Sealing device for separator of vertical roller mill

A technology of vertical roller mill and sealing device, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of difficult blade seal adjustment, unstable product quality, and poor sealing effect, so as to facilitate popularization and use , Disassembly and adjustment are simple and convenient, and the structure is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

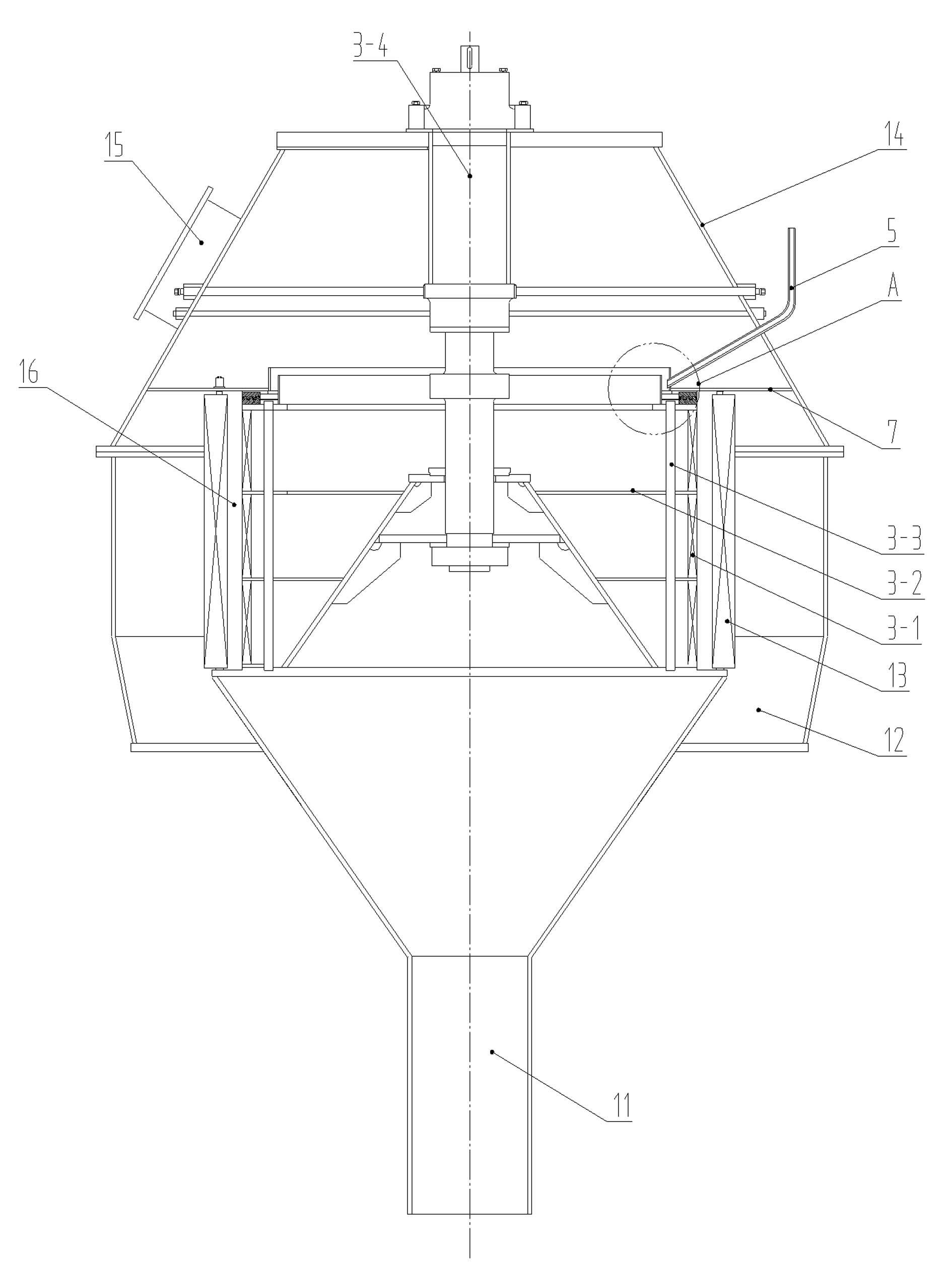

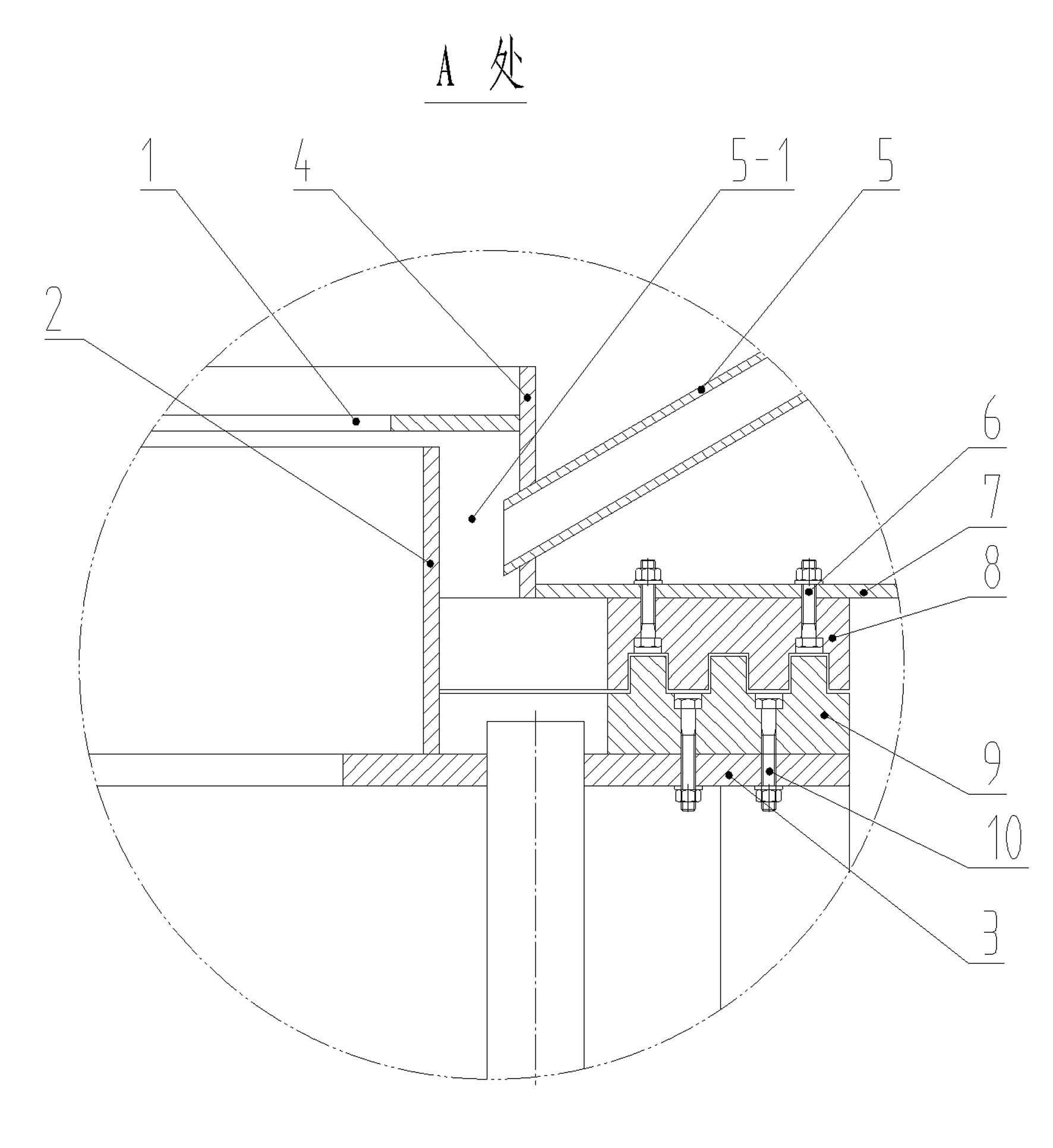

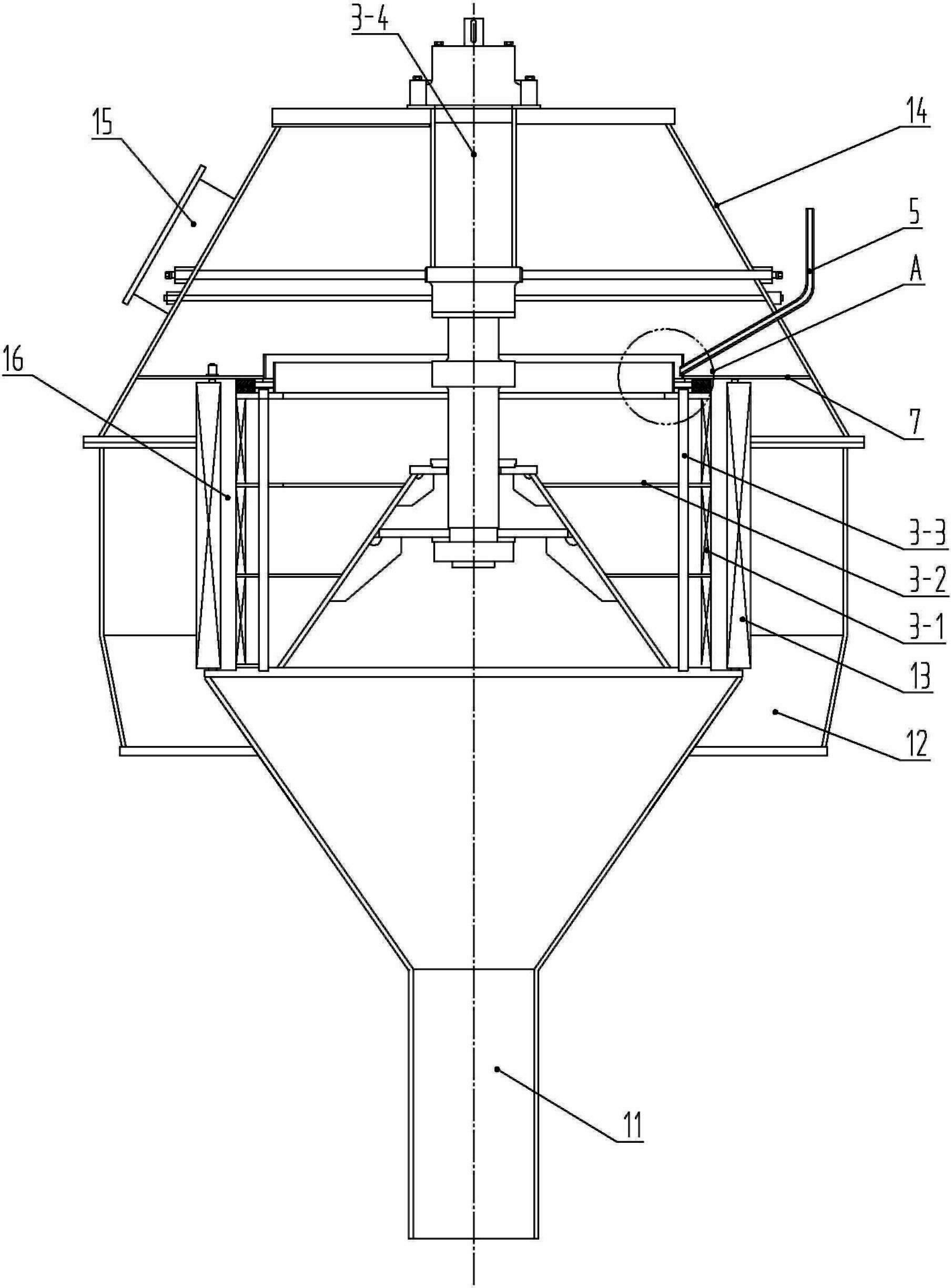

[0013] like figure 1 , figure 2 Shown: a sealing device used on a powder classifier of a vertical roller mill. In order to ensure that all the mixed materials in the powder selection area are sorted by the cage-shaped rotor blades, the distance between the rotor 3 of the powder classifier and the shell 14 of the classifier is There are two seals between them, and the sealing device includes: a radial annular sealing plate 1, an axial annular sealing plate 2 and a combined sealing device arranged between the diaphragm 7 in the casing and the rotor 3 of the powder classifier; the radial It is connected with the fixed plate 4 to the periphery of the annular sealing plate 1, and the fixed plate 4 is installed on the transverse partition plate 7 in the casing. The lower end of the axial annular sealing plate 2 is fixed on the upper end of the rotor 3 of the powder separator; there is a gap between the radial annular sealing plate 1 and the axial annular sealing plate 2 . A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com