Manufacturing technique of eyeglasses foot

A production process and technology of glasses legs, which are applied in the field of production technology of glasses legs, can solve the problems of low production efficiency, poor product consistency, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

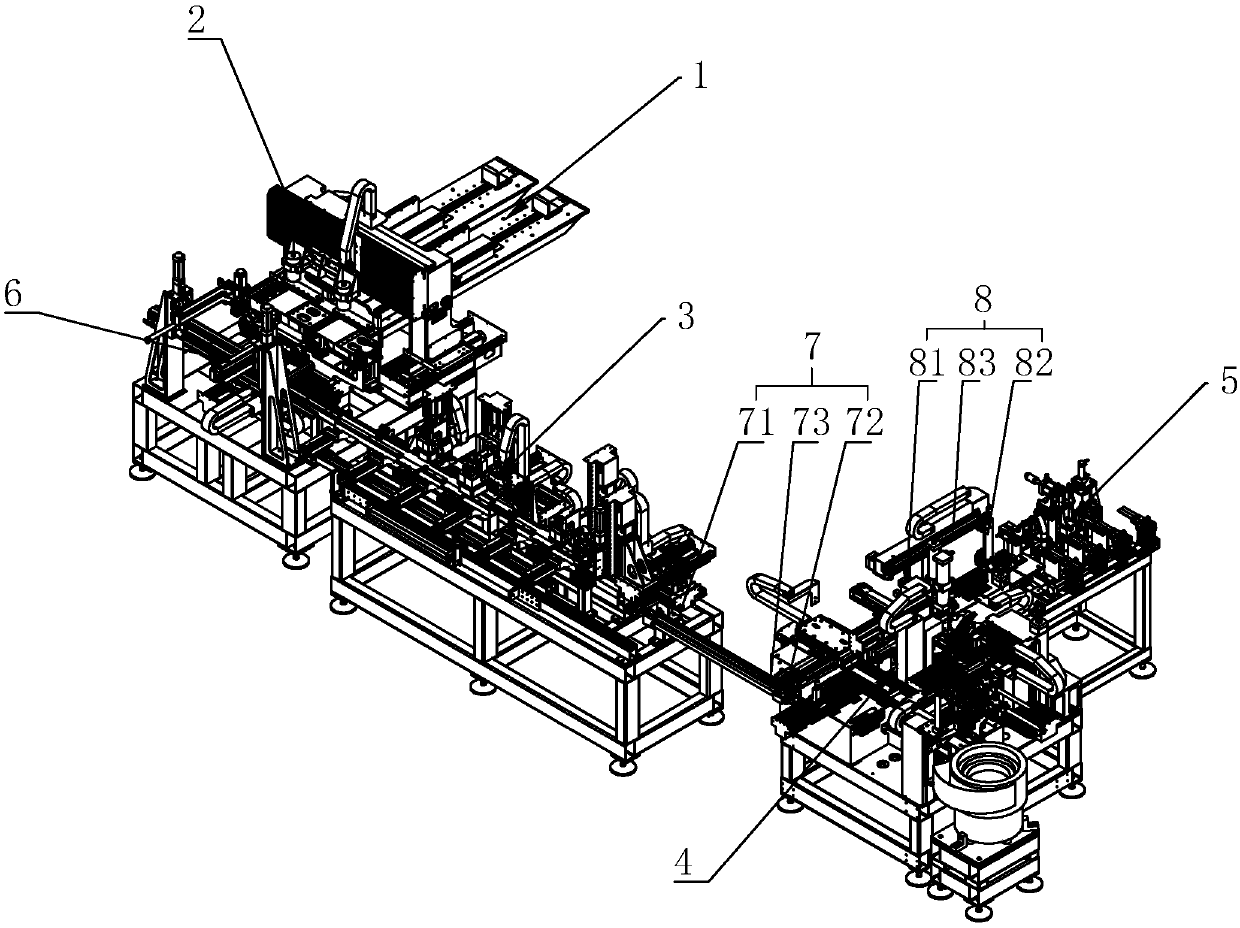

[0038] Refer to attached Figure 1 to Figure 14 The embodiment of an automatic production line for spectacle feet of the present invention will be further described in detail.

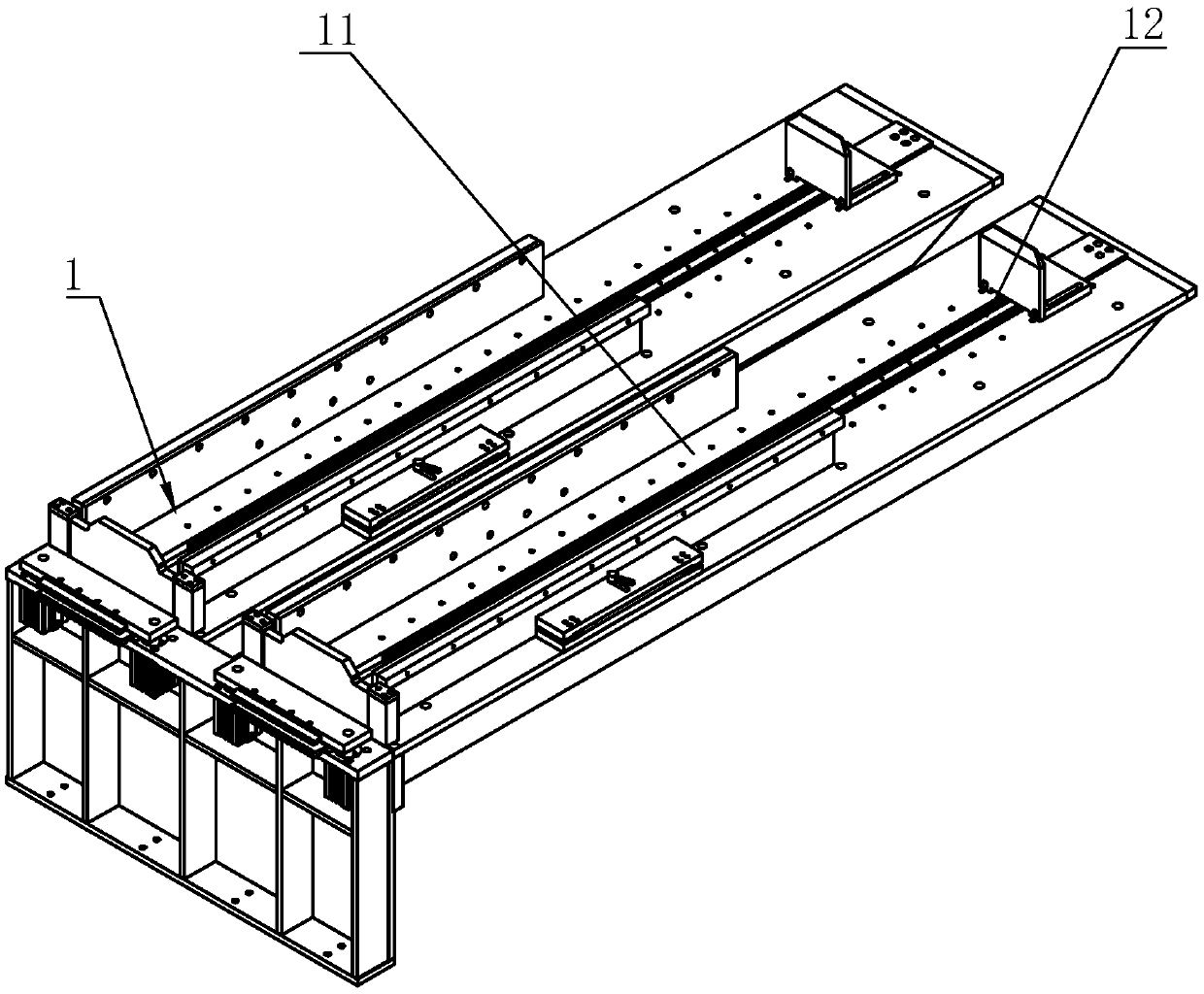

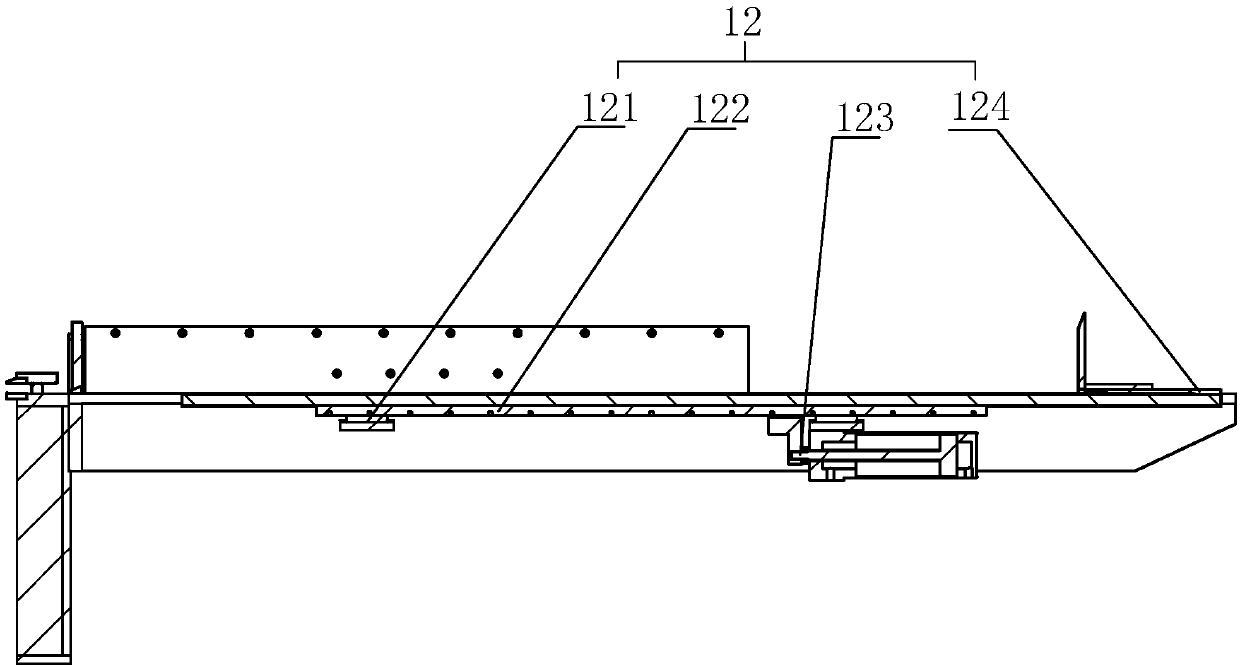

[0039] from figure 1 It can be seen that an automatic production line for spectacle temples includes a spectacle temple plate material loading station 1, a spectacle temple plate milling station 2, a spectacle temple blank material planing station 3, a spectacle temple blank material insertion station 4, and a spectacle temple cover Gluing station 5; the spectacle temple plate material loading station 1 includes a material discharging space 11 for placing the spectacle temple plate material and a plate material pusher for pushing the spectacle temple plate material from the discharging space 11 to the spectacle temple plate milling station 2 Device 12; a first material receiving and transferring mechanism 6 is arranged between the spectacle temple plate milling station 2 and the spectacle temple blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com