Self-priming pump

A technology of self-priming pumps and pump shafts, applied in pumps, rotary piston pumps, rotary piston machines, etc., can solve problems affecting the normal use of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

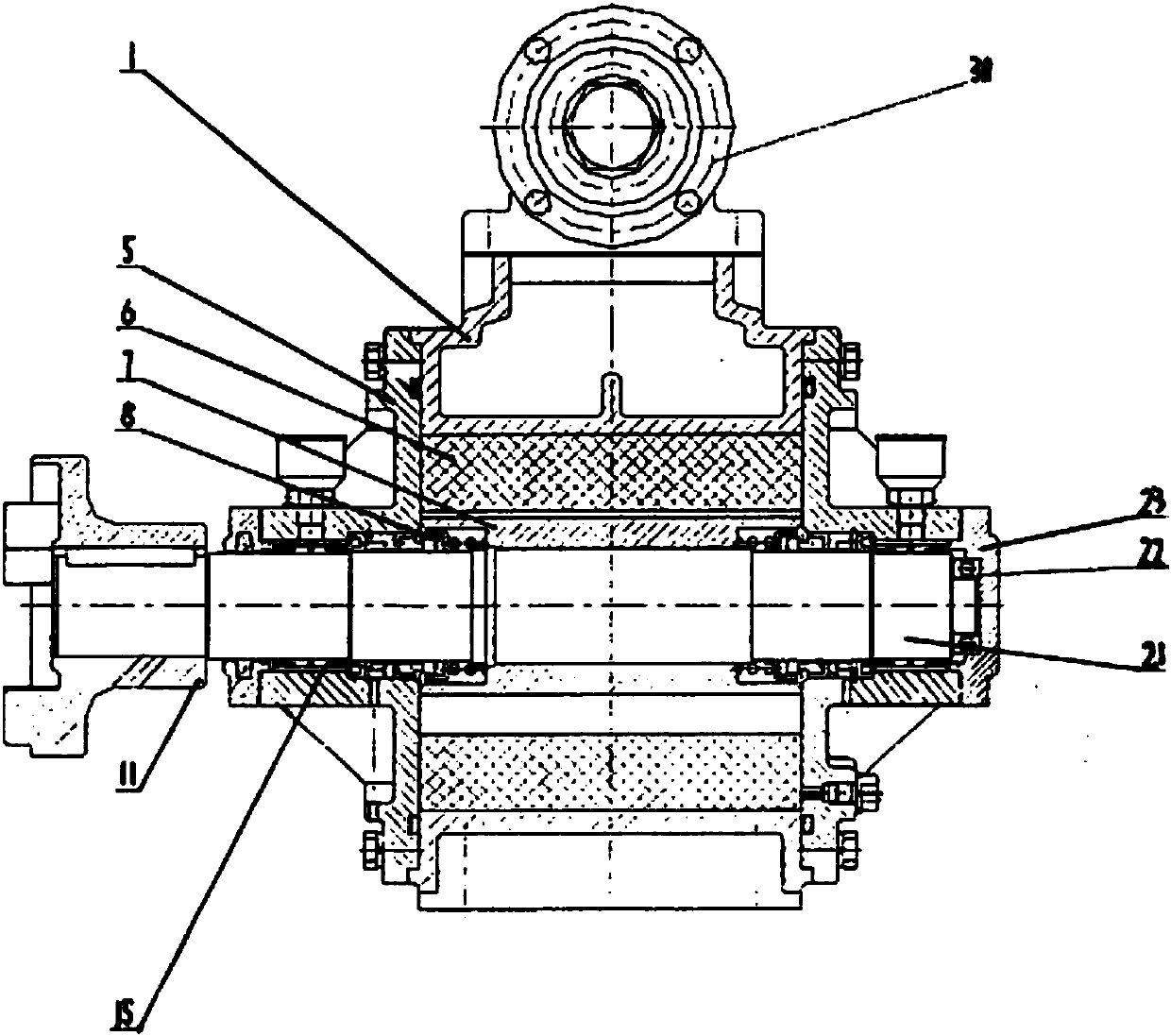

[0006] figure 1 As shown, the inner curve of the pump body 1 is composed of circular arcs and constant acceleration curves. There are suction and discharge ports in the radial direction. The suction port is connected with the pump inlet, and the liquid discharge port is connected with the pump outlet. There is a groove, and it is shrunk on the pump shaft 21. The sliding plate 6 is installed in the groove, and they are installed eccentrically in the pump body 1. The pump shaft 21 is positioned by the double needle roller bearing 15 whose two ends are installed on the pump bearing end cover 5. A flat bearing 22 is installed at the end of the pump shaft cover 23, two mechanical seals 8 are used for the shaft end seal, a safety valve 30 is installed on the upper part of the pump body 1, and a coupling 11 at the end of the pump shaft 21 is formed to form a new type of sliding vane self-priming pump .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com