Transverse piezoelectric driving deformation mirror and the assembling method thereof

A technology of piezoelectric drive and piezoelectric drive, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of reducing the stability of the mirror surface and resonance frequency, prone to print-through effect, and the influence of the shape change of the mirror surface. Simple and convenient, reducing support stiffness and increasing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

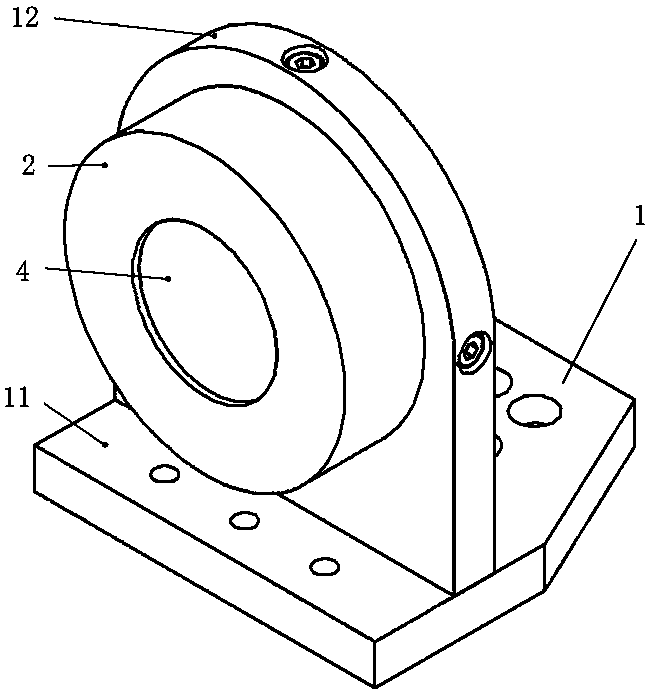

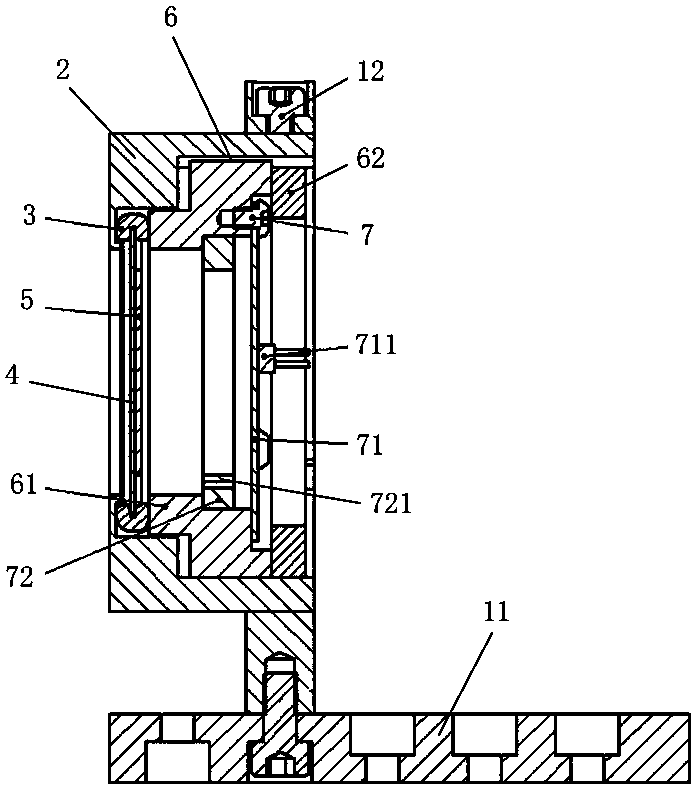

[0028] Such as figure 1 with figure 2 As shown, the transverse piezoelectrically driven deformable mirror of this embodiment includes a base 1, a transverse shell 2, an elastic washer 3, a mirror 4, a piezoelectric driver 5, a pressing device 6 and an electrical connection assembly 7, and the transverse shell 2 Installed laterally on the base 1, the reflector 4 and the piezoelectric driver 5 are bonded and fitted in the inner hole of the lateral shell 2, the elastic washer 3 is installed on the edge of the reflector 4, and one end surface of the elastic washer 3 is movable with the transverse shell 2 Contact, the pressure applying device 6 is screwed into the inner hole of the transverse shell 2, and the pressure applying device 6 is in movable contact with the elastic washer 3, and the electrical connection assembly 7 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com