Swing type superfine natural pearl powder screening device

A screening device and swing-type technology, applied in the field of swing-type ultra-fine natural pearl powder screening devices, can solve problems such as difficulties, blocking holes in the screen, and achieve the advantages of improving the flow rate, avoiding residues, and speeding up the discharge. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

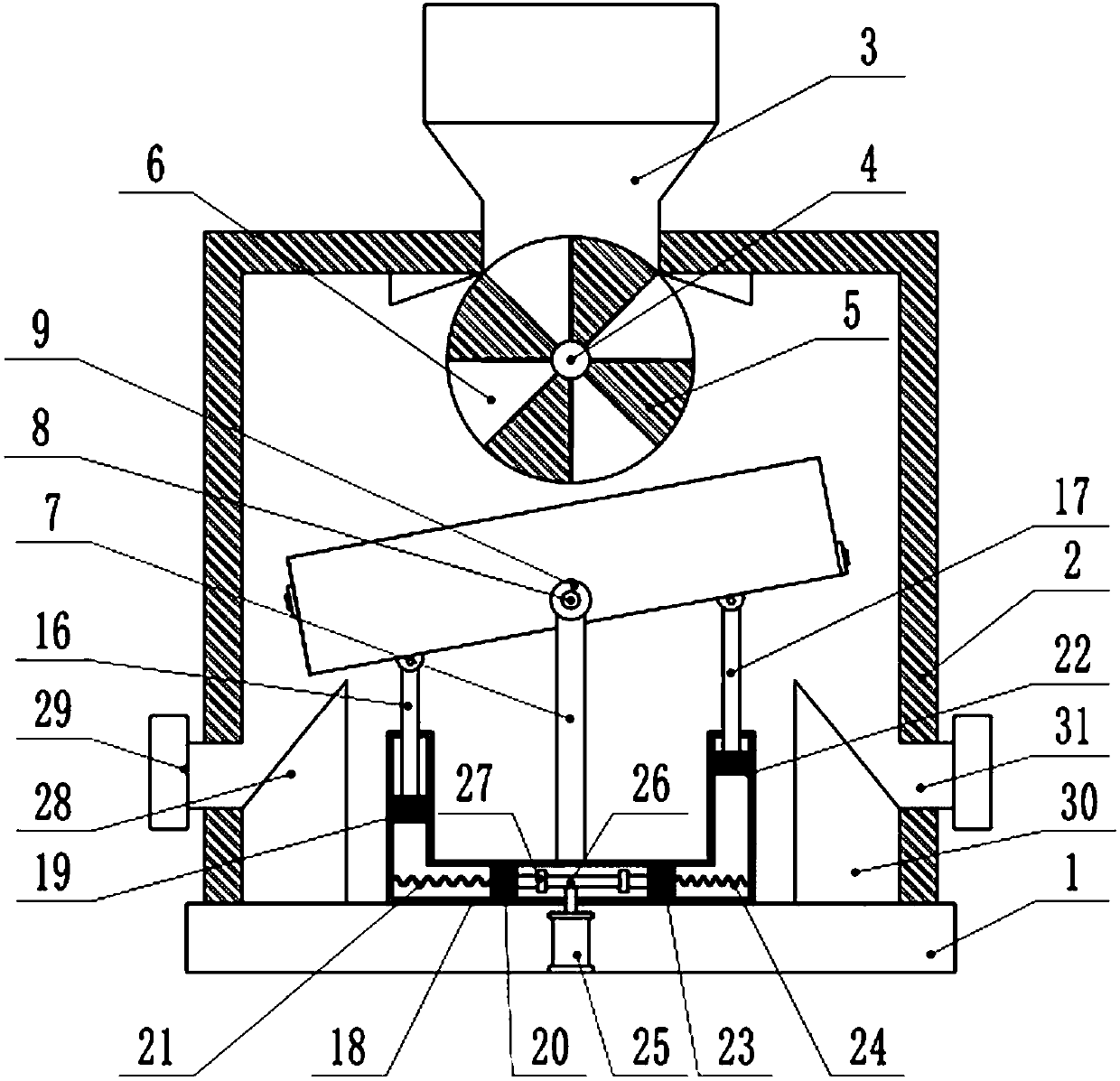

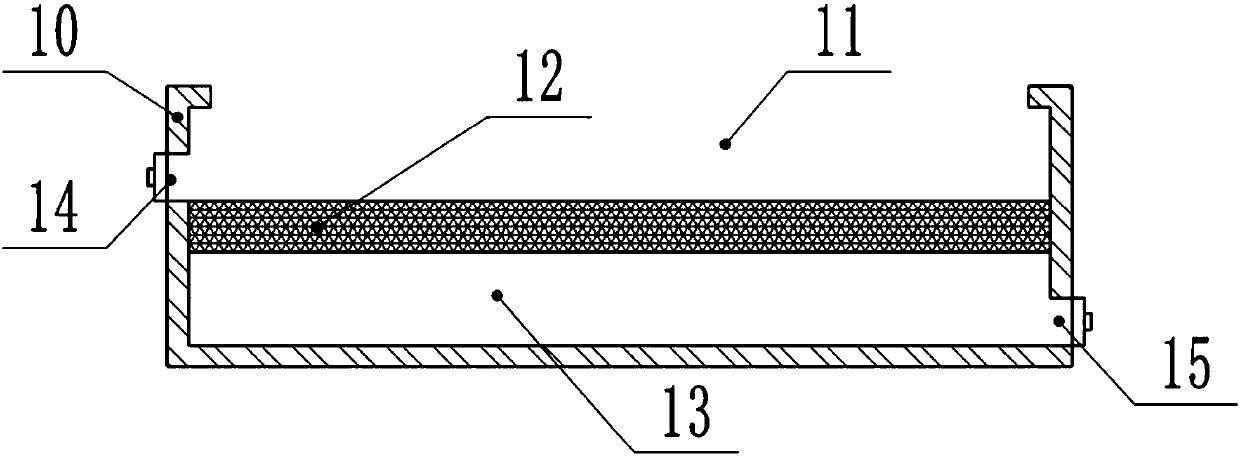

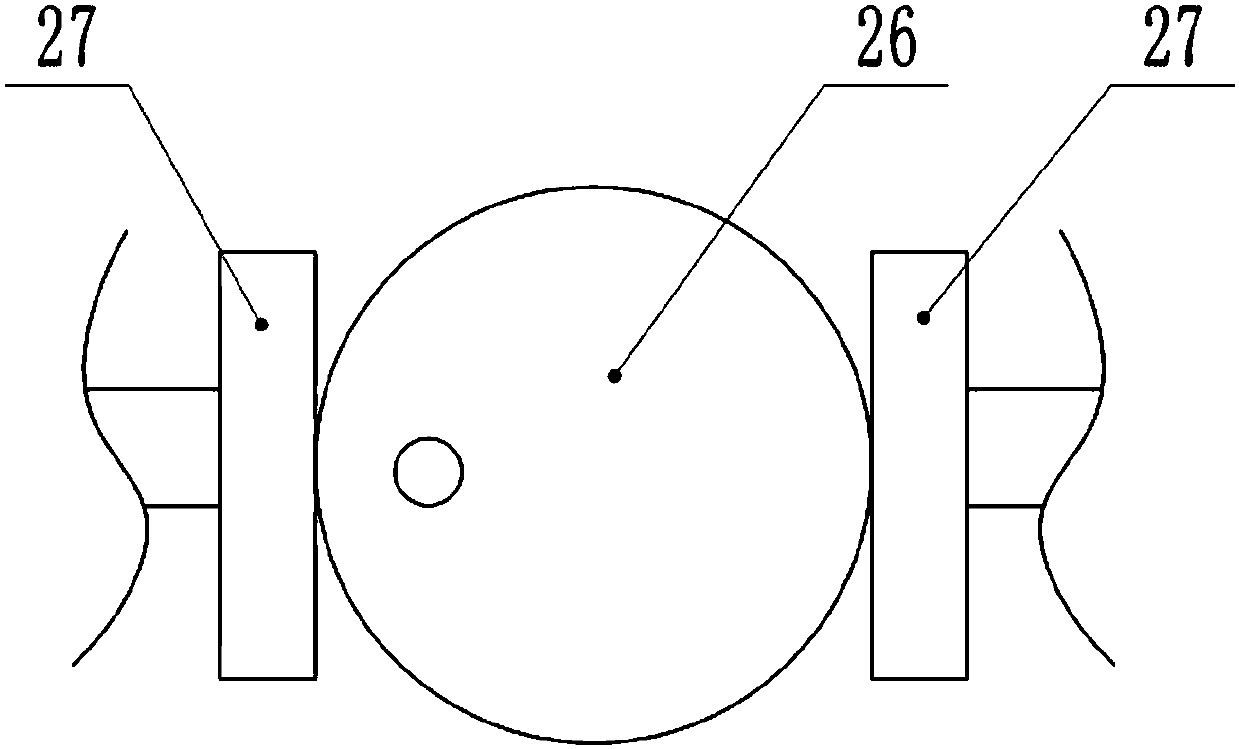

[0027] see Figure 1-3 , a swinging type superfine natural pearl powder screening device, comprising a base 1, a screening box 2 and a swing device 18, the base 1 is provided with a screening box 2, and a bolt is passed between the screening box 2 and the base 1 Fixedly connected, the sieving box 2 is provided with a feed funnel 3 for storing pearl powder after grinding, the rear side of the sieving box 2 is fixedly equipped with a rotating motor 4, and the output shaft of the rotating motor 4 is forward and On the output shaft of the rotating motor 4, the interference fit is installed with an interval feeding tray 5, which is positioned at the inside of the screening box 2 and is located directly below the feed funnel 3, and the interval lower tray 5 is positioned at the bottom of the feed funnel 3. There are material storage tanks 6 at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com