Injection molding method for mesh filter, injection molding mold, and mesh filter

An injection molding and filter technology, which is applied to membrane filters, chemical instruments and methods, fixed filter element filters, etc., can solve problems such as differences in filtration performance, increase in manufacturing man-hours, and uneven shapes and areas of openings 102. , to achieve the effect of improving durability, easy work control and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

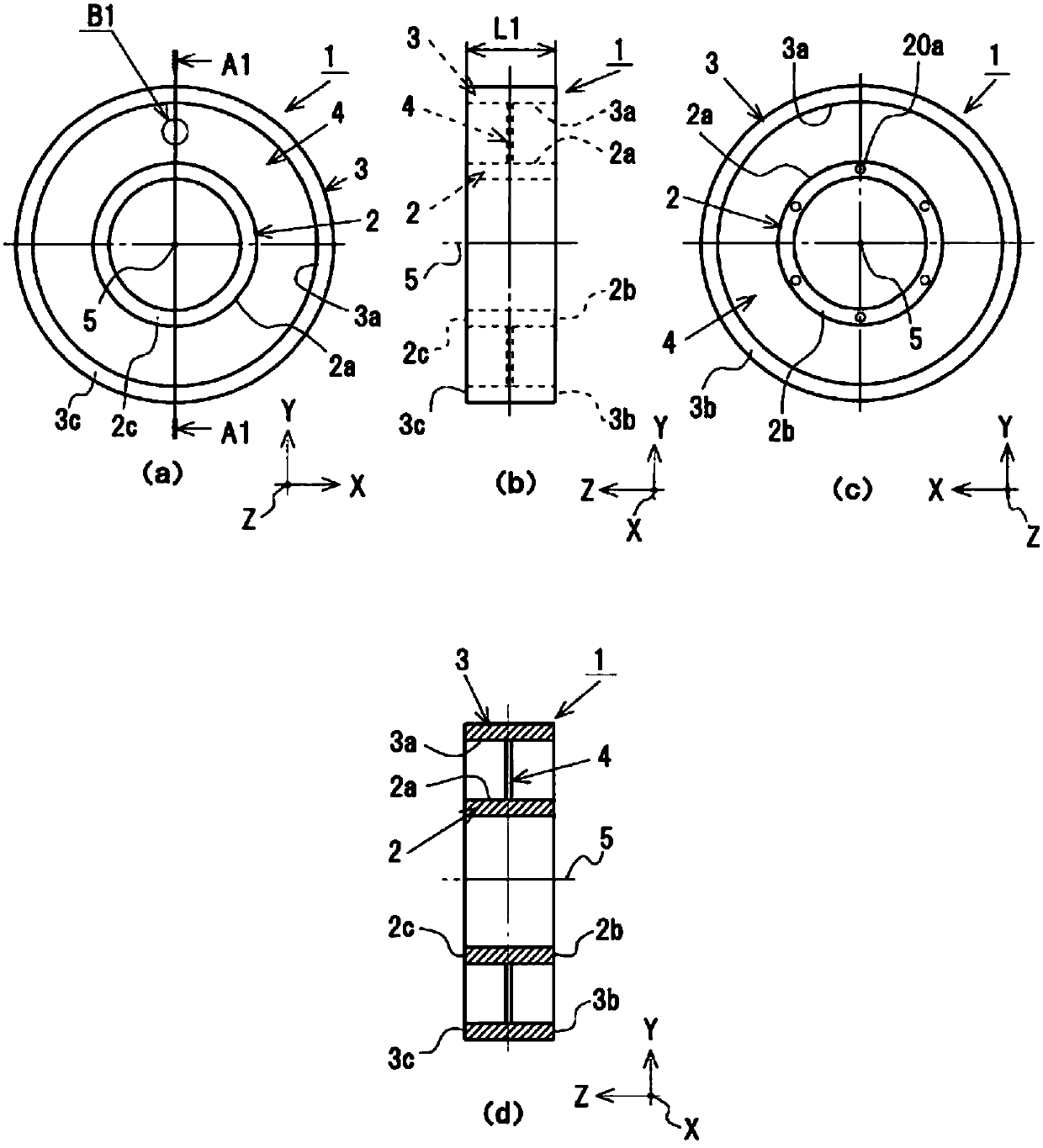

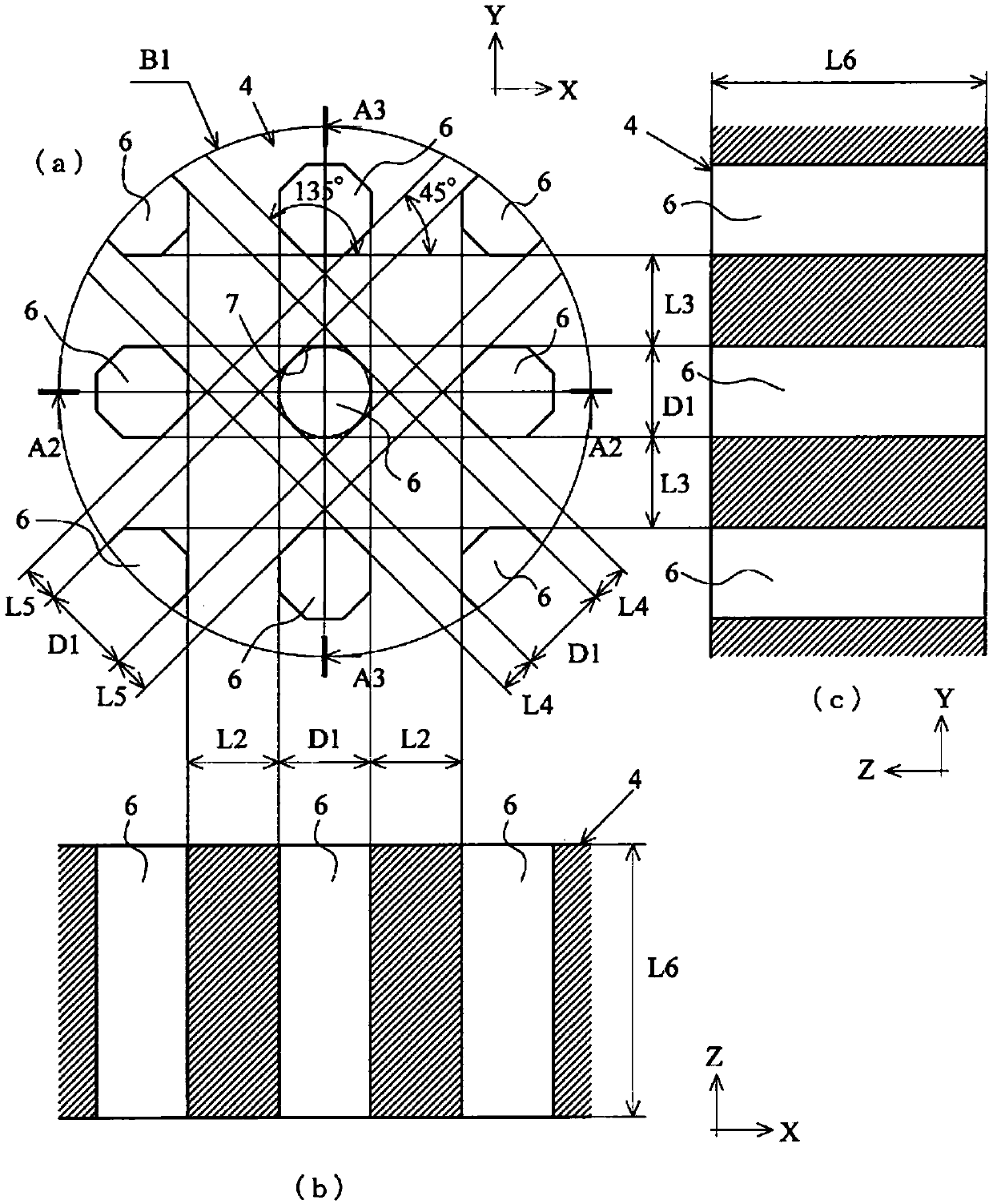

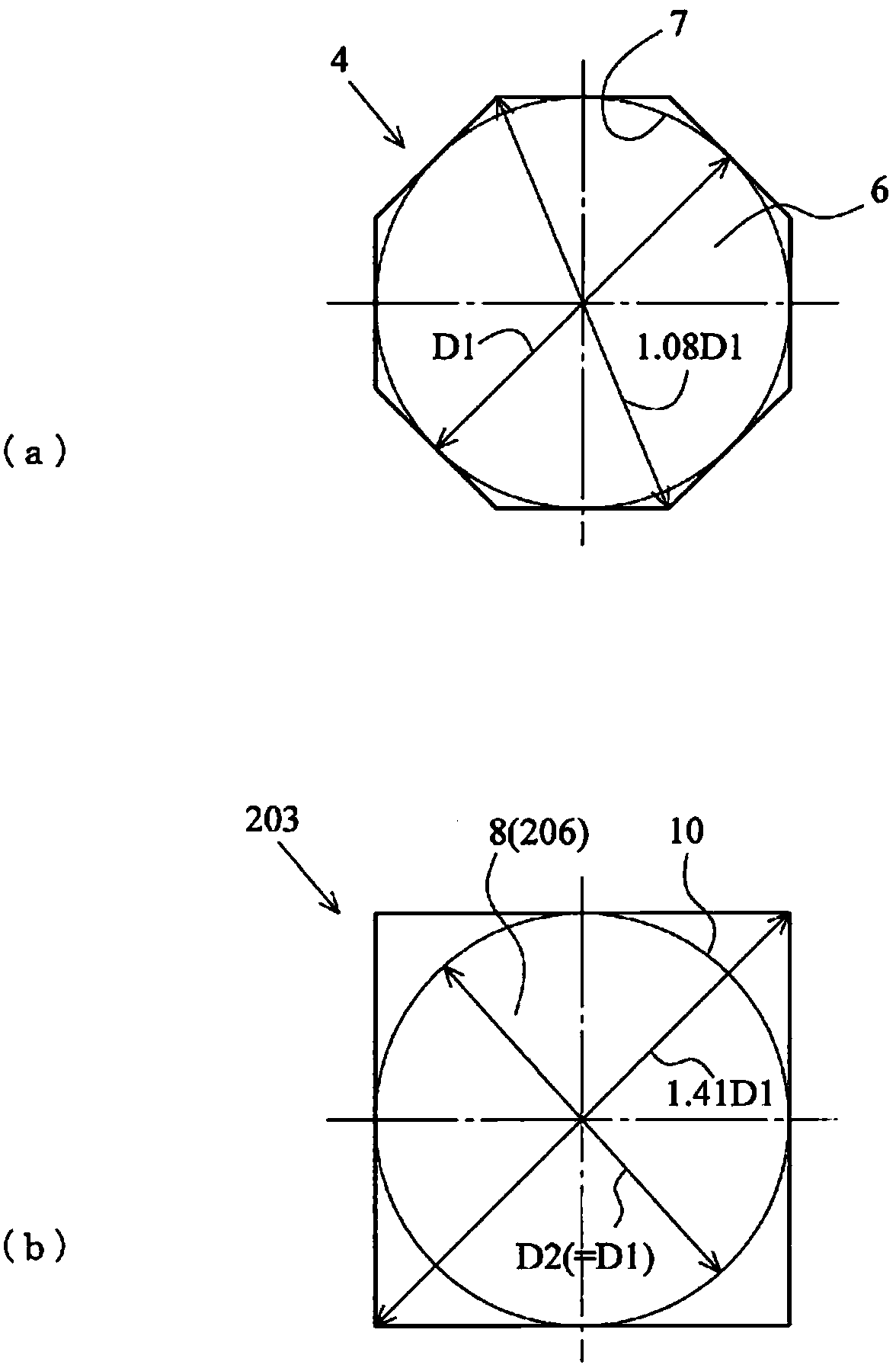

[0038] Figure 1 to Figure 2 It is a figure which shows the mesh filter 1 which concerns on 1st Embodiment of this invention. It should be noted, figure 1 (a) is a front view of the mesh filter 1, figure 1 (b) is a side view of the mesh filter 1, figure 1 (c) is a rear view of the mesh filter 1, figure 1 (d) is along figure 1 (a) is a cross-sectional view of the mesh filter 1 shown by the line A1-A1. also, figure 2 (a) is figure 1 Enlarged view of part B1 of (a) (partially enlarged view of mesh filter 1), figure 2 (b) is along figure 2 (a) A2-A2 line A2-A2 cross-sectional view (partial enlarged cross-sectional view of the screen filter 1), figure 2 (c) is along figure 2 (a) A3-A3 line cut-away cross-sectional view (partially enlarged cross-sectional view of the mesh filter 1).

[0039] As shown in these figures, the mesh filter 1 integrally has a cylindrical inner tube 2 (inner frame), and a cylindrical outer tube 3 (enclosed by an inner frame) concentric w...

no. 2 approach

[0060] Figure 6 It is a figure which shows the mesh filter 1 of 2nd Embodiment of this invention. to the Figure 6 In the shown mesh filter 1 of this embodiment, the same parts as those of the mesh filter 1 of the first embodiment are denoted by the same reference numerals, and descriptions that overlap with those of the mesh filter 1 of the first embodiment are omitted. . It should be noted, Figure 6 (a) is a front view of the mesh filter 1, Figure 6 (b) is a side view of the mesh filter 1, Figure 6 (c) is a rear view of the mesh filter 1, Figure 6 (d) is along Figure 6 (a) is a cross-sectional view of the mesh filter 1 shown by the line A6-A6.

[0061] The mesh filter 1 of the present embodiment has an inner filter portion 27 formed radially inside the inner cylinder 2 from the central axis 5 of the inner cylinder 2 to the inner peripheral surface 2 d of the inner cylinder 2 . The inner filter portion 27 is formed in the same manner as the filter portion 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com