Longitudinal connecting plate type ballastless track temperature force release device and method

A technology of slab-type ballastless track and release device, applied in the field of rail transit, can solve the problems that cannot be used to eliminate the risk of temperature deformation and instability of ballastless track, stress concentration of planting reinforcement holes, and degradation of anchoring effect, and achieves simple construction and little disturbance. , Good vertical displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the content, characteristics, and efficacy of the present invention, it is taken from the following examples and will be described in detail with reference to the following:

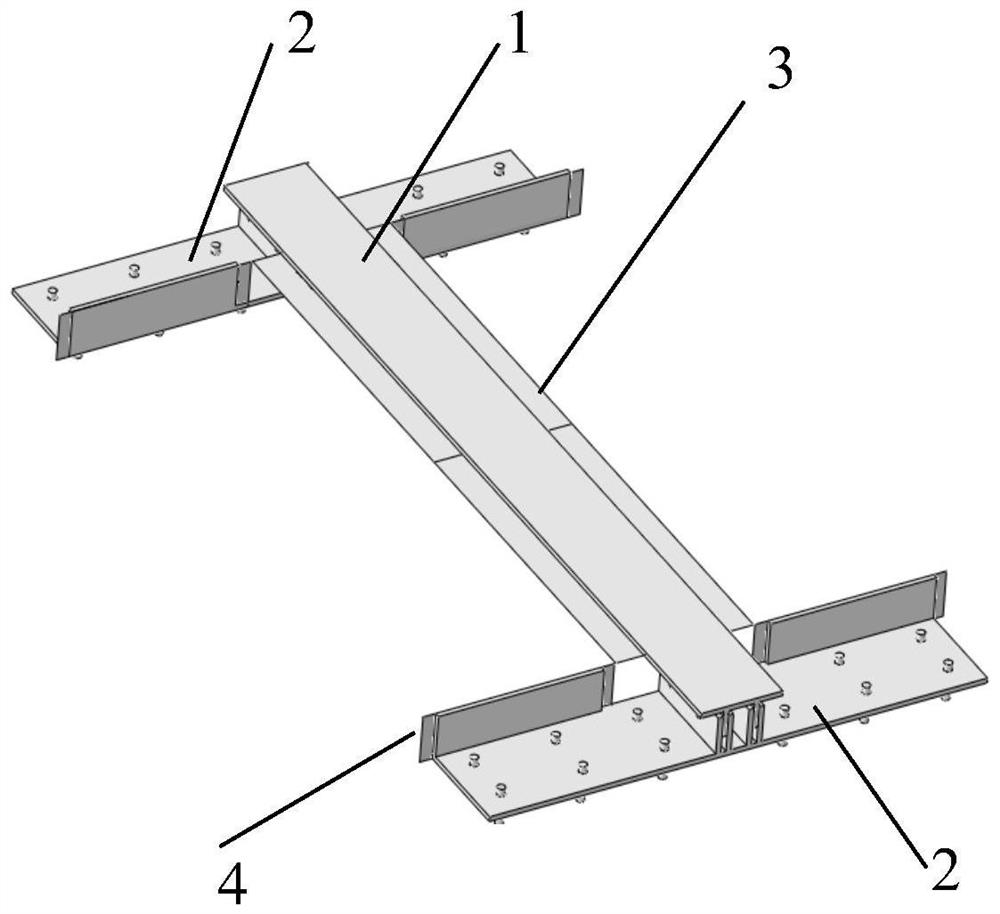

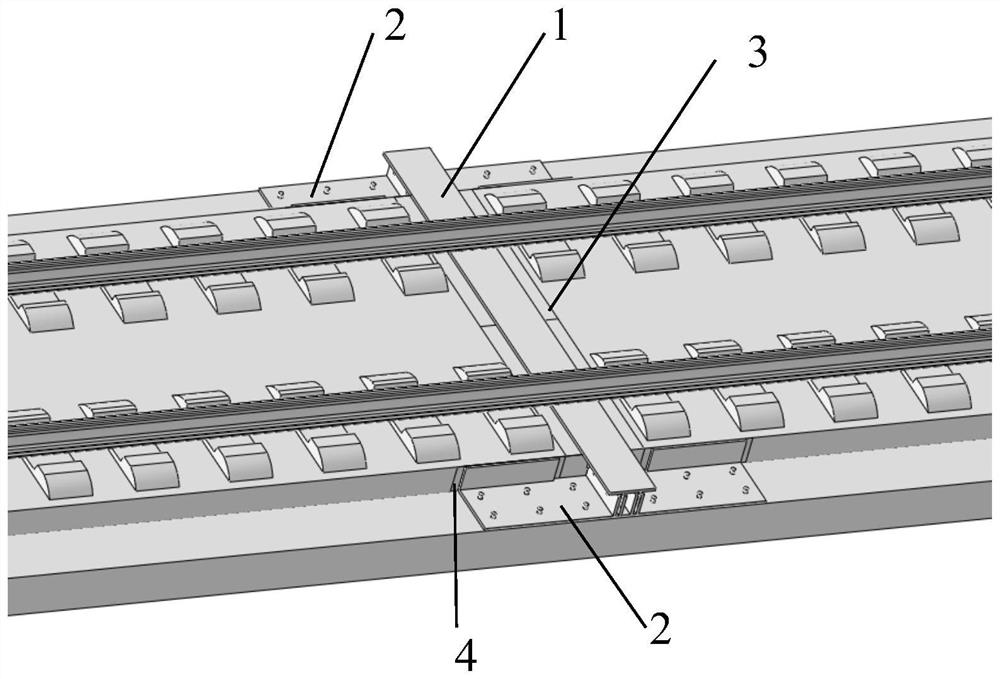

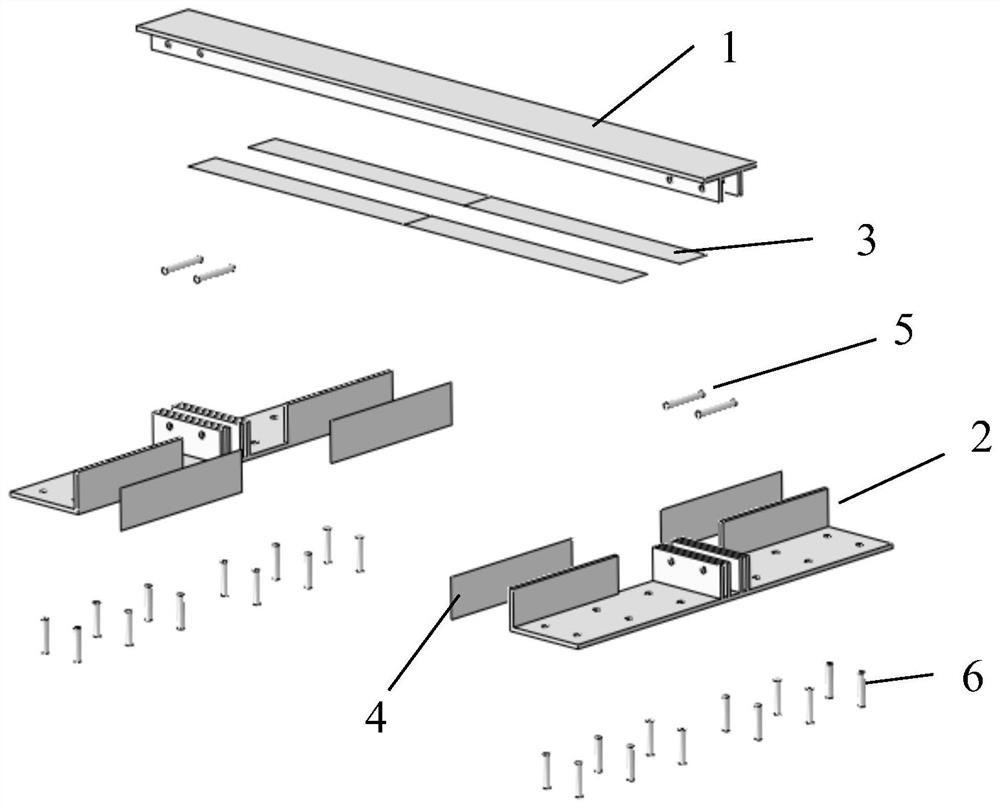

[0039] See Figures 1 to 10 A longitudinal plate-free orbital temperature relief device, including: a radiographic steel beam 1 between the two unit rail plates, a lateral limit frame 2 provided on both sides of the π-type steel beam 1 The side steel sheet 4 is fixed to the left and right side of the front and rear end of the unit rail plate, and the top surface of the top surface of the front and rear end of the unit rail plate is fixed to the top surface of the top and rear ends of the unit track; the π-type steel beam 1 includes parallel to the top of the unit orbord plate. The top plate 1-1 of the surface and two webs 1-2 perpendicular to the top plate 1-1; the lateral limit frame 2 includes a L-bend plate, the L-bending plate including a bottom plate 2-1 and lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com