Reset the front cover opening device

A front cover and equipment technology, applied in metal processing equipment, other manufacturing equipment/tools, positioning devices, etc., can solve the problems of increasing labor intensity of operators, burrs in box limit holes, and affecting production efficiency. Achieve the effect of improving the quality of opening, reducing production costs and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

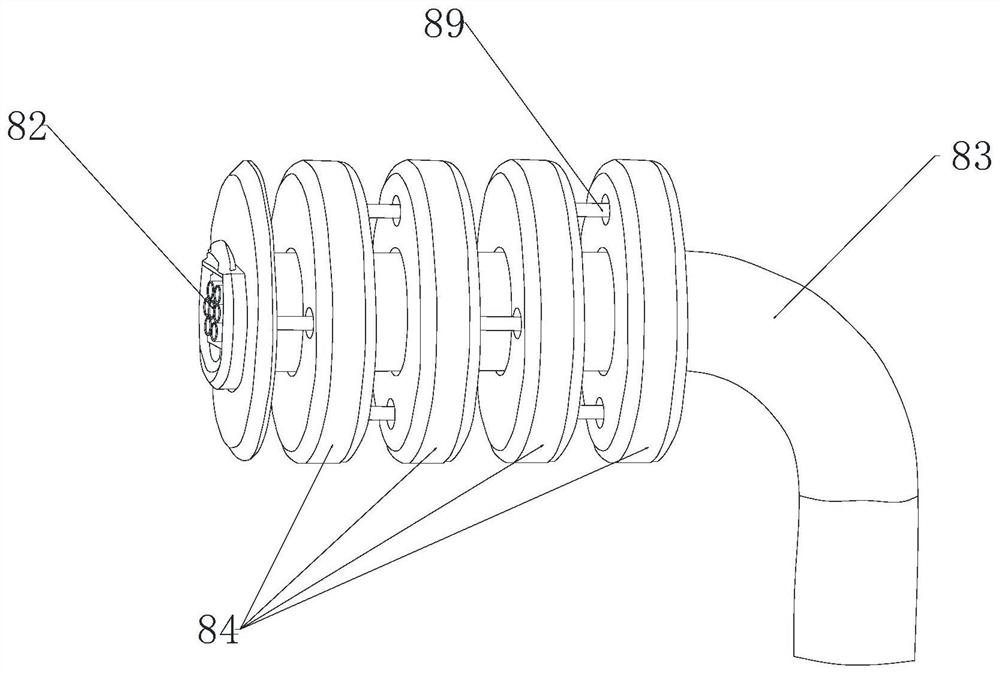

[0080] like Figure 1 to Figure 21 As shown, a hole tool unit and an open hole positioning unit are included;

[0081] The opening tool unit includes a tool support frame 54;

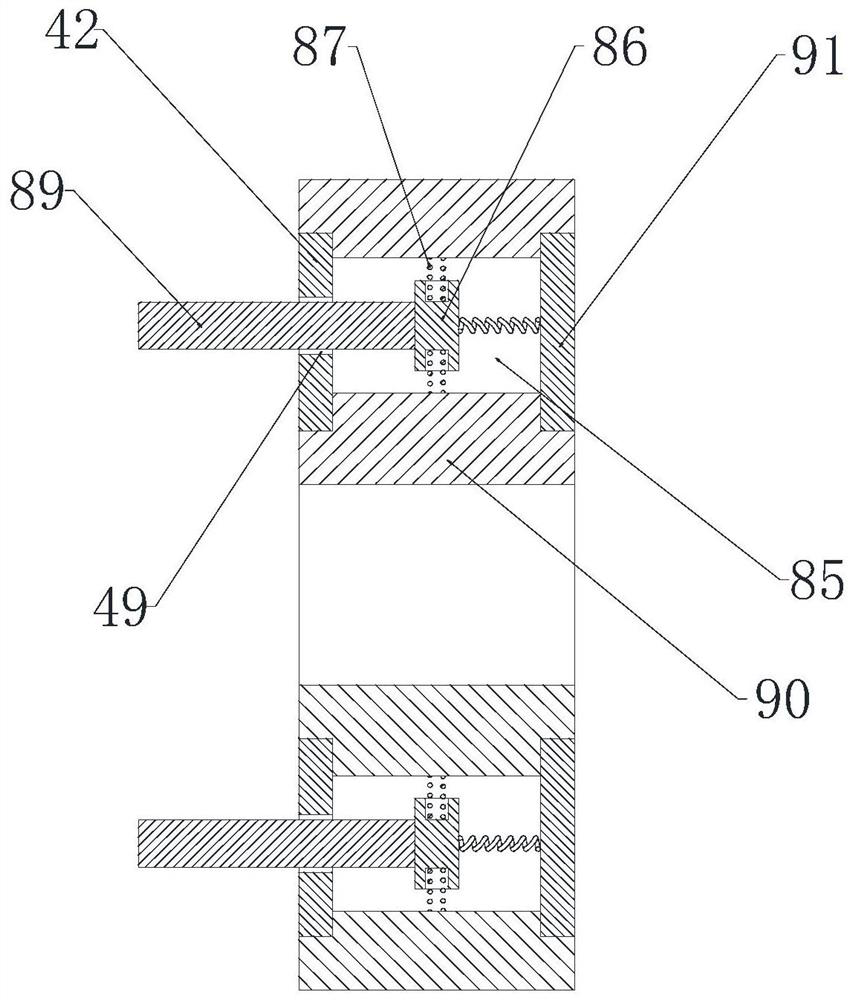

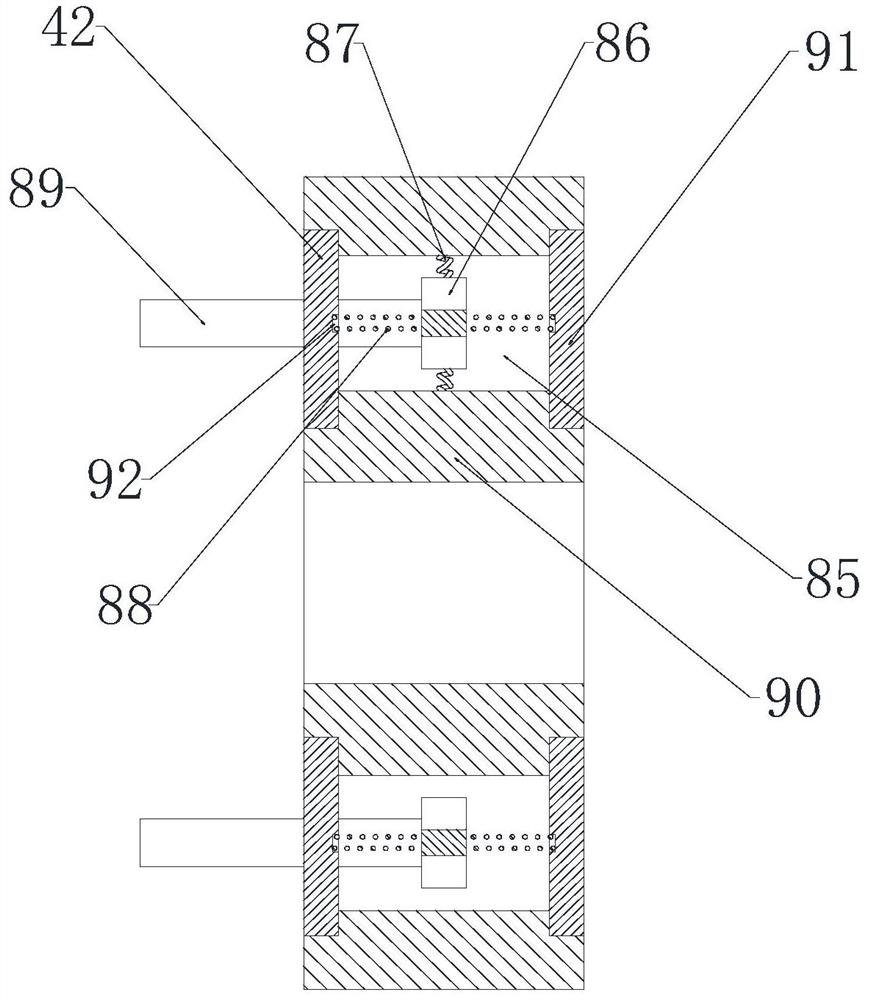

[0082]Tool support bracket 54 is mounted on the upper and lower blade drive device 108, the tool vertical drive means 108 is connected to the output terminal of the tool rotation driving means 58, a tool driving device 108 vertically act on the tool rotation driving means 58, such that: the tool rotation driving means 58 can support frame 54 moves up and down relative to the tool, the tool rotation driving means 58 is connected to the output of the drive tool driving shaft 59, the bottom end of the cutter drive transmitting lever 59 is provided with a blind bore tool driving gear 60, the inner cutter drive gear 60 provided with a blind bore a plurality of annular array 61 of cutter drive gear cogging;

[0083] Tool 54 is also mounted on the support frame mounting the turntable 55 and the tool 54 rotates the ...

Embodiment 2

[0097] The present embodiment is further defined as made in Example 1 based on the embodiment: the knife guard member by the elastic pressure drum at the lower end portion 111 of the outer cylinder 65 is connected to the outer cylinder relative knife guard 111 moves up and down under the tool pressure cylinder 66 ;

[0098] Knife guard 111 on the outer cylinder is also provided with a pressure cylinder anti preventing the tool 66 from the impression cylinder 67 of the release member 65 under the action of the resilient press member at the tool cylinder pressure cylinder 66, such that: the tool has moved downward pressure cylinder trend, the grinding tool 64 and the punch tool or the tool 63 is located within the cylinder 66 under pressure.

[0099] In this embodiment, for the realization of the lower blade pressure cylinder 66 movably connected to the knife guard outer cylinder 111 to protect the tool within the outer cylinder 111 is provided with a depressed cylindrical abutment ...

Embodiment 3

[0102] The present embodiment is further defined in the following be made based on Example 2: the turntable is provided with four mounting holes 57, four wheel mounting holes 57 are uniformly distributed in the turntable 55 is mounted on the tool;

[0103] The punch tool assembly and the grinding tool assembly are located in opposing positions;

[0104] Four wheel mounting hole 57 of the other two wheel mounting holes 57 are blow cylinder 67 is attached to the tool.

[0105] In this embodiment, the cutter cylinder 67 communicates with a blowing gas generator. Tool 67 is provided to blow cylinder cleaning litter on the positioning unit and the hole on the front cover semi reset, to avoid the accumulation of semifinished scratched.

[0106] When applying the present embodiment embodiment, the same drive means 56 is driven by a rotary cutter mounted turntable 55 is rotated, the tool 67 is aligned reset blowing pump cover on the front semi machined zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com