Method for etching one part of side wall to improve white pixel

A white pixel and sidewall technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of easy leakage current and great impact on device performance, and achieve the goal of improving white pixels and reducing etching damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

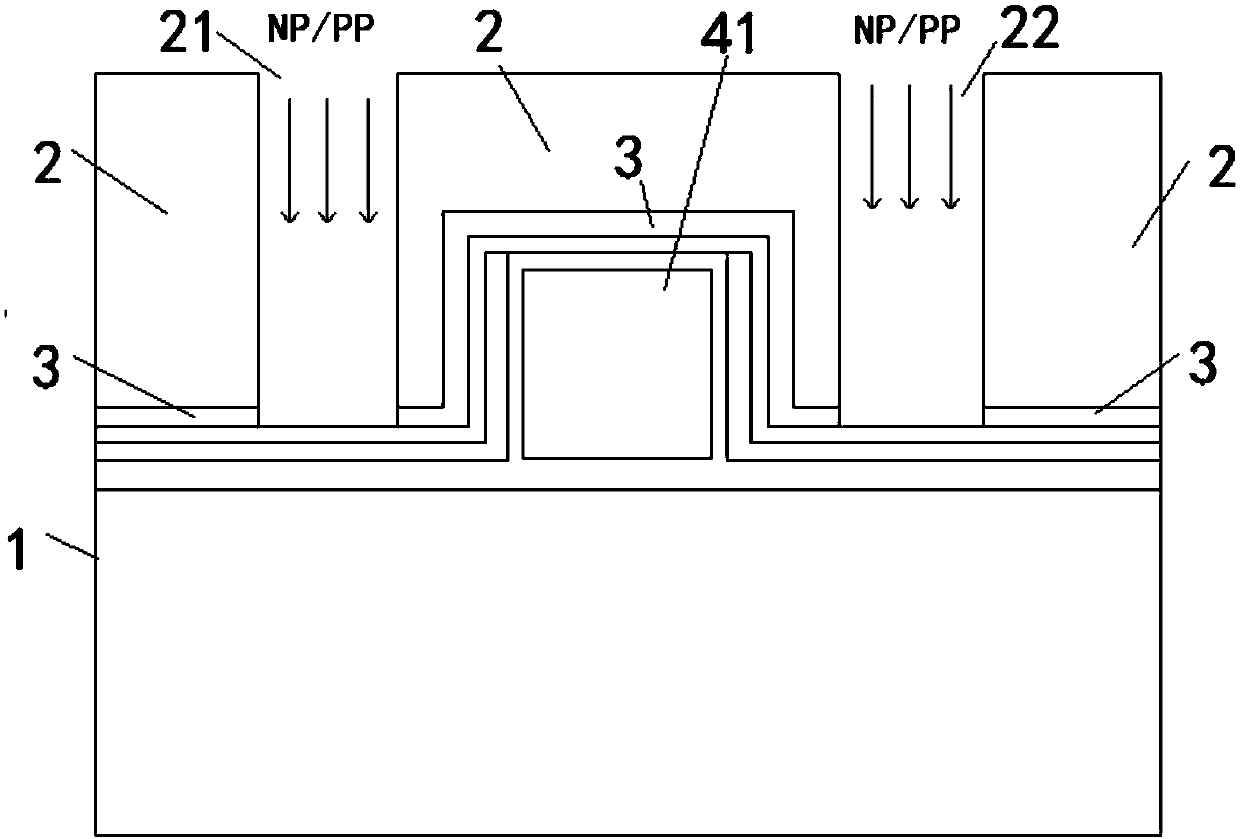

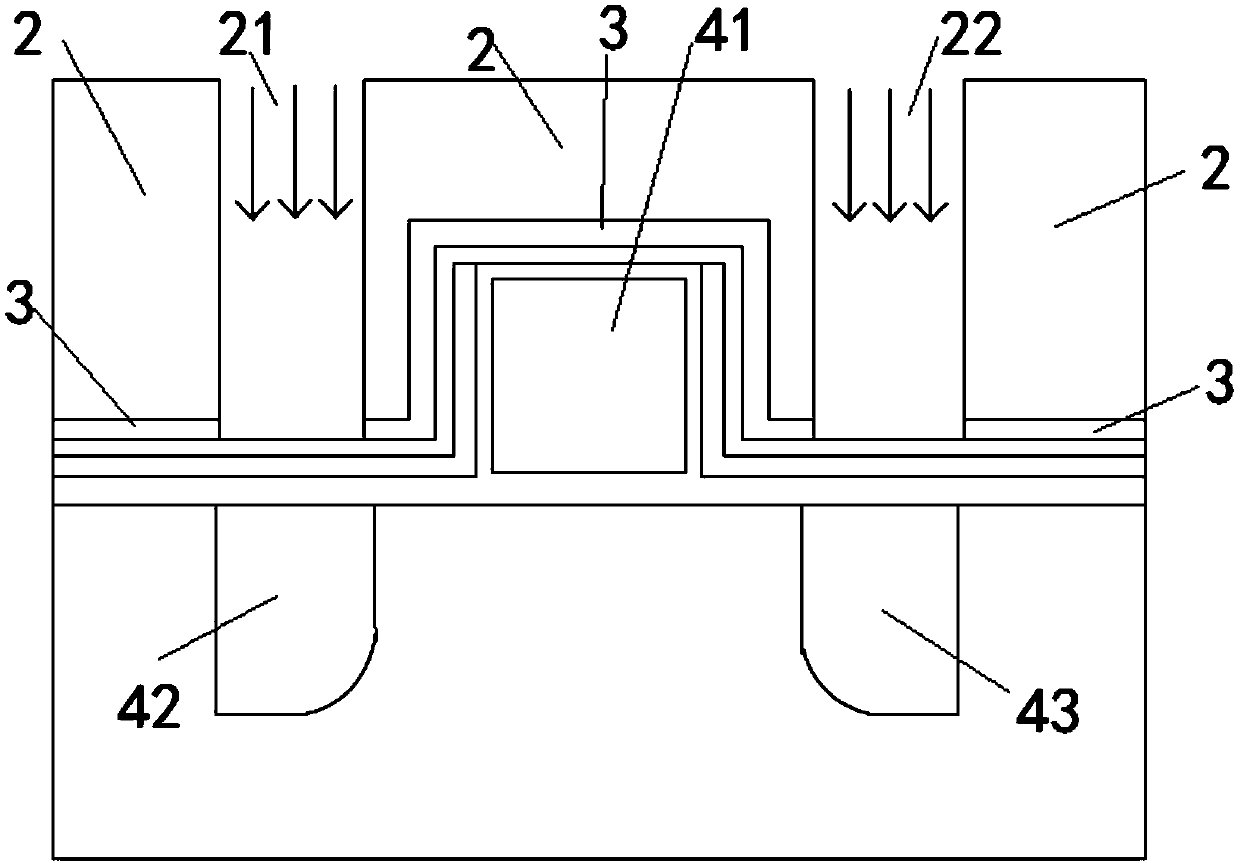

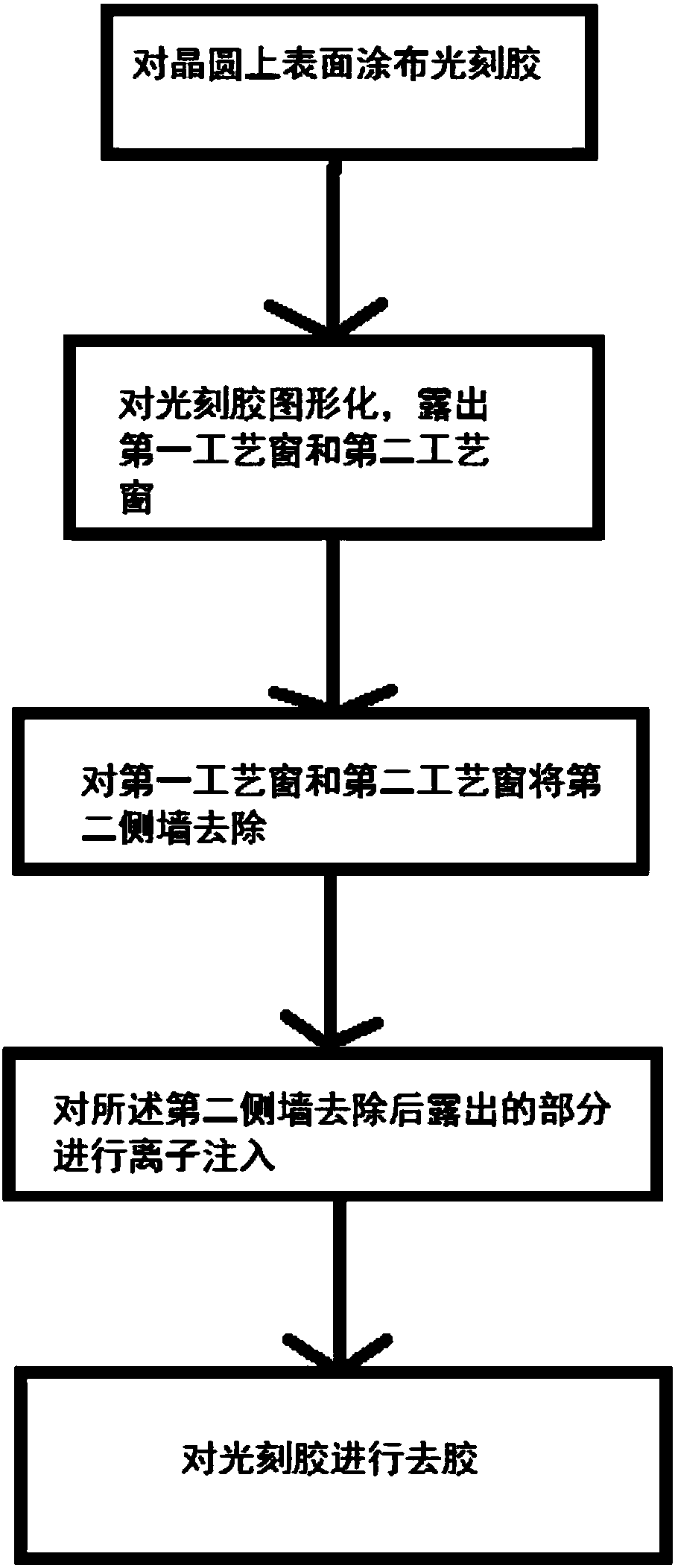

[0025] figure 1 is a schematic diagram of Step 3 of a method for improving white pixels by partial sidewall etching of the present invention; figure 2 is a schematic diagram of Step 4 of a method for improving white pixels by partial sidewall etching of the present invention; image 3 It is a flowchart of a method for improving white pixels by partial sidewall etching of the present invention.

[0026] The etching of the second sidewall 3 in the prior art is aimed at the entire wafer, but since there is no need to etch the other areas except the source 42 and the drain 43 , it needs to be reduced.

[0027] See Figure 1 to Figure 3 As shown, in a preferred embodiment, a method for improving white pixels by partial sidewall etching, including:

[0028] Step 1: Coating photoresist on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com