Internal cooling type clutch friction plate

A friction plate and cooling technology, which is applied in the field of auto parts, can solve the problems of clutch friction plate heat dissipation, etc., and achieve the effect of increasing heat dissipation efficiency and stabilizing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

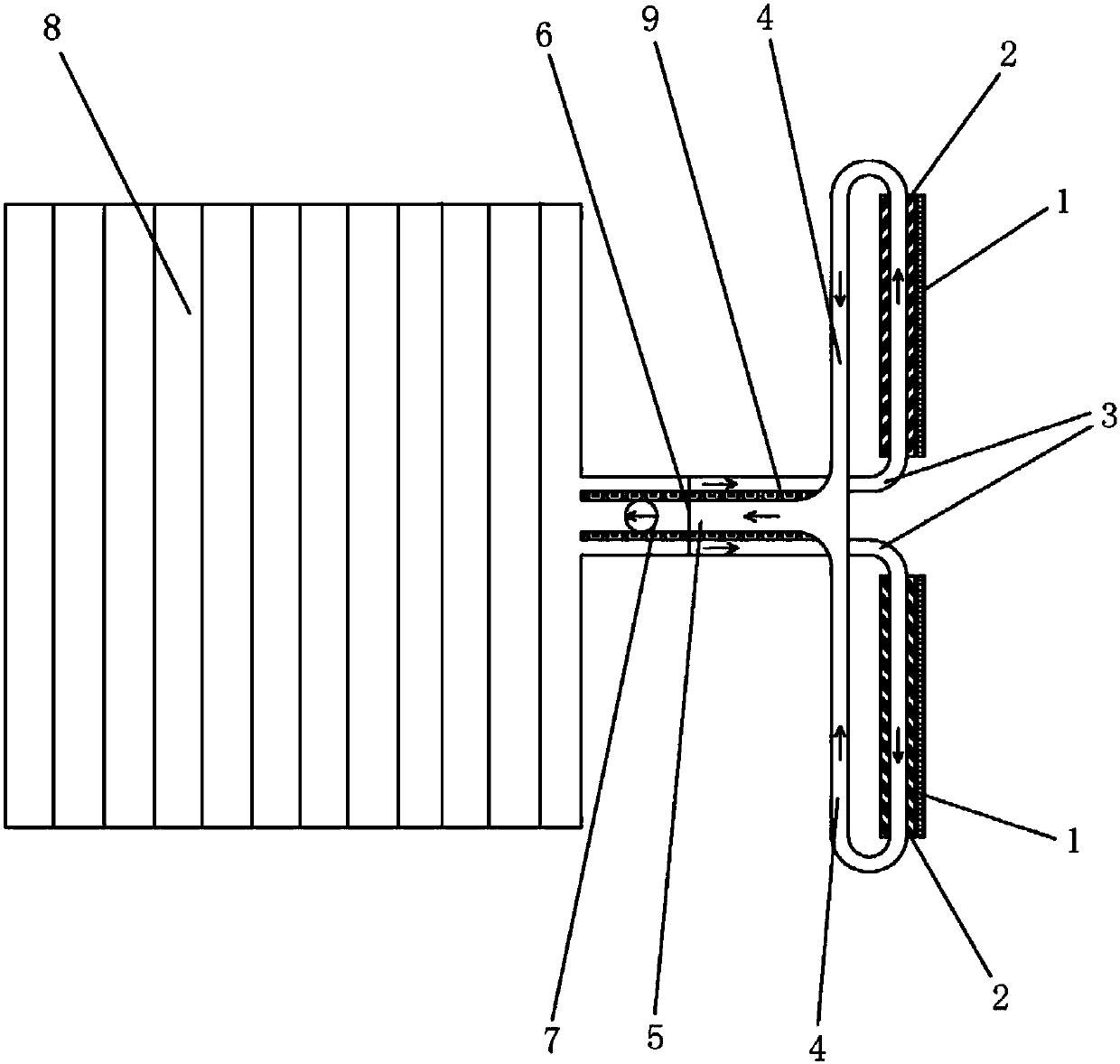

[0010] Internally cooled clutch friction plates include a friction plate 1 and a heat conductor 2 that fits closely with the friction plate 1. The heat conductor 2 is provided with a cooling liquid pipeline 3 that radiates from the center to the periphery. The coolant pipeline 3 extends from the heat conductor 2. After exiting, it enters the coolant return main pipeline 5 through the coolant return pipeline 4, and a rotating sealing ring 6 is arranged in the middle of the coolant return main pipeline 5, and a pressure pump 7 is also provided, and the pressure pump 7 exerts pressure on the coolant. A pressure, so that the coolant enters the radiator 8. After passing through the radiator 8, the cooling liquid enters the cooling liquid pipeline 3 again under the pressure exerted by the pressure pump 7, and continuously cools the heat conductor 2. The part from the rotary sealing ring 6 to the heat conductor 2 is a rotating part, and the part from the rotary sealing ring 6 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com