Automatic recycling device of waste lead storage battery electrolyte

A lead-acid battery and recycling device technology is applied in the field of waste lead-acid battery electrolyte automatic recycling device, which can solve the problems of increased recycling cost, high construction cost, and insufficient separation, and achieves improved recycling efficiency, high degree of automation, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

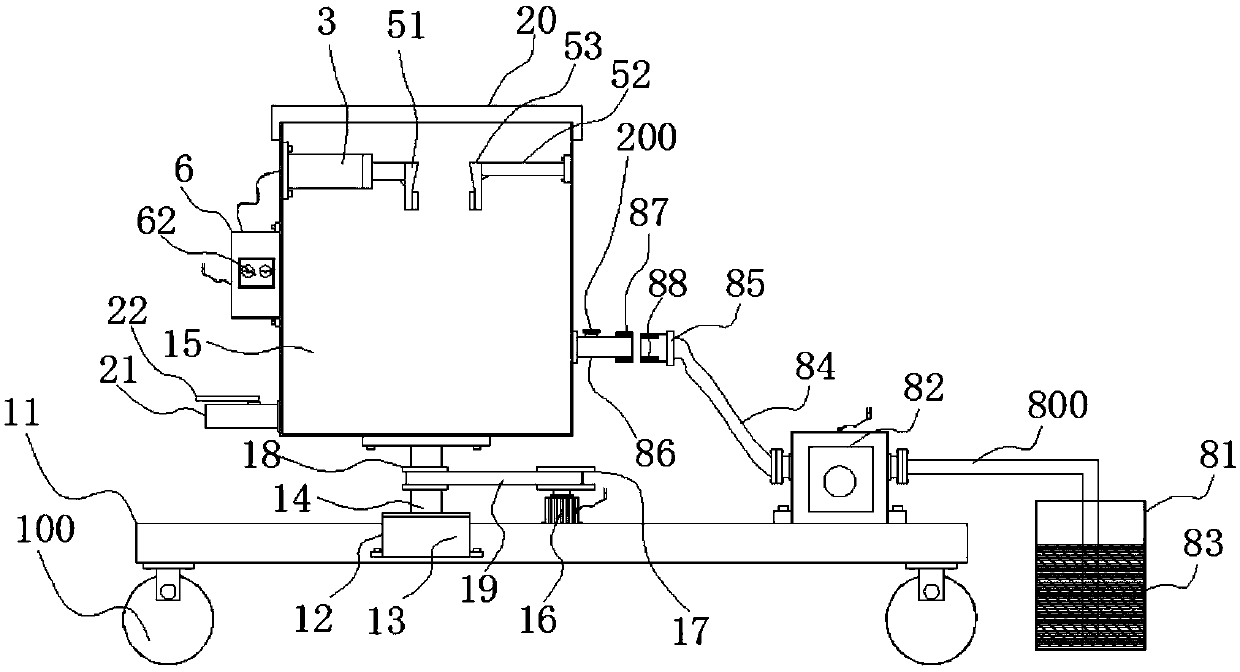

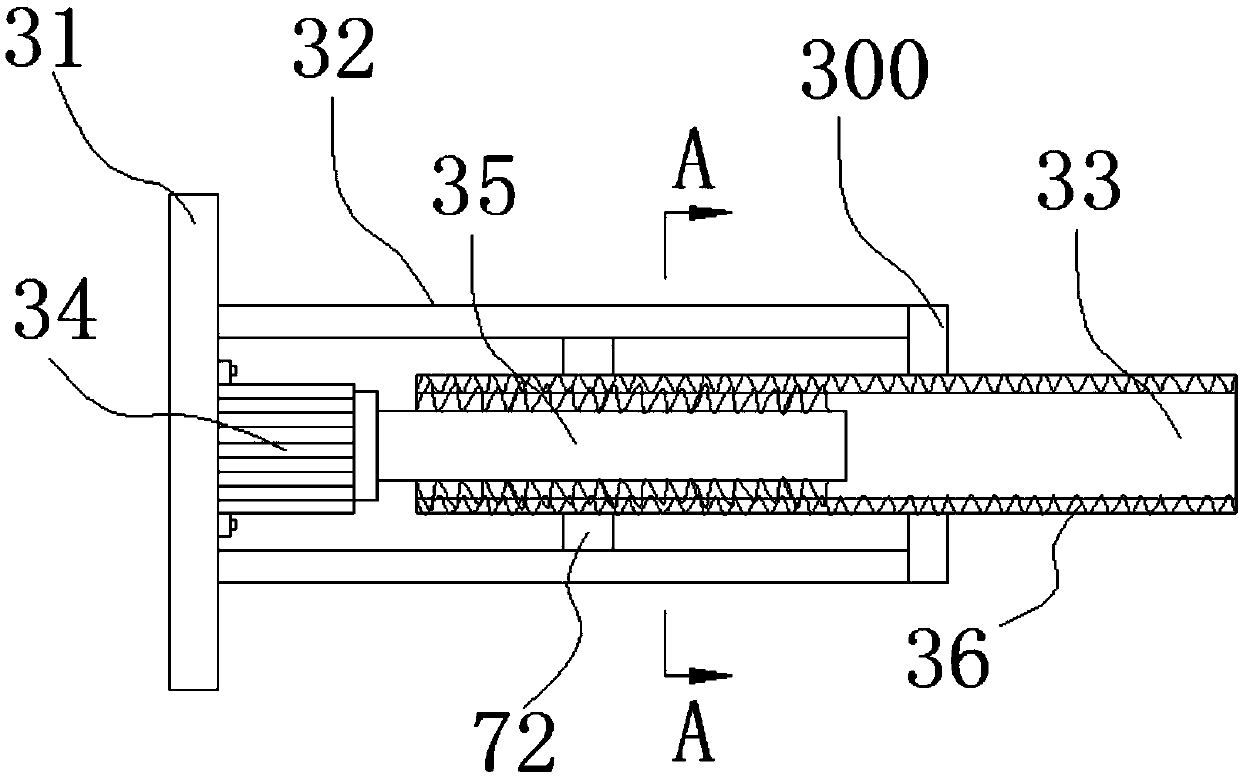

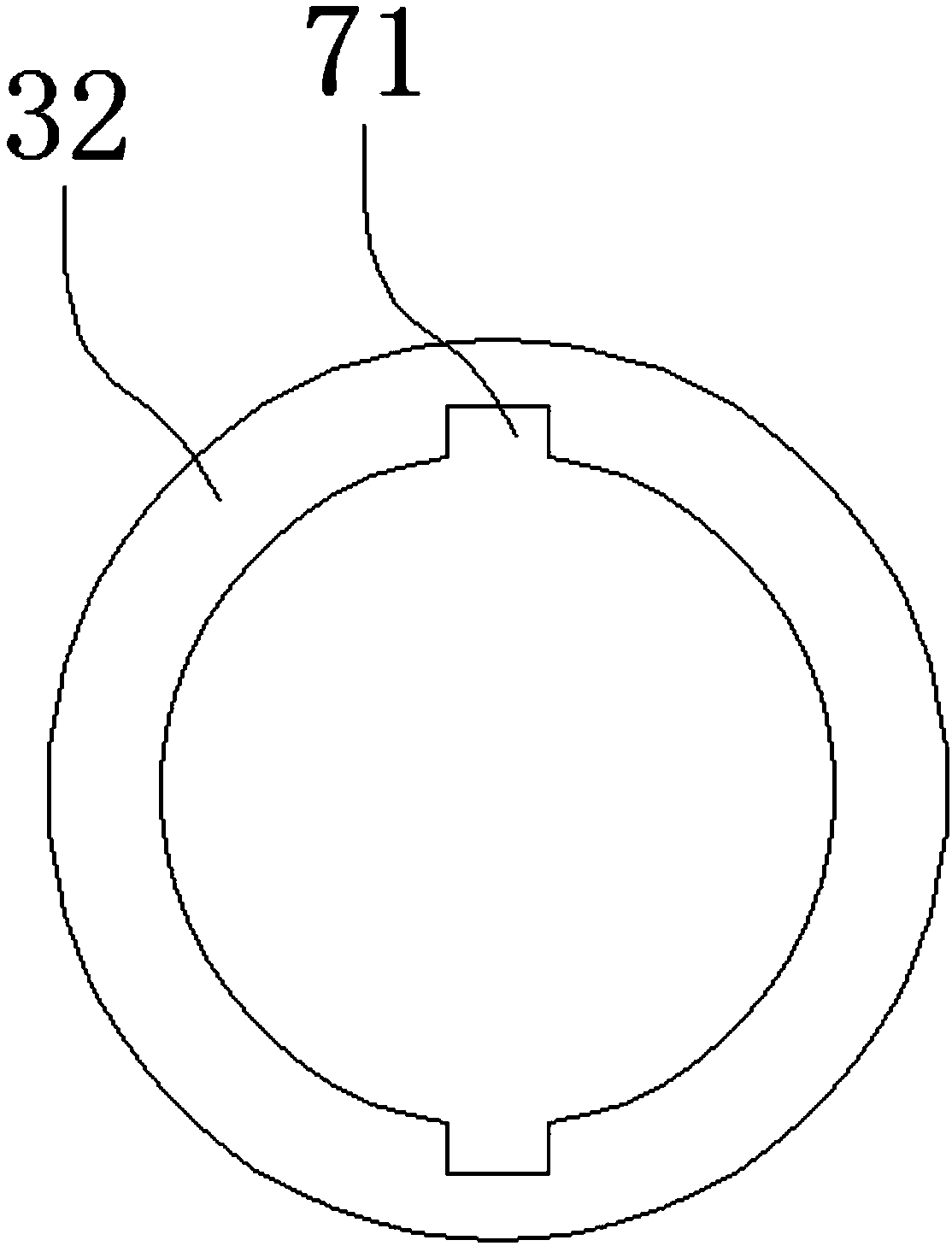

[0017] Such as figure 1 , 2 As shown in , 3 and 4, a waste lead storage battery electrolyte automatic recovery device comprises a horizontal horizontal plate 11, a groove 12 is arranged on the top of the horizontal horizontal plate 11, a bearing 13 is fixed in the groove 12, and the inner ring of the bearing 13 Connect a vertical column 14, the top of the vertical column 14 is fixed with a rotating container 15 with an opening, the top of the horizontal horizontal plate 11 is fixed with a driving motor 16 by screws, and a driving pulley 17 is fixed on the output shaft of the driving motor 16, the vertical column A passive pulley 18 is fixed on the 14, and the driving pulley 17 and the passive pulley 18 are connected by a belt 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com