Spring tobacco clip for tobacco flue curing

A technology of flue-cured tobacco and tobacco clips, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve problems such as overdrying, laying on the lower layer of tobacco clips, and reduced diameter, so as to avoid falling off, ensure the quality of curing, and avoid unsatisfactory uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

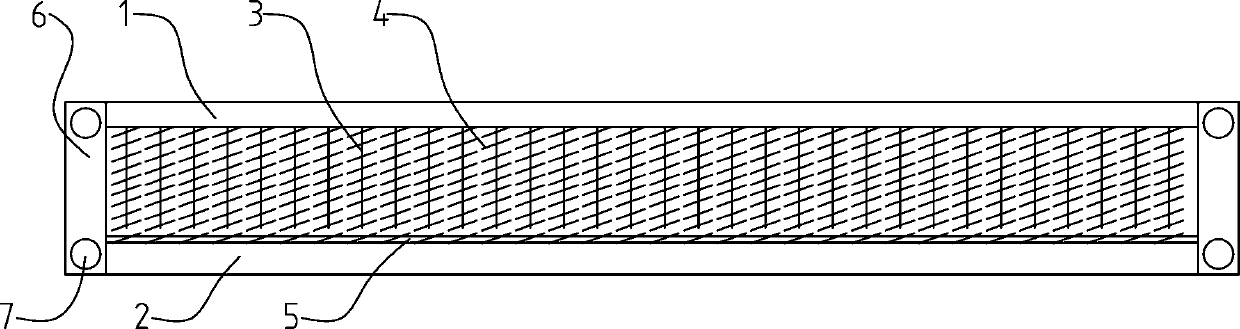

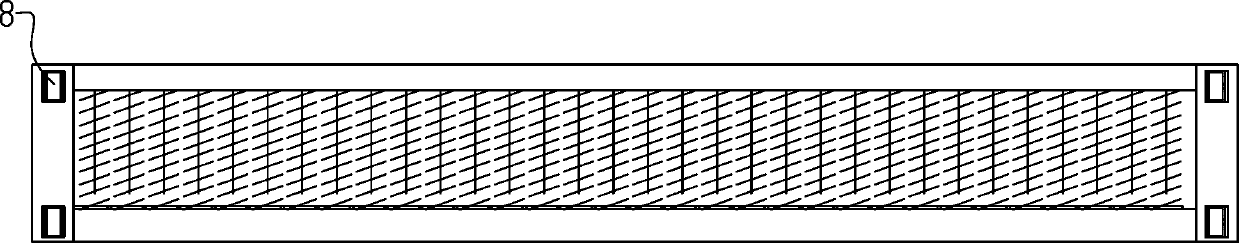

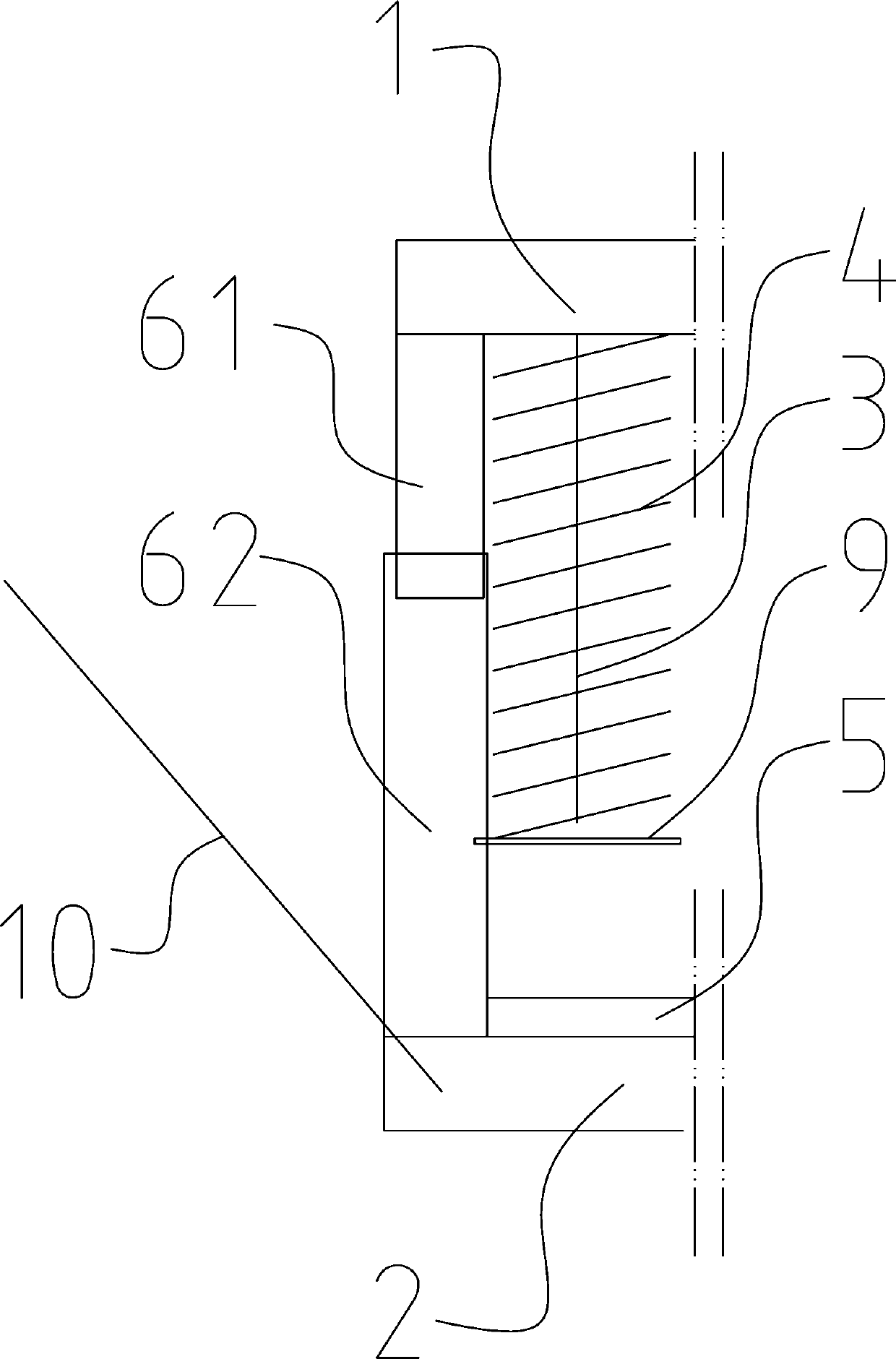

[0028] Such as Figure 1~7 Among them, a flue-cured tobacco spring cigarette clip, including a first beam 1 and a second beam 2, the first beam 1 is provided with a plurality of pins 3 along the length direction, and the first beam 1 and the second beam 2 are connected by a column 6 A spring 4 is sleeved around each pin 3, one end of the spring 4 is fixedly connected with the first beam 1, and the other end is a free end. When in use, place the fresh tobacco leaves roughly on the second crossbeam 2, and then align the pin 3 with the fresh tobacco leaves, so that the first crossbeam 1 and the second crossbeam 2 are connected together through the uprights, and the smoking operation is completed , during the curing process, the spring 4 will continue to compress the tobacco stems of the fresh tobacco leaves, so as to keep the tobacco leaves at approximately the same density, so as to ensure that the tobacco leaves meet the drying requirements at approximately the same time, and e...

Embodiment 2

[0039] On the basis of Example 1, in another preferred structure, a flue-cured tobacco spring clip includes a first crossbeam 1 and a second crossbeam 2, and the first crossbeam 1 and the second crossbeam 2 are connected by a column 6, which The feature is: the first beam 1 is provided with a plurality of springs 4 along the length direction, the free ends of the springs 4 are provided with a pressure frame 9, and an elastic pin is provided in the middle of the pressure frame 9;

[0040] The inner side of the second beam 2 is provided with two retaining strips 5 along the length direction, and a groove body for accommodating the free ends of the pins 3 is formed between the retaining strips 5, and the height of the retaining strips 5 is not less than 1 / 4 of the length of the elastic pins . In a preferred solution, an auxiliary rod is provided on the spring 4 to prevent radial bending deformation of the spring due to stress. With this structure, the pressure stroke of the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com