A rocking back drill drilling tooling device

A technology of drilling and back-drilling, applied in positioning devices, clamping devices, boring/drilling, etc., can solve the problems of small workpieces and unsuitable for processing large-length workpieces, and achieve high work efficiency and reasonable structural design , the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

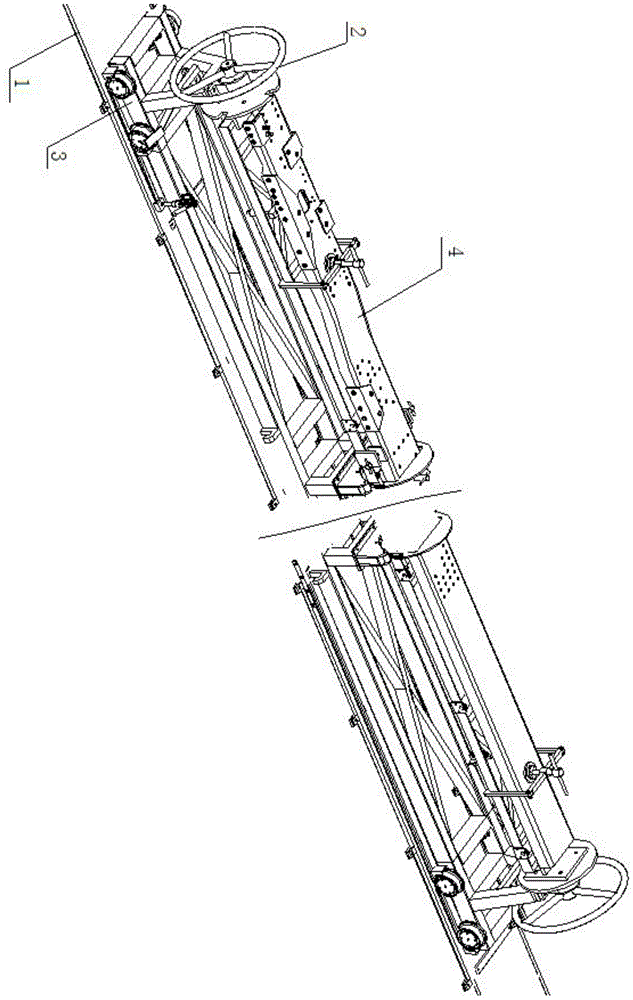

[0030] Such as figure 1 A kind of rocking back drill punching tooling device shown, comprises rail device 1, rotating device 2, mobile trolley device 3 and crossbeam drilling mold cover device 4, and described mobile trolley device 3 is installed on the described rail device 1, so The rotating device 2 is installed on the moving trolley device 3 , and the beam jig set device 4 is installed on the rotating device 2 .

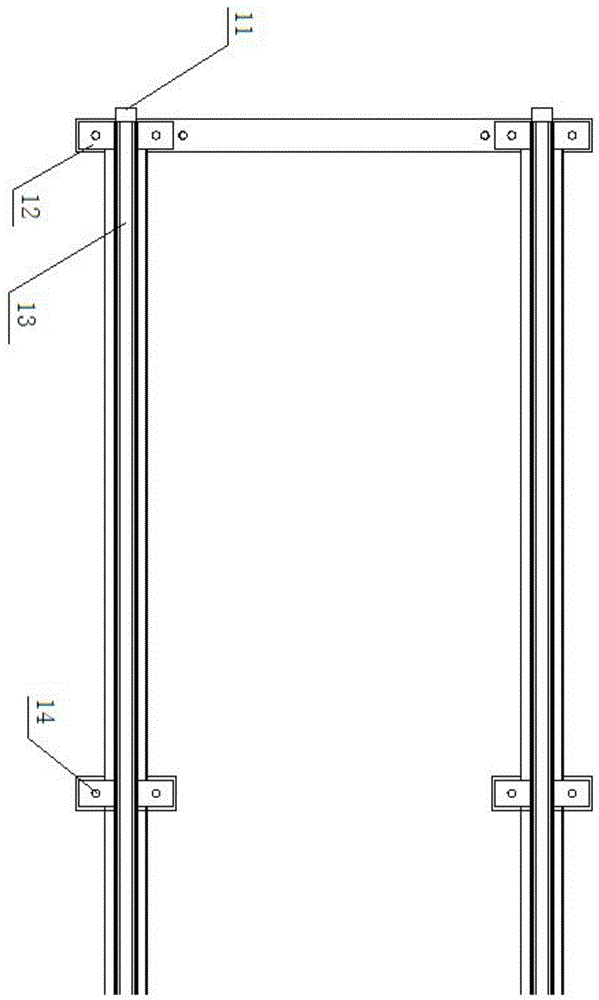

[0031] Such as figure 2 The schematic diagram of the track device structure is shown. This track device 1 comprises light rail 13, and the baffle plate 11 that is installed on the end of described light rail 13, is installed on the rail pressing plate 12 of described light rail 13 side, described rail pressing plate 12 fixes described light rail 13 at intervals, and distance is 900-1000mm, and fixed by expansion screws 14.

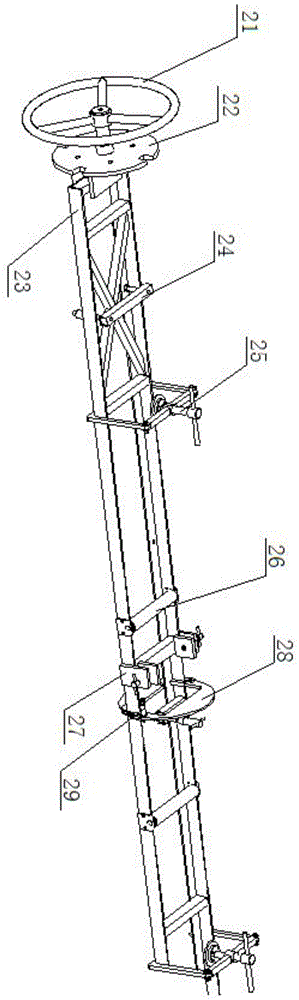

[0032] Such as image 3 Schematic diagram of the structure of the rotating device shown. The rotating device includes a rotating body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com