Looseness-preventing rope protection device of steel wire rope used for crane

A protection device, wire rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of poor use effect, low use reliability, large mechanical wear, etc., to achieve rapid response, prolong service life, mechanical wear and tear small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

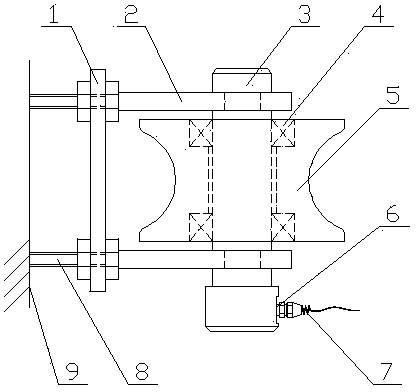

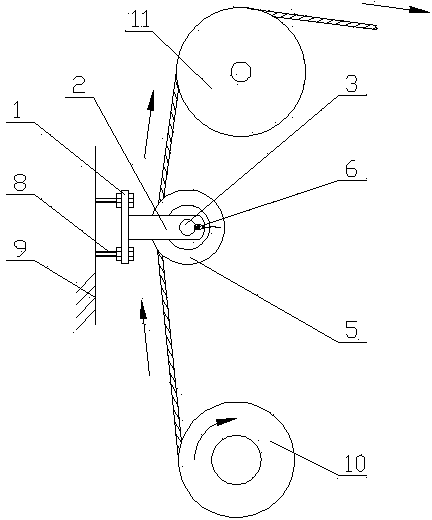

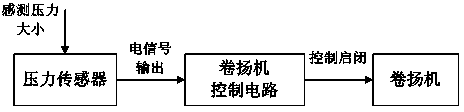

[0010] The present invention is used for the wire rope anti-loosening protection device of the crane, such as figure 1 , 3 As shown, it includes a height-adjustable tension-adjusting seat plate 1, and the tension-adjusting seat plate 1 is connected with a force-bearing mandrel 3 through a connecting frame 2 provided thereon, and the outer periphery of the force-bearing mandrel 3 is passed through a bearing 4 is connected with the wire rope guide wheel 5, the wire rope guide wheel 5 is located between the winch 10 and the working guide wheel 11, and the pressure sensor 6 that can sense the force of the force mandrel is installed inside the force mandrel 3 , the electric signal output end 7 of the pressure sensor 6 is connected with the hoist control circuit for controlling the operation of the hoist 10 .

[0011] In order to calculate the hoisting weight of the crane, the above-mentioned pressure sensor 6 is a piezoelectric load cell to sense the magnitude of the force on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com