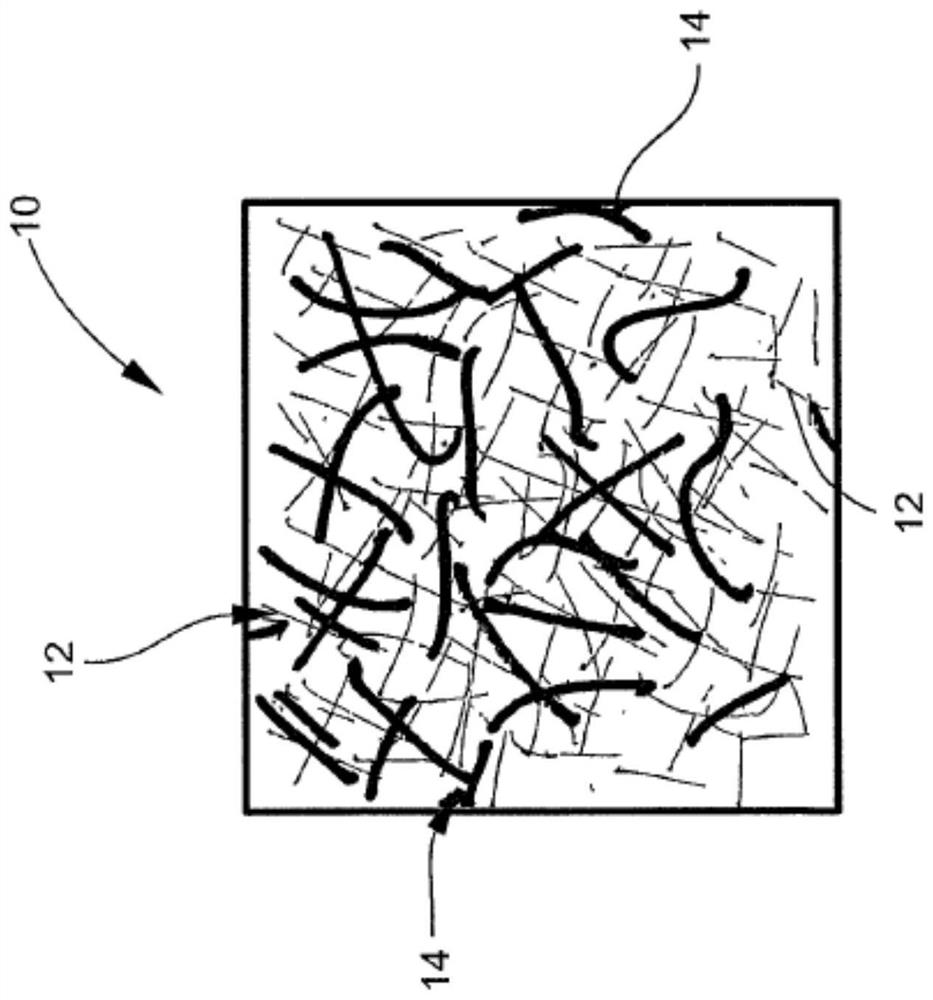

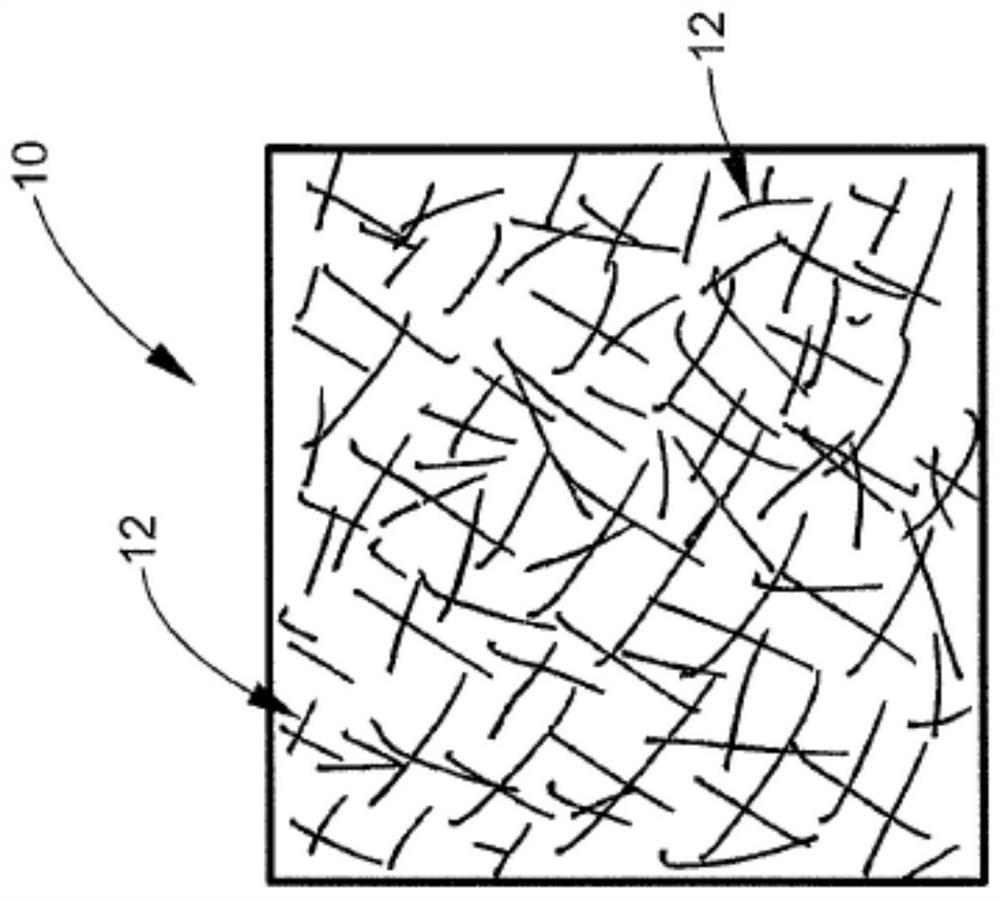

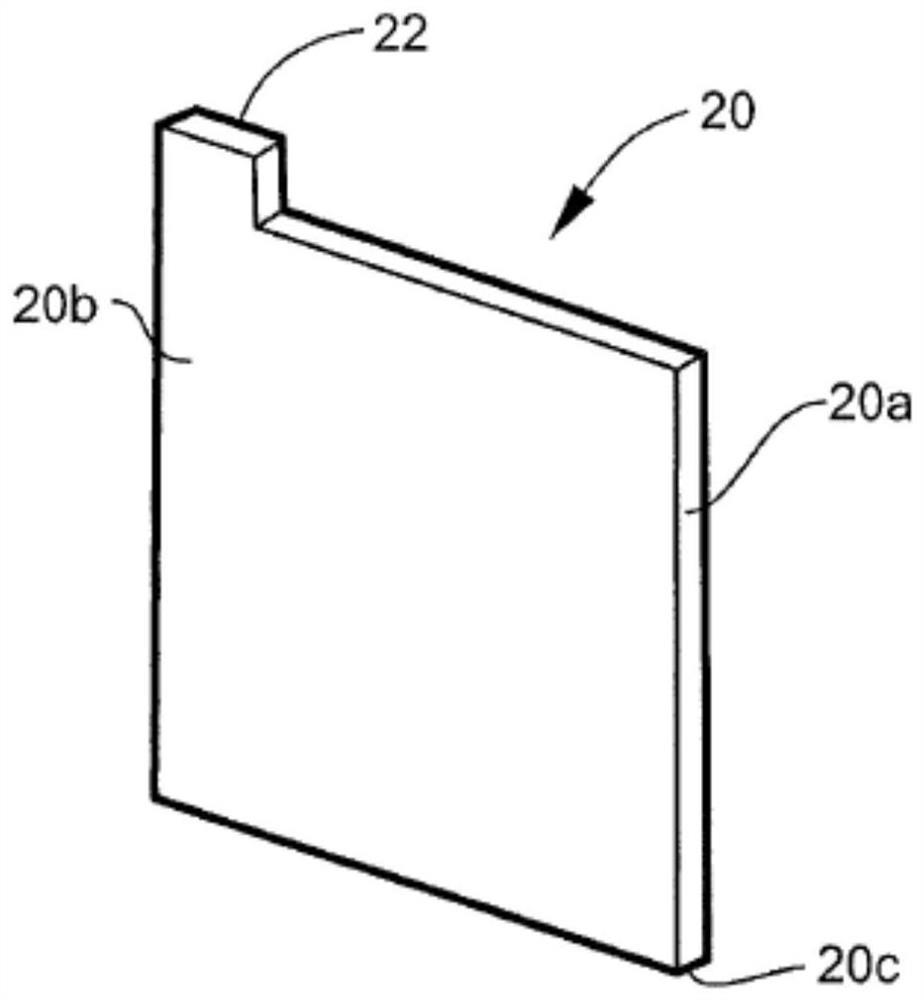

Absorbent glass mat, lead-acid battery, and related manufacturing methods

A glass mat, absorbent technology, used in absorbent glass mat, lead-acid battery and related manufacturing fields, can solve the problem of slow acid filling process of AGM separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] Possible non-limiting examples include:

[0107] 1. AGM up to 20% solubles

[0108] 2. AGM up to 10% solubles

[0109] 3. AGM up to 5% solubles

[0110] 4. Soluble fiber + soluble granular AGM

[0111] 5. Compressed AGM separators change from 80% or less porosity to 85% or more porosity upon addition of acid

[0112] 6. Compressed AGM separators change from 90% or less porosity to 95% or more porosity upon addition of acid

[0113] 7. Positive plate / thin dissolved layer / AGM

[0114] 8. Negative plate / thin dissolved layer / AGM

[0115] 9. Positive plate / thin soluble layer / soluble AGM

[0116] 10. Negative plate / thin soluble layer / soluble AGM

[0117] 11. Thin soluble layer / AGM / thin soluble layer

[0118] 12. Sticky paper with dissolvable layer

[0119] 13. Soluble AGM / Soluble Sticker

[0120] 14. Soluble AGM / Soluble Sticker

[0121] 15. Soluble AGM / Soluble layer paste paper

[0122] 16. Soluble layer AGM / Soluble layer paste paper

[0123] 17. Soluble ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com