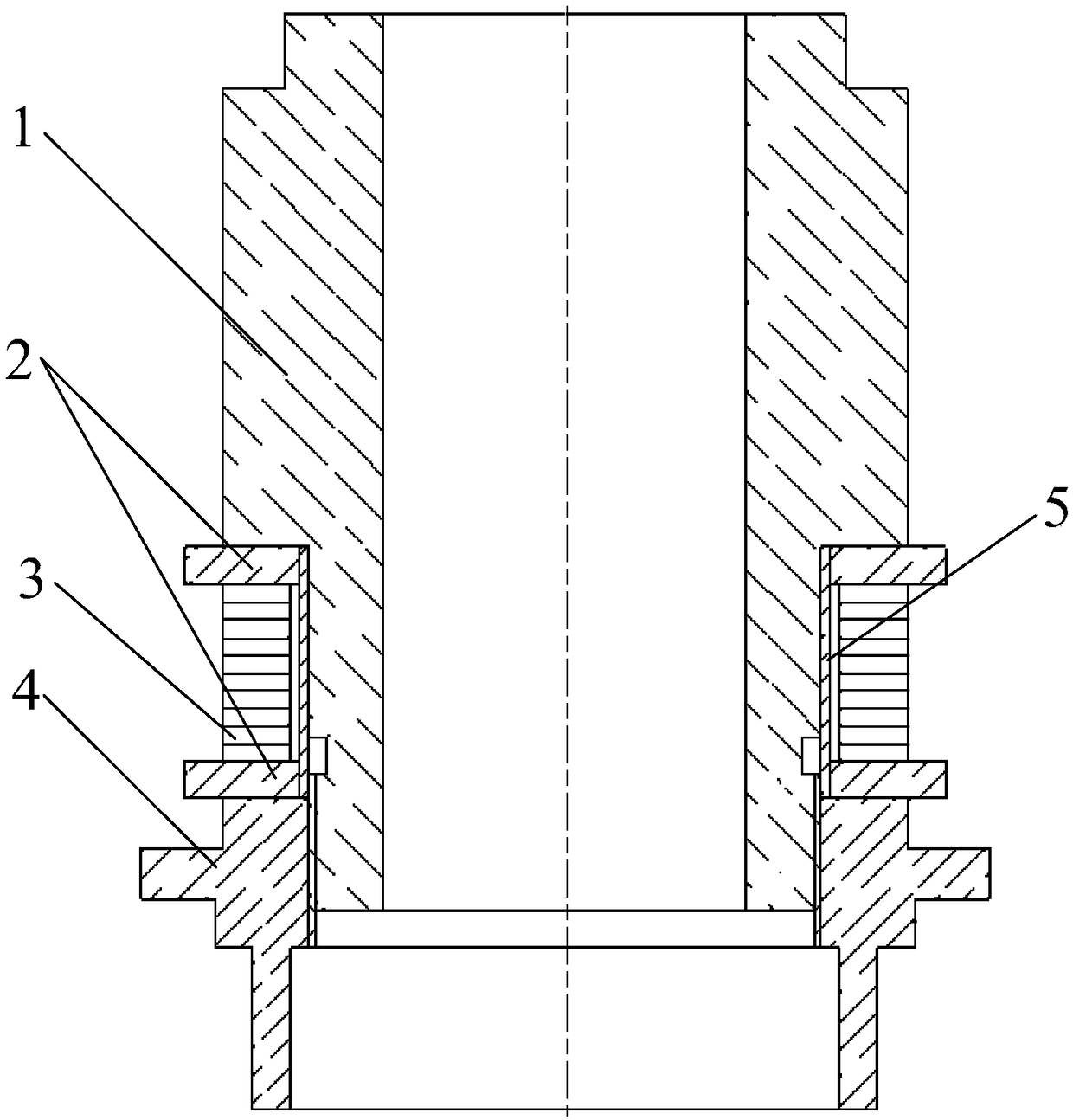

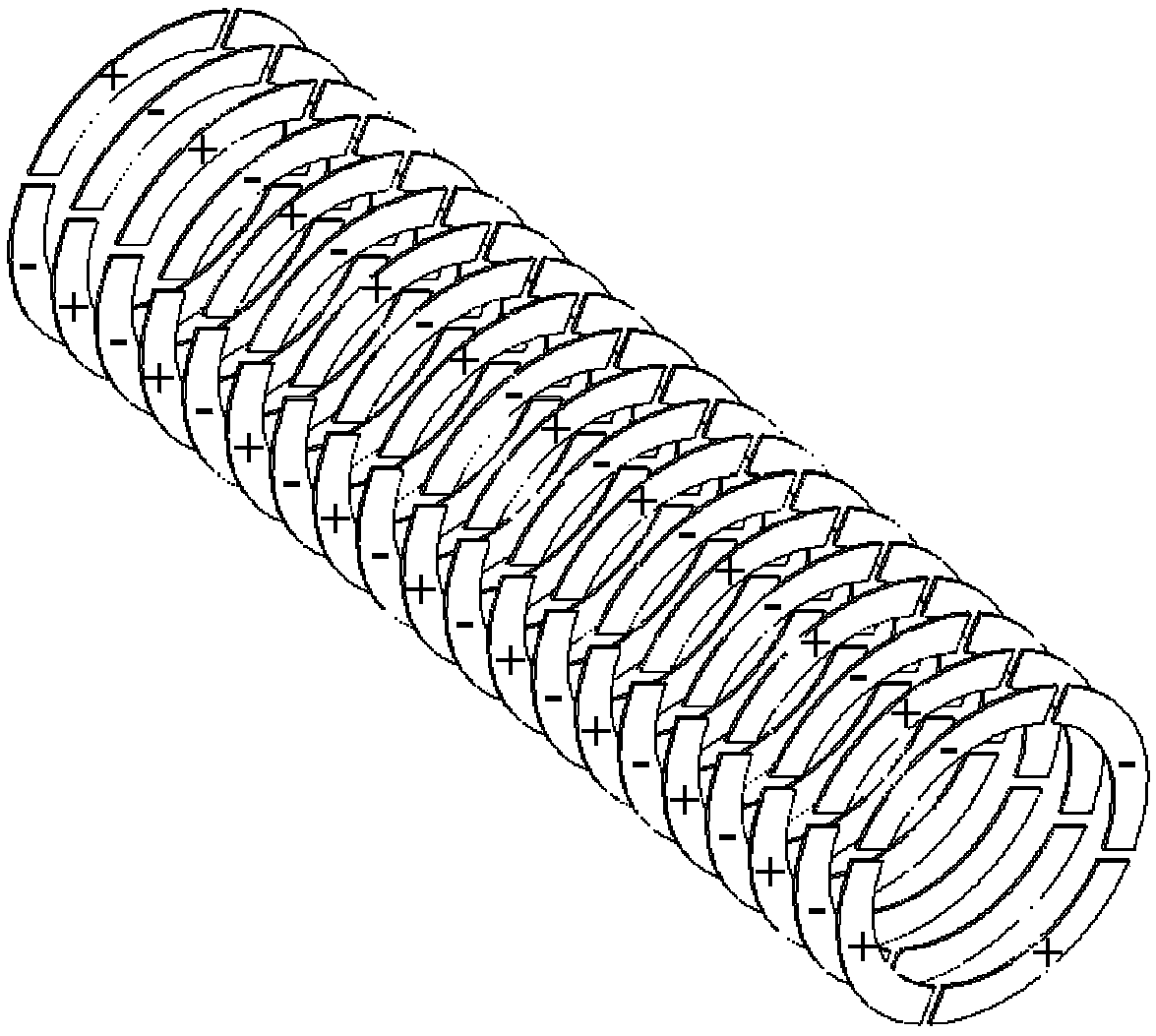

[0029] see figure 1 , 2 , 3, 4 and 6 illustrate this embodiment, the active compensation device for shaft rotation error includes: metal end cap 1, metal gasket 2, piezoelectric actuator 3, bottom support 4, insulating sleeve 5 and corresponding Drive circuit, displacement sensor 6 and controller;

[0030] Rotation error compensation is carried out for the rotating shaft 12 (the rotor 11 is installed on the rotating shaft 12). The shaft is supported by the angular contact ball bearing 9, and the driving force is provided by the motor. The rotor 11 is used as a single-ended load, and the bearing 9 is composed of the sleeve 8 and the upper end cover. 10. The retaining ring 14, the lower end cover 13, and the tightening nut 7 are fixed;

[0031] In particular, a mass block can be added in the radial plane of the rotor 11 to simulate the static unbalanced force;

[0032] The metal end cap 1 and the bottom support 4 are threaded to fix the piezoelectric actuator, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com