Improve the purity of materials recycled from disposable absorbent articles

An absorbent product, disposable technology, applied in the direction of plastic recycling, recycling technology, application, etc., can solve the problems of material waste, low efficiency of recycling technology, difficulty in separating cellulose fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

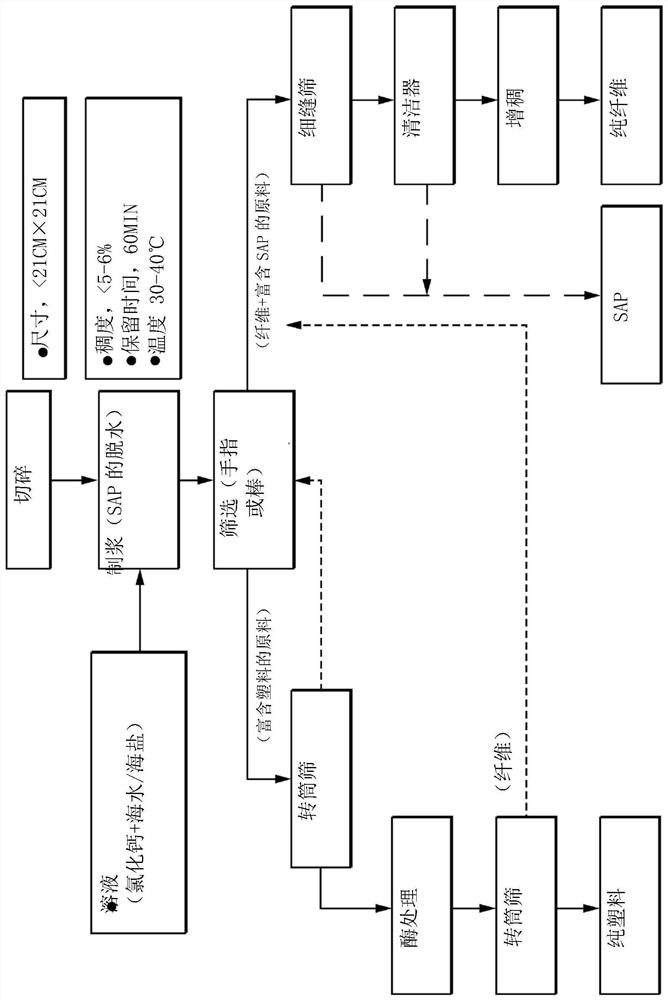

[0014] The present disclosure relates to methods for increasing the purity and quantity of materials, including synthetic materials, recovered from recycled disposable absorbent articles.

[0015] More specifically, the present disclosure relates to methods for easily and economically separating materials in disposable absorbent articles, removing moisture absorbed by superabsorbent polymers (SAP), and recovering constituent materials such as polymers, cellulose fibers, and superabsorbent polymers. way of things.

[0016] The goal of the recycling method is to create a clean stream of recycled fibre, plastic and SAP. Residual fibers need to be removed from the plastic stream in order to consider it a "clean" recycled plastic stream.

[0017] In order to separate such superabsorbent polymer (in the gel state) and cellulose pulp into separate resources, the superabsorbent polymer must be transformed from the gel state into primary particles or other state.

[0018] Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com