Automatic glasses leg production line

An automatic production line and spectacle temple technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor skill requirements, low production efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

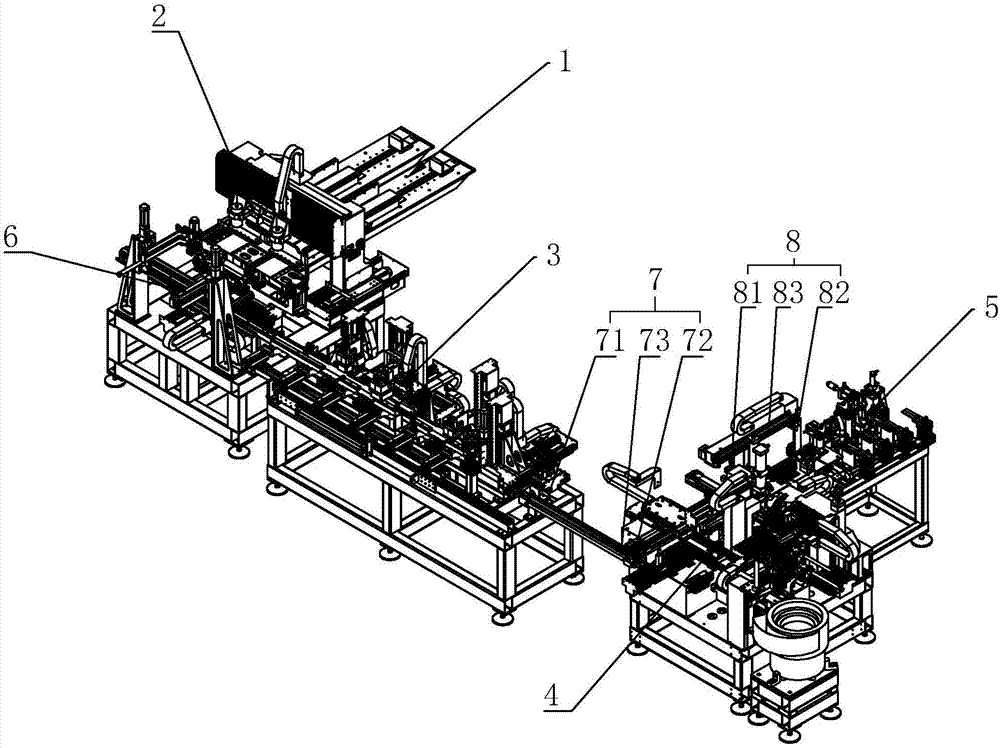

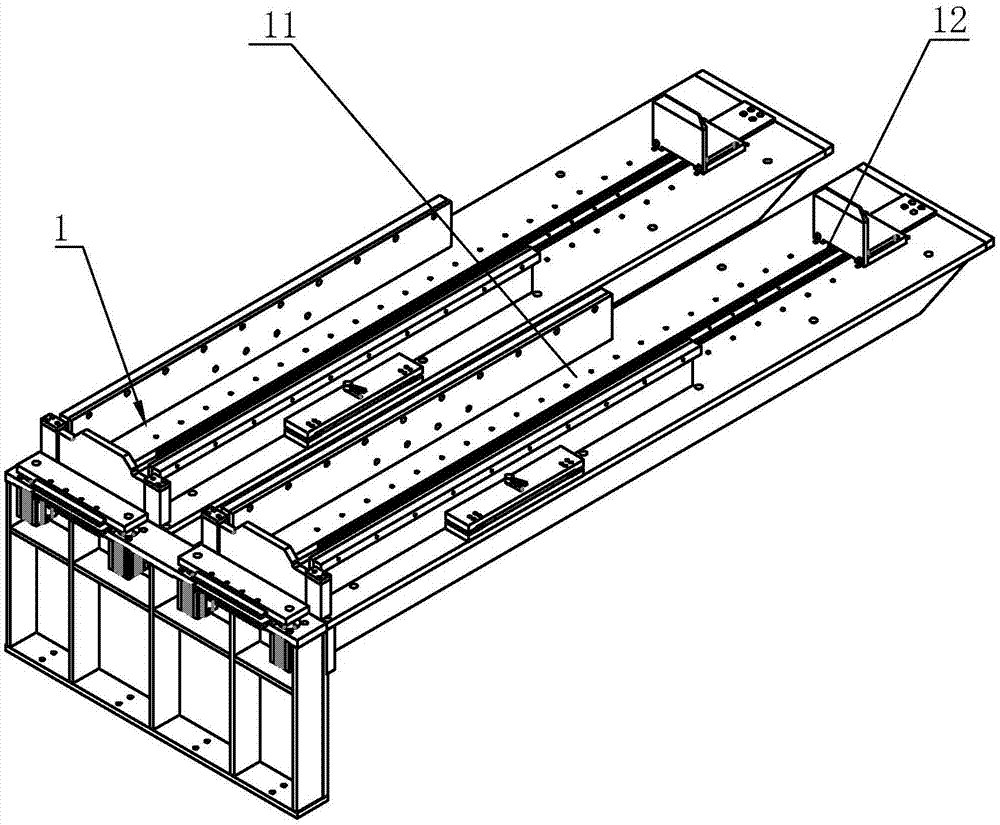

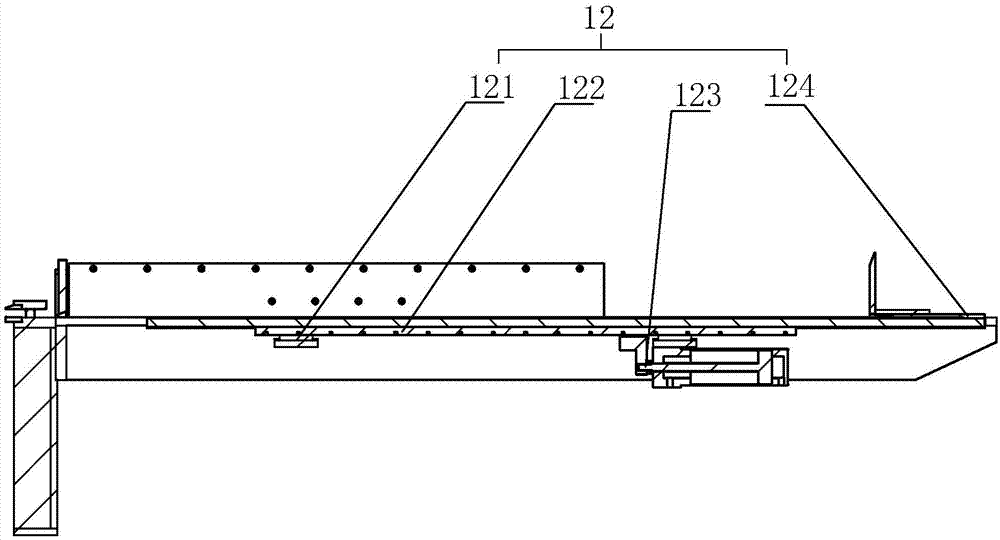

[0041] Refer to attached Figure 1 to Figure 14 The embodiment of an automatic production line for spectacle feet of the present invention will be further described in detail.

[0042] from figure 1 It can be seen that an automatic production line for spectacle temples includes a spectacle temple plate material loading station 1, a spectacle temple plate milling station 2, a spectacle temple blank material planing station 3, a spectacle temple blank material insertion station 4, and a spectacle temple cover Gluing station 5; the spectacle temple plate material loading station 1 includes a material discharging space 11 for placing the spectacle temple plate material and a plate material pusher for pushing the spectacle temple plate material from the discharging space 11 to the spectacle temple plate milling station 2 Device 12; a first receiving and transferring mechanism 6 is set between the spectacle temple plate milling station 2 and the spectacle temple blank planing stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com