Positioning device for box body limiting hole machining

A technology of positioning device and limit hole, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting production efficiency and increasing the labor intensity of operators, so as to improve stability and improve stability The effect of sex and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

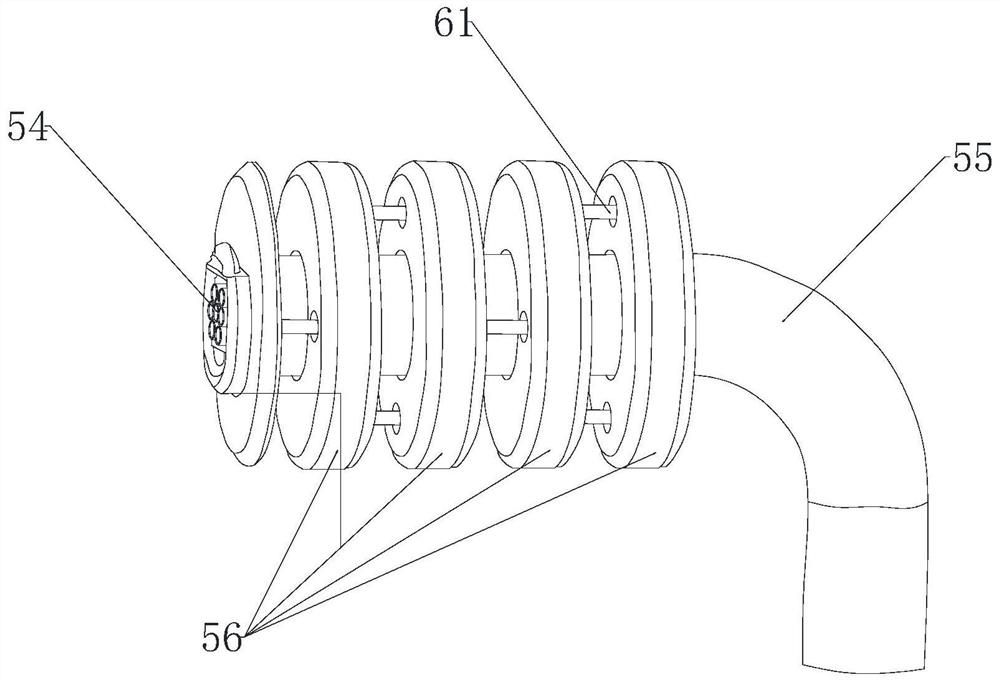

[0062] Such as Figure 1 to Figure 16 As shown, the positioning device for processing the limit hole of the box body includes a positioning seat 1;

[0063] The positioning support seat 1 is connected with a positioning support seat 2, and the positioning support seat 2 is connected with a positioning linkage seat 4 located above the positioning support seat 2 through a support seat connecting rod 3;

[0064] The bottom end of the positioning linkage seat 4 is provided with two symmetrically arranged linkage seat abutment columns 7;

[0065] The area between the positioning support seat 2 and the positioning linkage seat 4 is also provided with a positioning lower pressure seat 5, and the positioning lower pressure seat 5 is provided with a lower pressure seat arc opening 15 for giving way to the support seat connecting rod 3, and the support seat The connecting rod 3 can move relatively in the arc-shaped opening 15 of the lower pressing seat 5 along the circumferential direc...

Embodiment 2

[0074] This embodiment makes the following further limitations on the basis of Embodiment 1: the bottom end of the positioning protrusion 14 of the positioning lower pressure seat 5 is provided with a downwardly convex elastic abutment section 41 of the lower pressure seat;

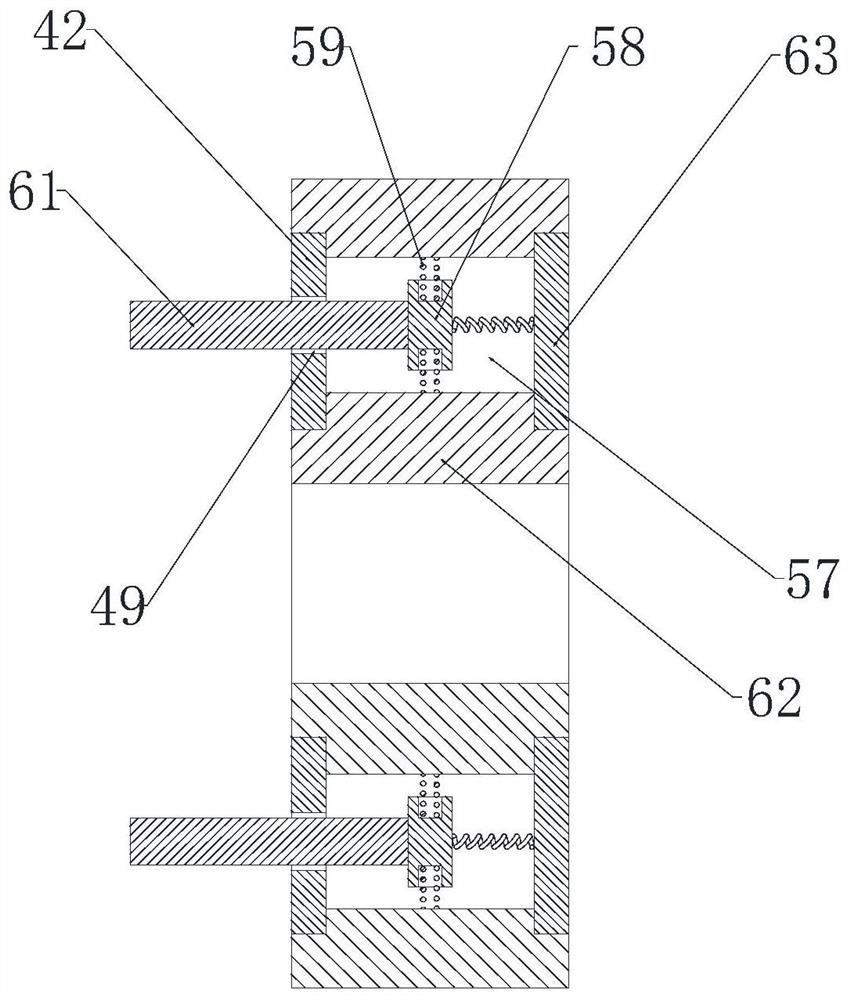

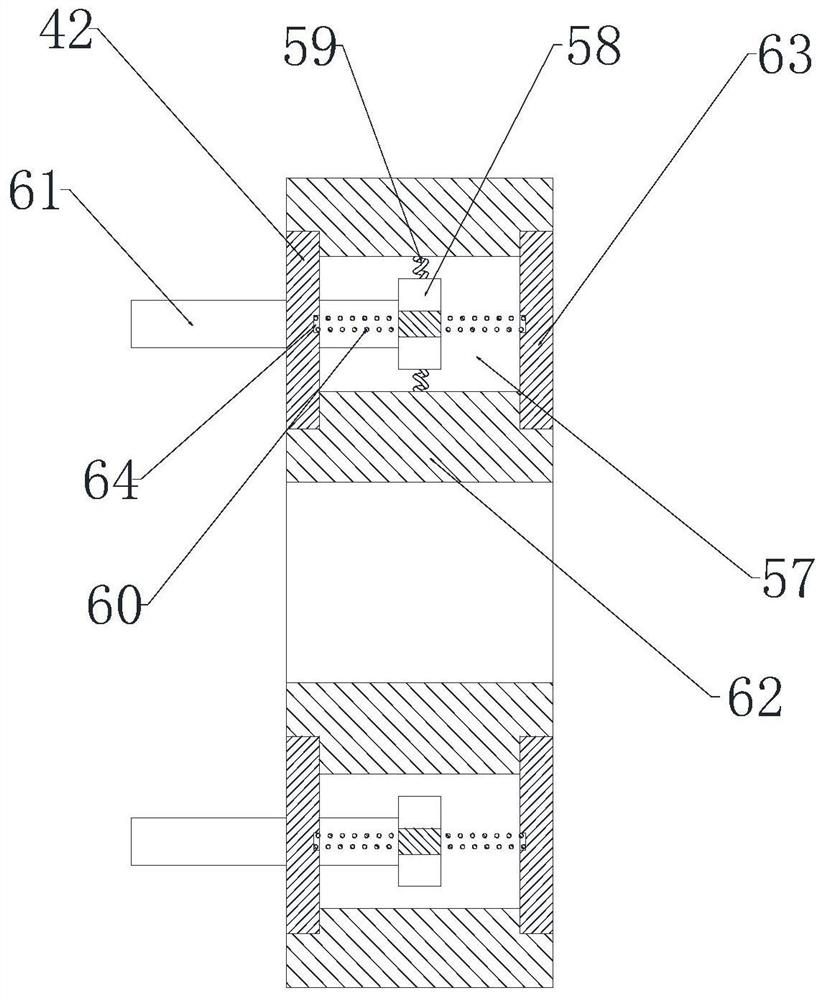

[0075] The support seat elastic assembly includes at least two support seat abutment grooves 6 provided on the positioning support seat 2, the support seat abutment groove 6 has a large opening and a small inner cavity;

[0076] The support base elastic component also includes a support base connecting rod 8 that can pass through the opening of the support base abutting groove 6, and the bottom end of the support base connecting rod 8 is connected with a connecting rod anti-off head 9 located in the support base abutting groove 6;

[0077] At least two support seat connecting rods 8 are connected with the same lower press seat support plate 19, and the lower press seat support plate 19 is provided with a s...

Embodiment 3

[0084] In this embodiment, the following further limitations are made on the basis of Embodiment 1: the top end of the positioning support seat 2 is provided with a support plate receiving groove 21 capable of accommodating the support plate 19 of the lower pressing seat.

[0085] In this embodiment, the support plate receiving groove 21 is provided for accommodating the support plate 19 of the lower press seat, so that the positioning of the lower press seat 5 can be ensured to have sufficient downward movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com