Optical Densitometer for Automatically Measuring Blackness Range and Optical Density Calculation Method

An optical densitometer, automatic measurement technology, applied in computer control, transmittance measurement, program control and other directions, can solve the problems of high labor intensity, black level meter can only measure blackness at a single point, low efficiency, etc. Interfere and improve the effect of automatic measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

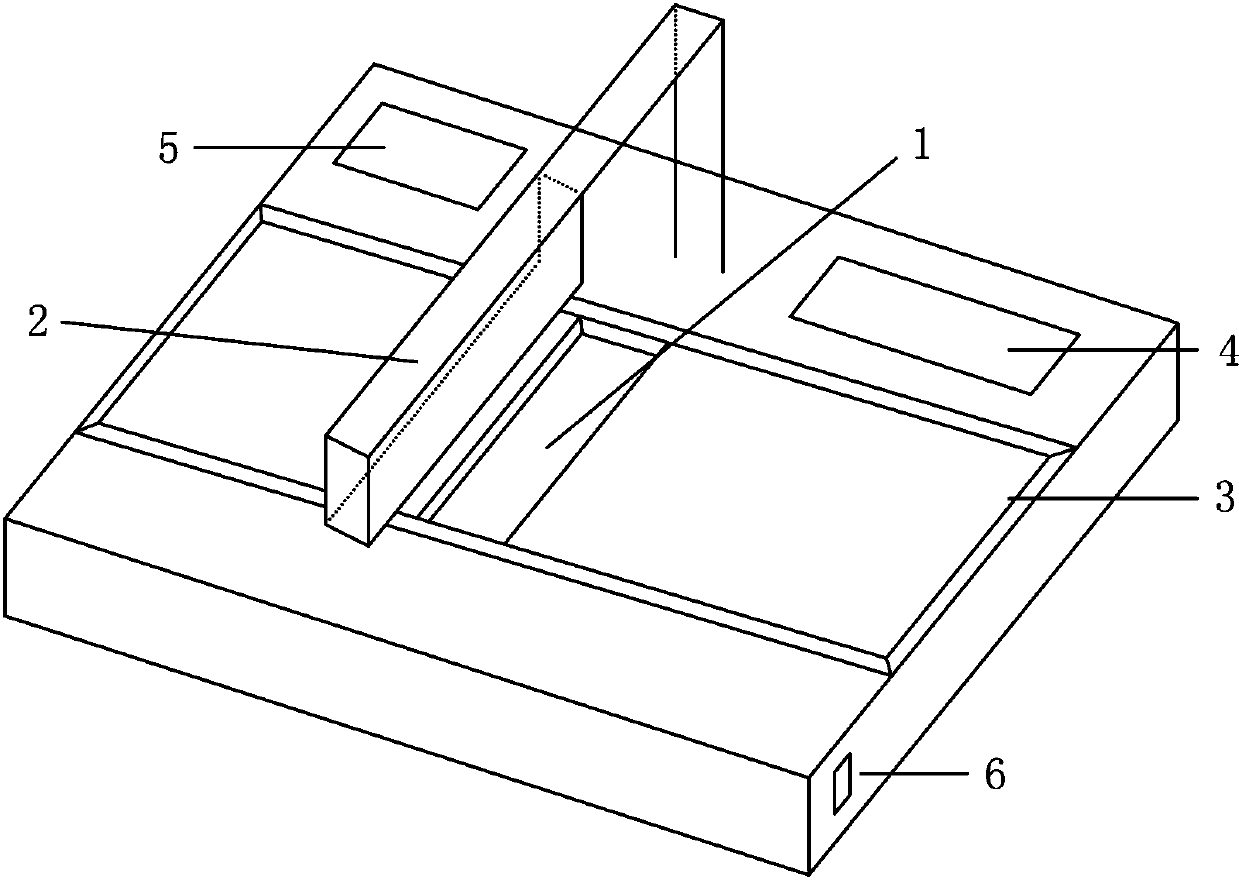

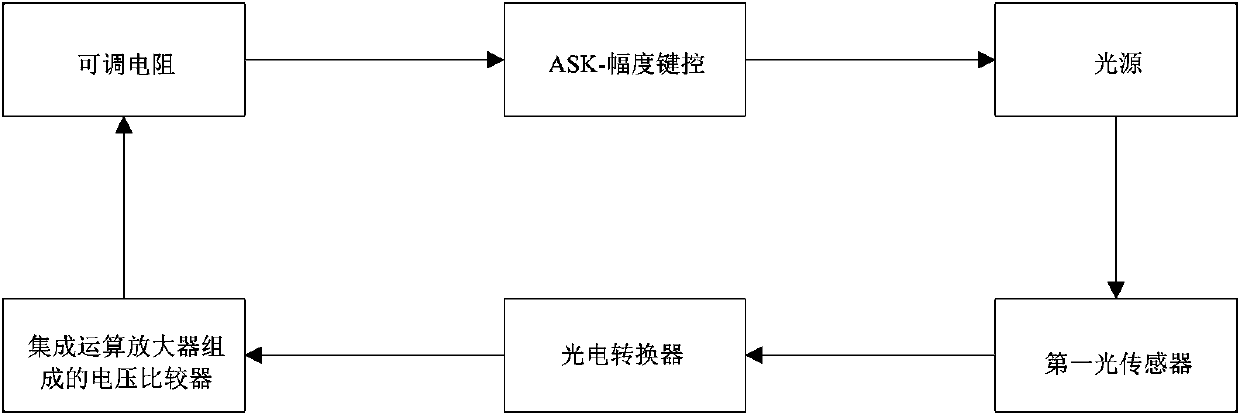

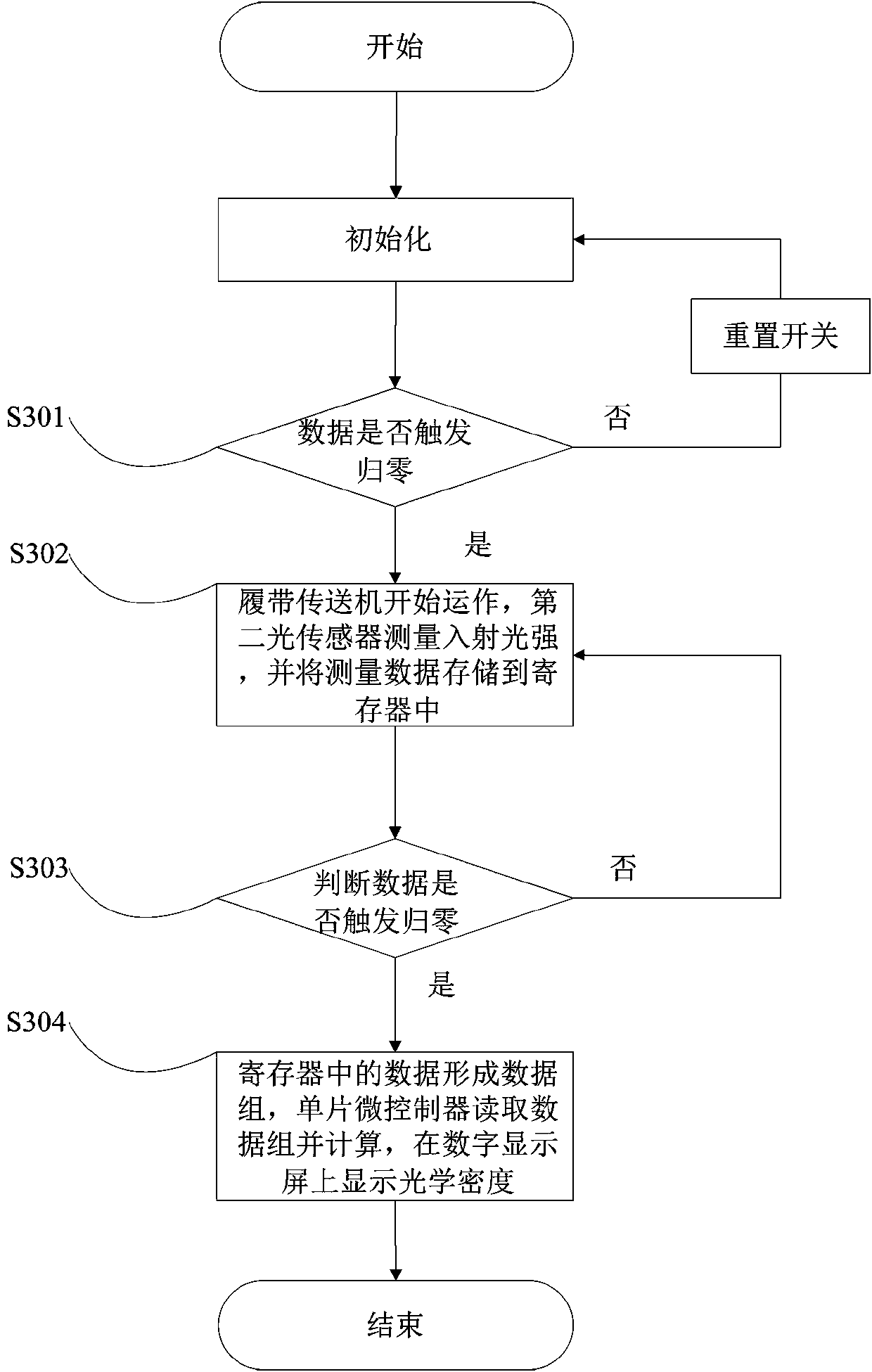

[0030] The core of the present invention is to provide an optical density meter that can automatically measure the range of blackness, introducing a linear sensor array to solve the problem that traditional blackness meters can only measure blackness at a single point; another core of the present invention is to provide an optical density meter. Density calculation method.

[0031] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of the embodiments of the present invention, not all the embodiments. Based on the embodiments of the present invention, all the embodiments obtained by those of ordinary skill in the art without creative work shall fall within the prote...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap