Long tongue type hoop

A long tongue and clamp technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of affecting the sealing effect of clamps, high production costs, and many parts, so as to avoid the problem of sealing dead angle, Low production cost and the effect of reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

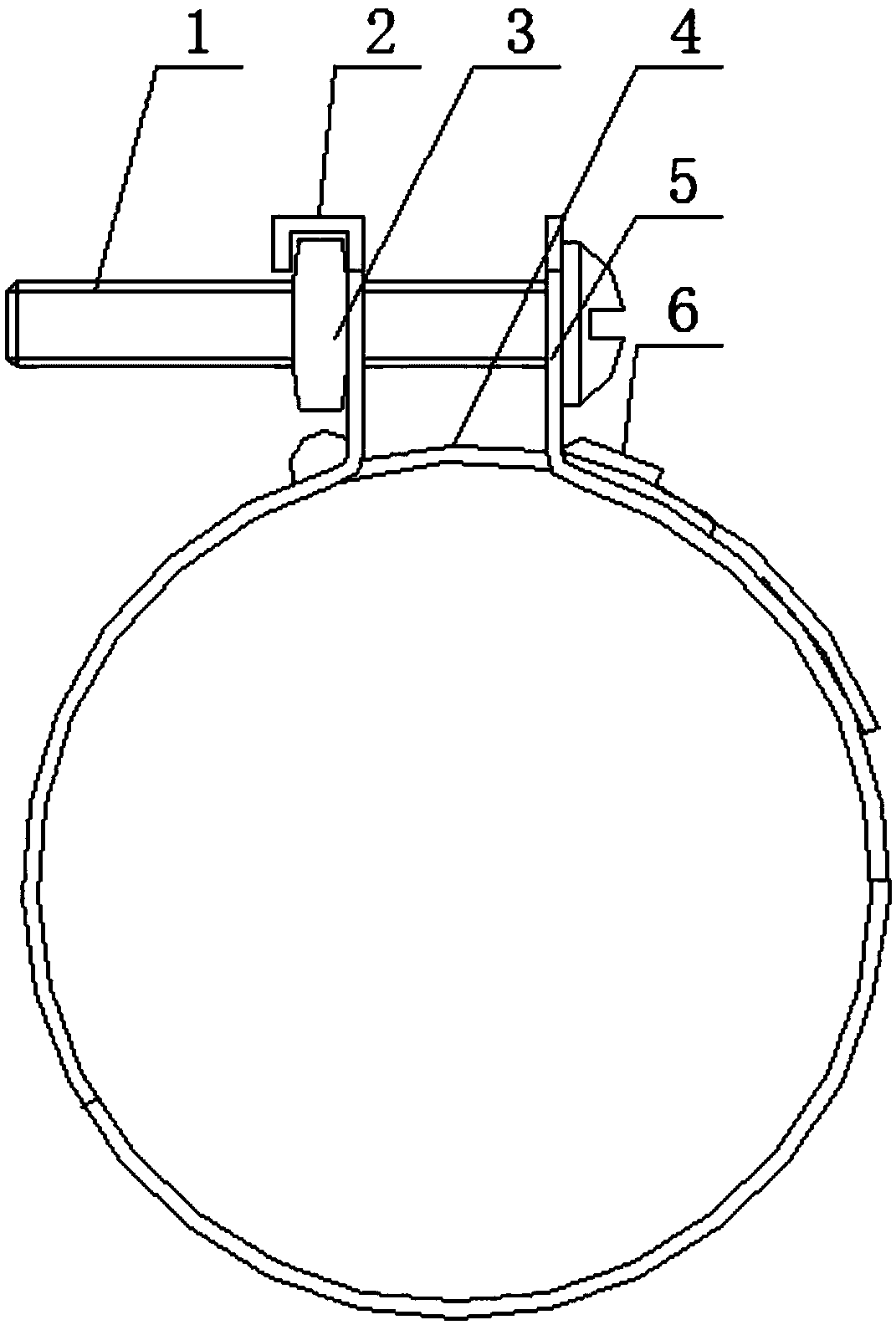

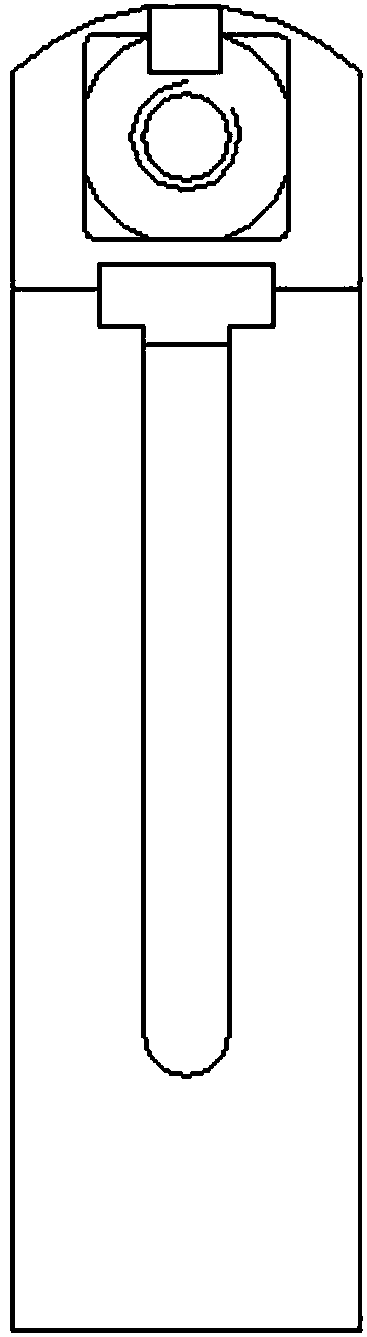

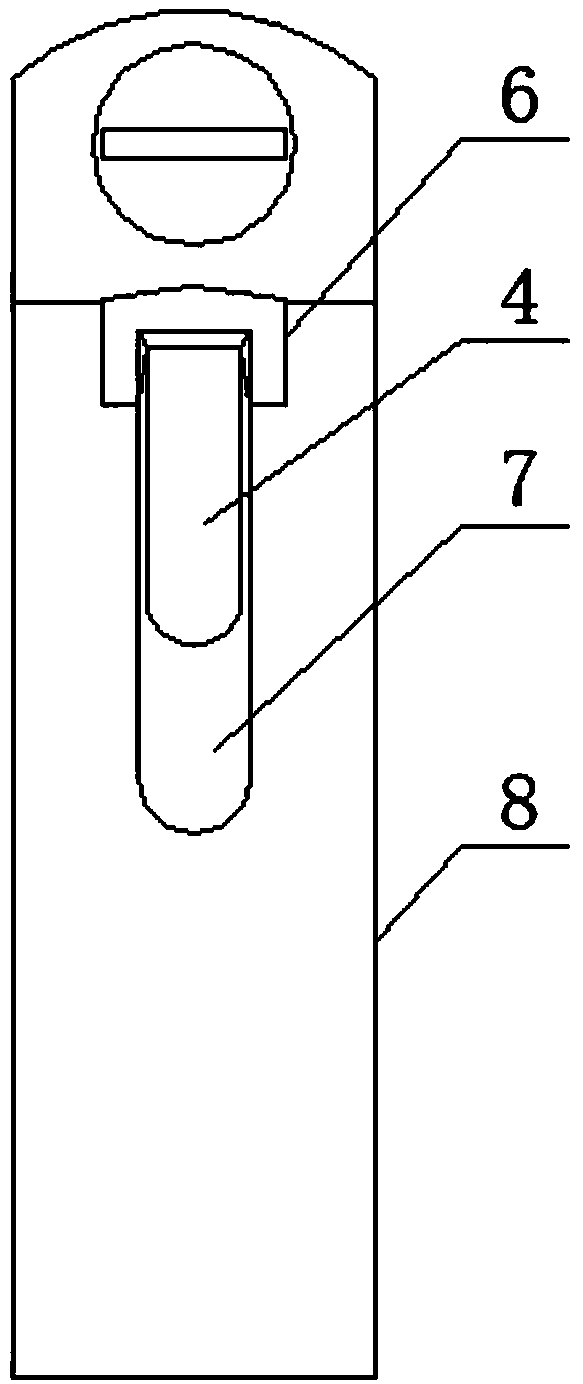

[0020] A long-tongue clamp, including a steel strip coil 8, a bolt 1 and a nut 3, the innovation of which is that both ends of the steel strip coil are bent vertically upward to form a baffle part 5, and the two baffle parts Mounting holes are provided on each of them, and the nuts are opposite to the mounting holes and welded on the outside of one of the baffles. The bolts are fitted on the mounting holes and cooperate with the nuts to adjust the diameter of the steel coil. A long tongue 4 is stamped on the steel strip roll below the baffle at one end, and a long hole 7 is formed on the steel strip below the other end baffle. The long tongue is bent 180° and embedded in the long inside the hole.

[0021] A shield 2 is also bent outwards ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com