Method for performing quantitative evaluation on device operation mode

A quantitative evaluation, operation and maintenance technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problem of not carrying out quantitative evaluation, unable to carry out the effectiveness of equipment operation and maintenance work and cost analysis to evaluate the benefits, not yet carrying out the operation and maintenance work benefit evaluation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The description of the following embodiments refers to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

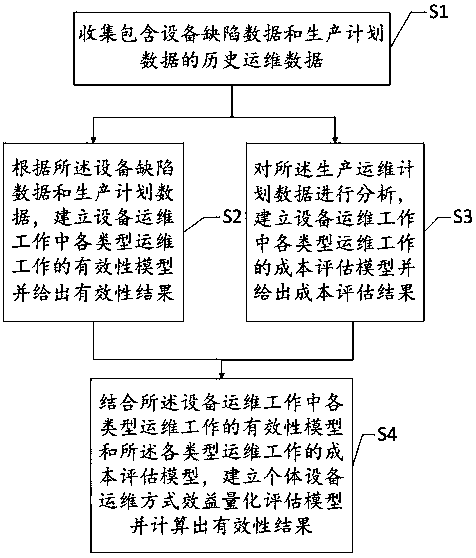

[0027] figure 1 A schematic flowchart of a method for quantitatively evaluating the benefits of equipment operation and maintenance methods is provided for an embodiment of the present invention. Here we take the operation and maintenance work of a generator set as an example, and use the quantitative evaluation method of this operation and maintenance method to perform quantitative evaluation.

[0028] Step S1, collect the daily historical operation and maintenance data of the steam turbine equipment in the generator set. The defect data includes: the number of defects found in the steam turbine inspection work and the elimination time, the number of defects found in the test work and the elimination time, and the inspection work. The number of defects and the time to eliminate the defects, the number of def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com