Track damping support

A vibration damping support and track technology, applied in the field of track vibration damping, can solve problems affecting the stability and safety of rail vehicles, can not meet the limit requirements of track displacement, and the vibration damping effect of damping fasteners is limited, etc., to achieve replaceable Strong performance, convenient engineering application, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

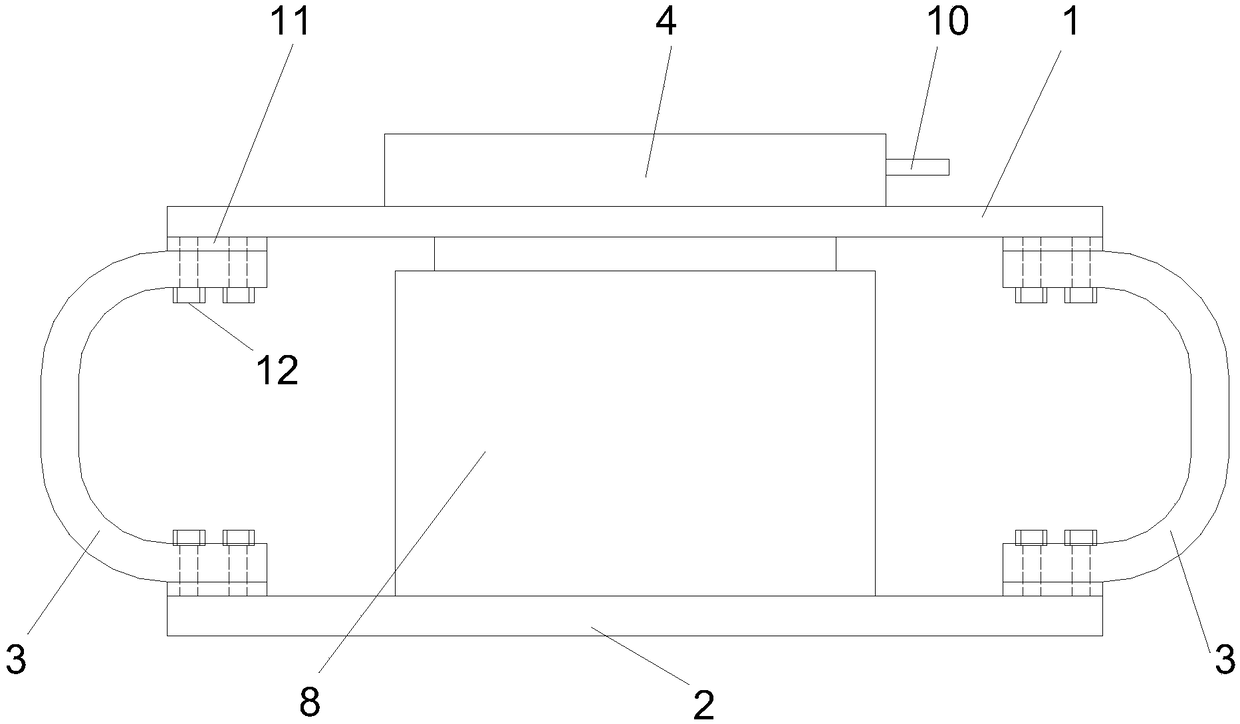

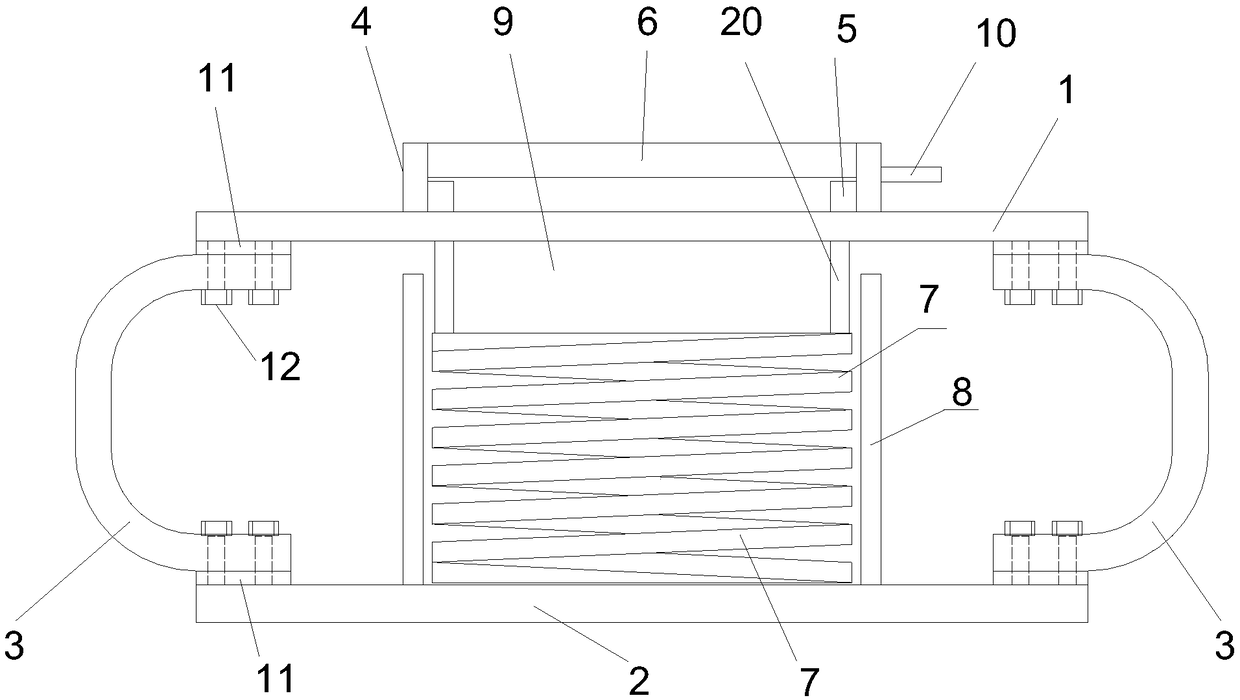

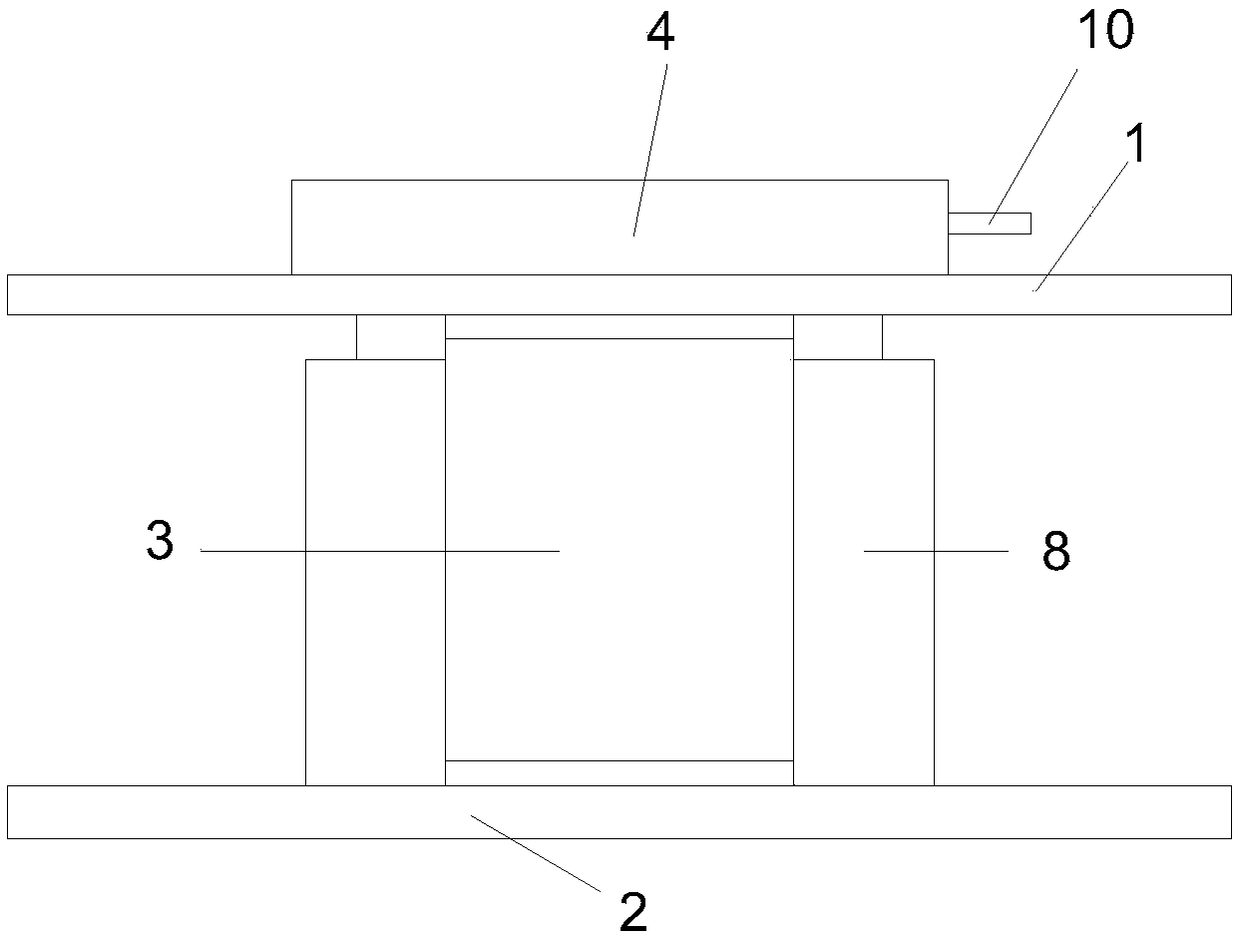

[0039] Such as Figure 1~4 , Figure 9-10 As shown, the present embodiment provides a track damping support device 100, comprising an upper connecting plate assembly, a lower connecting plate 2, an elastic damping assembly and a damper 3, the upper connecting plate assembly is used to support the track beam 300; the lower connecting plate 2 is used to connect with the bridge main body 400; the two ends of the elastic damping component in the vertical direction are respectively connected with the upper connecting plate component and the lower connecting plate 2, and the elastic damping component can be elastically deformed at least in the vertical direction to reduce the The vertical connection stiffness between the upper connecting plate assembly and the lower connecting plate 2; at least one damper 3 is respectively arranged on both sides of the elastic damping assembly, the upper end of the damper 3 is connected with the upper connecting plate assembly, and the lower end of ...

Embodiment 2

[0049] This embodiment provides a rail vibration-damping support device 100. The difference between the rail vibration-damping support device 100 provided in this embodiment and the rail vibration-damping support device 100 in Embodiment 1 is that:

[0050] Such as Figure 5-10 As shown, the elastic damping assembly includes a stacked damping body 13, a positioning piece 14 and a second anchor bolt 15, and the stacked damping body 13 includes a plurality of upper steel plates 16, a plurality of lower steel plates 17 and a plurality of rubber sheets 18, and the upper steel plate 16 and the lower steel plate 17 are alternately arranged at intervals, and an adjacent upper steel plate 16 and a lower steel plate 17 are connected by a rubber sheet 18. The upper steel plate 16, the lower steel plate 17 and the rubber sheet 18 are vulcanized and connected together. Both the upper steel plate 16 and the outermost lower steel plate 17 are connected with a positioning piece 14, the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com