Noise reduction device for transformer

A transformer and sound insulation board technology, which is applied in the direction of transformer/inductor noise damping, transformer/inductor housing, instruments, etc., can solve the problems of poor noise reduction effect, and achieve the effect of noise reduction, easy installation and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

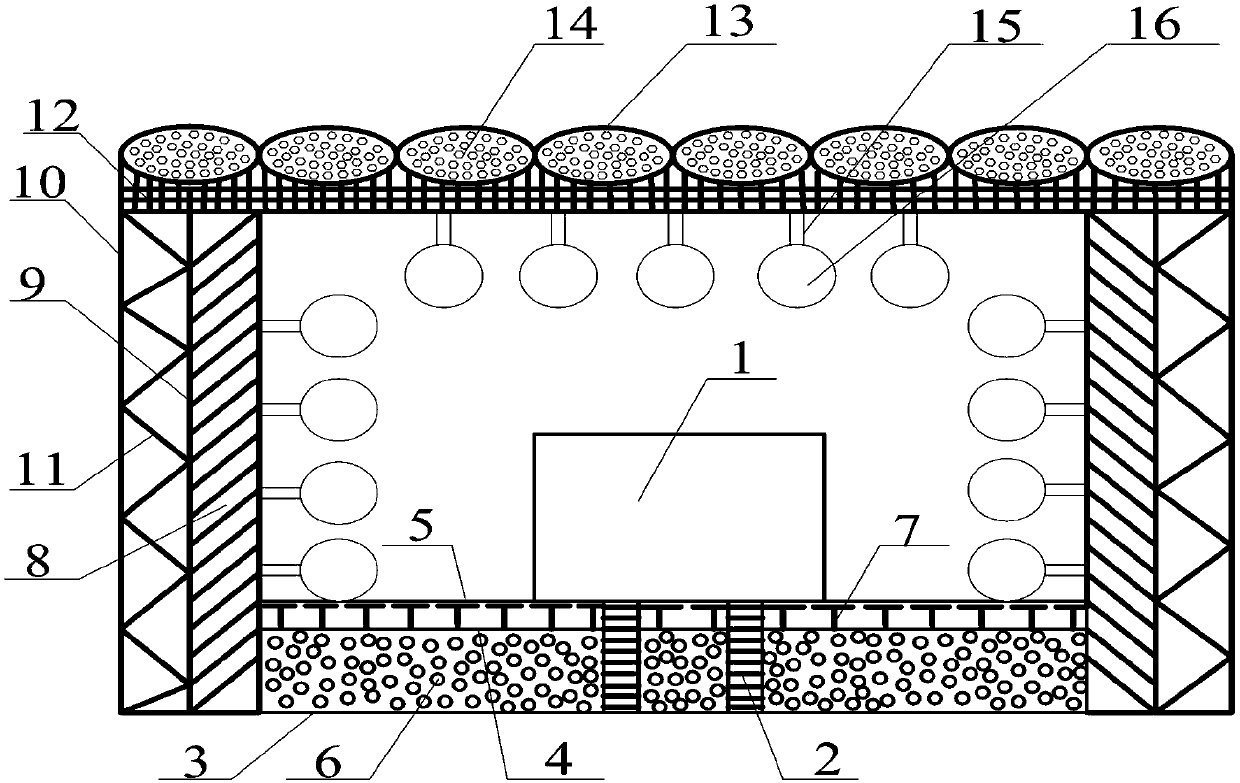

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

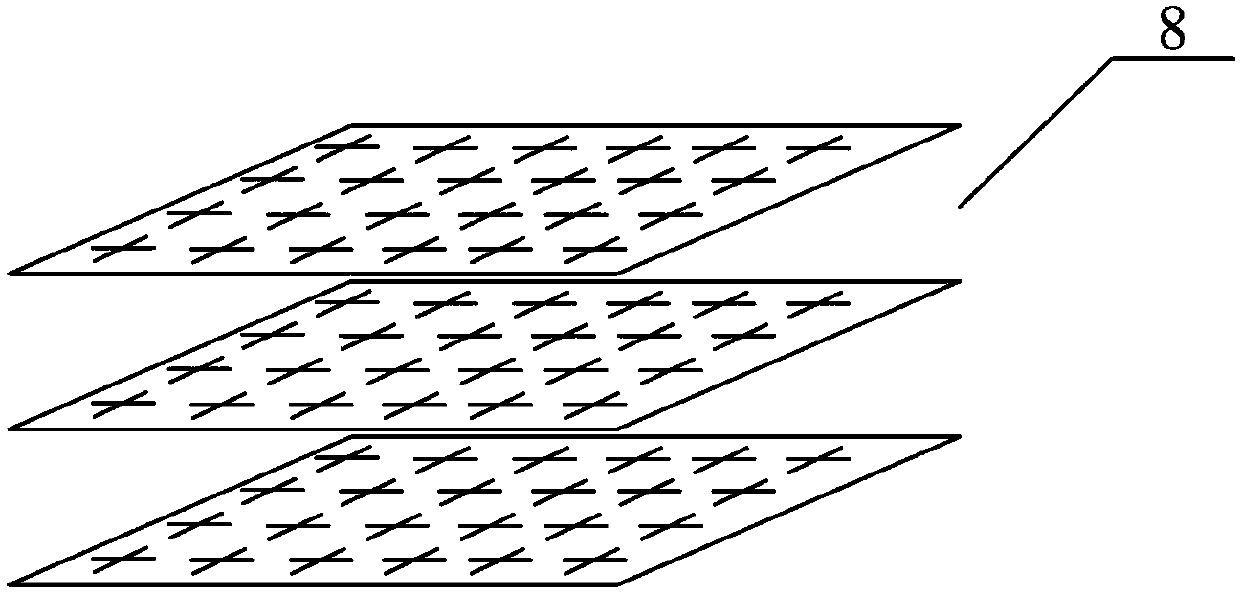

[0033] Such as figure 1 As shown, a transformer noise reduction device of the present invention mainly includes the following components: a sound-insulating reinforcing plate 3, a middle sound-insulating plate 4, an upper sound-insulating plate 5, a sound-absorbing material 6, a plurality of T-shaped sound-absorbing interlayers 7, and two sound-insulating layers 8. Two middle sound insulation panels 9, two outer sound insulation panels 10, two broken-line sound insulation panels 11, sound absorption panels 12, multiple oval sound absorption layers 13, sound absorption material 2 14, multiple fixed brackets 15, multiple 16 attracting balls.

[0034] The two ends of the sound insulation reinforcement board 3 are respectively fixed on the left sound insulation layer 8 and the right sound insulation layer 8 correspondingly, and the transformer 1 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com