A method for controlling the smooth running of an engine

A control method and engine technology, applied in the direction of engine control, automatic control, automatic control, etc., can solve the problems of engine jitter and uneven energy of engine cylinders, and achieve the effect of reducing energy fluctuation, solving jitter problems, and being simple and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

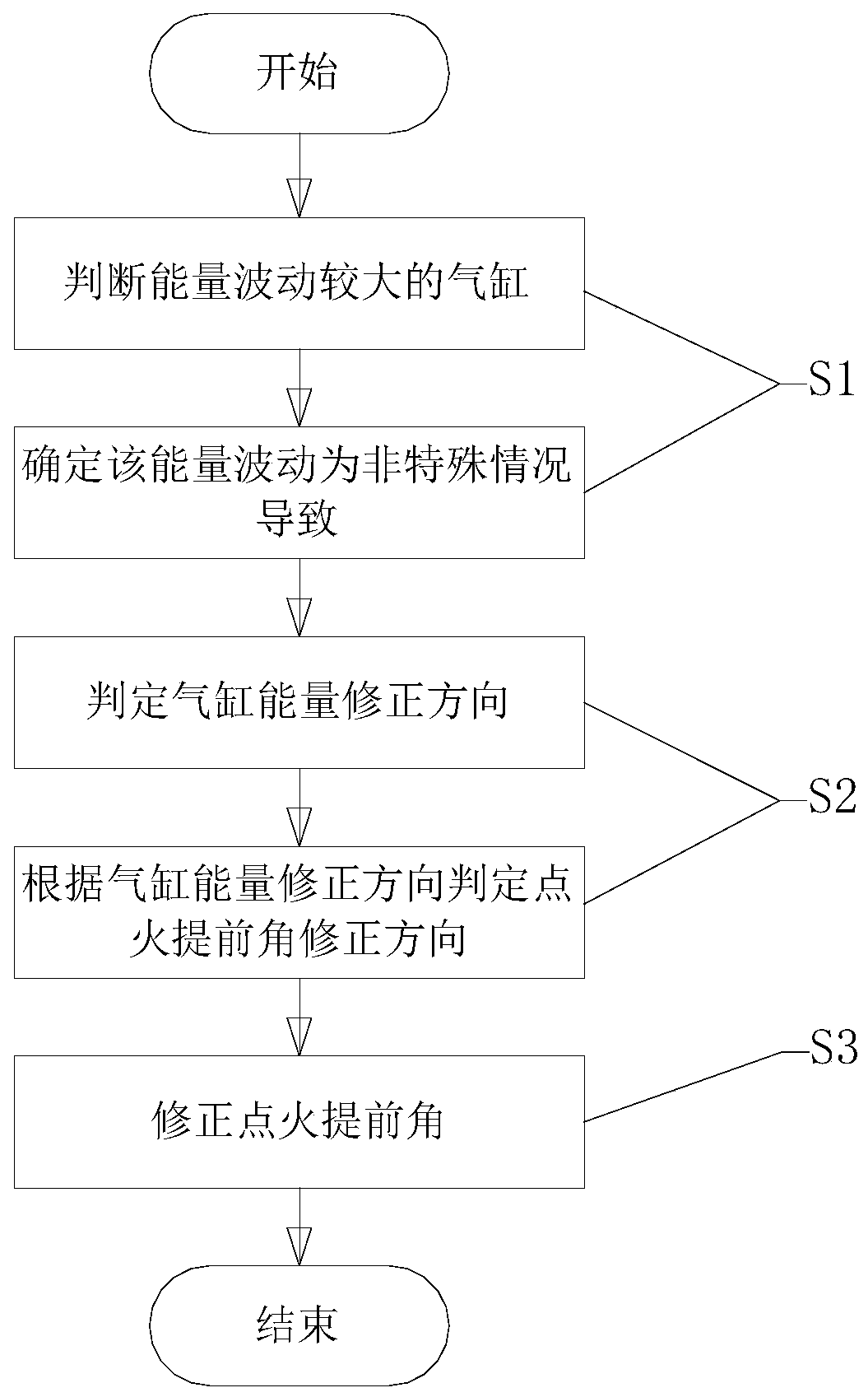

[0030] refer to figure 1 , which shows a flow chart of the method for controlling the smooth running of the engine in this embodiment.

[0031] S1: Determine the cylinder with large energy fluctuation and determine that the energy fluctuation is not caused by special working conditions. Specifically, to determine the cylinders with large energy fluctuations, the inventors found that the engine management system can obtain the segment time of each cylinder of the engine when the engine is running, and the comparison with the segment time of the cylinders adjacent to the work can be reflected. The working energy status of the cylinder. Segmentation time refers to the effective work time of each cylinder that is started, that is, the time used in the power stroke, which can be obtained by the engine management system. If the working energy of a certain cylinder is large, its running speed will be faster during the power stroke. The segmentation time is also small. If the absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com