A cost-sensitive early fault detection method for industrial big data based on graph semi-supervised

An early failure and cost-sensitive technology, applied in electrical testing/monitoring, testing/monitoring control systems, program control, etc., can solve the problem of failure to effectively avoid failure losses, equipment misdiagnosis costs are not equal, and failure to meet fault diagnosis requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

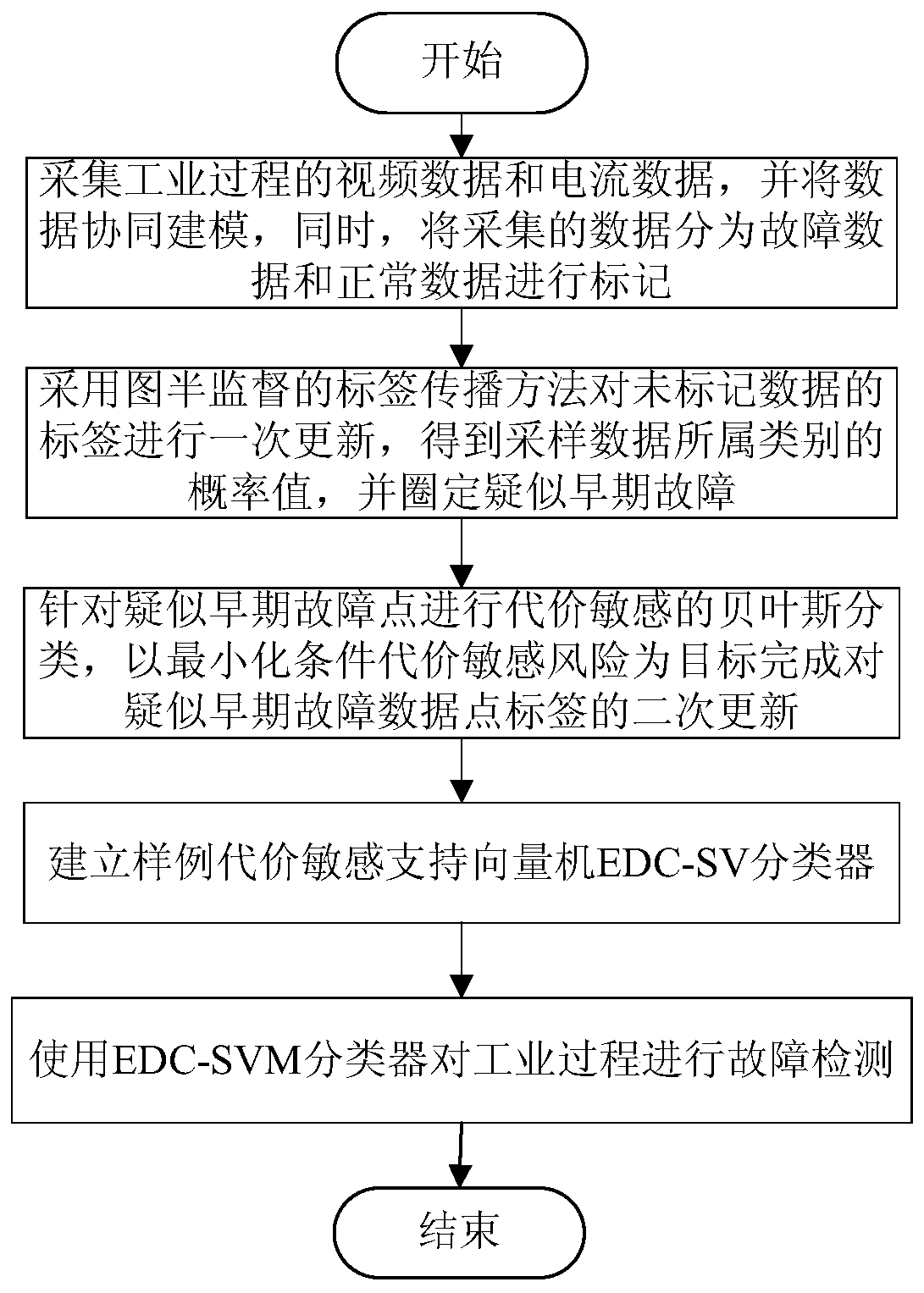

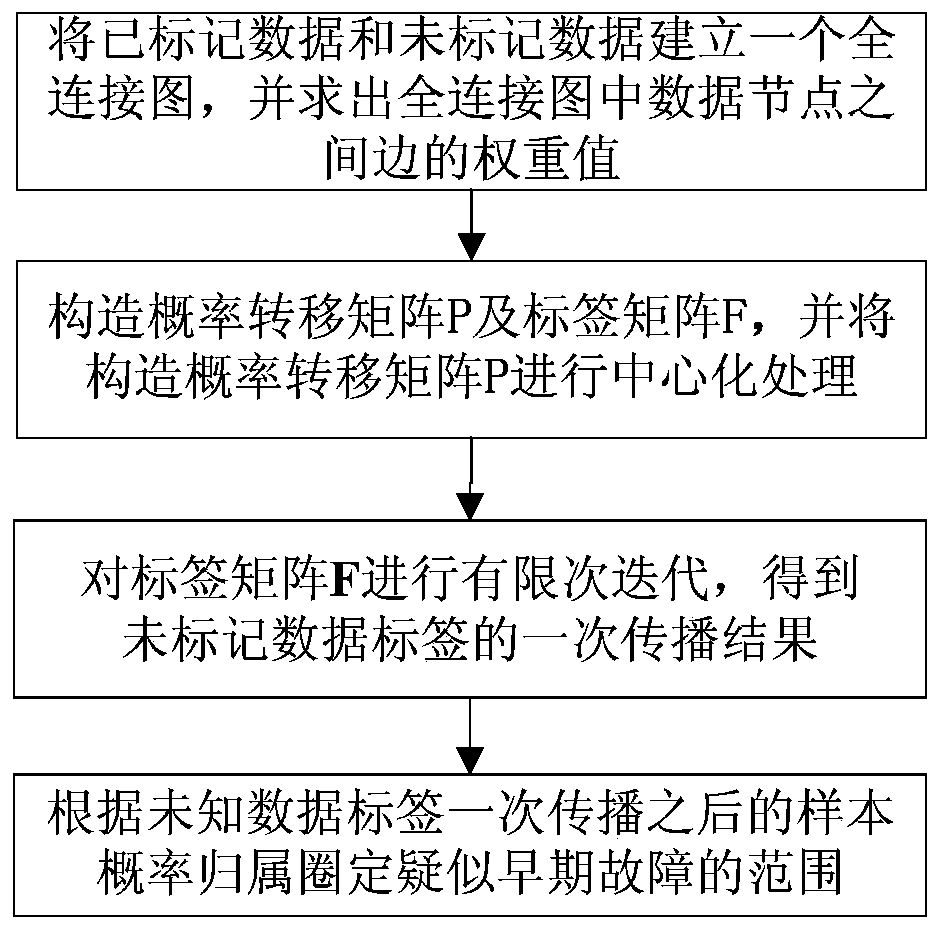

Method used

Image

Examples

Embodiment Construction

[0092] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

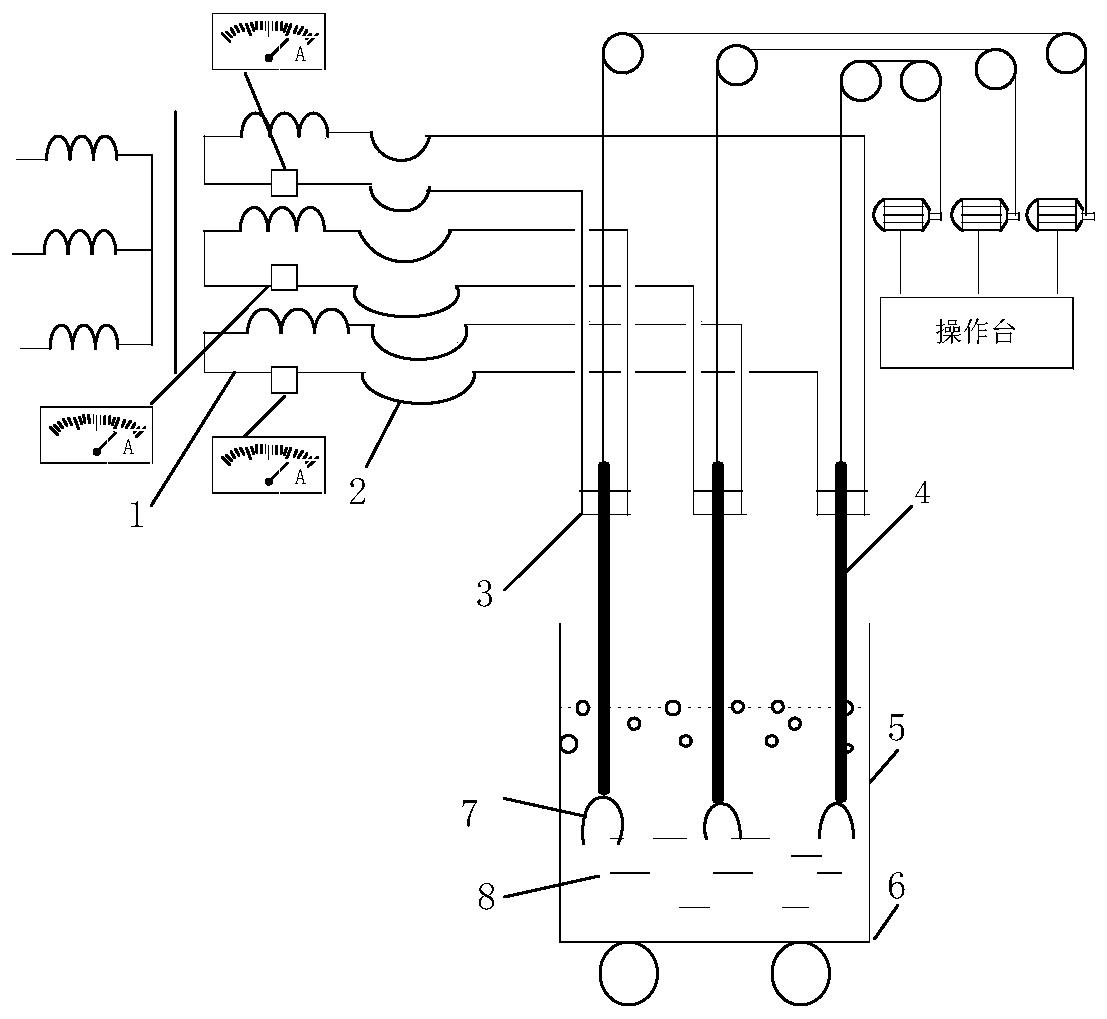

[0093] Fused magnesia furnace is one of the main equipment used to produce fused magnesia. With the development of smelting technology, fused magnesia furnace has been widely used in the magnesia production industry. Electric smelting magnesia furnace is a kind of smelting furnace with electric arc as heat source. Its heat is concentrated and can smelt magnesia well. The smelting process of the electric fused magnesium furnace goes through the process stages of melting, separation, purification and crystallization. The industrial process of smelting magnesium furnace is as follows: figure 1 As shown, the equipment used includes a transformer 1, a short network 2, an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com