Gear type multi-level coupling parallel mechanism

A gear-type, parallel technology, applied in the field of robotics, can solve problems such as the difficulty of kinematics positive and negative solutions, reduce the dynamic characteristics of the mechanism, and increase the volume of the upper-level drive, so as to reduce the number of drives, reduce the number, and increase the expansion ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

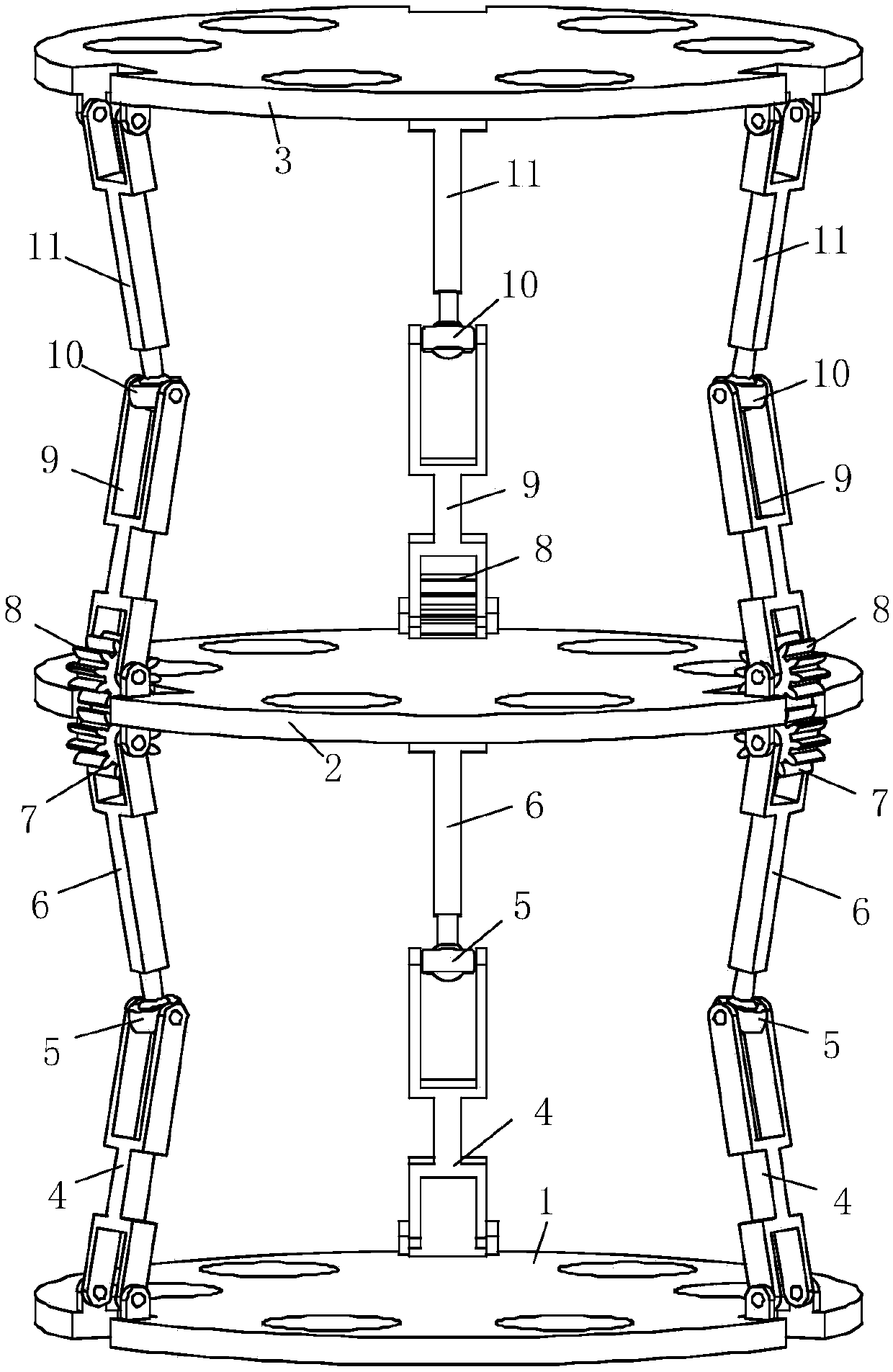

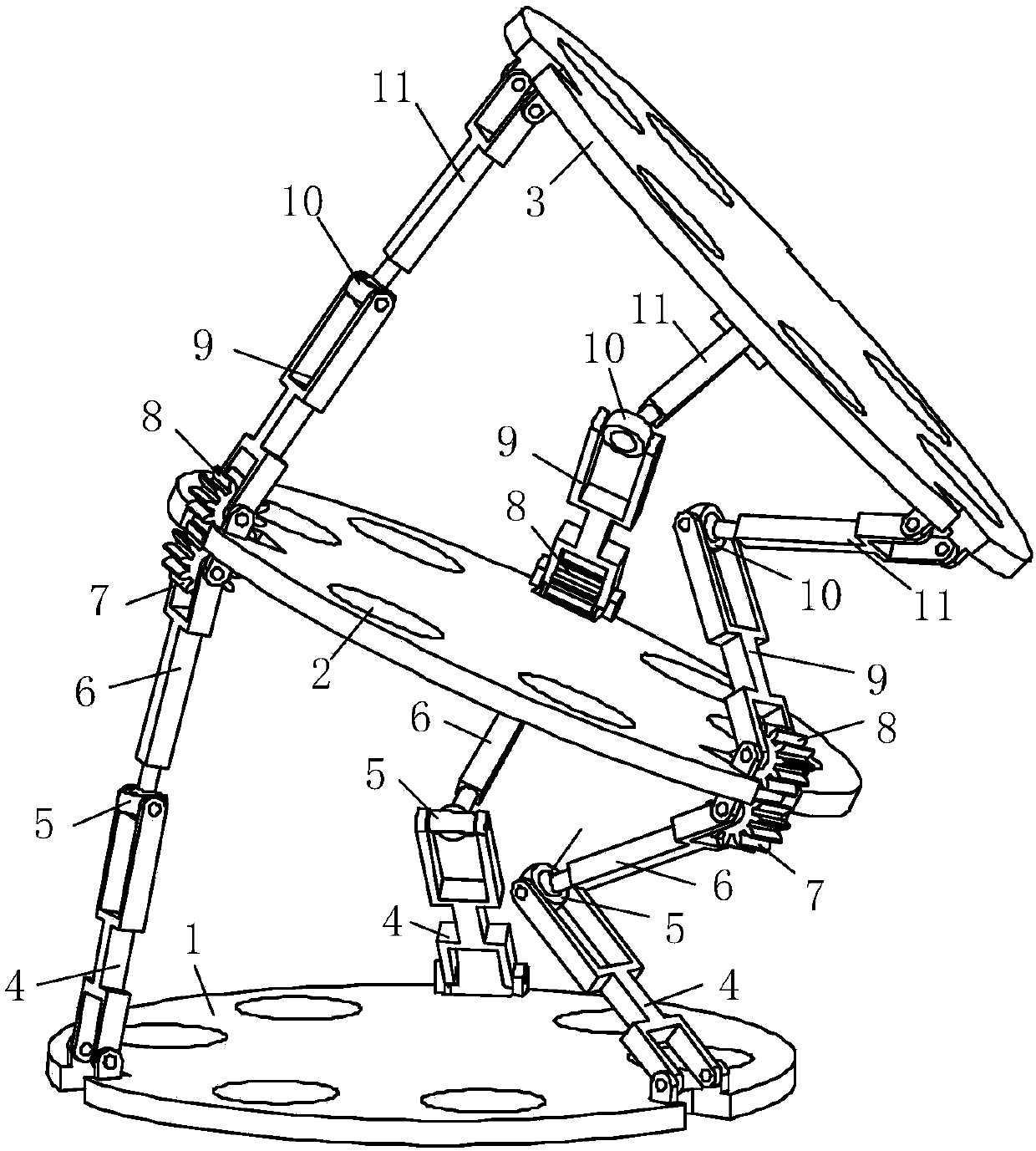

[0026] exist figure 1 , figure 2 and image 3 In the schematic diagram of the gear-type multi-stage coupling parallel mechanism shown, there are three evenly distributed opening slots on the fixed platform 1, the coupling platform 2 and the moving platform 3, and these three platforms are connected by three kinematic branch chains with the same structure. One end of the active rod 4 in the motion branch chain is connected with the fixed platform through the rotating pair arranged on the opening groove of the fixed platform, and the other end of the active rod is provided with a ball bowl 5 connected through the rotating pair, and is connected with the driven wheel through the spherical pair. One end of the rod 6 is connected, and the other end of the driven rod is rotationally connected with the first spur gear 7 through a rotating pair arranged on the lower surface of the coupling platform, and the second spur gear 8 is rotated through the rotating pair arranged on the uppe...

Embodiment 2

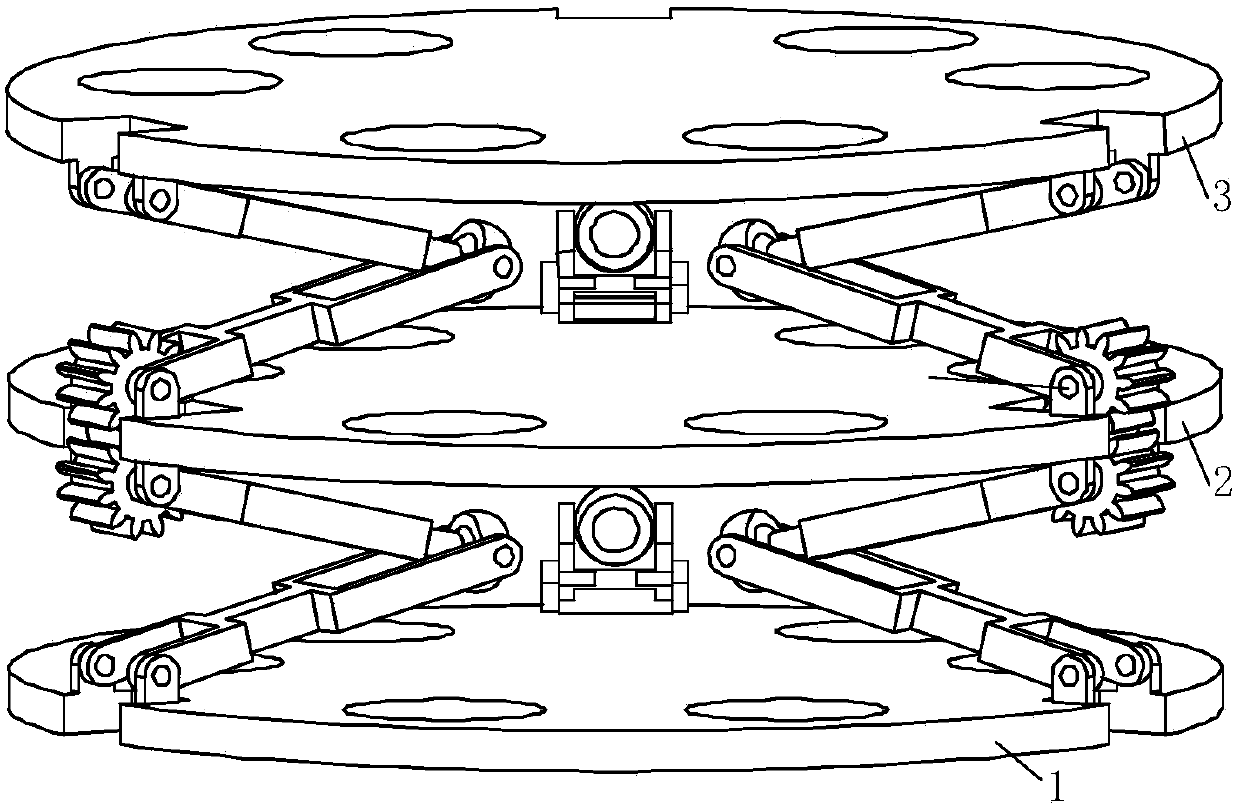

[0029] Such as Figure 4 , Figure 5 and Figure 6 As shown, there are three evenly distributed opening slots on the fixed platform 1, the coupling platform 2 and the moving platform 3, and among the three kinematic branch chains connecting the three platforms, two kinematic branch chains have the same structure. The components and connection method are the same as those in Embodiment 1. One end of the active rod 4 in the other branch chain is connected with the fixed platform through the rotating pair arranged on the opening groove of the fixed platform, and the other end of the active rod is connected with the driven rod through the rotating pair. 6, the other end of the driven rod is connected to the first spur gear 7 through a rotating pair on the lower surface of the coupling platform, and the second spur gear 8 is connected through the rotating pair on the upper surface of the coupling platform. Rotately connected with one end of another driving rod 9, the meshing mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com